A welding method for high-purity rare earth and alloy targets

A welding method and alloy target technology are applied in welding equipment, electron beam welding equipment, metal processing equipment, etc. to achieve the effect of reducing material feeding, simple operation and ensuring thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

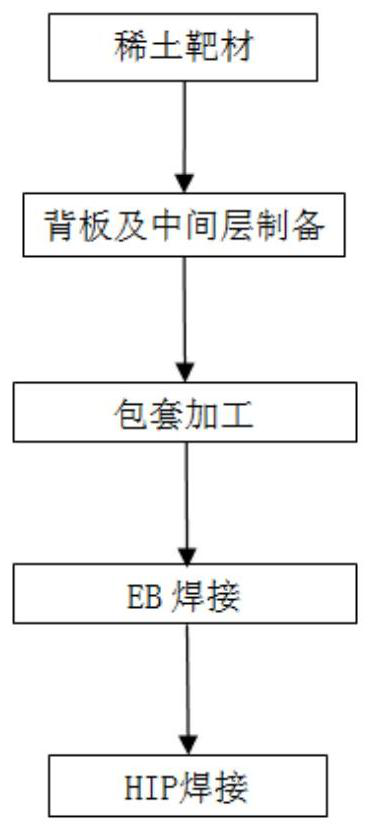

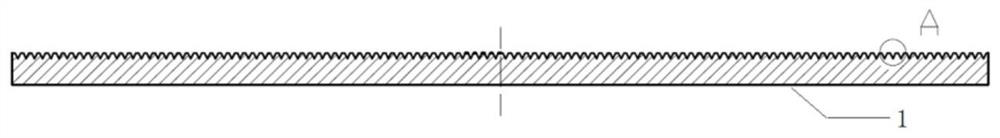

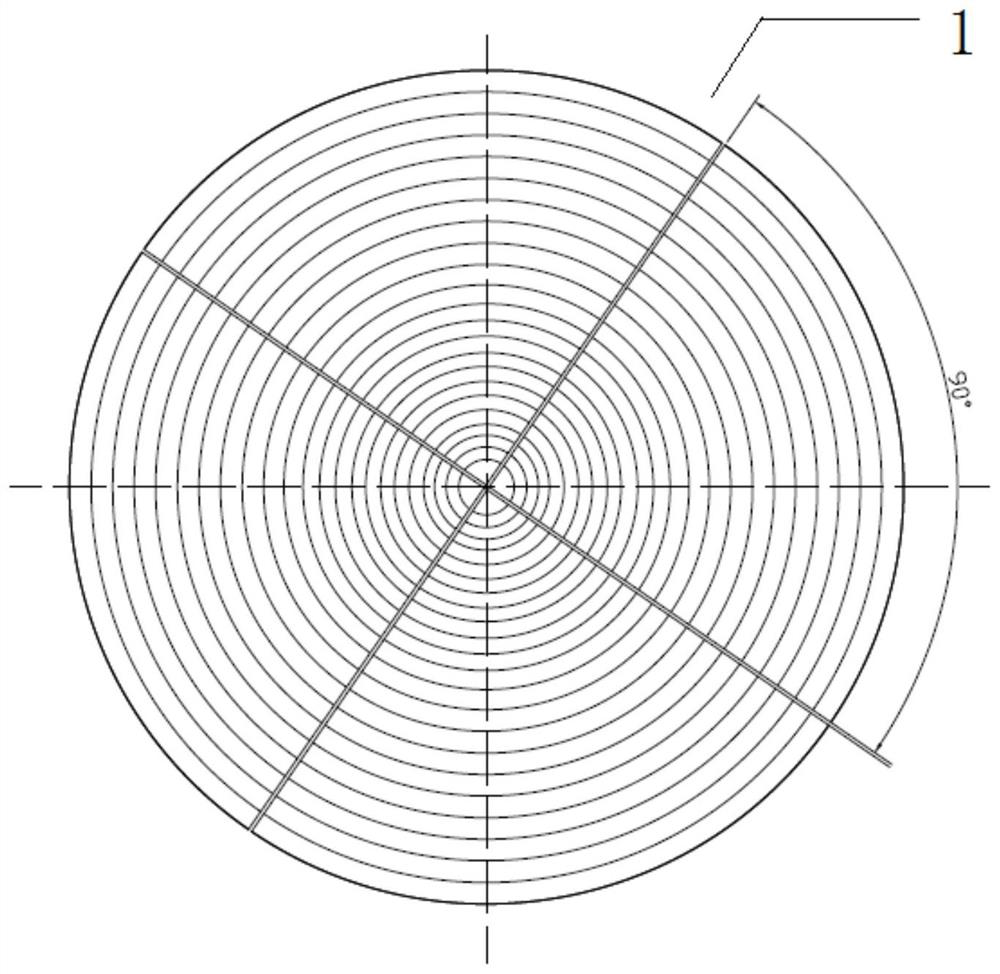

[0052] according to figure 1 The process flow chart of the processing process is carried out, and the welding surface of the rare earth Y target blank is cut and Ni back gold treatment is carried out, the back gold surface is protected, and the other surfaces of the rare earth target blank are sputtered with a protective material TaN; the back plate adopts Copper alloy C18000, gearing on the welding surface of the back plate (the gearing structure is shown in figure 2 ) and carry out Ni back gold treatment; the middle layer material is 1060Al material with a thickness of 2 mm; the 6061Al sheath material is processed by ordinary car, and it is cleaned before welding, and the inner surface of the sheath is coated with BN for protective treatment; the rare earth target material and the back plate Assemble into the sheath, and carry out electron beam sealing and welding processing; HIP welding processing is performed on the sealing and welding target material, the HIP pressure is...

Embodiment 2

[0054] The welding surface of the rare earth Y target blank is turned and Ni back gold treatment is carried out to protect the back gold surface, and the other surface of the rare earth target blank is sputtered and plated with protective material TaN; the back plate is made of copper alloy C18000, and the back plate is welded on The teeth are treated with Ni back gold; the middle layer material is 1060Al material with a thickness of 2mm; the 6061Al sheath material is processed by a general car, and it is cleaned before welding, and the inner surface of the sheath is coated with BN for protection; the rare earth target and the back plate Assemble into the sheath, and carry out electron beam sealing and welding processing; HIP welding processing is performed on the sealing and welding target material, HIP pressure is 100MPa, temperature is 300°C, heat preservation and pressure holding time is 3h, the sheath and the rare earth Y target have no reaction after welding and diffuse p...

Embodiment 3

[0056] The welding surface of the rare earth Y target blank is turned and Ni back gold treatment is carried out to protect the back gold surface, and the other surface of the rare earth target blank is sputtered and plated with protective material TaN; the back plate is made of copper alloy C18000, and the back plate is welded on The teeth are treated with Ni back gold; the middle layer material is 1060Al material with a thickness of 2mm; the 6061Al sheath material is processed by a general car, and it is cleaned before welding, and the inner surface of the sheath is coated with BN for protection; the rare earth target and the back plate Assemble into the sheath, and carry out electron beam sealing and welding processing; HIP welding is performed on the sealing and welding target material, the HIP pressure is 110MPa, the temperature is 300°C, the heat preservation and pressure holding time is 3h, and the sheath and the rare earth Y target have no reaction after welding. and dif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com