Preparation method of paper compound surface sizing agent

A technology of composite surface and sizing agent, applied in papermaking, paper coating, adding water repellent, etc., can solve the problems of difficult large-scale application and high cost of water-based polyurethane, achieve stable reaction, excellent sizing performance, and improved water resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

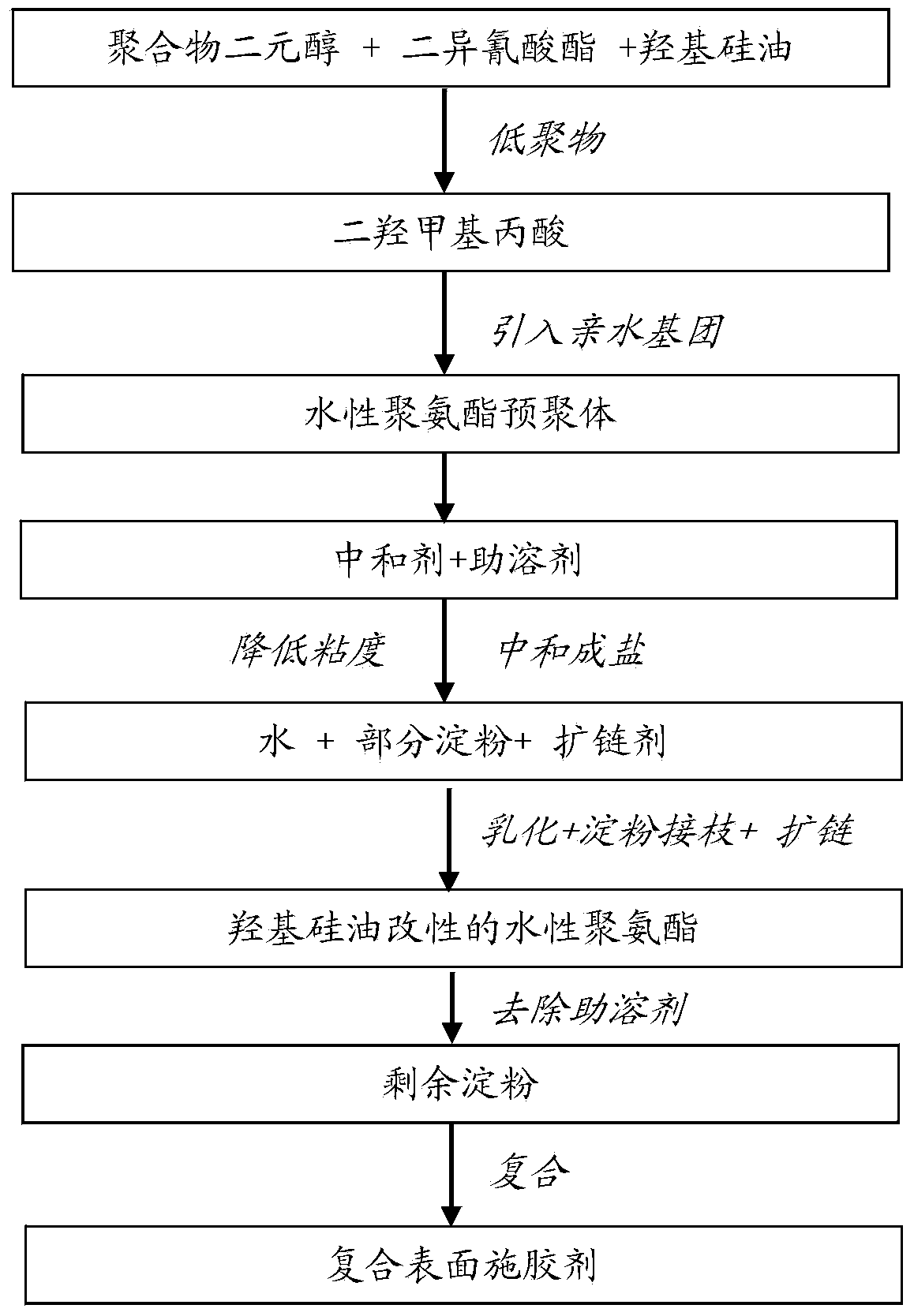

Method used

Image

Examples

Embodiment 1

[0032] (1) Stir and react 0.1 mol of polycaprolactone diol, 0.43 mol of isophorone diisocyanate and 41 g of polydimethylsiloxane whose terminal group is a hydroxyl group at 80°C under nitrogen protection for 1 hour to obtain Waterborne polyurethane oligomer;

[0033] (2) Dissolve 0.21mol of DMPA in 0.57mol of N-methylpyrrolidone, then add it to the water-based polyurethane oligomer obtained in step (1), stir and react at 80°C for 2.5-3.5 hours to obtain a water-based polyurethane prepolymer .

[0034] (3) Lower the temperature of the system to 45°C, add 0.21mol of neutralizing agent triethylamine and 206ml of acetone, stir for 0.5 hours, and neutralize the obtained water-based polyurethane prepolymer to form a salt;

[0035] (4) Continue to lower the temperature to 5°C, add 1232g of water, 32.5g of oxidized corn starch, and 0.12mol of ethylenediamine, then raise the temperature to 50°C, and react for 1.5-2 hours to obtain hydroxy silicone oil-modified waterborne polyurethane....

Embodiment 2

[0038] (1) 0.1 mol of polycarbonate diol, 0.44 mol of toluene diisocyanate and 46 g of hydroxyl silicone oil were stirred and reacted for 1 hour at 90°C under nitrogen protection to prepare water-based polyurethane oligomers;

[0039] (2) Dissolve 0.17mol of DMPA in 0.47mol of N-methylpyrrolidone, then add it to the water-based polyurethane oligomer obtained in step (1), stir at 90°C, and continue to react for 2.5-3.5 hours to obtain a water-based polyurethane oligomer Polymer;

[0040] (3) Lower the temperature to 50°C, add 0.15mol of triethanolamine and 228ml of methyl ethyl ketone as neutralizing agents, stir for 0.5 hours, and neutralize the obtained water-based polyurethane prepolymer to form a salt;

[0041] (4) Continue to lower the temperature to 10°C, add 885g of water, add 60g of anionic tapioca starch, and 0.17mol of ethylenediamine, then raise the temperature to 60°C, and react for 1.5-2 hours to obtain a water-based polyurethane modified with hydroxyl silicone oil...

Embodiment 3

[0044] (1) 0.1 mol of polycaprolactone diol, 0.46 mol of isophorone diisocyanate and 39.5 g of hydroxyl silicone oil were stirred and reacted for 1 hour at 85 °C under the protection of nitrogen to prepare a water-based polyurethane oligomer;

[0045] (2) Dissolve 0.16mol of DMPA in 0.43mol of N-methylpyrrolidone, then add it to the water-based polyurethane oligomer obtained in step (1), stir at 85°C, and continue the reaction for 2.5-3.5 hours to obtain a water-based polyurethane oligomer Polymer;

[0046] (3) Lower the temperature to 50°C, add 0.16mol of neutralizing agent triethylamine and 206ml of acetone, stir for 0.5 hours, and neutralize the obtained waterborne polyurethane prepolymer to form a salt;

[0047] (4) Continue to lower the temperature to 8°C, add 922g of water, then add 48.7g of wheat acid modified starch, 0.20mol of ethylenediamine, then raise the temperature to 70°C, and react for 1.5-2 hours to obtain hydroxy silicone oil modified waterborne polyurethane ;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com