Patents

Literature

42results about How to "Increase pyrolysis rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

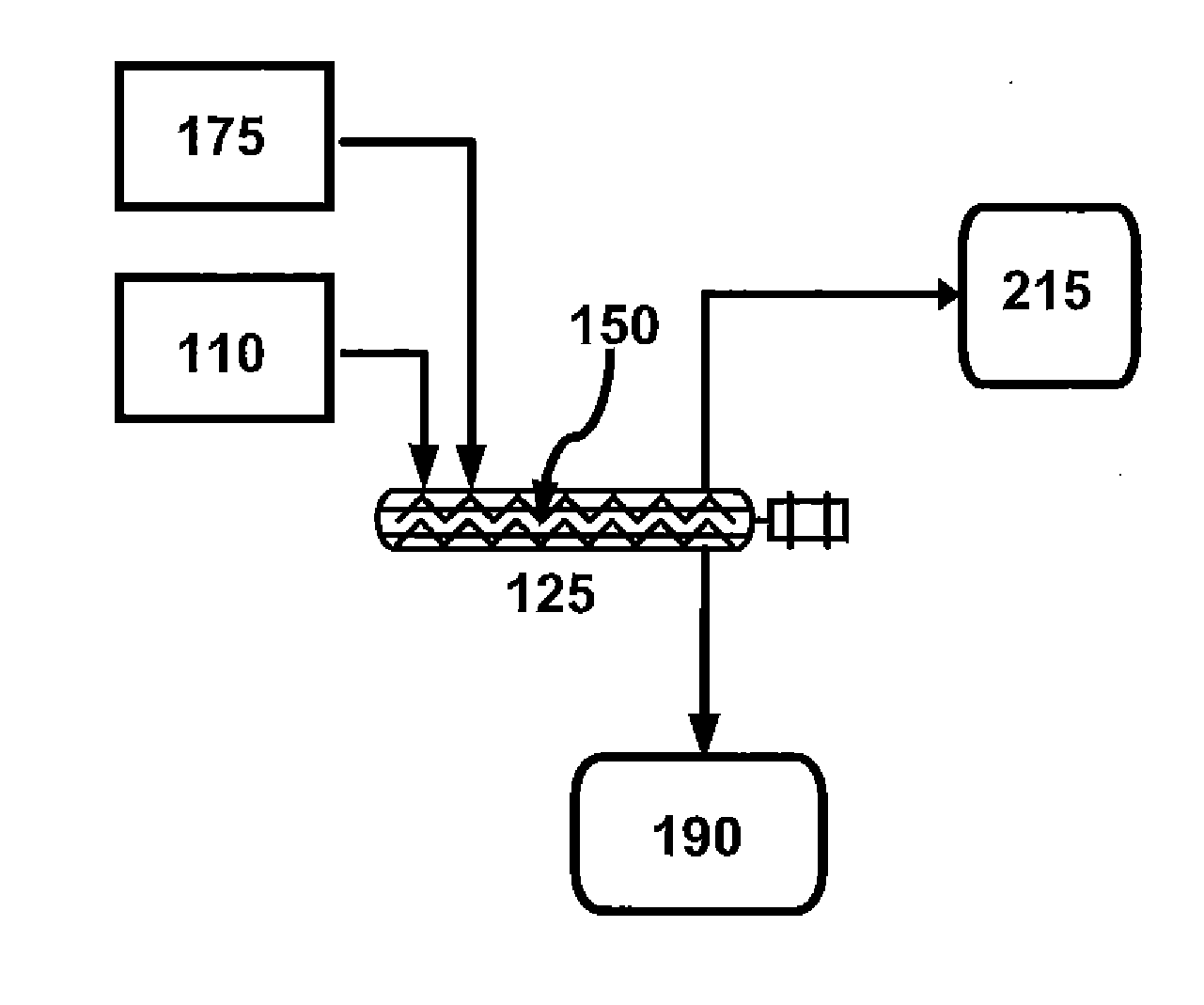

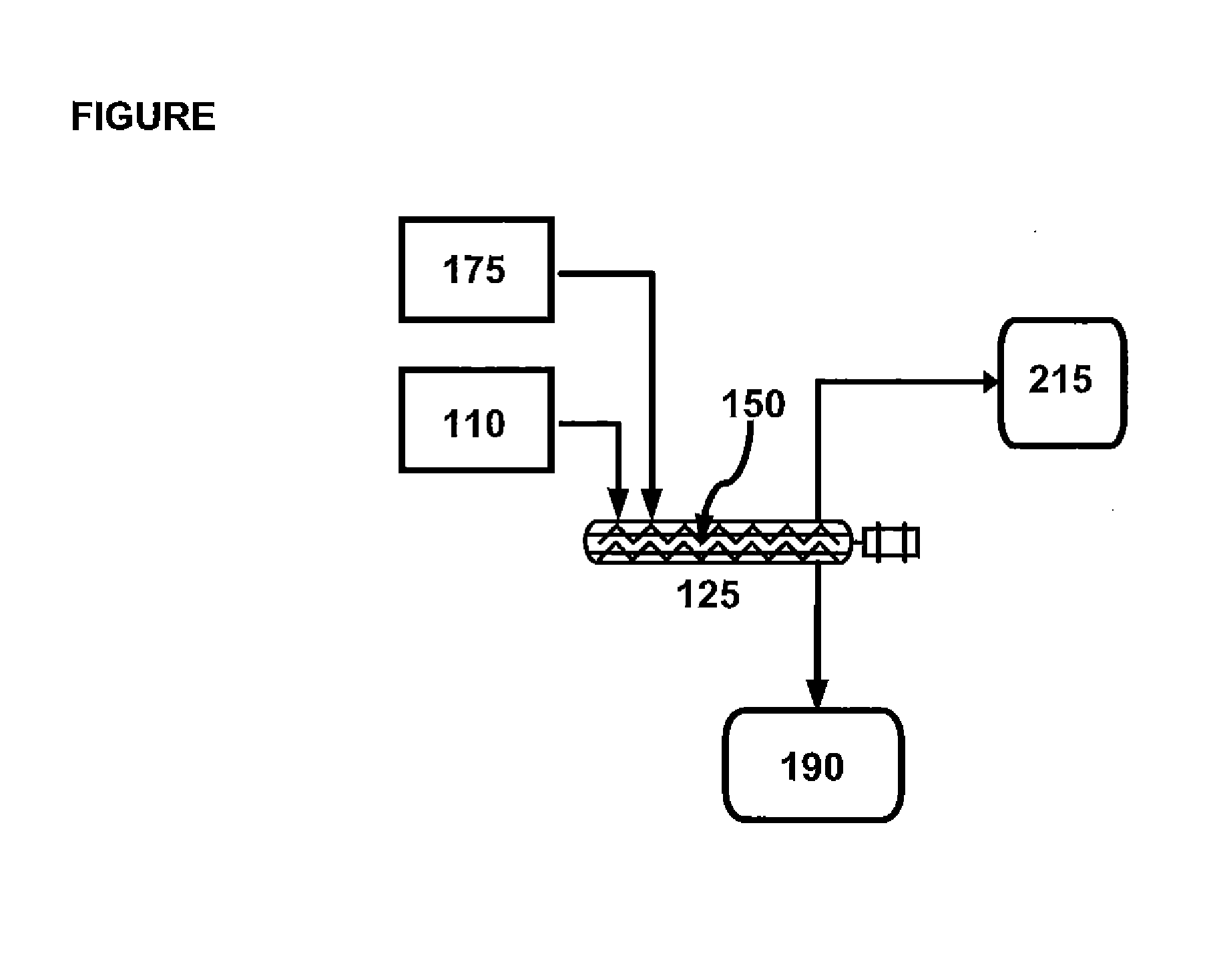

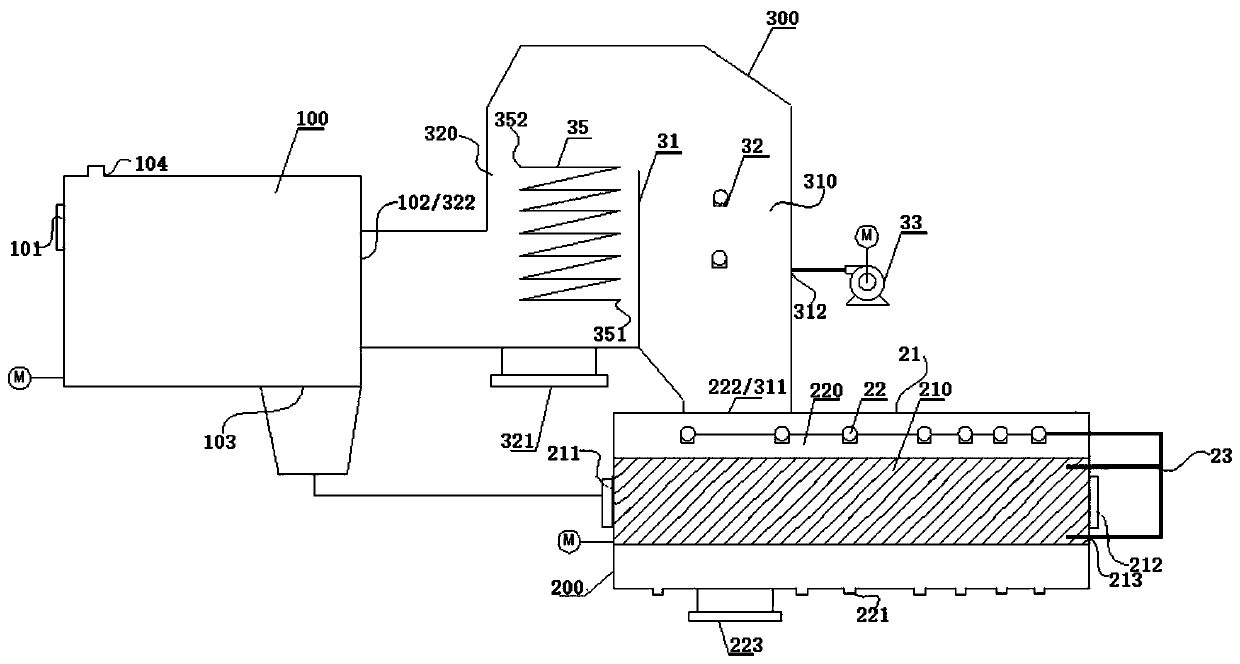

Catalytic pyrolysis of biomass in an auger reactor

InactiveUS20130327626A1Low costImprove throughputCoke ovensLiquid hydrocarbon mixture productionCatalytic pyrolysisHydrocarbon

The present invention relates generally to the thermal conversion of biomass. Processes are disclosed for converting algal biomass to condensable vapor intermediates such as pyrolysis oil by means of pyrolysis in a reactor comprising at least one auger. The intermediates may be further processed for production of renewable hydrocarbon fuels. The disclosed processes assist in preventing premature devolatization of algal biomass during pyrolysis, thereby increasing efficiency and commercial feasibility.

