Oxamide synthesizing production device and method

A production device, oxamide technology, applied in the field of synthetic oxamide production device, can solve the problems of high cost, complicated process, low safety factor, etc., and achieve the effects of high recovery rate, accelerated reaction rate, and easy absorption and treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

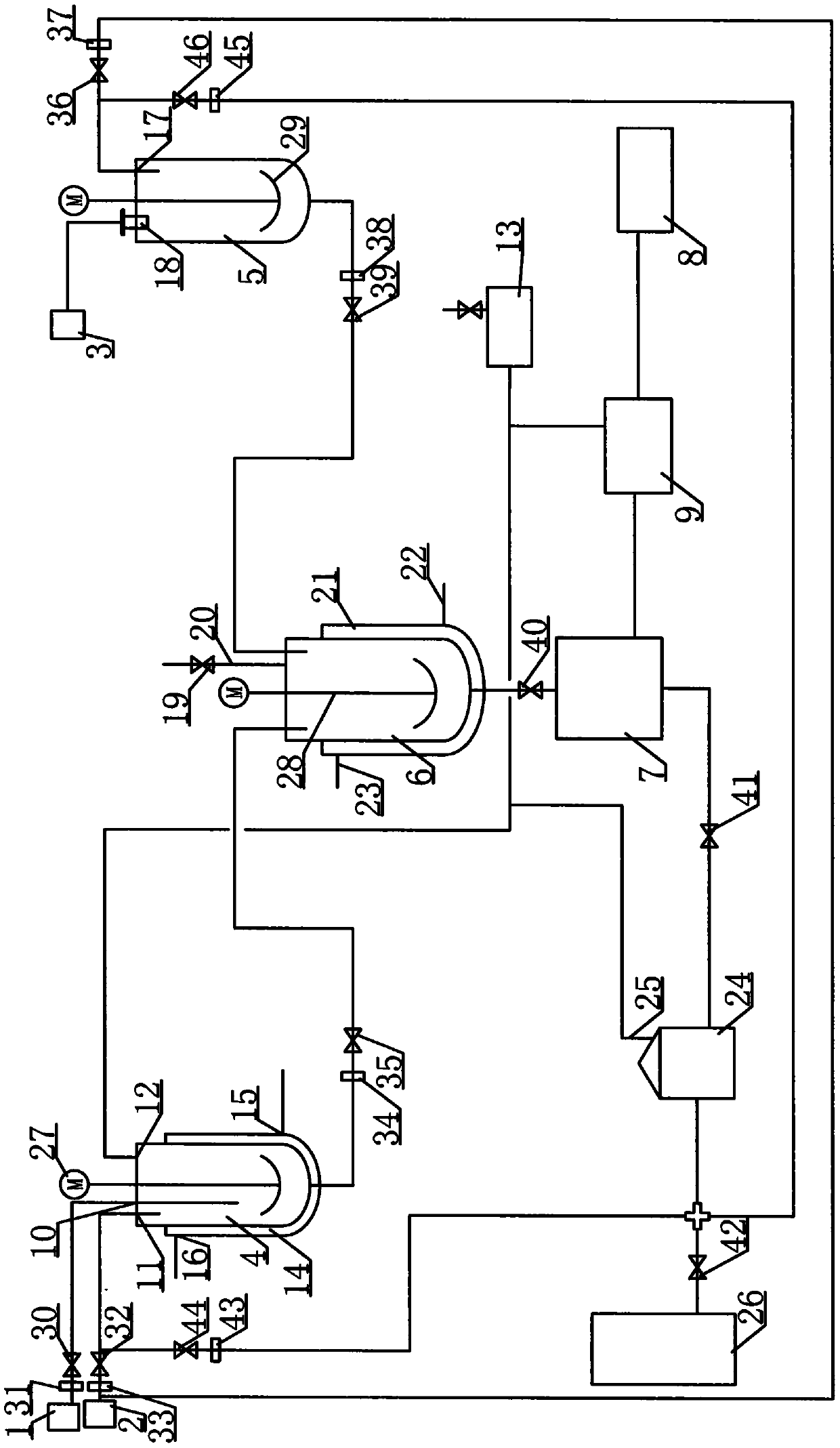

Embodiment 1

[0052]A production device for synthesizing oxamide, comprising an ammonia absorption unit and a dimethyl oxalate dissolving unit, the ammonia absorption unit and the dimethyl oxalate dissolving unit are connected to the oxamide synthesis reaction unit respectively, and the bottom of the oxamide synthesis reaction unit passes through The solid-liquid separator 7 is connected with the oxamide storage tank 8 . Described ammonia absorption unit comprises ammonia absorption tank 4, and the top of ammonia absorption tank 4 is provided with the ammonia gas inlet 10 that links to each other with ammonia gas storage tank 1, the first methanol inlet 11 that links to each other with methanol storage tank 2 and ammonia gas The first vent pipe 12 of the absorption tank, the liquid outlet at the bottom of the ammonia absorption tank 4 is connected to the first liquid inlet of the reaction kettle 6 in the oxamide synthesis reaction unit through the pipeline, and the first vent pipe 12 is conn...

Embodiment 2

[0062] A production device for synthesizing oxamide, comprising an ammonia absorption unit and a dimethyl oxalate dissolving unit, the ammonia absorption unit and the dimethyl oxalate dissolving unit are connected to the oxamide synthesis reaction unit respectively, and the bottom of the oxamide synthesis reaction unit passes through The solid-liquid separator 7 is connected with the oxamide storage tank 8 . Described ammonia absorption unit comprises ammonia absorption tank 4, and the top of ammonia absorption tank 4 is provided with the ammonia gas inlet 10 that links to each other with ammonia gas storage tank 1, the first methanol inlet 11 that links to each other with methanol storage tank 2 and ammonia gas The first vent pipe 12 of the absorption tank, the liquid outlet at the bottom of the ammonia absorption tank 4 is connected to the first liquid inlet of the reaction kettle 6 in the oxamide synthesis reaction unit through the pipeline, and the first vent pipe 12 is con...

Embodiment 3

[0072] A production device for synthesizing oxamide, comprising an ammonia absorption unit and a dimethyl oxalate dissolving unit, the ammonia absorption unit and the dimethyl oxalate dissolving unit are connected to the oxamide synthesis reaction unit respectively, and the bottom of the oxamide synthesis reaction unit passes through The solid-liquid separator 7 is connected with the oxamide storage tank 8 . Described ammonia absorption unit comprises ammonia absorption tank 4, and the top of ammonia absorption tank 4 is provided with the ammonia gas inlet 10 that links to each other with ammonia gas storage tank 1, the first methanol inlet 11 that links to each other with methanol storage tank 2 and ammonia gas The first vent pipe 12 of the absorption tank, the liquid outlet at the bottom of the ammonia absorption tank 4 is connected to the first liquid inlet of the reaction kettle 6 in the oxamide synthesis reaction unit through the pipeline, and the first vent pipe 12 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com