Self-weight spiral progressive type high-efficiency and energy-saving biomass pyrolysis furnace device

A high-efficiency, energy-saving, pyrolysis furnace technology, applied in the direction of biofuels, coke ovens, special forms of dry distillation, etc., can solve the problems of low production efficiency, many devices, and high cost, achieve sufficient reaction, promote pyrolysis reaction, and increase gas heat. value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

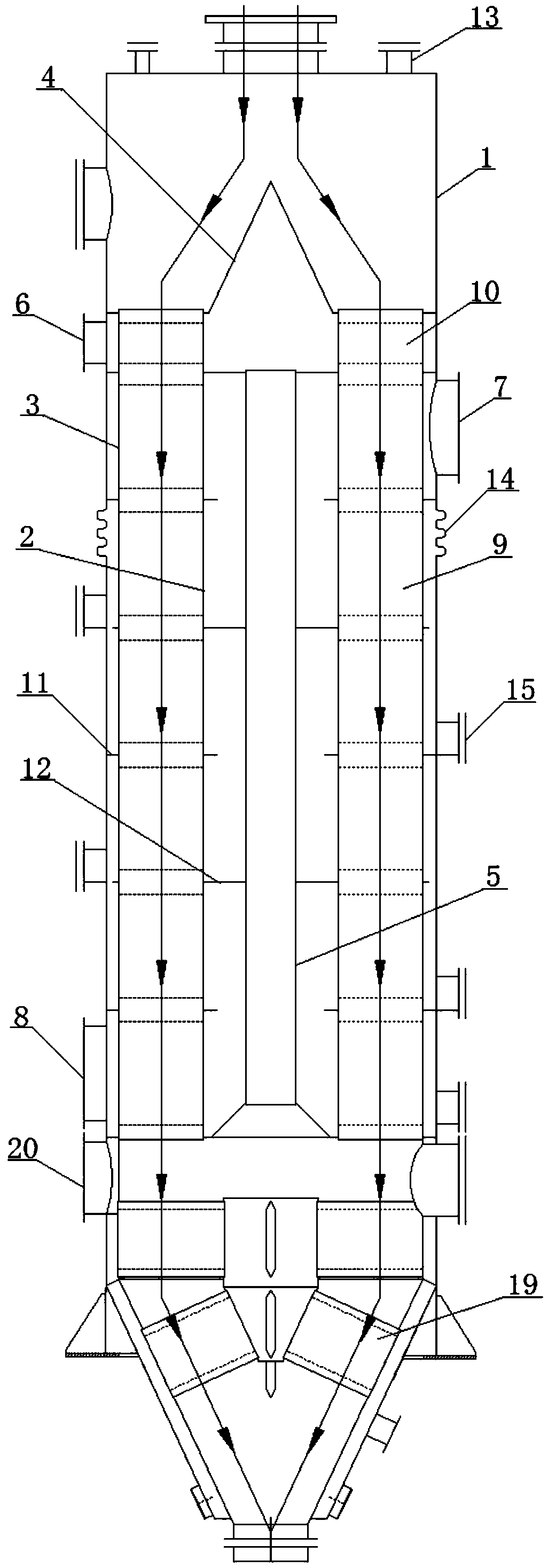

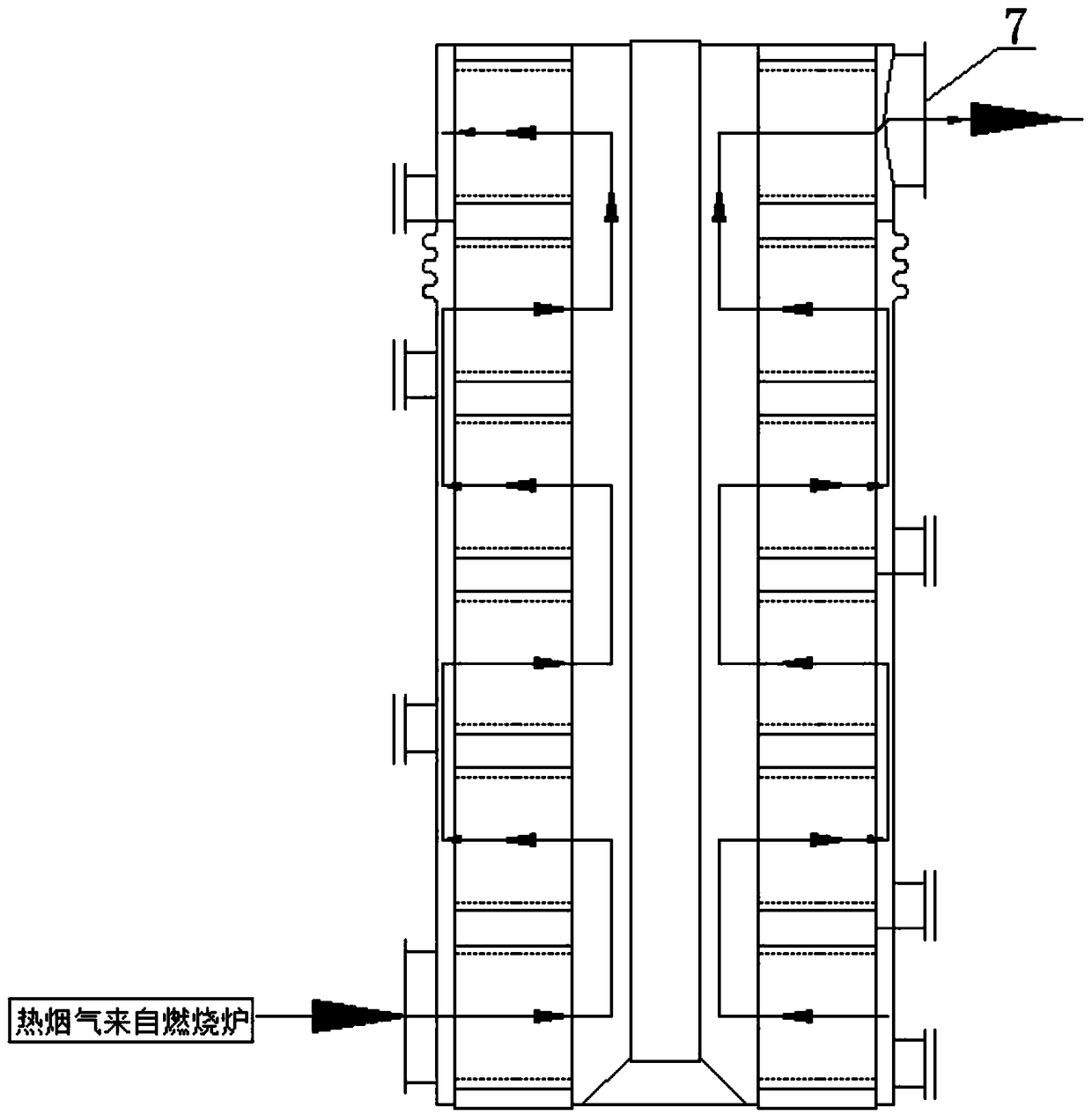

[0027] see figure 1 A high-efficiency and energy-saving biomass pyrolysis furnace device includes a pyrolysis furnace and an air cooler, and the biomass charcoal outlet at the bottom of the pyrolysis furnace is connected with the upper material inlet of the air cooler.

