Universal coating adhesive and preparation method thereof

A general-purpose coating technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of different glue characteristics, achieve moderate softening point, easy to use process, smooth viscosity Sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

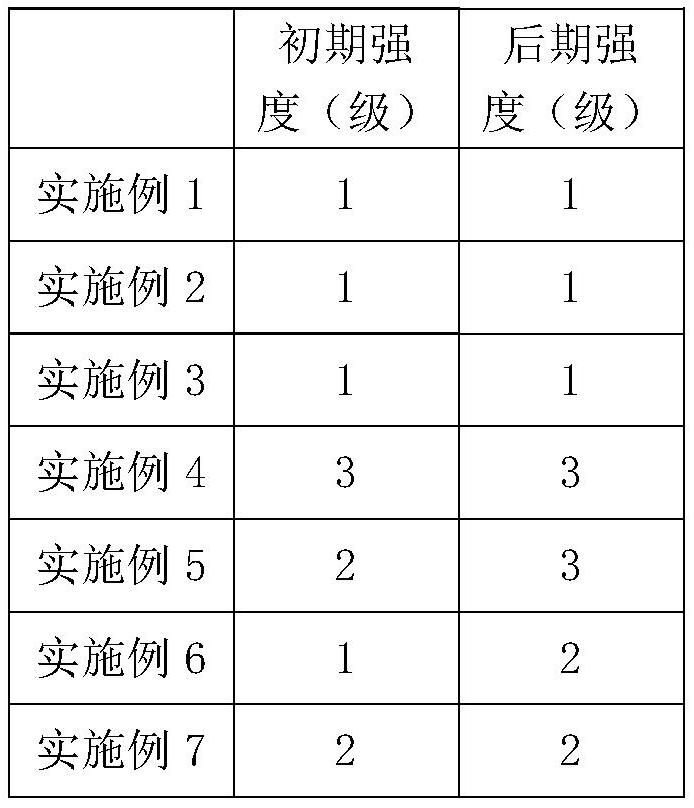

Examples

preparation example Construction

[0092] A second aspect of the present invention provides a method for preparing a general-purpose covering glue, comprising the following steps:

[0093] (1) Add polyether polyol, acrylic resin, defoamer, and filler into reaction kettle A with high-speed dispersion characteristics, adjust the temperature to 130-150°C to melt for 2 hours, and vacuumize and dehydrate for 30 minutes;

[0094] (2) Add polyester polyol and polyurethane elastomer into reaction kettle B, adjust the temperature to 130-150°C, melt for 1-1.5 hours, and vacuum dehydrate for 30 minutes;

[0095] (3) Add an appropriate amount of the mixture in the reactor A to the reactor B, and then vacuumize, stir and dehydrate for 1 hour at 120-140°C;

[0096] (4) Cool down to 100-110°C, add macromolecular chain extender to reactor B, and vacuum dehydrate for 30 minutes;

[0097] (5) Cool down to 70°C, add isocyanate, react and defoam for 1-2 hours in the state of nitrogen, and the temperature of the whole reaction is ...

Embodiment 1

[0103] Embodiment 1 of the present invention specifically provides a general-purpose coating glue, the raw materials of the coating glue include, by weight, 15 parts of polyether polyol, 10 parts of acrylic resin, 35 parts of polyester polyol, 0.01 part of defoamer, 5 parts of polyurethane elastomer, 1 part of filler, 5 parts of chain extender, 10 parts of isocyanate, 0.03 part of catalyst;

[0104] The polyether polyol is a mixture of a polyether polyol with a functionality of 2 and a hydroxyl value of 56 mg KOH / g and a polyether polyol with a functionality of 4 and a hydroxyl value of 28 mg KOH / g, wherein the functionality is 2. The weight ratio of the polyether polyol with a hydroxyl value of 56 mg KOH / g to the polyether polyol with a functionality of 4 and a hydroxyl value of 28 mg KOH / g is 1:2;

[0105] The acrylic resin is a polar acrylic resin;

[0106] The hydroxyl content of the polar acrylic resin is 1.6%, and the acid value is 6mg KOH / g;

[0107] The polar acrylic...

Embodiment 2

[0126] Embodiment 2 of the present invention specifically provides a general-purpose coating glue, the raw materials of the coating glue include, in parts by weight, 30 parts of polyether polyol, 20 parts of acrylic resin, 70 parts of polyester polyol, 0.05 parts of defoamer, 15 parts of polyurethane elastomer, 5 parts of filler, 10 parts of chain extender, 20 parts of isocyanate, 0.1 part of catalyst;

[0127] The polyether polyol is a mixture of a polyether polyol with a functionality of 2 and a hydroxyl value of 56 mg KOH / g and a polyether polyol with a functionality of 4 and a hydroxyl value of 28 mg KOH / g, wherein the functionality is 2. The weight ratio of the polyether polyol with a hydroxyl value of 56 mg KOH / g to the polyether polyol with a functionality of 4 and a hydroxyl value of 28 mg KOH / g is 1:3;

[0128] Described acrylic resin is with embodiment 1;

[0129] Described polyester polyol comprises liquid polyester polyol, crystalline polyester polyol, amorphous p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com