Method for preparing metal organic framework film having specific orientation by using template method

A metal-organic framework and template technology, which is applied in the fields of organic chemistry, electrolytic inorganic material coating, nanotechnology for materials and surface science, etc. and other problems, to achieve the effect of being conducive to large-scale industrial production, improving production efficiency and repeatability, and speeding up the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

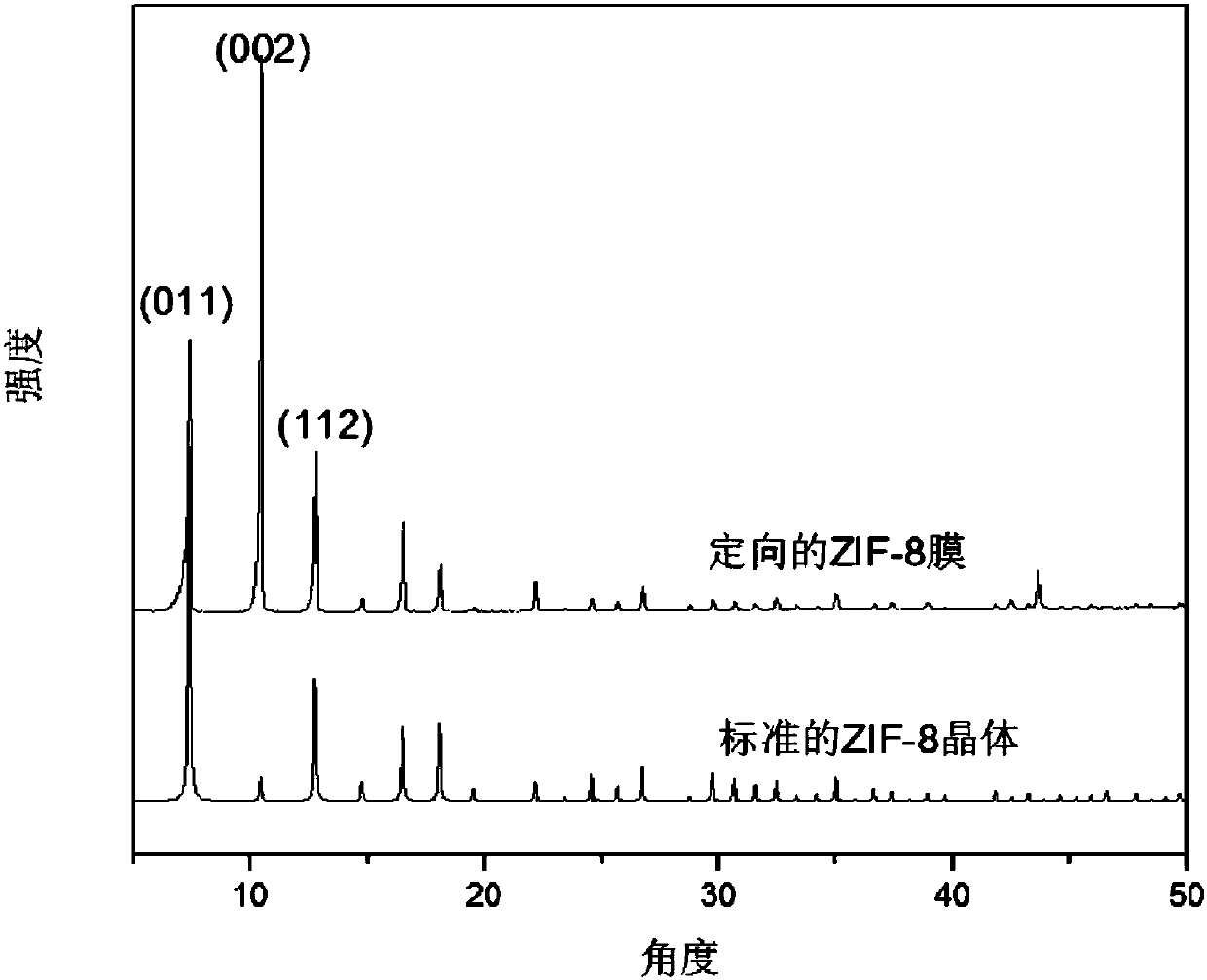

[0041] Using dense and flat conductive glass as a substrate to introduce a one-dimensional nanorod array template to prepare a ZIF-8 film with a specific orientation, specifically includes the following steps:

[0042] (1) Commercialized conductive glass was ultrasonically cleaned with ethanol for 10 minutes to remove surface stains;

[0043] (2) Prepare the solution required for electrodeposition of one-dimensional nanorod array templates: weigh zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O) Dissolve 1.34g of granules in 100mL of distilled water, then add 2g of ammonium nitrate (NH 4 NO 3 ) particles, stirred at room temperature for half an hour to obtain a colorless transparent clear solution;

[0044] (3) Immerse the cleaned conductive glass in step (1) into the clarified solution obtained in step (2), pass a 0.8mA current, and react at 55°C for 120 minutes to obtain a zinc oxide one-dimensional nanorod array template-modified conductive glass. Glass;

[0045]The obta...

Embodiment 2

[0050] Using dense and flat conductive glass as a substrate to introduce a one-dimensional nanorod array template to prepare a ZIF-8 film with a specific orientation, specifically includes the following steps:

[0051] (1) Commercialized conductive glass was cleaned with ethanol ultrasonic cleaning for 15 minutes to remove surface stains;

[0052] (2) Prepare the solution required for electrodeposition of one-dimensional nanorod array templates: weigh zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O) Dissolve 1.54g of granules in 100mL of distilled water, then add 2g of ammonium nitrate (NH 4 NO 3 ) particles, stirred at room temperature for half an hour to obtain a colorless transparent clear solution;

[0053] (3) Immerse the cleaned conductive glass in step (1) into the clarified solution obtained in step (2), feed a current of 1.5mA, and react at 70°C for 90 minutes to obtain a zinc oxide one-dimensional nanorod array template-modified conductive glass. Glass;

[0054] ...

Embodiment 3

[0059] The ZIF67 film with specific orientation is prepared by using a porous stainless steel mesh as a substrate to introduce a one-dimensional nanorod template, which specifically includes the following steps:

[0060] (1) A commercial porous stainless steel substrate (500 mesh, 316L) was ultrasonically cleaned with ethanol for 20 minutes to remove surface stains;

[0061] (2) Prepare the solution required for electrodeposition of one-dimensional nanorod array templates: weigh zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O) Dissolve 2.98g of granules in 100mL of distilled water, then add 2g of ammonium nitrate (NH 4 NO 3 ) particles, stirred at room temperature for half an hour to obtain a colorless transparent clear solution;

[0062] (3) Immerse the porous stainless steel mesh cleaned in step (1) into the clarified solution obtained in step (2), feed a current of 3mA, and react at 95°C for 70 minutes to obtain a zinc oxide one-dimensional nanorod array template-modified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com