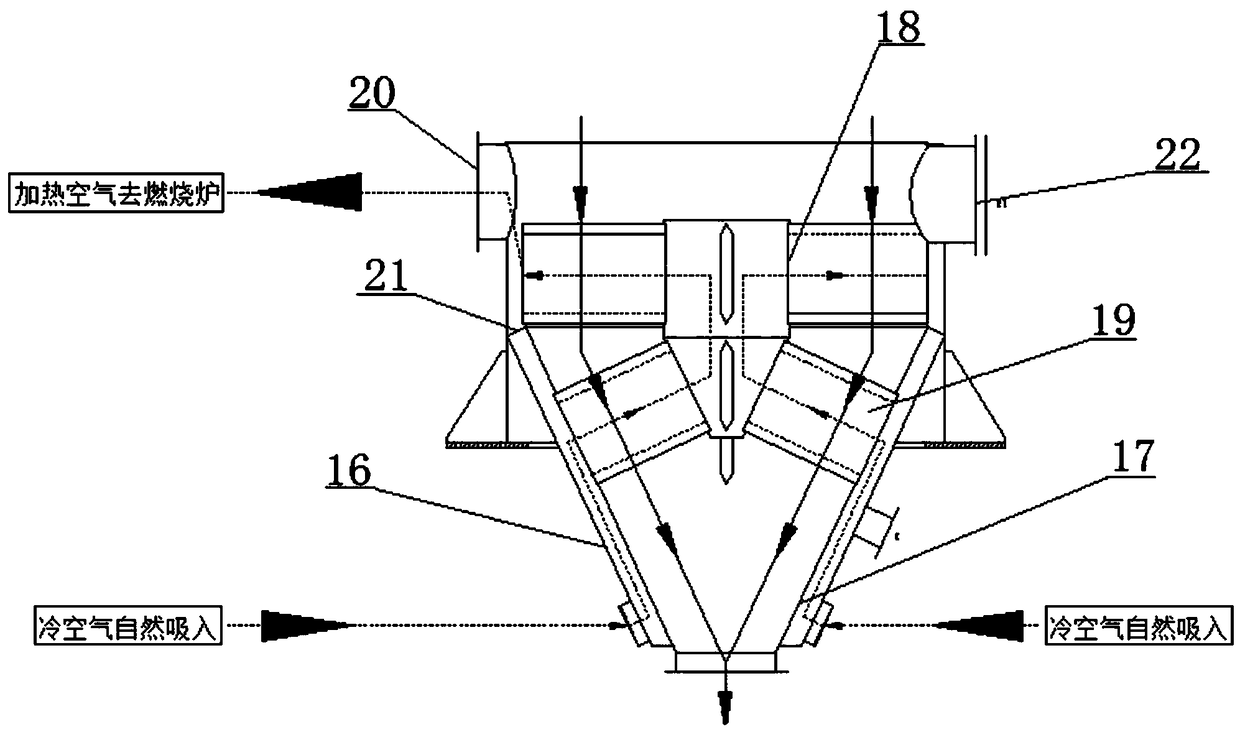

[0028] see figure 2 , the air cooler includes an outer box 16 and an inner box 17, a closed cavity is formed between the outer box 16 and the inner box 17, and the inner box 17 is provided with a closed A biochar channel is formed between the cylinder body 18 , the inner box body 16 and the cylinder body 17 . A multi-layer air cooling deflector 19 is arranged between the inner box 17 and the cylinder 18. The air cooling deflector 19 is a hollow plate with openings at both ends. The inner cavity of cylinder body 18 is connected, and the other end opening of air coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com