Owner:PHILLIPS 66 CO

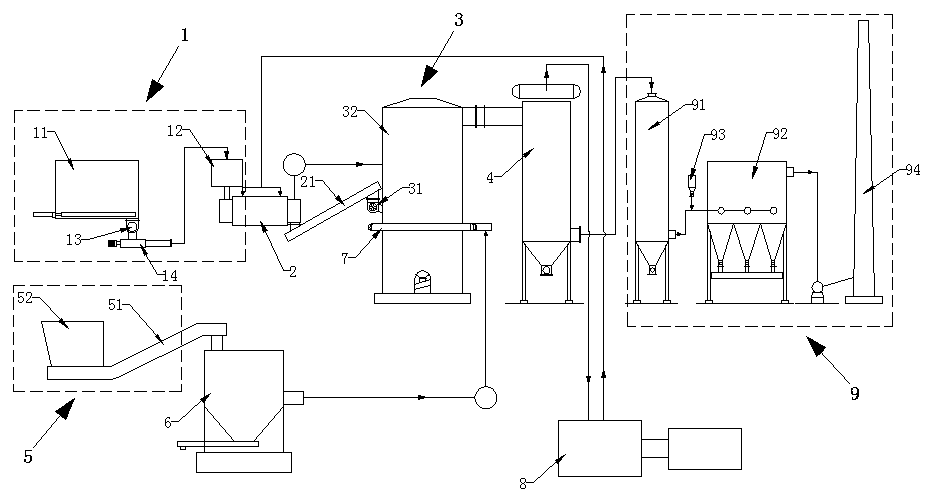

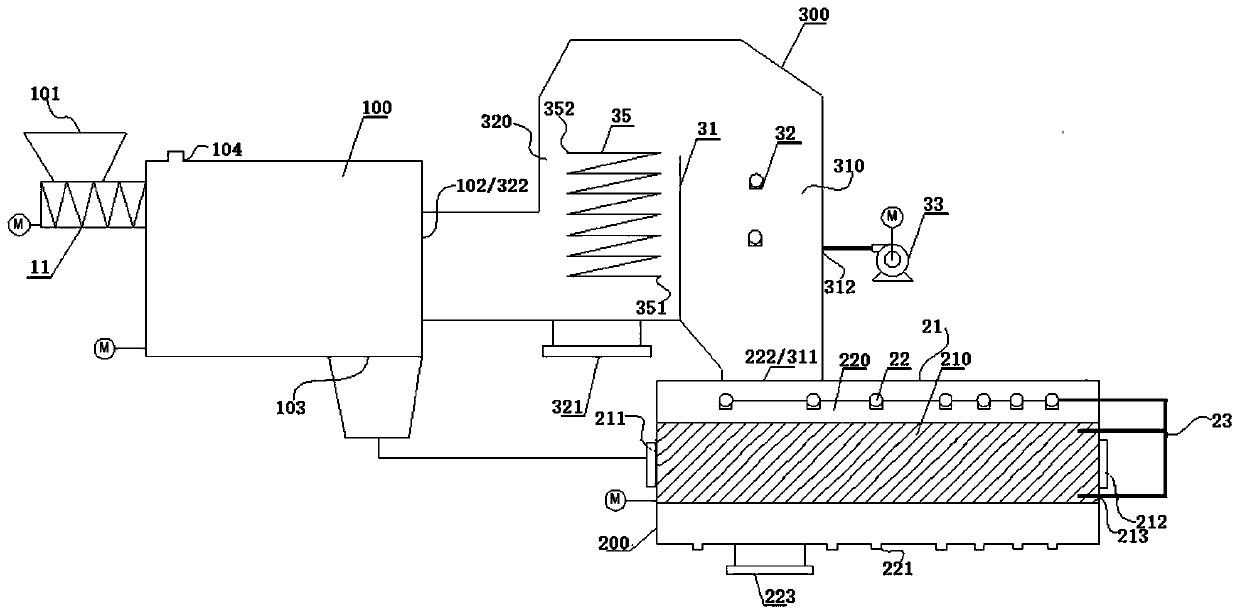

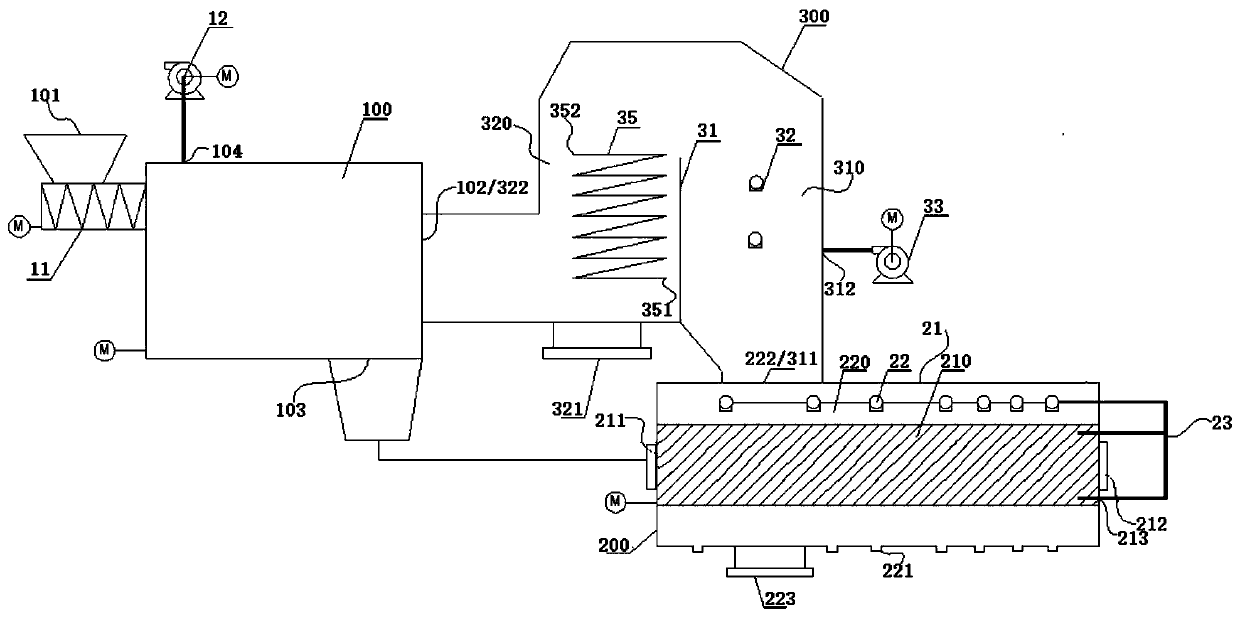

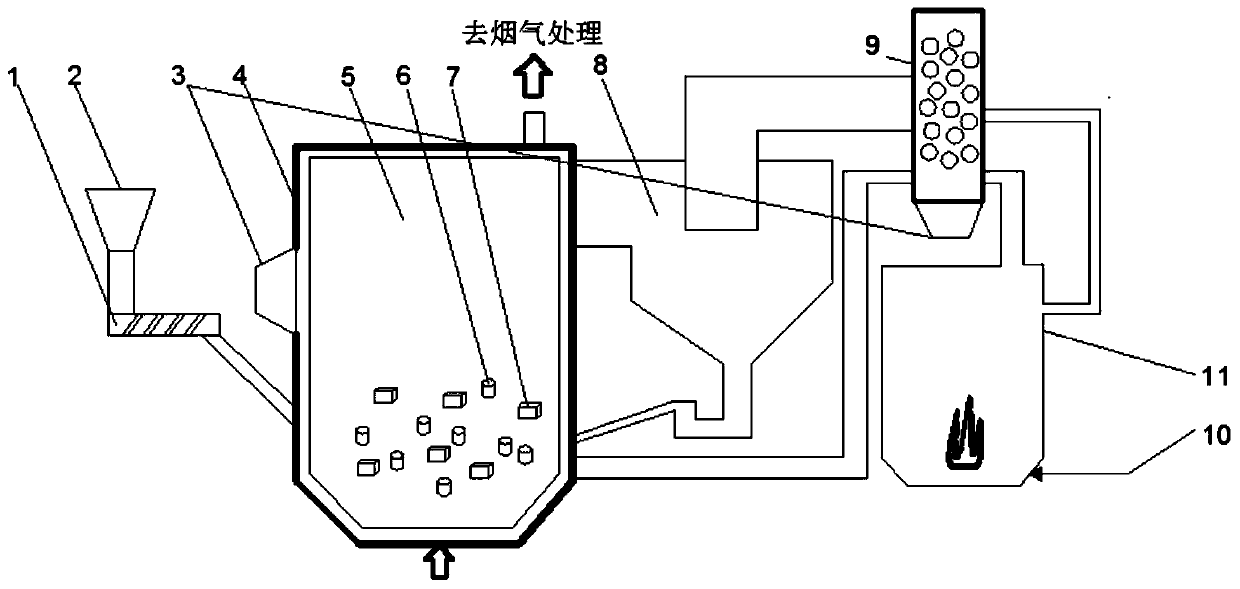

Small-scale municipal sludge and household waste synergetic incineration treatment method

PendingCN110285430ALarge capacitySignificantly harmlessSludge treatment by de-watering/drying/thickeningSteam useElectricityCombustion

The invention relates to a small-scale municipal sludge and household waste synergetic incineration treatment method. The small-scale municipal sludge and household waste synergetic incineration treatment method comprises a municipal sludge incineration system, a household waste synergetic treatment system, a waste heat recycling device and a smoke purifying system. The municipal sludge incineration system comprises a sludge feeding device, a sludge drying machine and a sludge incineration device which are sequentially connected in series. The household waste synergetic treatment system comprises a waste feeding device and a waste pyrolysis gasification furnace which are connected in series. The gas outlet end of the waste pyrolysis gasification furnace communicates to the sludge incineration device, and generated pyrolysis gasification gas is introduced into an assistant combustion device through a draught fan. The waste heat recycling device is a waste heat boiler, the waste heat boiler is used for generating steam by heating boiler feed water, the steam communicates with a turbine generator set, the turbine generator set utilizes the steam generated by the waste heat boiler through absorbing heat to generate electricity, the electricity is used for auxiliary power supply supplementation of the municipal sludge incineration system and the household waste treatment system. First-grade exhausted steam of the turbine generator set is conveyed into the sludge drying machine to be used as a heat source for drying the sludge. The smoke generated after sludge incineration is processed by the smoke purifying system and is discharged after reaching standards.

