Modified styrene-maleic anhydride copolymer and thermosetting resin composition

A technology of resin composition and maleic anhydride, which is applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problems of harsh reaction conditions, processing technology and storage effects, dielectric constant and Problems such as increased dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

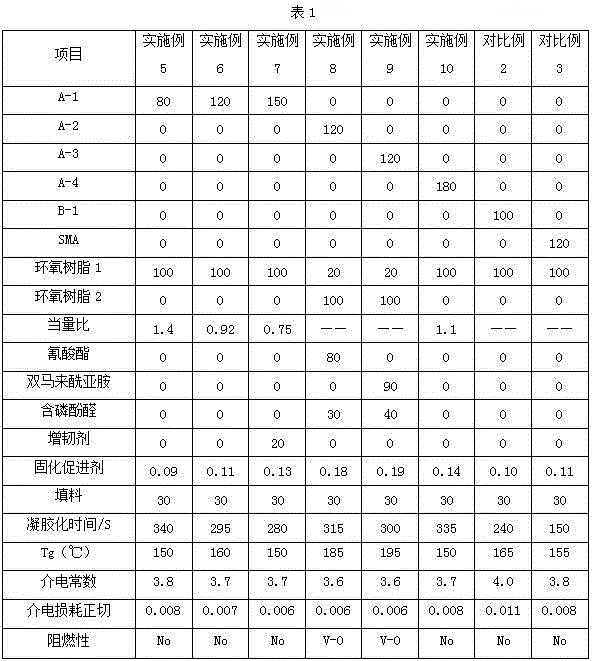

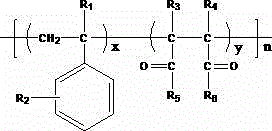

[0048] Dissolve 250g of styrene-maleic anhydride copolymer resin (the ratio of styrene to maleic anhydride is 4:1), 110g of dicyclohexylcarbodiimide, and 100g of phenol in ethyl acetate and place them in a three-neck reaction flask Mix well, then add 1.0g of 4-dimethylaminopyridine under stirring, react at room temperature for 8 hours, place the reaction solution in a low temperature environment of 0-5°C to cool for a period of time, then filter to separate solid impurities, and then prepare The product distillation, purification obtains the styrene-maleic anhydride copolymer A-1 of phenol modification, and GPC method records its number-average molecular weight and is 8000g / mol, and structural formula is as follows:

[0049]

[0050] In the formula, n is an integer ranging from 1 to 30, x and y are both positive integers and the ratio of x to y is 4:1; R1, R2, R3 and R4 are all hydrogen atoms, and R5 and R6 are phenoxy groups.

Embodiment 2

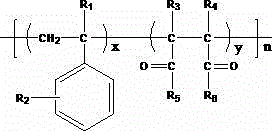

[0052] Mix 150 g of styrene-maleic anhydride copolymer resin (the ratio of styrene to maleic anhydride is 2:1), 110 g of dicyclohexylcarbodiimide, 3-hydroxyl-1,2,3-benzene with ethyl acetate 170g of triazin-4(3H)-one was fully dissolved and placed in a three-neck reaction flask for thorough mixing, then 3.0g of 4-dimethylaminopyridine was added under stirring, and the reaction was carried out at room temperature for 10 hours, and the reaction solution was placed at 0~ Cool at a low temperature of 5°C for a period of time and then filter to separate solid impurities, then distill and purify the obtained product to obtain 3-hydroxy-1,2,3-benzotriazin-4(3H)-one modified Styrene-maleic anhydride copolymer A-2, using GPC method to record its number average molecular weight is 13000g / mol, structural formula is as follows:

[0053]

[0054] In the formula, n is an integer ranging from 1 to 30, x and y are positive integers and the ratio of x to y is 2:1; R1, R2, R3 and R4 are all ...

Embodiment 3

[0056] 100g of styrene-maleic anhydride copolymer resin (the ratio of styrene and maleic anhydride is 1:1), 110g of dicyclohexylcarbodiimide, N-(4-hydroxyphenyl)maleimide were mixed with tetrahydrofuran. After fully dissolving 200g of amine, place it in a three-neck reaction flask and mix thoroughly, then add 2.0g of 4-dimethylaminopyridine under stirring, react at room temperature for 10 hours, and place the reaction solution in a low-temperature environment of 0-5°C to cool for a period of time Then filter and separate the solid impurities, then distill and purify the obtained product to obtain N-(4-hydroxyphenyl)maleimide-modified styrene-maleic anhydride copolymer A-3, which is obtained by GPC method Its number average molecular weight is 21000g / mol, and its structural formula is as follows:

[0057]

[0058] In the formula, n is an integer from 1 to 30, x and y are positive integers and the ratio of x to y is 1:1; R1, R2, R3 and R4 are all hydrogen atoms, R5 and R6 are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com