Method and device for optimizing iron ore through coal-based coking reduction roasting coke magnetic separation

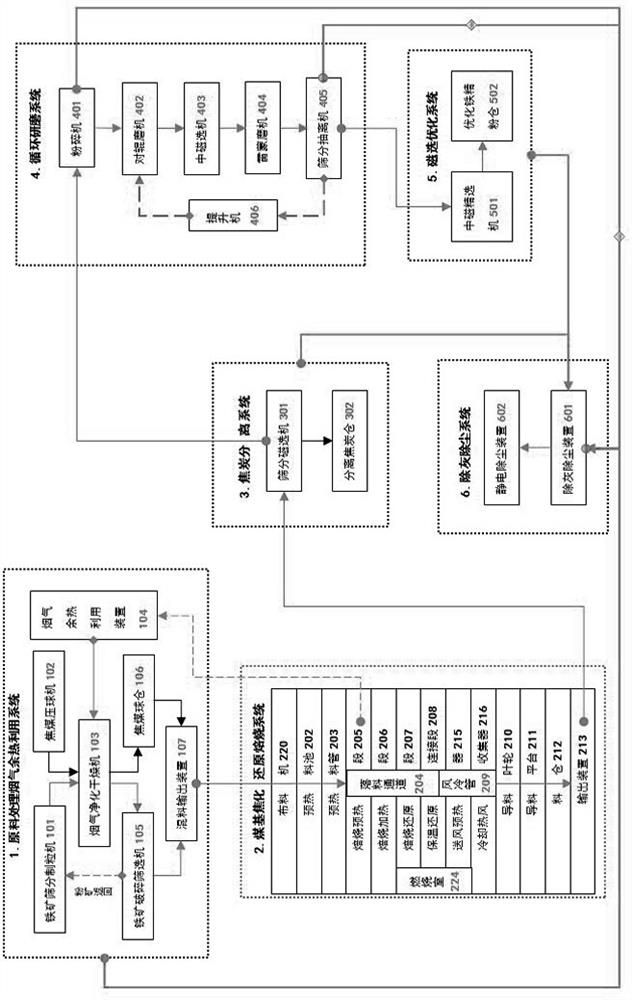

A technology for burning coke and iron ore, which is applied in the field of coal-based direct reduction roasting kiln and mineral optimization, coal-based coking reduction roasting coke magnetic separation optimization of iron ore, can solve the problem that natural raw materials are difficult to meet the needs of large-scale production of direct reduced iron raw materials, gas Based on the problems of industrial production and application of shaft furnace technology and low efficiency of thermal energy recycling, the effect of improving the quality structure and energy structure of steel products, easy promotion, and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] An iron oxide ore contains 38.94% iron TFe. Follow these steps:

[0092] (1) Raw material processing: the TFe38.94% iron ore is screened and granulated, heated and dried, crushed and screened to obtain dry iron ore particles with a particle size of 6-40 mm; Drying treatment to obtain dry coke briquettes with a particle size of 45-55 mm; mixing the dry coke briquettes with a particle size of 45-55 mm with iron ore particles with a particle size of 6-40 mm according to a mass percentage of 30% to obtain iron ore particle mixture, mixing The moisture weight percentage of <10%.