Owner:HUEYA ENVIRONMENTAL ENG

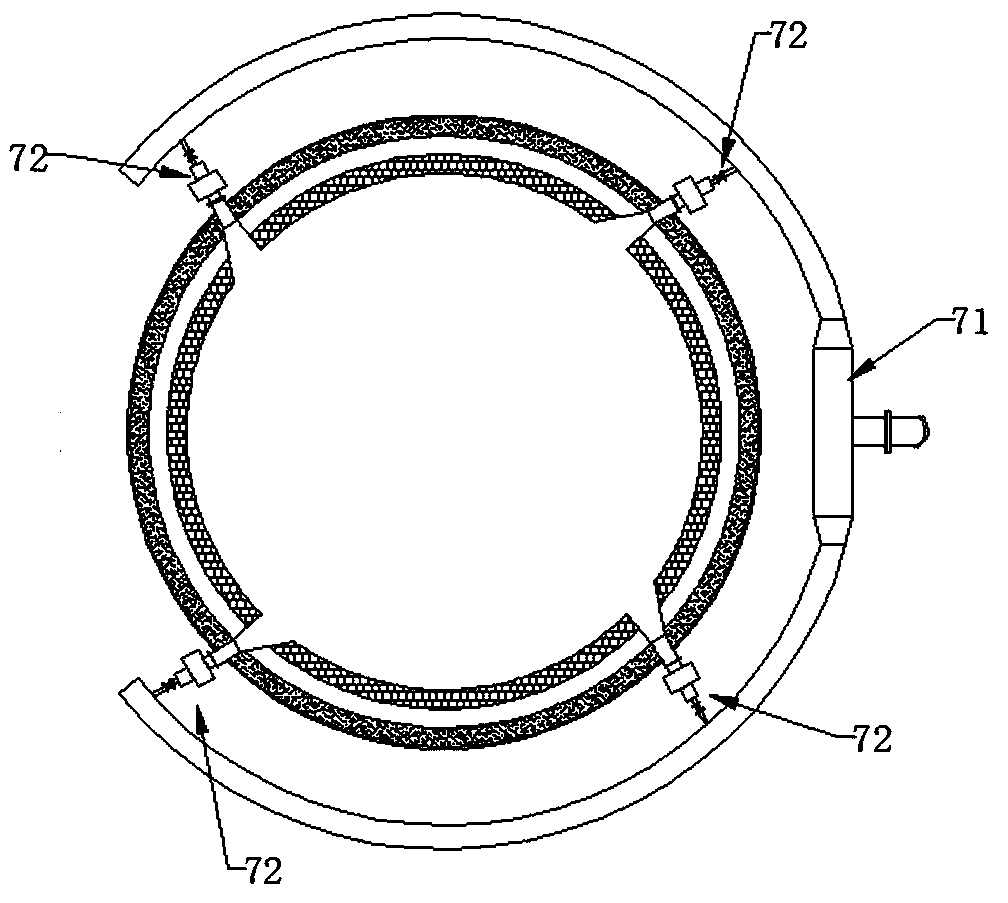

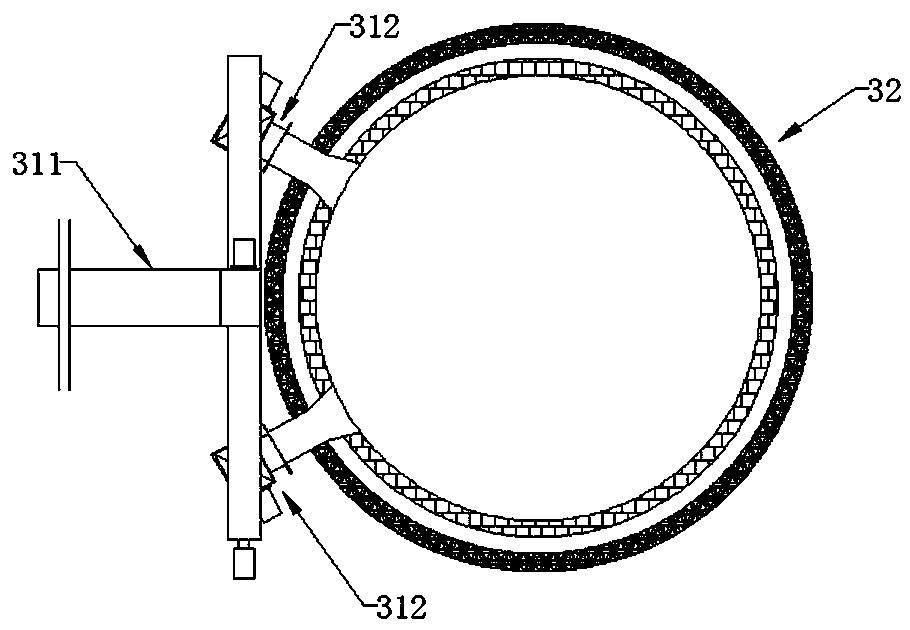

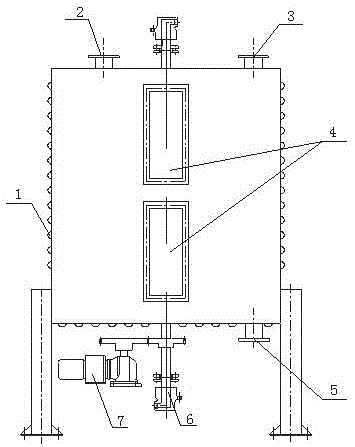

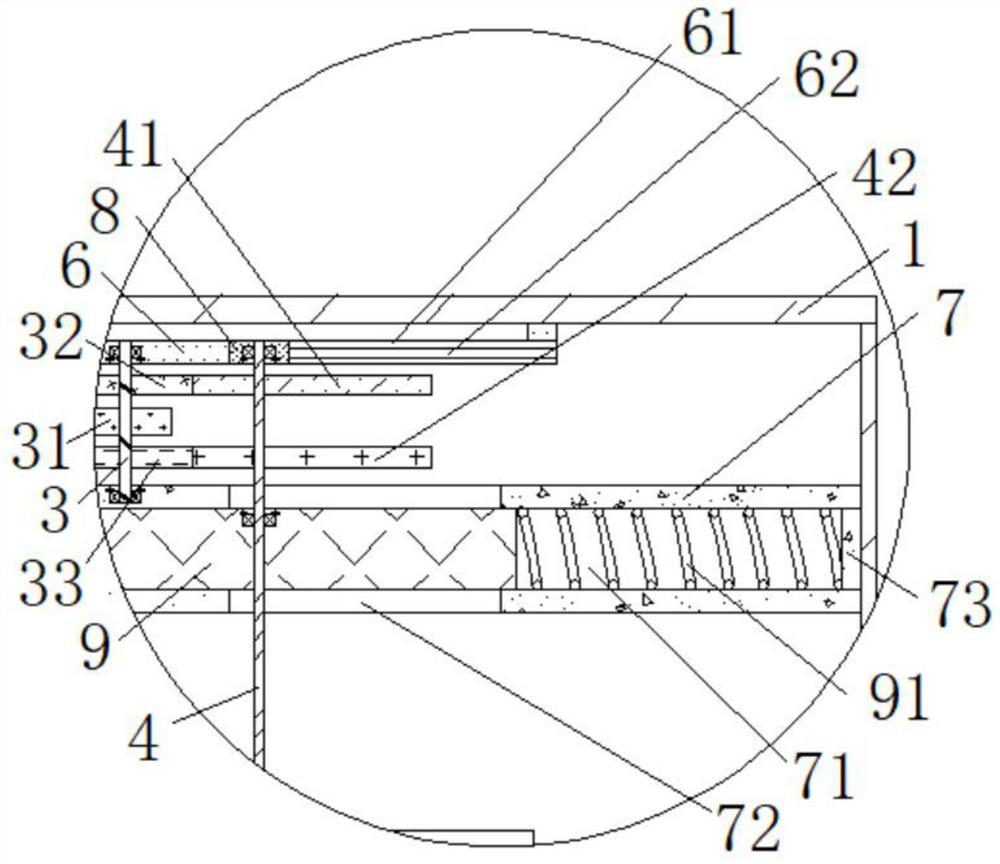

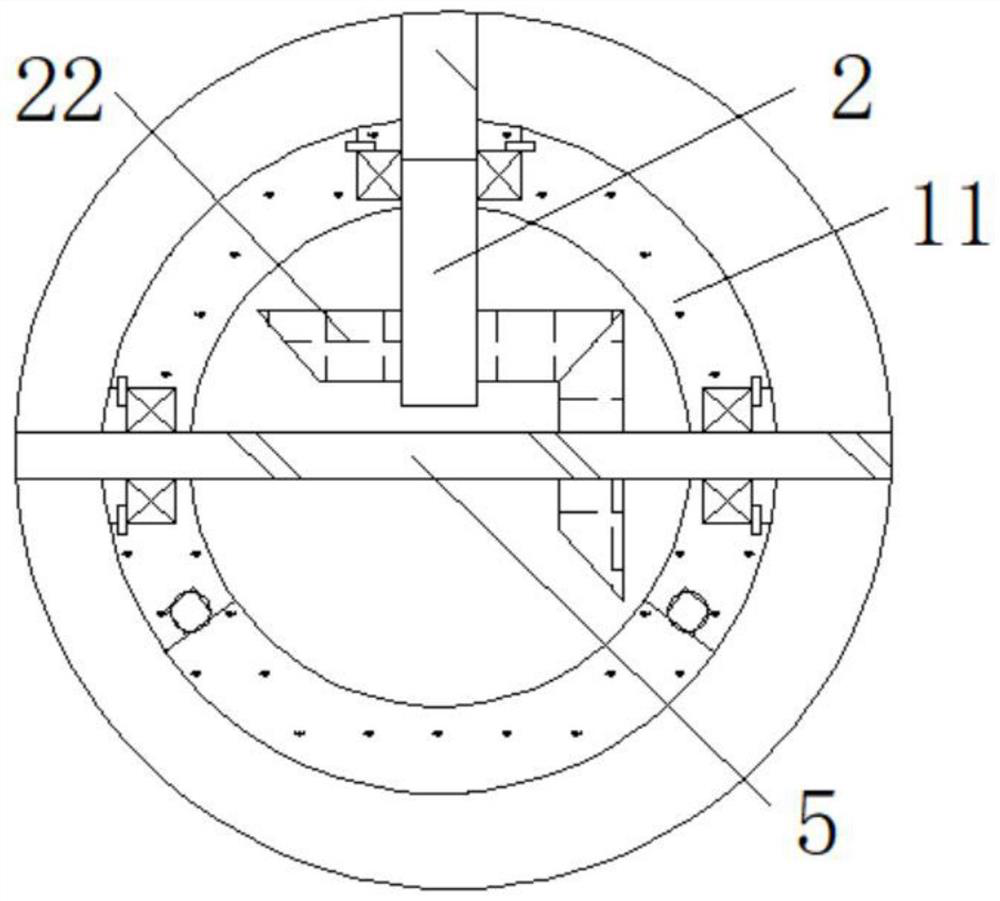

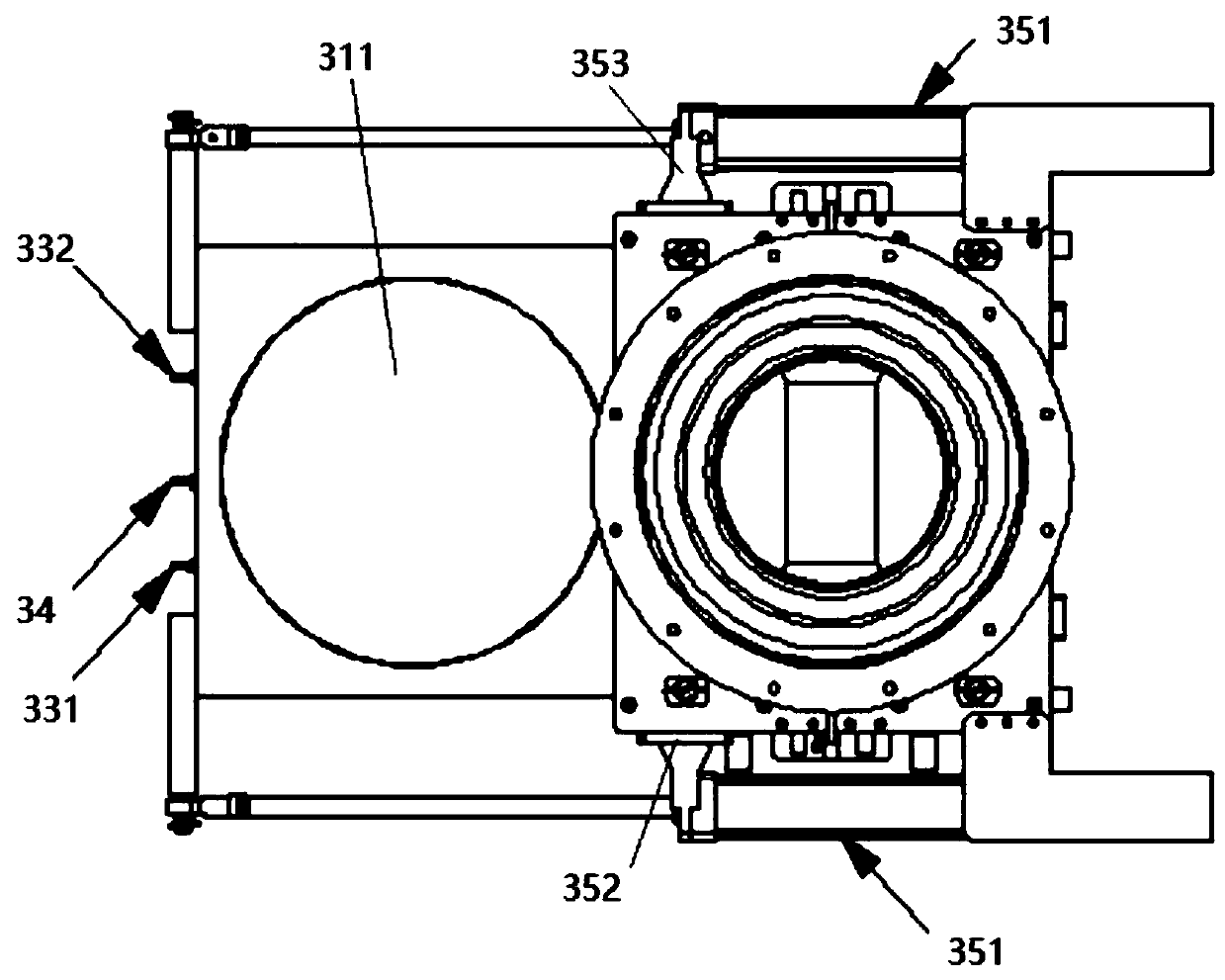

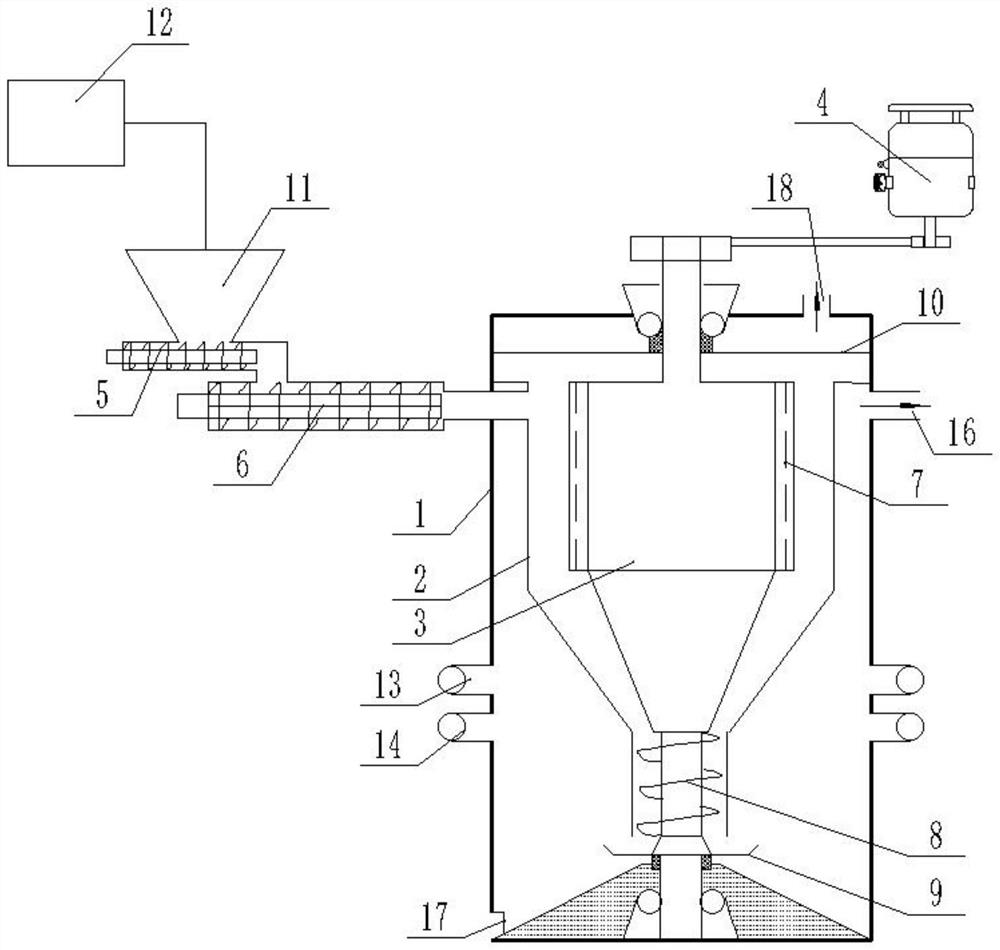

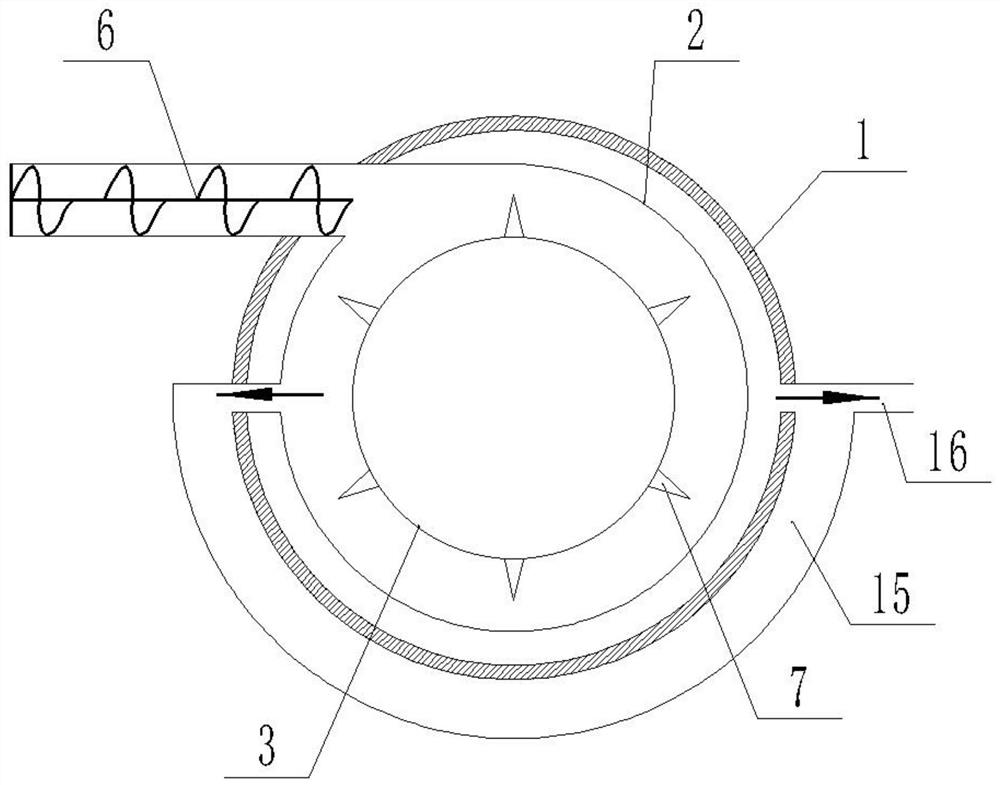

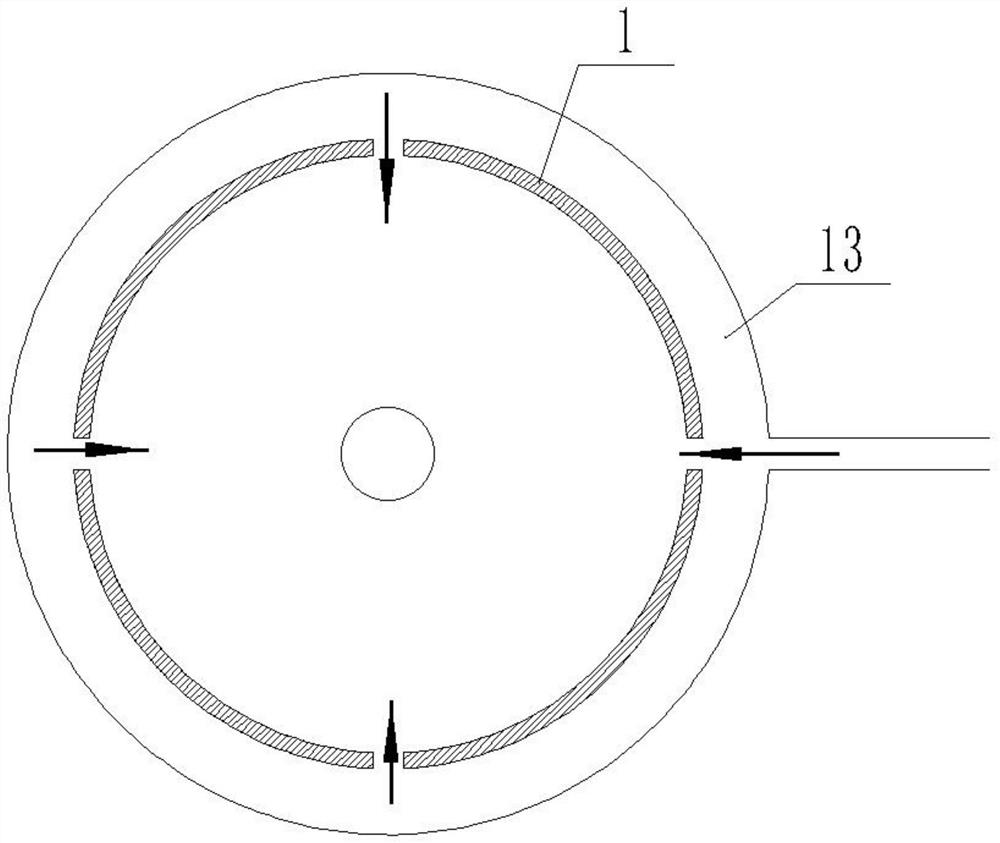

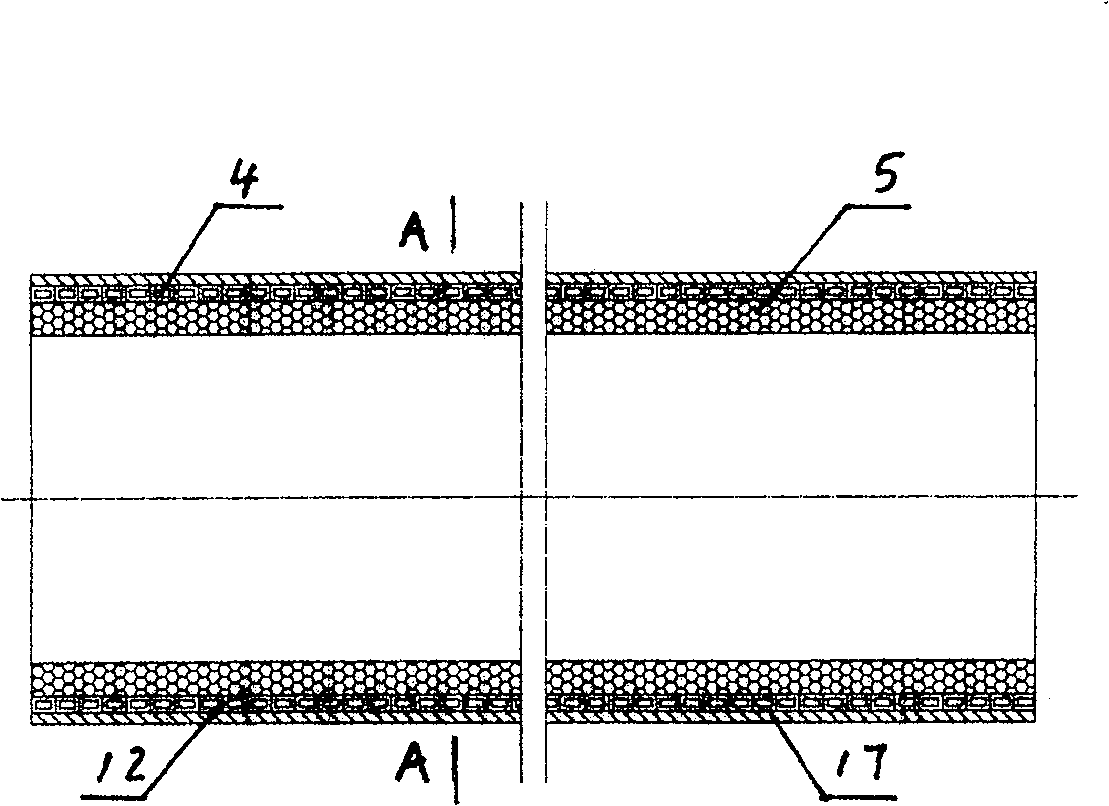

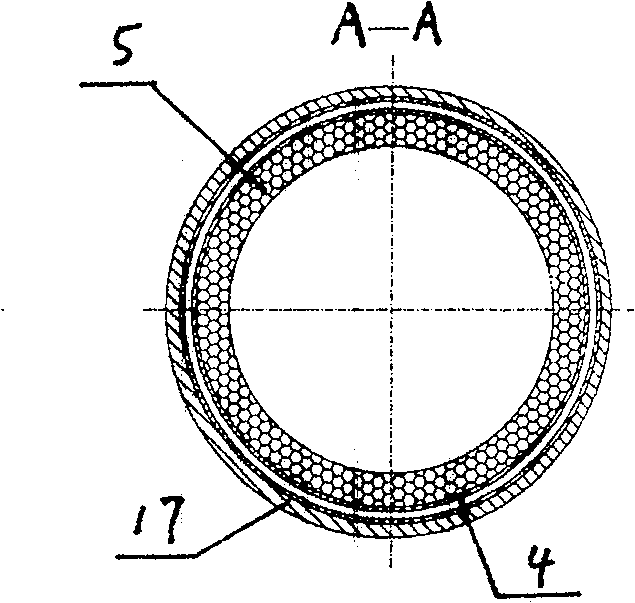

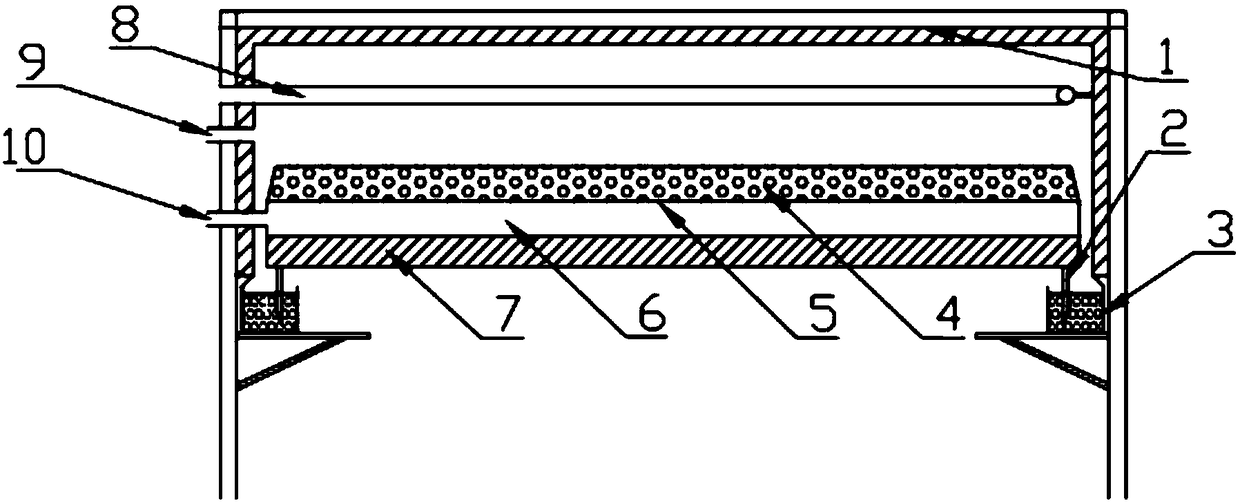

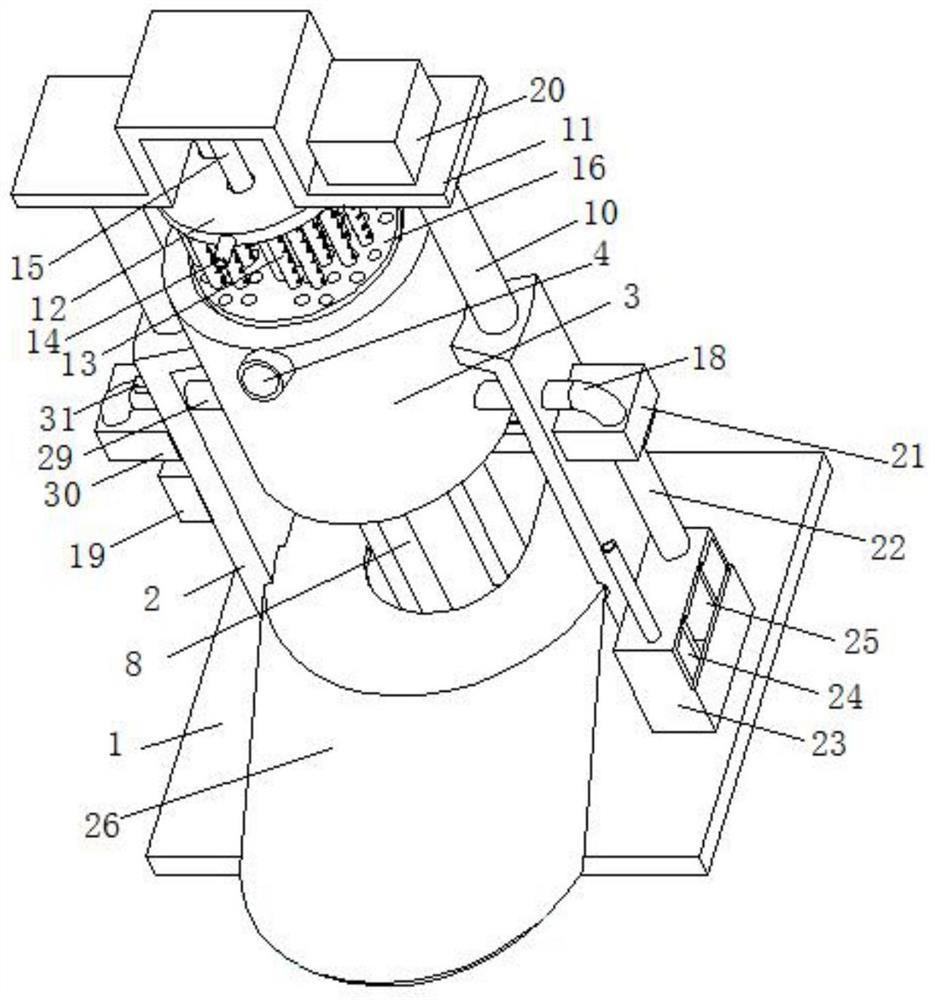

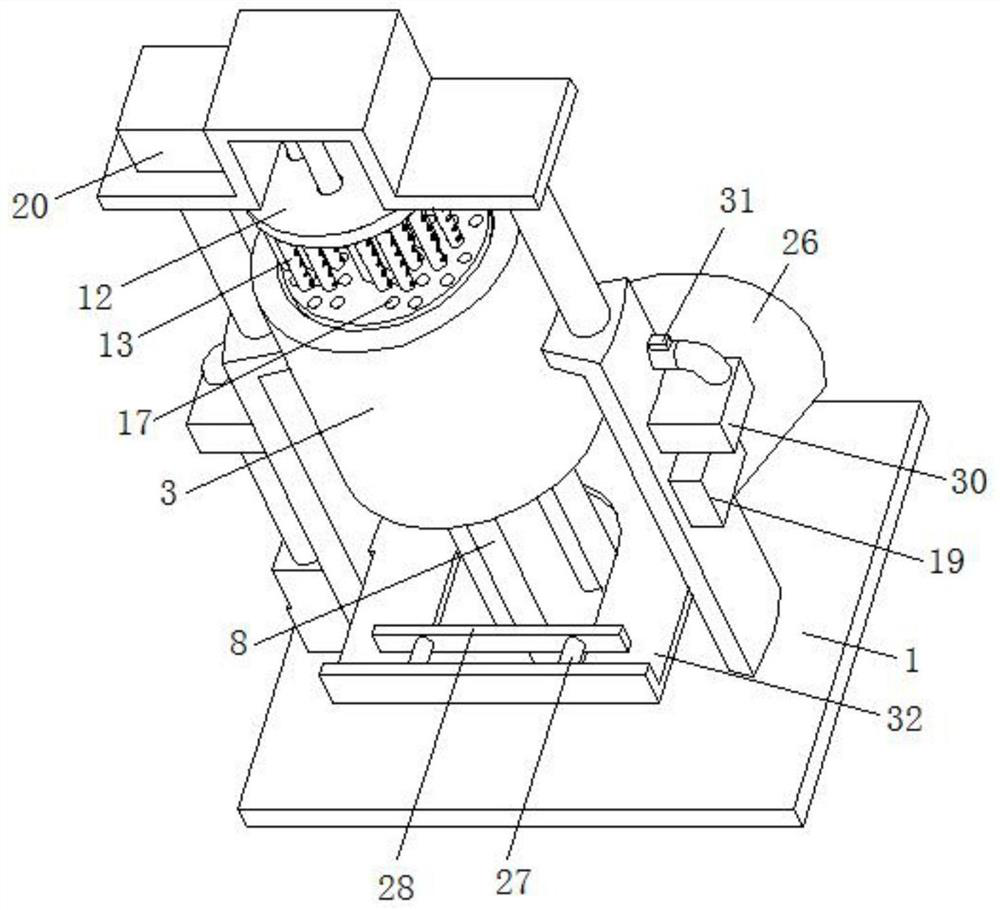

Acid leaching ore pulp liquid drying pyrolysis device

ActiveCN106500484AIncreased contact surface areaIncrease pyrolysis rateDrying gas arrangementsDrying machines with non-progressive movementsCircular discSlurry

An acid leaching ore pulp liquid drying pyrolysis device comprises an outer shell, ore pulp liquid pyrolysis disc sets arranged in the shell, a feeding pipe, a scraping knife, a steel brush, a material absorption device, a heat source system and a transmission device, wherein the feeding pipe, the scraping knife, the steel brush and the material absorption device are used in cooperation with the disc