System and method for producing biomass charcoal by utilizing flue gas of power station boiler

A technology for power station boilers and biomass charcoal, which is applied in the fields of biofuels, coke ovens, special forms of dry distillation, etc., can solve the problems of high energy consumption and large pollution, and achieve the effect of saving fuel consumption and environmental protection investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

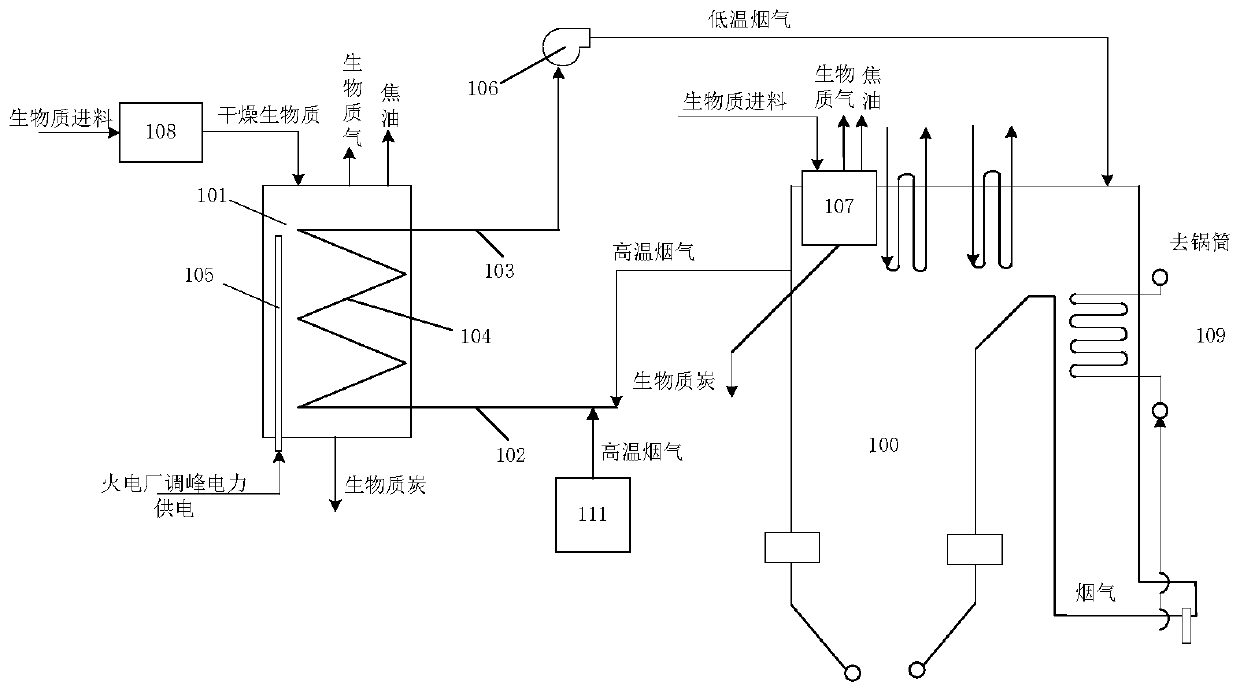

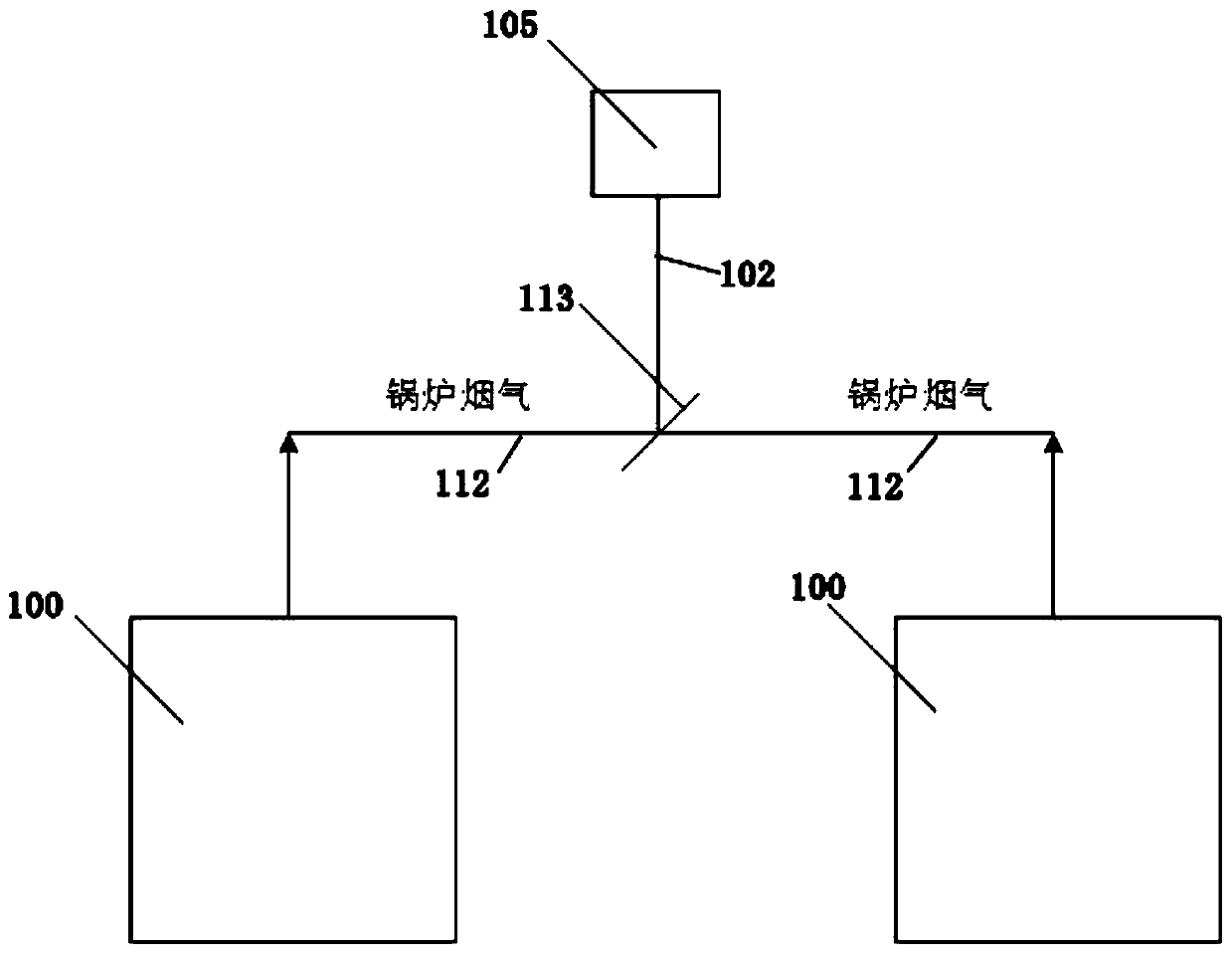

[0035] A system for producing biochar from power plant boiler flue gas, such as figure 1 As shown, it includes a pyrolysis furnace; the pyrolysis furnace is provided with a biomass inlet, a biomass charcoal outlet and a biomass gas outlet; the flue gas produced by the utility boiler 100 of a thermal power plant provides a heat source for the pyrolysis furnace; it also includes a supplementary A thermal device, the supplementary heat device is used to supplement the heat source when the temperature in the pyrolysis furnace does not reach the preset pyrolysis temperature.

[0036] The working principle of the above system is: add biomass raw materials into the pyrolysis furnace from the biomass inlet, and use the high-temperature flue gas produced by the utility boiler of the thermal power plant to provide the main heat source for the pyrolysis of the biomass raw materials in the pyrolysis furnace. When the temperature in the pyrolysis furnace does not reach the preset pyrolysis...