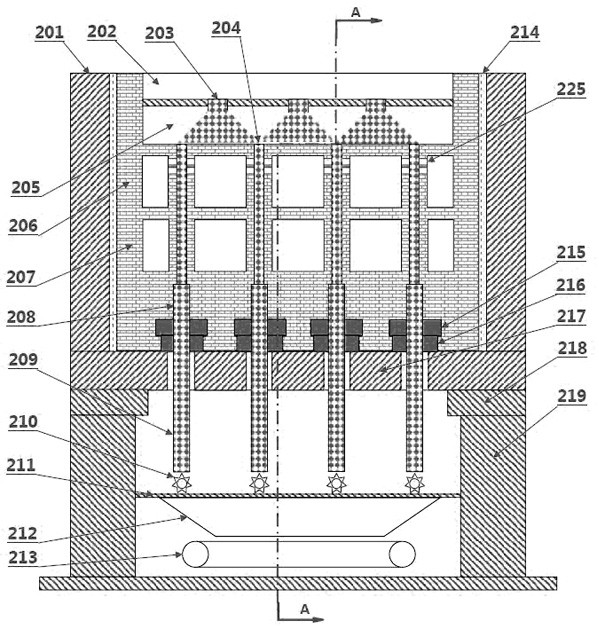

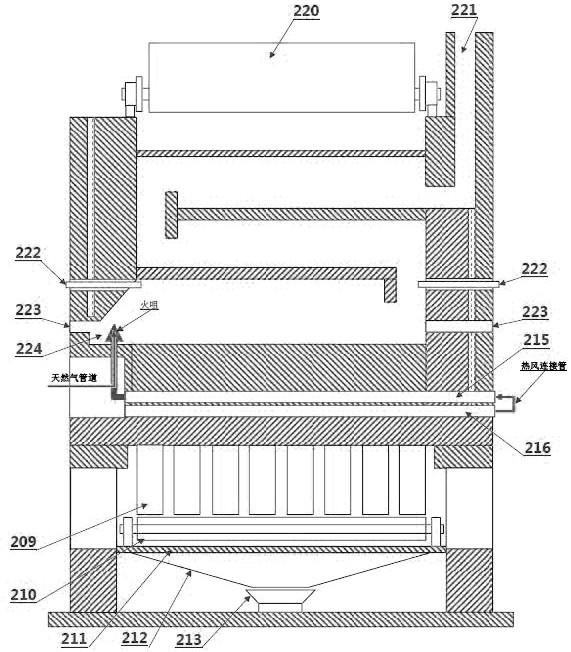

[0093] (2) Coal-based coking reduction roasting kiln: fill the coal-based coking reduction roasting test kiln with the iron ore particle mixture; lay the pile in the preheating pool with a thickness of 200-300mm; start the burner in the combustion chamber and heat up Speed ≤ 2°C / min. When the flue gas temperature in the reduction section reaches 900-960°C, start the material guide impeller to f...

Embodiment 2

[0098] An iron oxide ore contains 56.72% iron TFe. Follow these steps:

[0099] (1) Raw material processing: TFe56.72% iron ore is granulated, dried, crushed and screened to obtain dry iron ore particles with a particle size of 6-40 mm; the prepared coking coal is dried with coking coal briquettes to obtain a particle size of 45 mm ~55mm dry coke briquettes; mix dry coke briquettes with a particle size of 45~55mm at a mass percentage of 30% with iron ore particles with a particle size of 6~40mm to obtain a mixture of iron ore particles, and the water weight percentage of the mixture is <10%.

[0100] (2) Coal-based coking reduction roasting kiln: The iron ore particle mixture is roasted in a coal-based coking reduction roasting test kiln to obtain coking reduction roasting material.

[0101] (3) Separation of coke: the coke reduction roasting material is separated by a sieving magnetic separator to obtain coke with a volatile content of 0.74%, and the quality and strength of ...

Embodiment 3

[0105] A magnetite oxide contains 24.57% iron TFe. Follow these steps:

[0106] (1) Raw material processing: The magnetite with TFe24.57% is granulated, dried, crushed and screened to obtain dry iron ore particles with a particle size of 6-40mm; 45-55mm dry coke briquettes; mix dry coke briquettes with a particle size of 45-55mm at a mass percentage of 30% with iron ore particles with a particle size of 6-40mm to obtain a mixture of iron ore particles, and the water weight percentage of the mixture is <10%.

[0107] (2) Coal-based coking reduction roasting kiln: The iron ore particle mixture is roasted in a coal-based coking reduction roasting test kiln to obtain coking reduction roasting material.

[0108] (3) Separation of coke: The coke reduction roasting material is separated by a screening magnetic separator to obtain coke with a volatile content of 0.79%, and the quality and strength of the coke meet the requirements of steelmaking; at the same time, the reduction mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com