sets and arranged in the shell. The acid leaching ore pulp liquid drying pyrolysis device has the beneficial effects that compared with traditional liquid material drying equipment, the device is of a vertical structure, space arrangement is small, the material contact superficial area is enlarged, the drying pyrolysis efficiency is improved, and energy consumption is reduced; innovation is carried out on the basis of a traditional disc drying machine, an outer jacket type and disc hollow inner cavity dual heating system is adopted, the pyrolysis rate of pulp is increased, meanwhile, pulp liquid pyrolysis discs can rotate intermittently, other auxiliary components such as the scraping knife and the steel brush do not rotate, the number of rotating components is small, the device operating stability is good, and power consumption is low; and a dust suction manner is adopted by dry materials, and compared with a scraper blade chute structure, discharging is simple and thorough.

Owner:JINCHUAN GROUP LIMITED

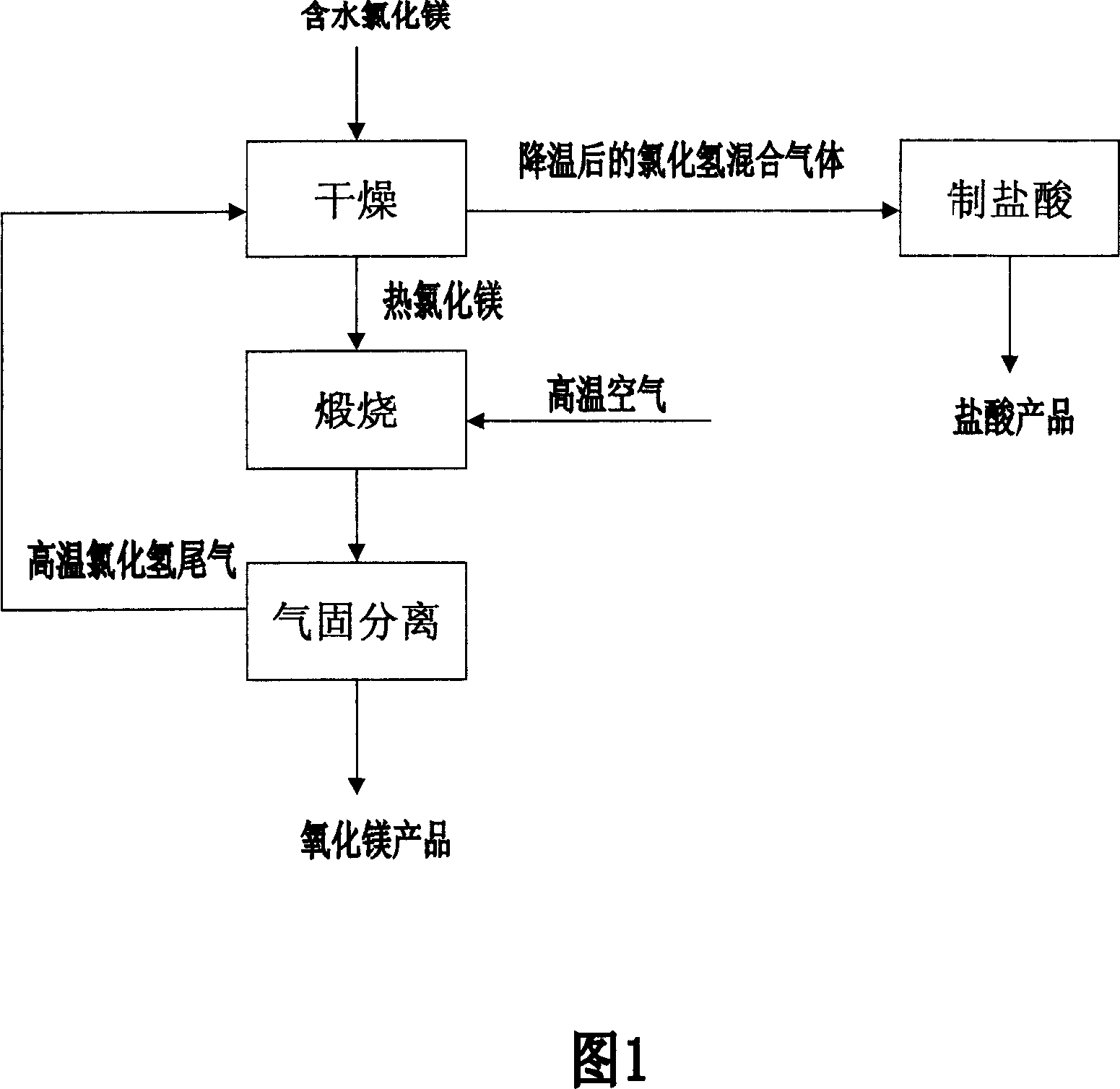

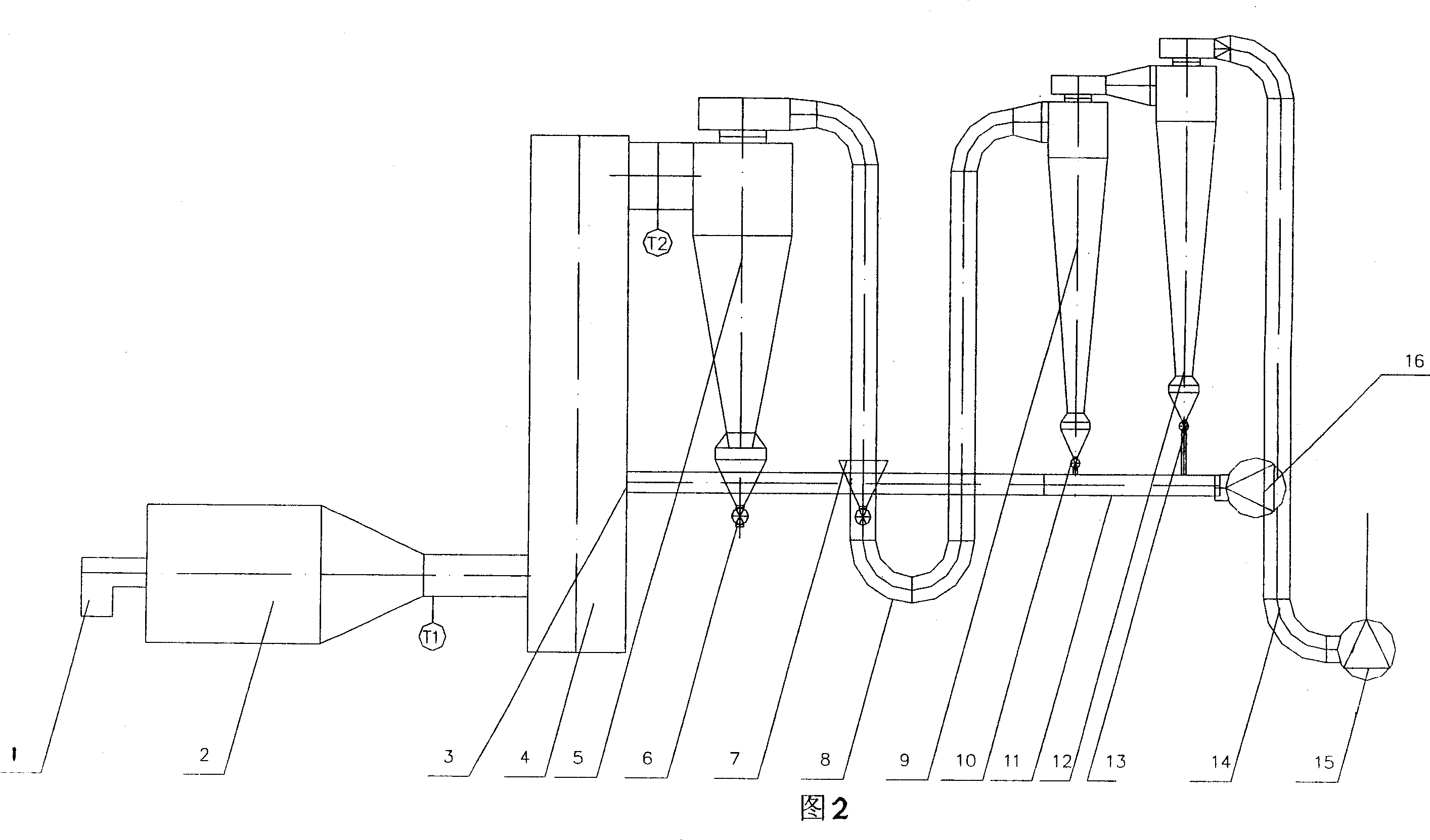

Process and apparatus for preparing magnesium oxide and hydrogen chloride mixed gas by two-stage dynamic calcining of magnesium chloride