Embodiment 2

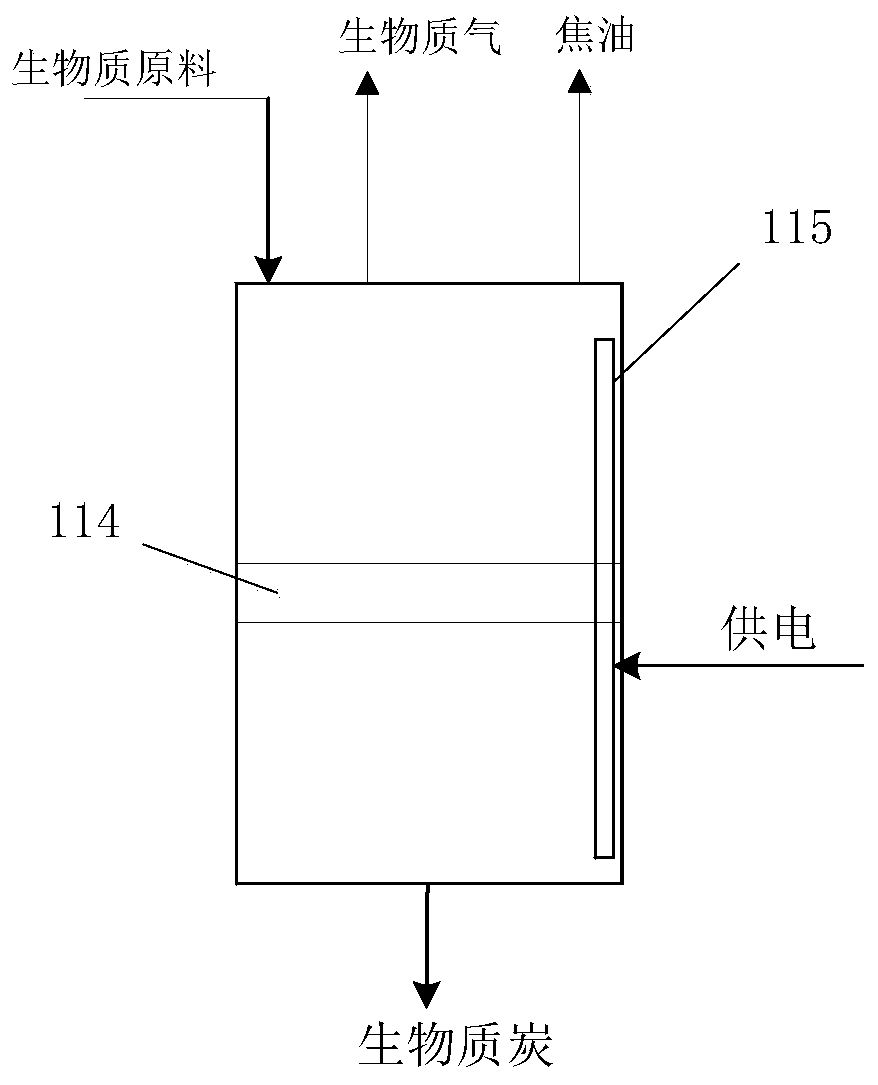

[0060] This embodiment provides a system for producing biomass charcoal using power plant boiler flue gas, such as Figure 4 As shown, the system structure of this embodiment is basically the same as that of Embodiment 1, and the main difference is that the system of this embodiment only adopts the pyrolysis furnace 200 that is set up in the same way as the first pyrolysis furnace of Embodiment 1, instead of using The pyrolysis furnace setting method of the second pyrolysis furnace in example 1.

Embodiment 3

[0062] This embodiment provides a system for producing biomass charcoal using power plant boiler flue gas, such as Figure 5 As shown, the system structure of this embodiment is basically the same as that of Embodiment 1, and the main difference is that the system of this embodiment only adopts the pyrolysis furnace 300 that is set up in the same way as the second pyrolysis furnace of Embodiment 1, instead of using The pyrolysis furnace setting method of the first pyrolysis furnace in example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com