Method for optimizing low-grade laterite-nickel ore through gas-coal double-base direct reduction magnetic separation

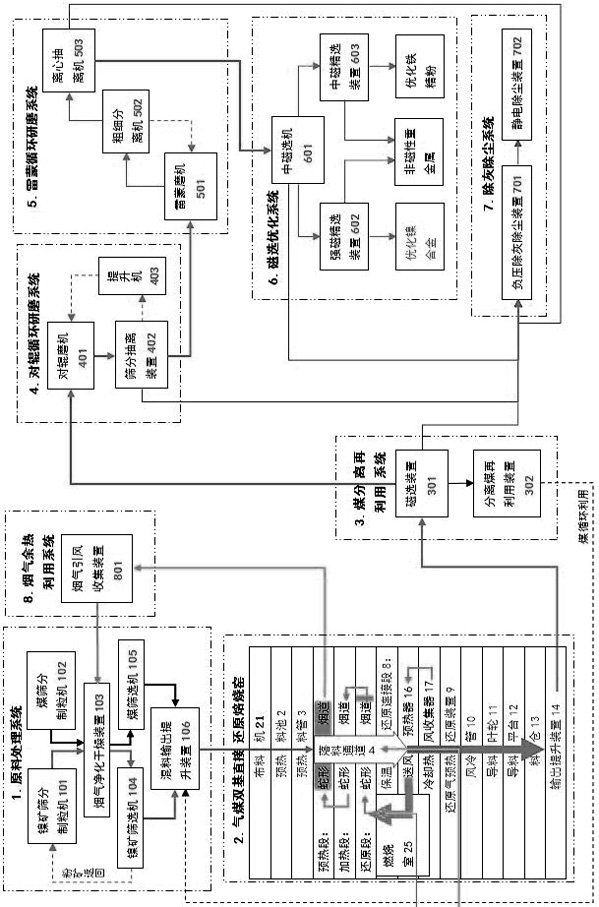

A kind of laterite nickel ore, low-grade technology, applied in gas-coal double-base direct reduction roasting kiln and mineral selection, gas-coal double-base direct reduction magnetic separation optimization low-grade laterite nickel ore field, can solve the gas-coal double-base shaft furnace process The industrial production and application are frustrated, the nickel recovery rate is not high, the nickel alloy grade is low, and the production efficiency is low, which achieves the effect of easy promotion, huge energy-saving development potential, and reduced investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] A laterite nickel ore contains 0.85% Ni and 46.37% Fe. Follow these steps:

[0102] ①Raw material treatment: Ni0.85%, Fe46.37% low-grade laterite nickel ore raw materials and reducing agent coal were screened, granulated, and dried to obtain laterite nickel ore particles with a particle size of 3-40 mm and laterite nickel ore particles with a particle size of 5-10 mm. Millimeter coal particles, mix 5-10 mm coal particles in a proportion of 8%, and a particle size of 1-5 mm in proportion to 6% of re-used coal particles and 3-40 mm laterite nickel ore particles to obtain a mixed material, the weight percentage of the mixed material moisture <10%.

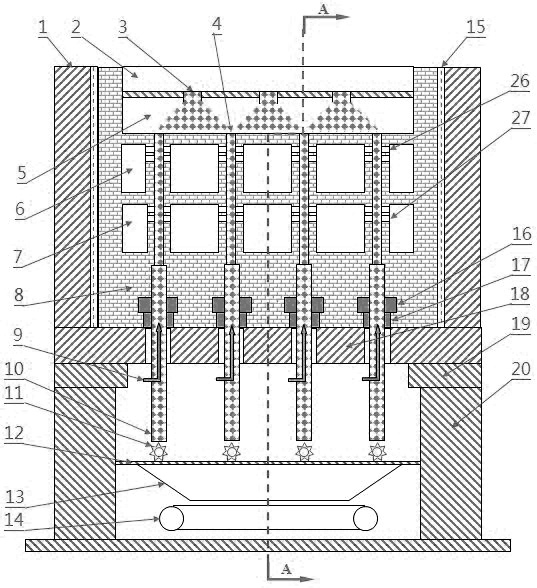

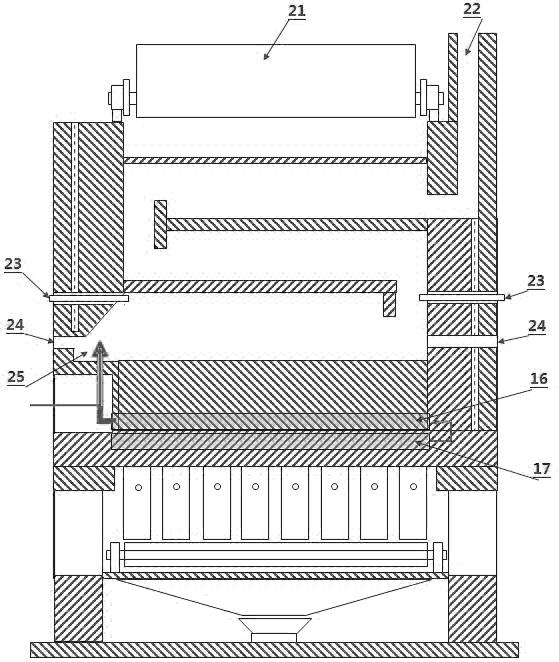

[0103] ②Gas-coal double-base direct reduction roasting: Roast 3-40mm nickel ore particle mixture in the gas-coal double-base direct reduction roasting test kiln, the gas-base reducing gas pressure is controlled at 600-1200Pa higher than the marked pressure, and the reduction section reduces The temperature is controlled at ab...

Embodiment 2

[0110] Ni0.97% and Fe49.41% of a low-grade lateritic nickel ore. Follow these steps:

[0111] ①Raw material processing: Ni0.97%, Fe49.41% low-grade laterite nickel ore raw materials and reducing agent coal were screened, granulated and dried to obtain laterite nickel ore particles with a particle size of 3 to 40 mm and laterite nickel ore particles with a particle size of 5 to 10 mm. Millimeter coal particles, mix 5-10 mm coal particles in a proportion of 8%, and a particle size of 1-5 mm in proportion to 6% of re-used coal particles and 3-40 mm laterite nickel ore particles to obtain a mixed material, the weight percentage of the mixed material moisture <10%.

[0112] ②Gas-coal double-base direct reduction roasting: Roast 3-40mm nickel ore particle mixture in the gas-coal double-base direct reduction roasting test kiln, the pressure of gas-base reducing gas is controlled at 600-1200Pa higher than the marked pressure, and the reduction section reduces The temperature is cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com