ActiveCN101007643AIncrease pyrolysis rateAdvanced, mature and reliable technologyMagnesiaPreparation from chloridesGas solidPhysical chemistry

Owner:青海中信国安锂业发展有限公司

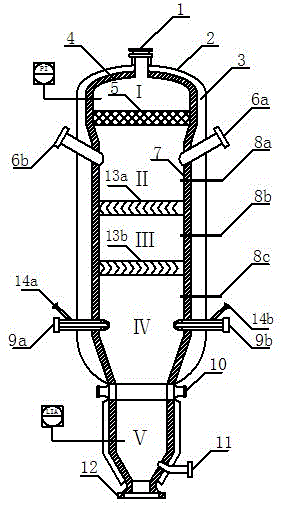

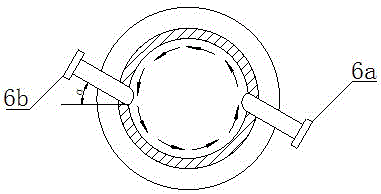

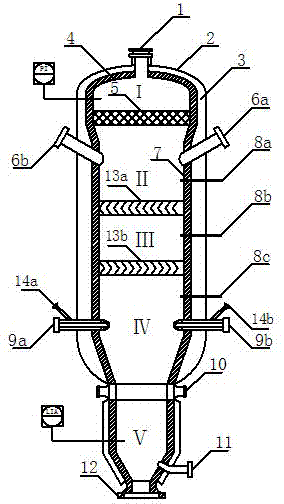

Pyrolysis device for processing desulfurization waste liquid in partial oxidation environment

InactiveCN103951131AAchieve recyclingFlexible operationMultistage water/sewage treatmentLiquid wastePartial oxidation

The invention discloses a pyrolysis device for processing desulfurization waste liquid in a partial oxidation environment. The pyrolysis device comprises a pressure-bearing housing, a jacket, an insulating layer and a refractory brick which are arranged from outside to inside and connected together, and a gas separation section I, a spray pyrolysis section II, a mixed flow pyrolysis section III, an inactive salt pyrolysis section IV and a pyrolysis salt chilling section V are communicated from top to bottom to treat the desulfurization waste liquid in the partial oxidation environment. The device adopts a segmental treatment mode, so that decomposition of aromatic compounds and organic matters in the desulfurization waste liquid is ensured in the partial oxidation environment, COD and sulfides in the generated wastewater are reduced, meanwhile, pyrolysis of the inactive salt in the desulfurization waste liquid in the reducing atmosphere is ensured; therefore, the pollution problem of the desulfurization waste liquid is thoroughly solved and effective components in the desulfurization waste liquid can be recycled.

Owner:TAIYUAN UNIV OF TECH

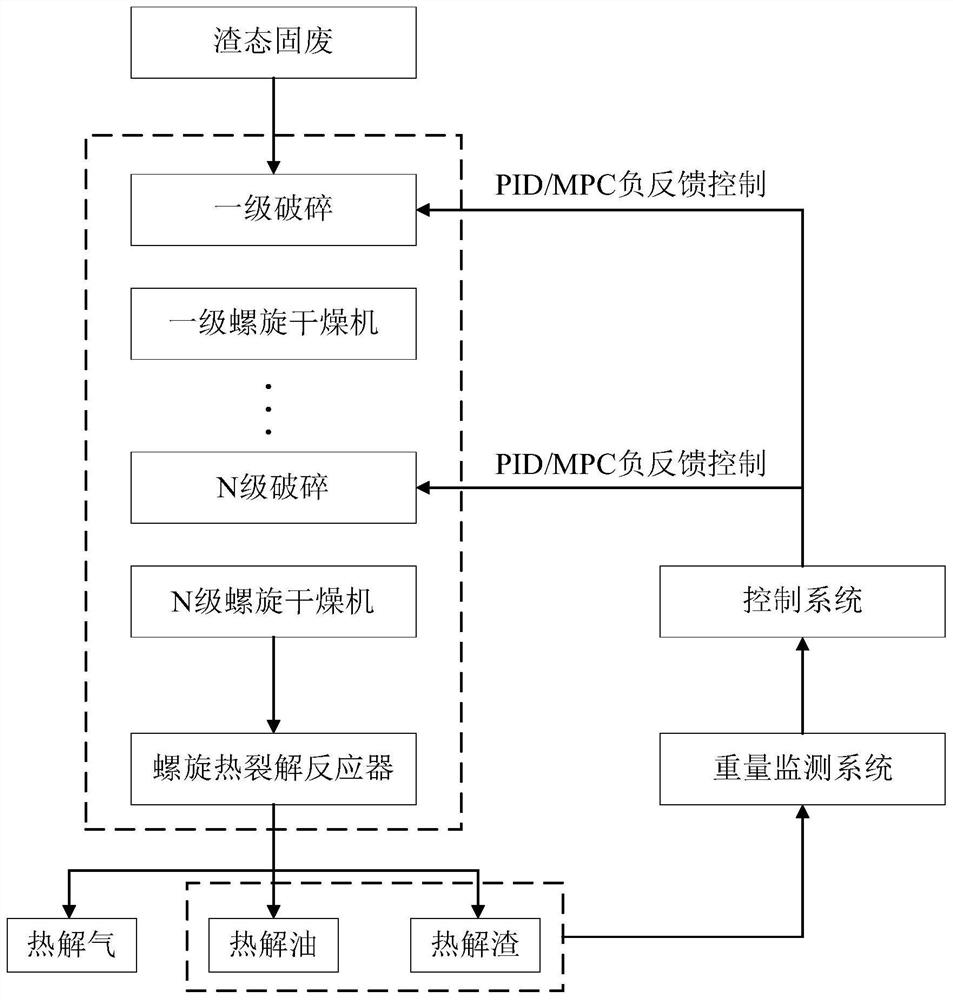

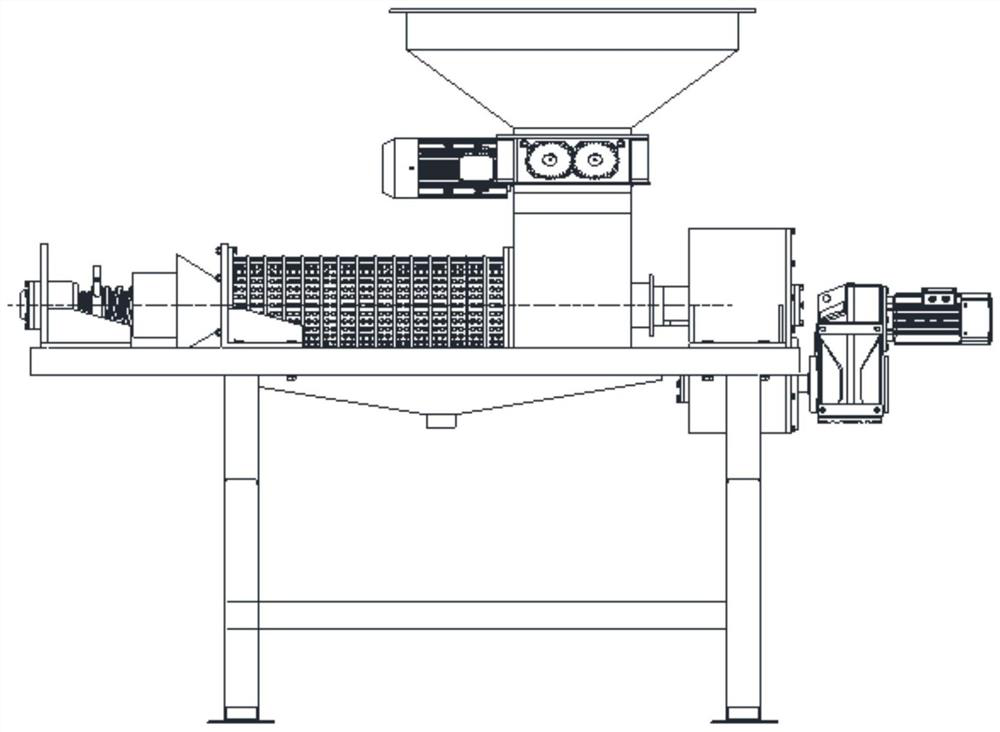

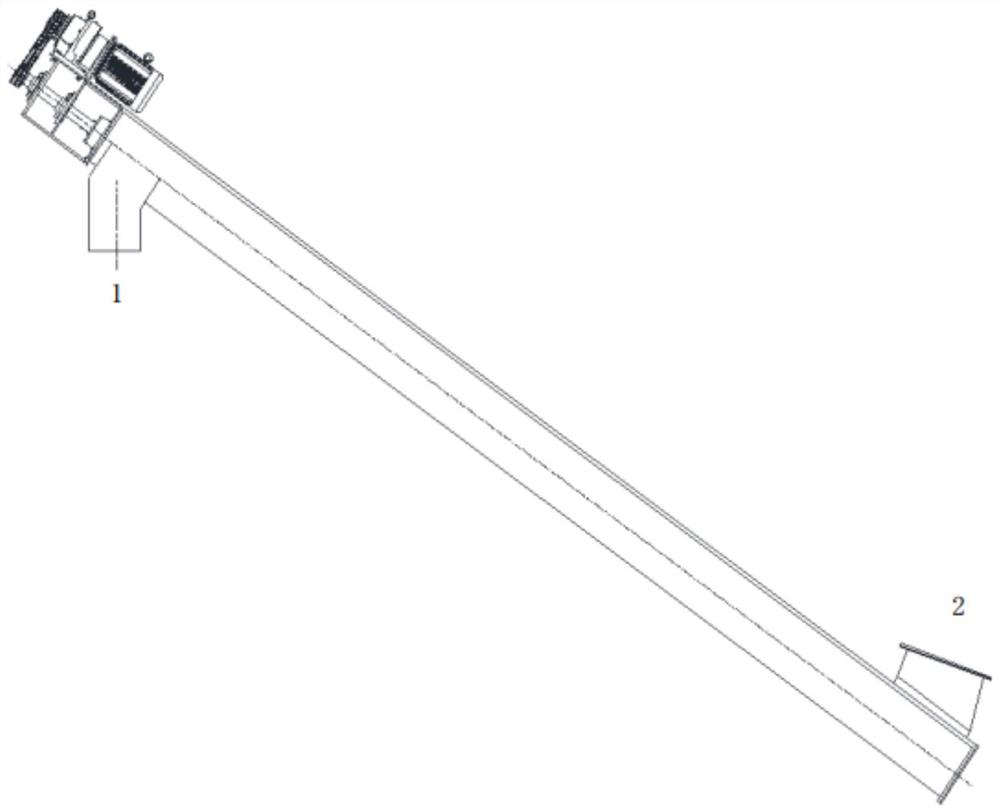

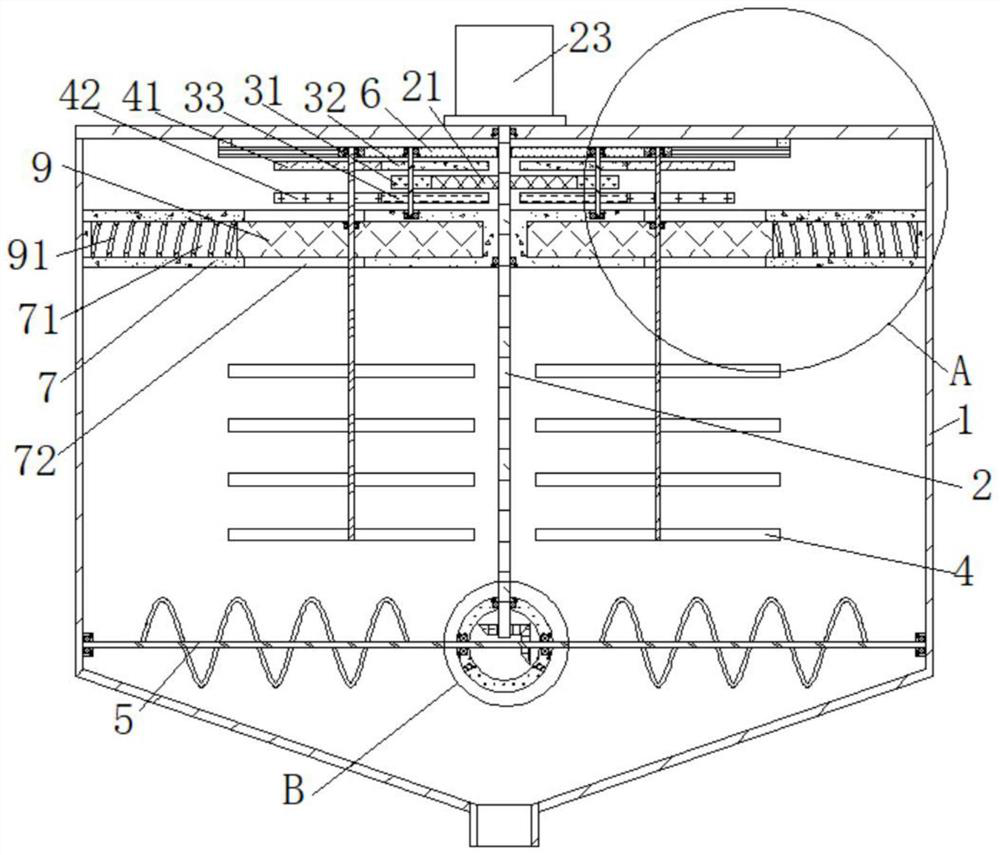

Multi-stage crushing intelligent treatment device and method for high-water-content slag-state solid waste

ActiveCN112254146AAvoid Thermal Stress Fatigue ProblemsBreak through the status quo of low intelligenceIncinerator apparatusNegative feedbackSlag

The invention belongs to the field of solid waste treatment, and particularly discloses a multi-stage crushing intelligent treatment device and method for high-water-content slag-state solid waste. The multi-stage crushing intelligent treatment device comprises a multi-stage crushing and drying module, a thermal cracking reaction module and a negative feedback control module, wherein the multi-stage crushing and drying module comprises multi-stage crushing and drying units connected in sequence. Each crushing and drying unit comprises a crusher and a dryer which are connected, wherein the crusher is used for crushing and granulating the slag-state solid waste, and the dryer is used for drying and dehydrating the slag-state solid waste. The thermal cracking reaction module comprises a thermal cracking reactor, wherein the thermal cracking reactor is connected with the last-stage dryer and is used for carrying out thermal cracking reaction on the crushed and dried slag-state solid waste.The negative feedback control module is used for monitoring the quality of cracking oil and cracking slag, controlling the working frequency and power of the crushers and further controlling the thermal cracking reaction degree. According to the multi-stage crushing intelligent treatment device, the intelligent treatment of the slag-state solid waste is realized, the treatment efficiency and thequality of cracking oil and cracking gas are improved, and meanwhile, the energy consumption is reduced.

Owner:深圳市捷晶科技股份有限公司 +1

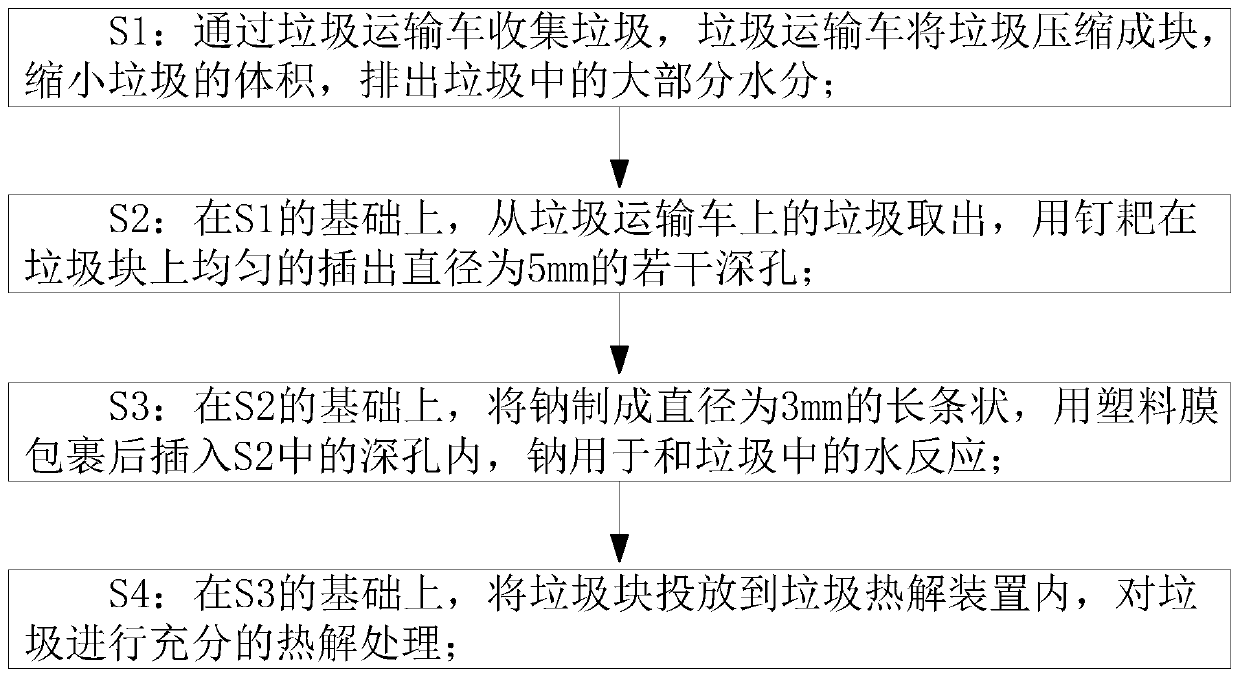

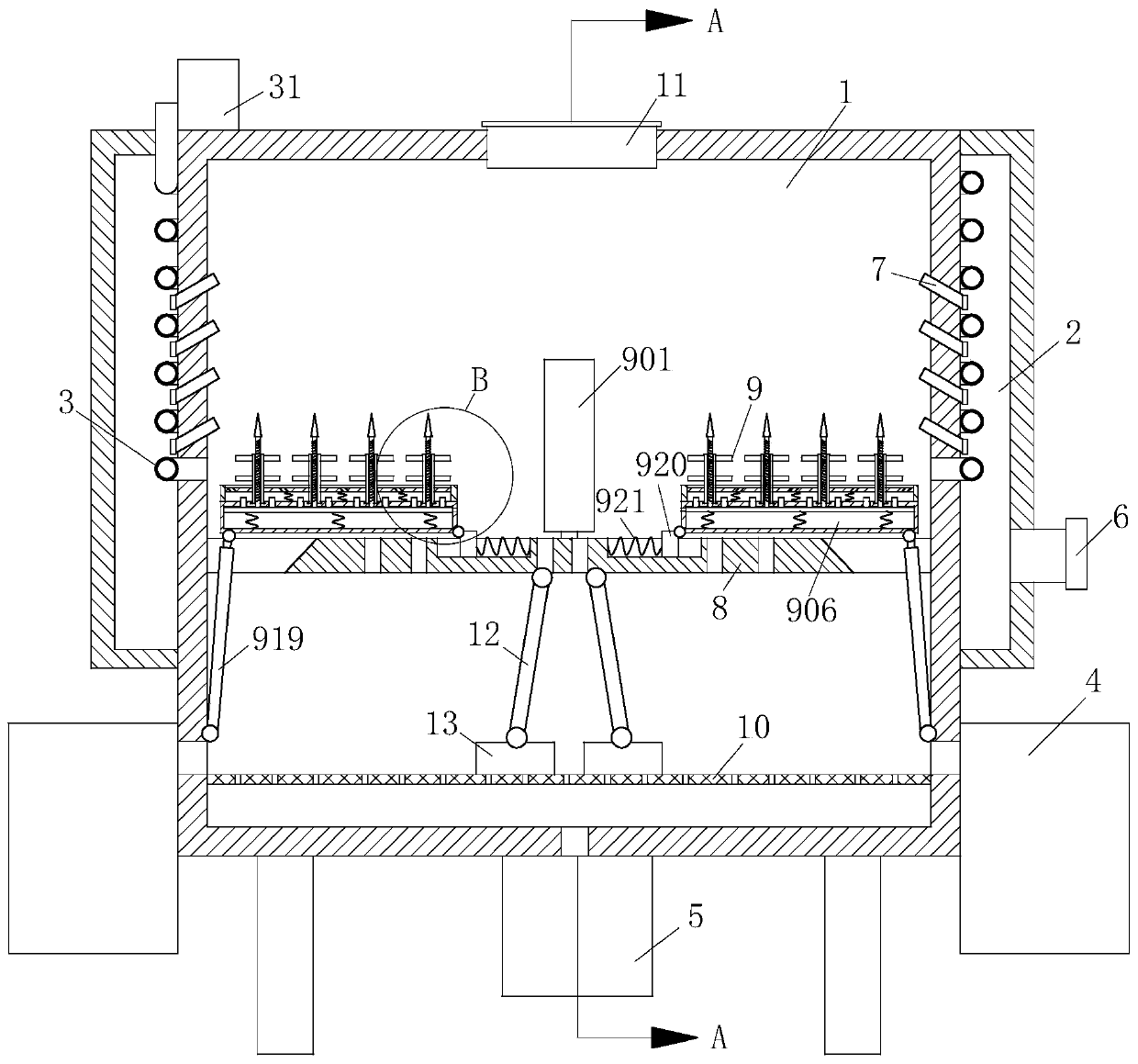

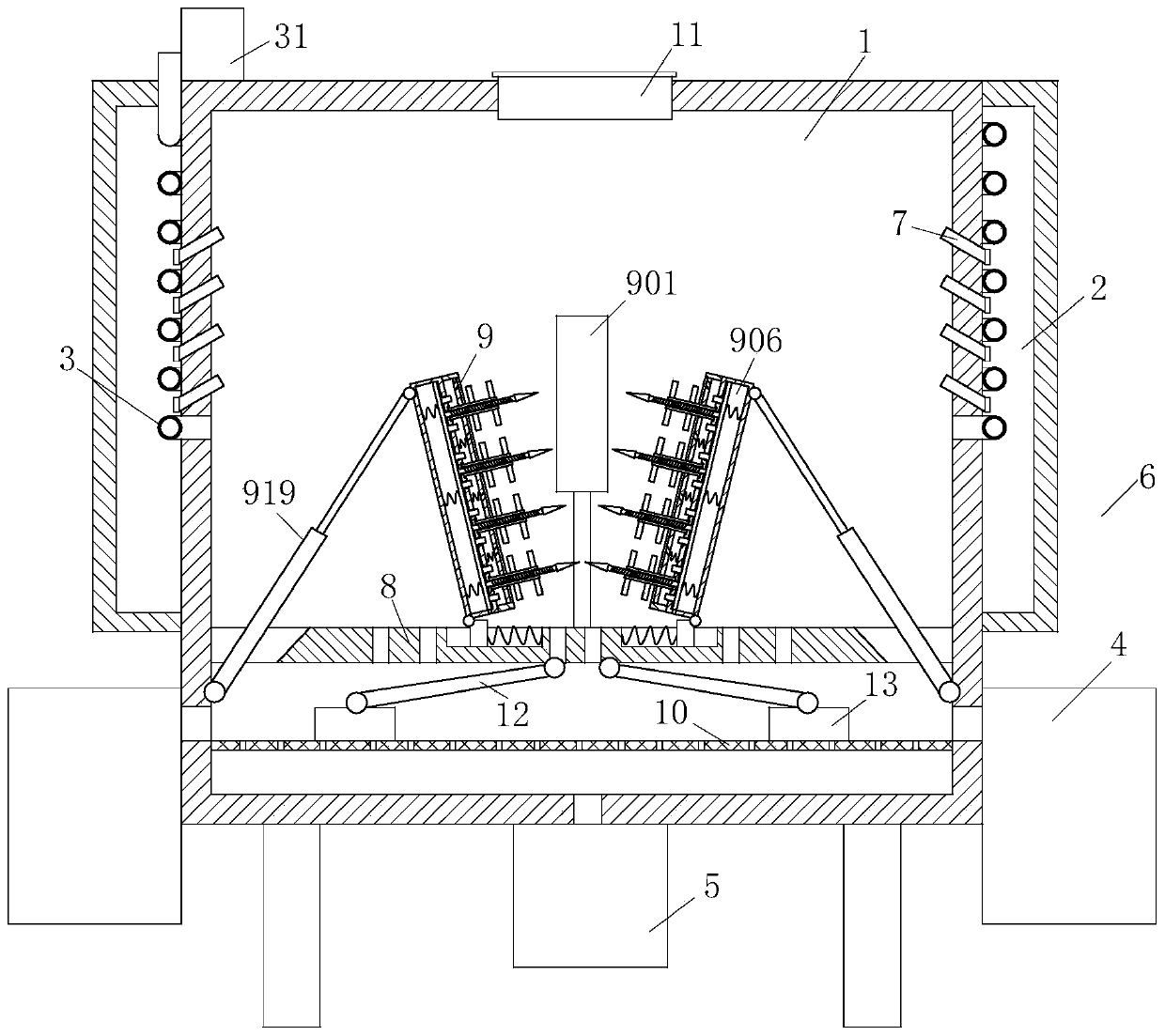

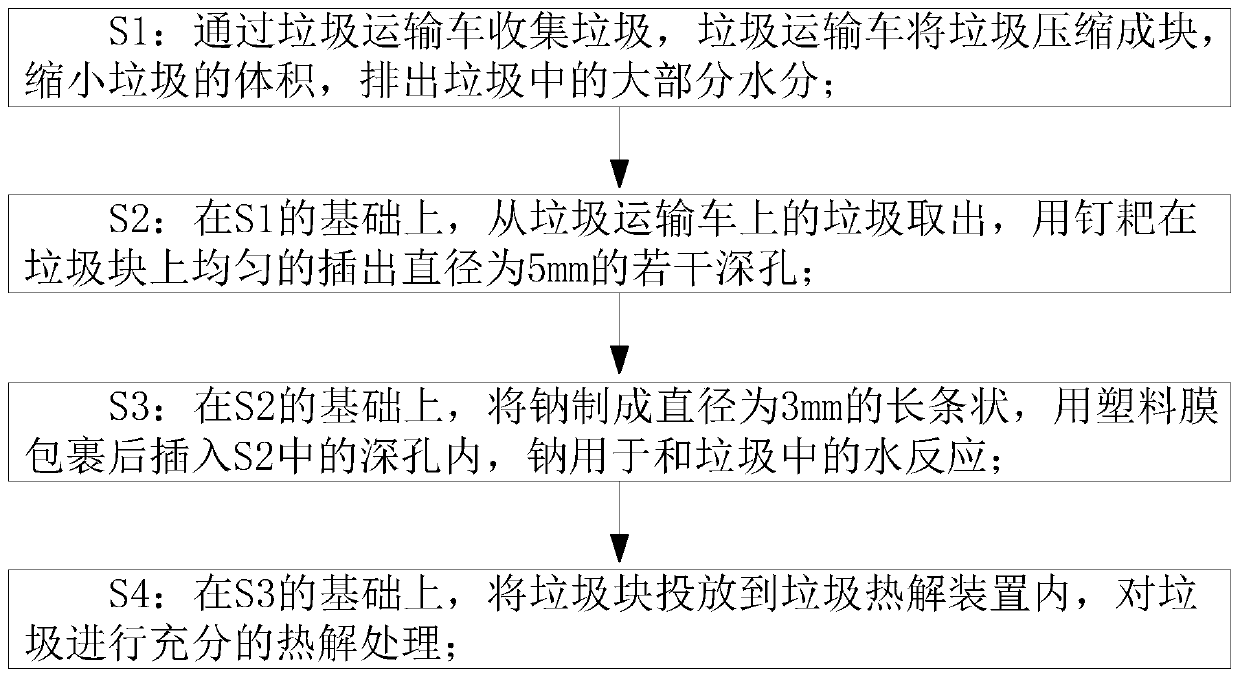

High-efficiency environment-friendly garbage pyrolysis process

ActiveCN109737424AIncrease pyrolysis rateEfficient combustionIncinerator apparatusHydrogenCombustion

The invention belongs to the technical field of garbage treatment, and particularly relates to a high-efficiency environment-friendly garbage pyrolysis process. A garbage pyrolysis device comprises anincineration chamber, a hot air chamber, a smoke discharge pipe, a slag collecting box, a garbage water recycling tank, an air conveying channel, an air conveying pipe, a partition plate, a combustion-supporting mechanism, a filter screen and a feeding port with a sealing cover; the hot air chamber is arranged on the outer side of the incineration chamber, a gas conveying pipeline is arranged onthe hot air chamber; the air conveying channel is used for conveying hot air for pyrolysis to the hot air chamber; the waste is compressed, punched and inserted into the sodium; the garbage pyrolysisdevice can tear the plastic film on the sodium when the waste pyrolysis device works, so that the sodium is in contact with the water in the garbage, a large amount of hydrogen is released, the hydrogen enables the garbage blocks to be opened, and hydrogen is ignited in the pyrolysis device, so that the interior and the exterior of the rubbish block are simultaneously combusted, so that the rubbish pyrolysis speed is greatly increased.

Owner:JINGMEN TUODA TECH CO LTD

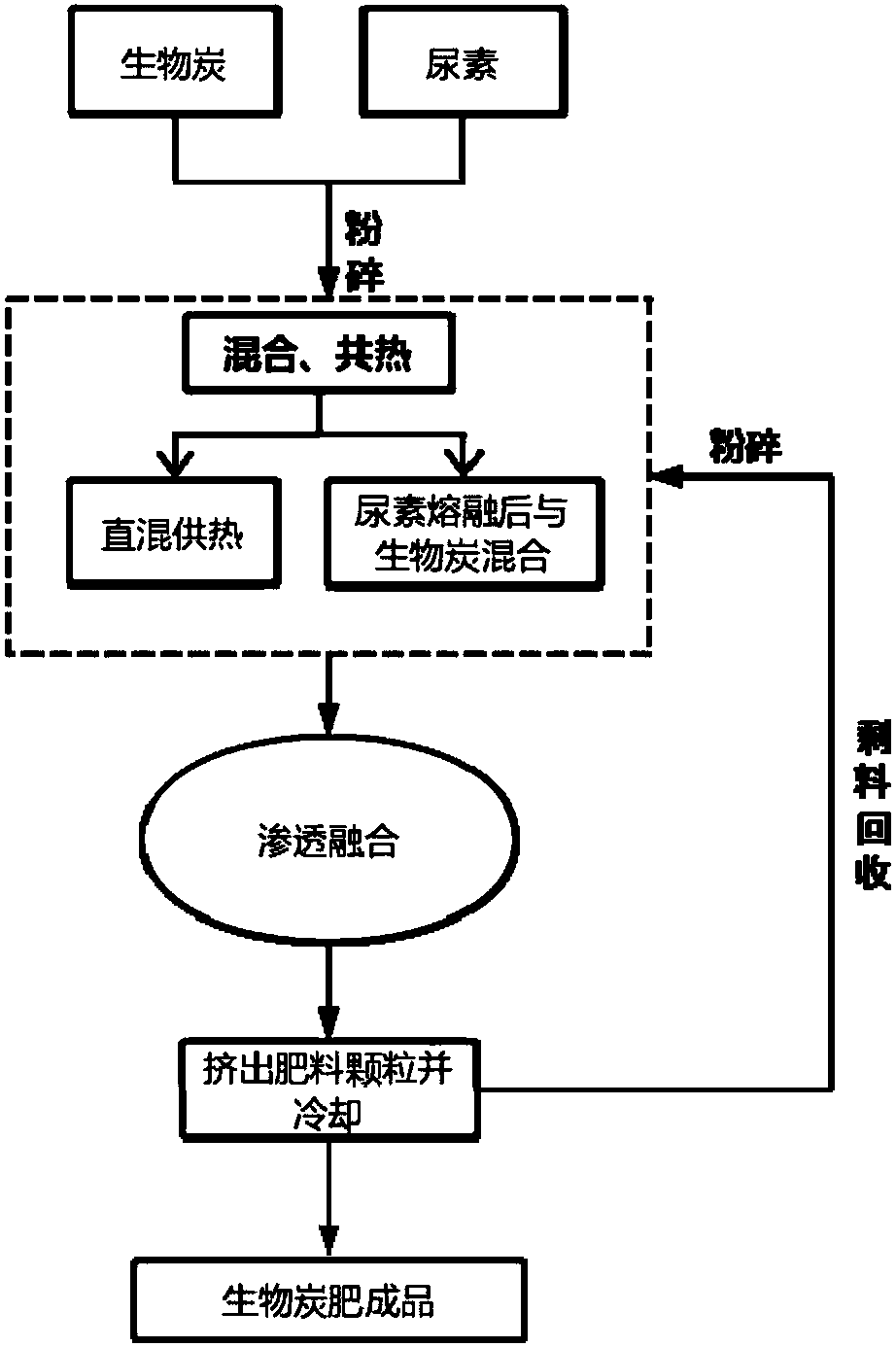

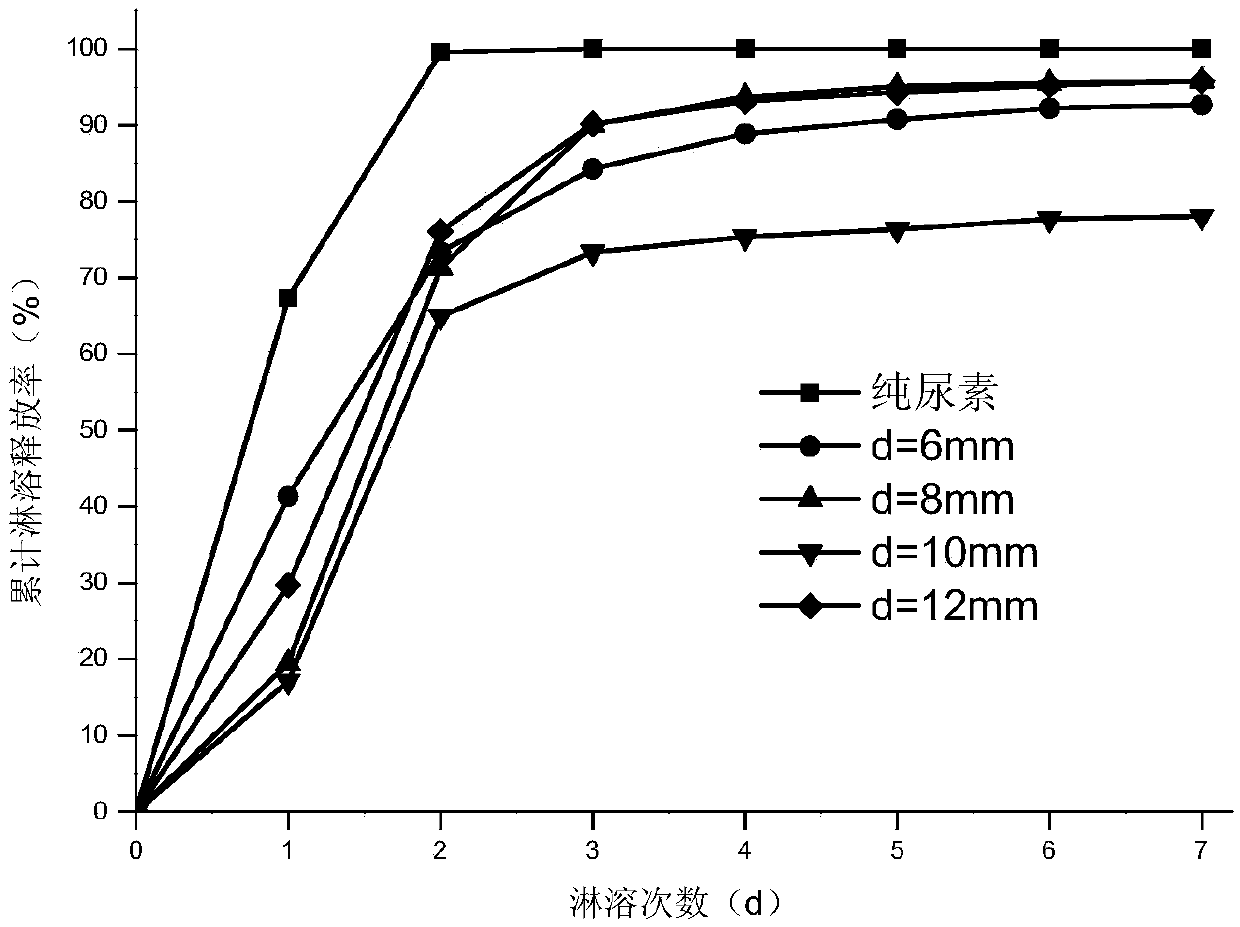

Permeation fusion method for preparing charcoal-based urea fertilizer

The invention discloses a permeation fusion method for preparing a charcoal-based urea fertilizer. The method comprises the following steps: raw material preparation; permeation fusion of charcoal andurea; and rapid cooling for forming the fertilizer. The main fertilizer preparation method is characterized by preheating urea powder and charcoal powder, the temperature of a system of the urea powder and charcoal powder is controlled to reach a urea melting temperature in order to realize the complete permeation fusion of the molten urea and the charcoal powder, and the charcoal-based urea fertilizer is finally obtained through cooling. The method has the advantages of adaption to different charcoal kinds, easiness in adjustment and control of the ratio, high charcoal fertilizer shaping rate, moderate mechanical strength, high stability, easiness in combination with an existing urea production technology to realize in situ shaping, certain promotion application industry foundation, andwide prospect. The method can be well combined with an existing urea shaping device in situ during the preparation, so the shaping time is short, the efficiency is high, the shaped product contains asmall amount of water, the particle size of the product is convenient to regulate and control, and the strength of the product is 50 N or more.

Owner:SOUTH CHINA AGRI UNIV

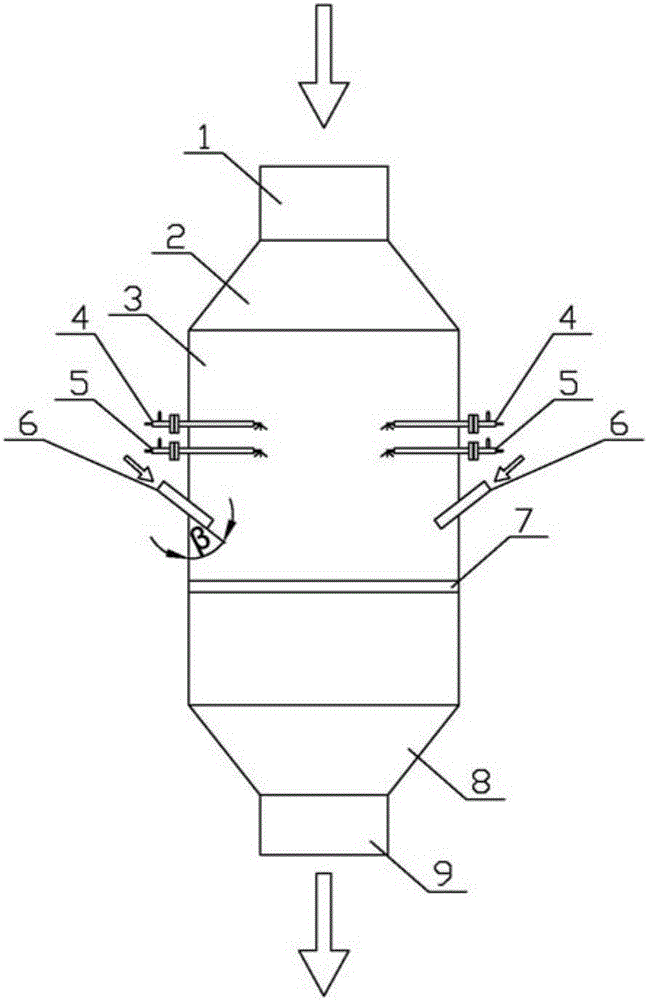

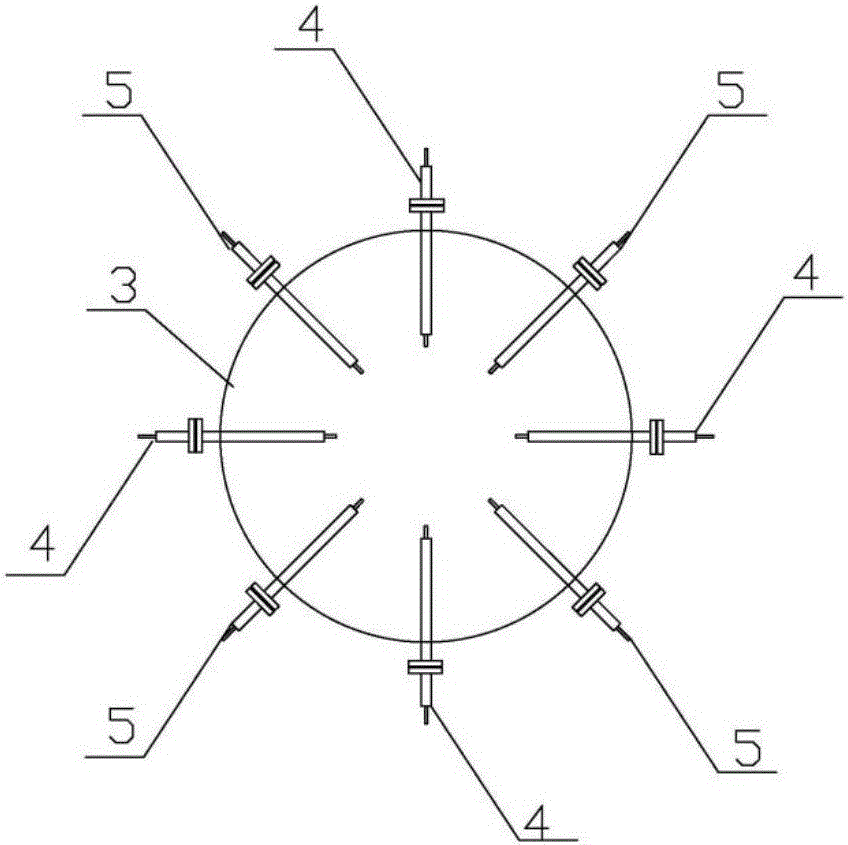

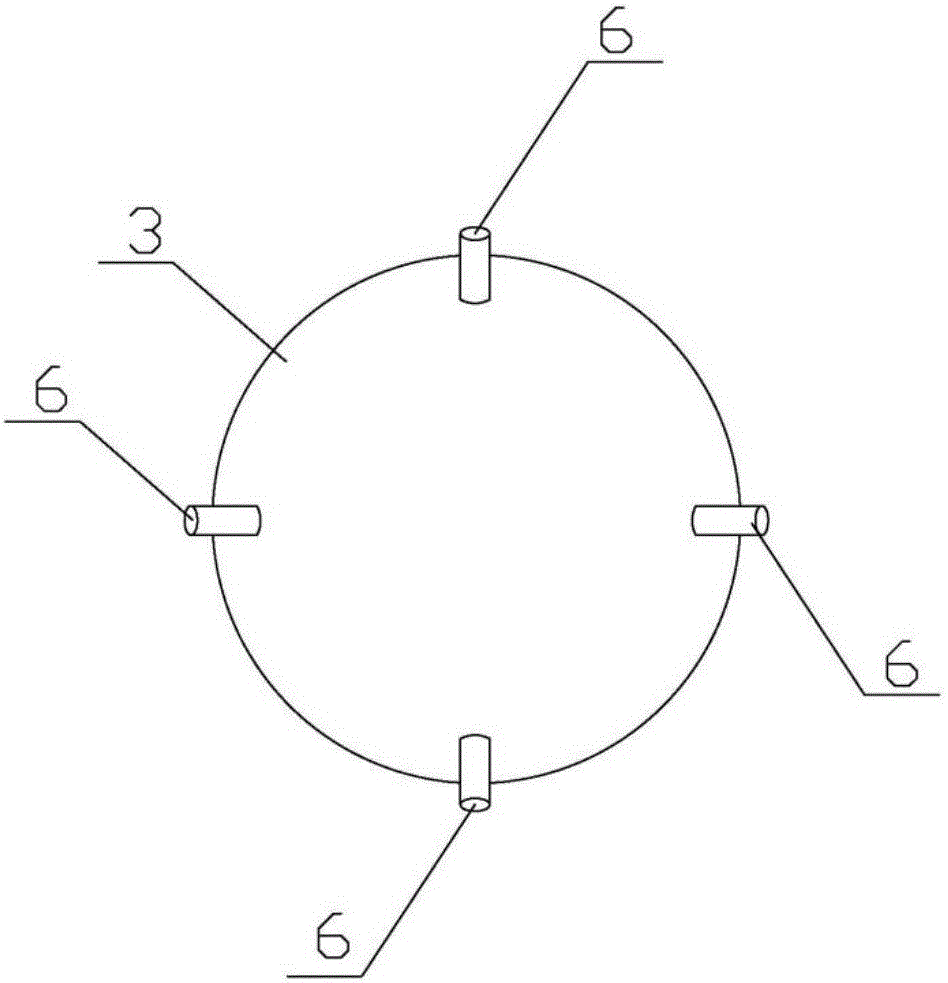

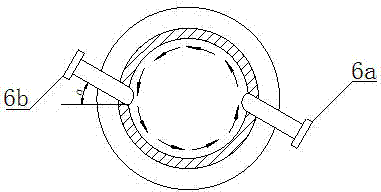

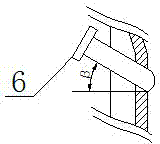

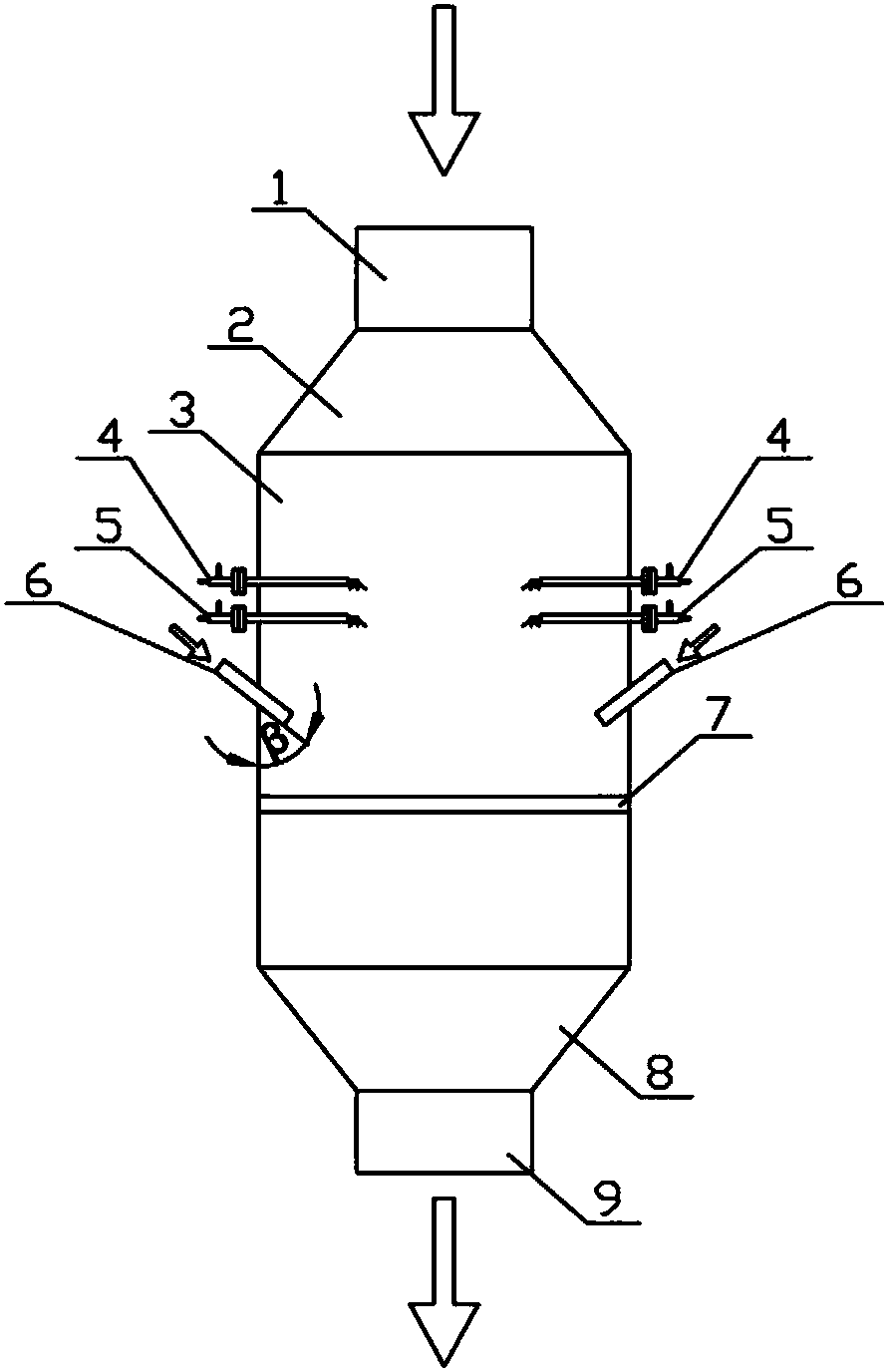

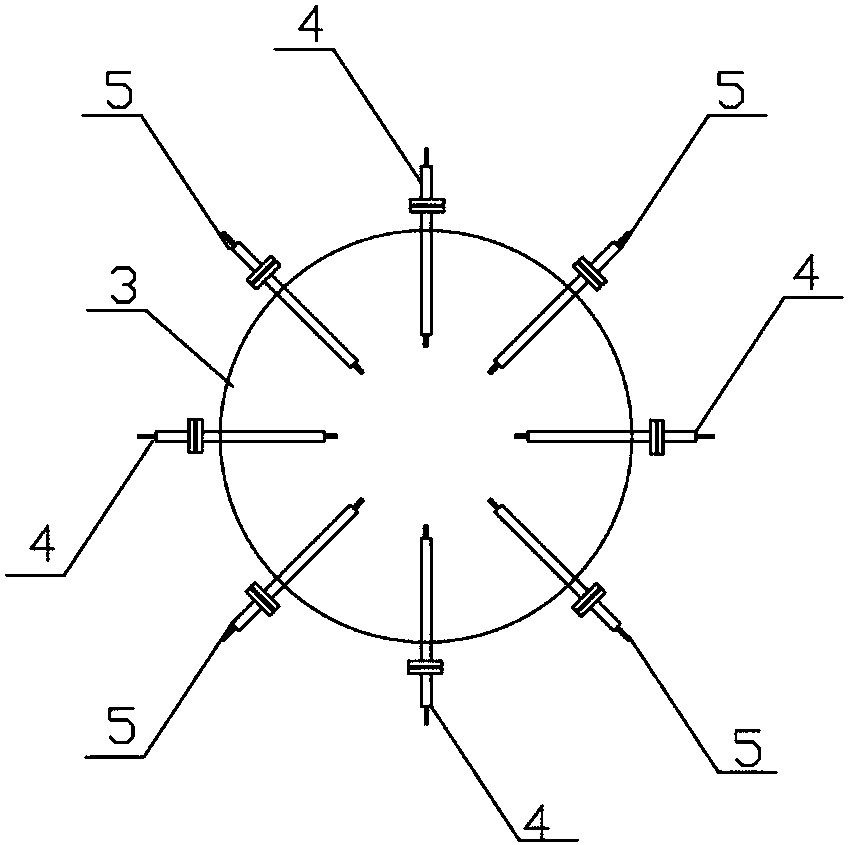

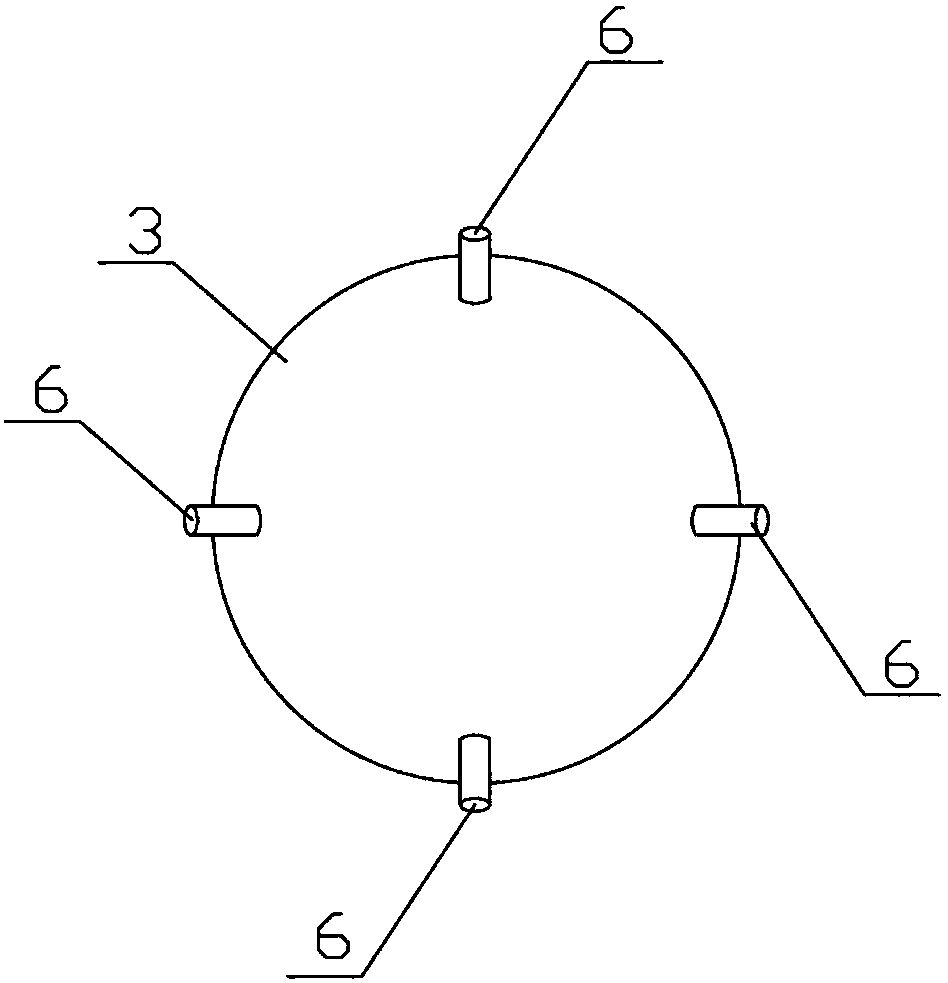

Urea backmixing and pyrolysis apparatus applicable to SCR denitration system and pyrolysis method

ActiveCN106082271AOvercoming sticky wallsOvercome efficiencyDispersed particle separationAmmonia preparation/separationCombustionDecomposition

The invention discloses a urea backmixing and pyrolysis apparatus applicable to a SCR denitration system and a pyrolysis method. The apparatus comprises a tower body; the tower body is provided with, from top to bottom, a combustion-supporting wind pipeline, an inlet variable-diameter section, a pyrolytic reaction section, an outlet variable-diameter section and an outlet pipeline; the pyrolytic reaction section is provided with a spray gun layer, a compensation wind pipeline layer and a gas flow equalizing plate from top to bottom; the number of the spray gun layer is at least one; and the spray gun layer is provided with a plurality of spray guns used for spraying an atomized urea solution, the plurality of spray guns are uniformly and radially distributed on the tower wall of the pyrolytic reaction section, and the spraying direction of each of the spray guns downwardly extending along the axial direction of the pyrolytic reaction section. According to the invention, the urea solution is mixed with combustion-supporting wind for primary pyrolysis and then with compensation wind for secondary pyrolysis, so the mixing degree of the urea solution and hot gas is promoted and generation of urea deposit and crystal is prevented; thus, the decomposition efficiency of the urea solution is improved.

Owner:FUJIAN LONGKING +1

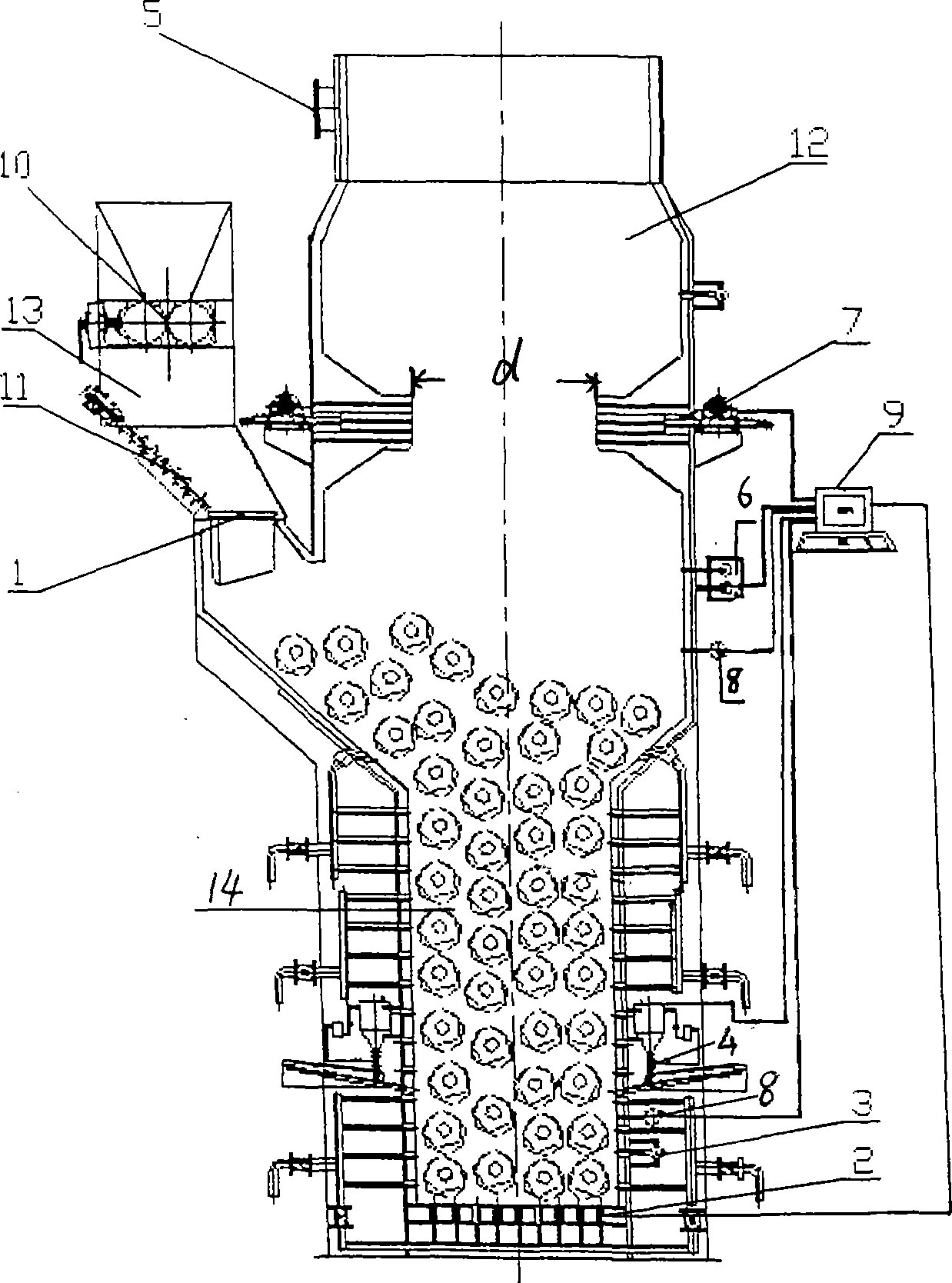

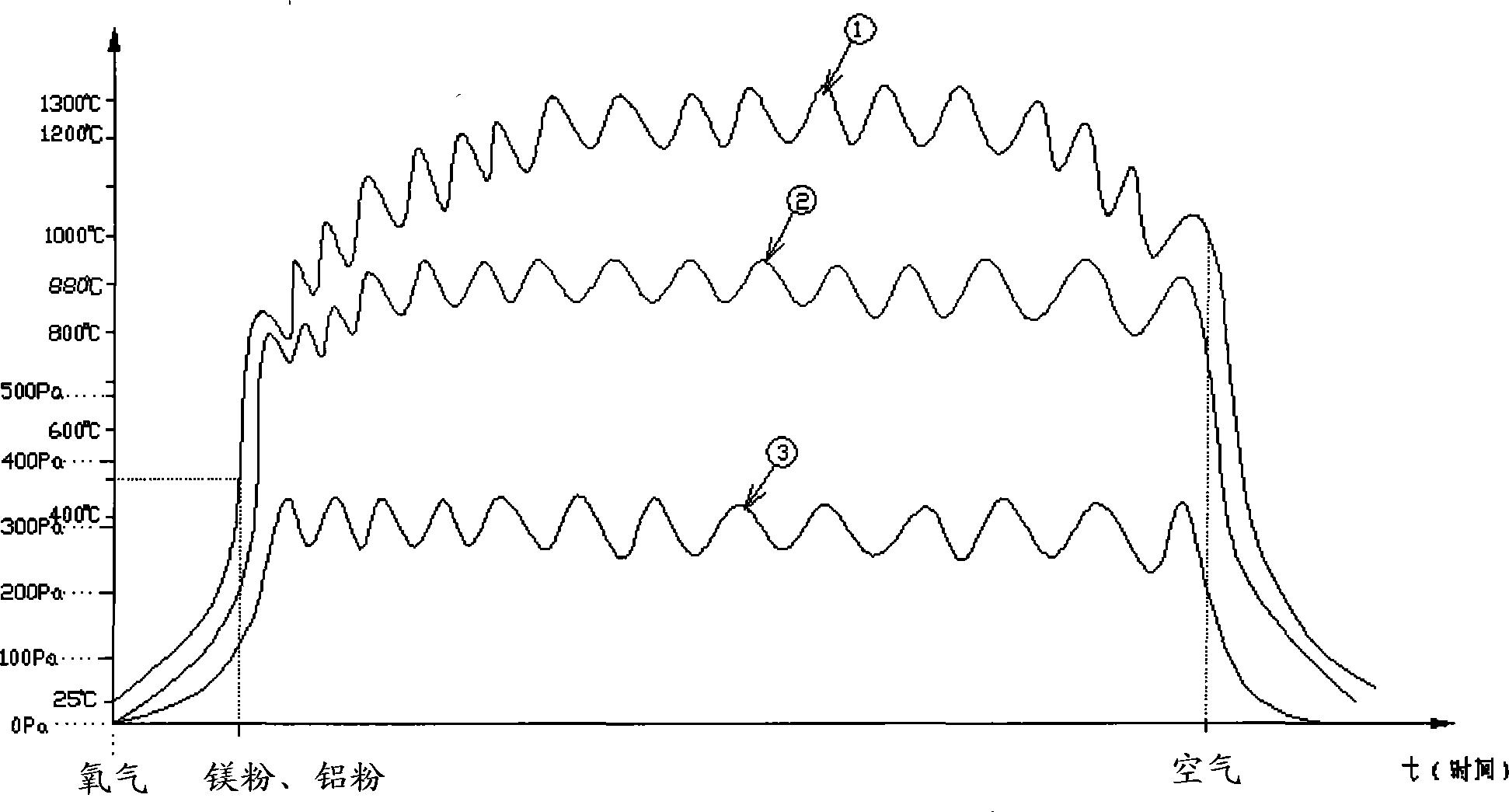

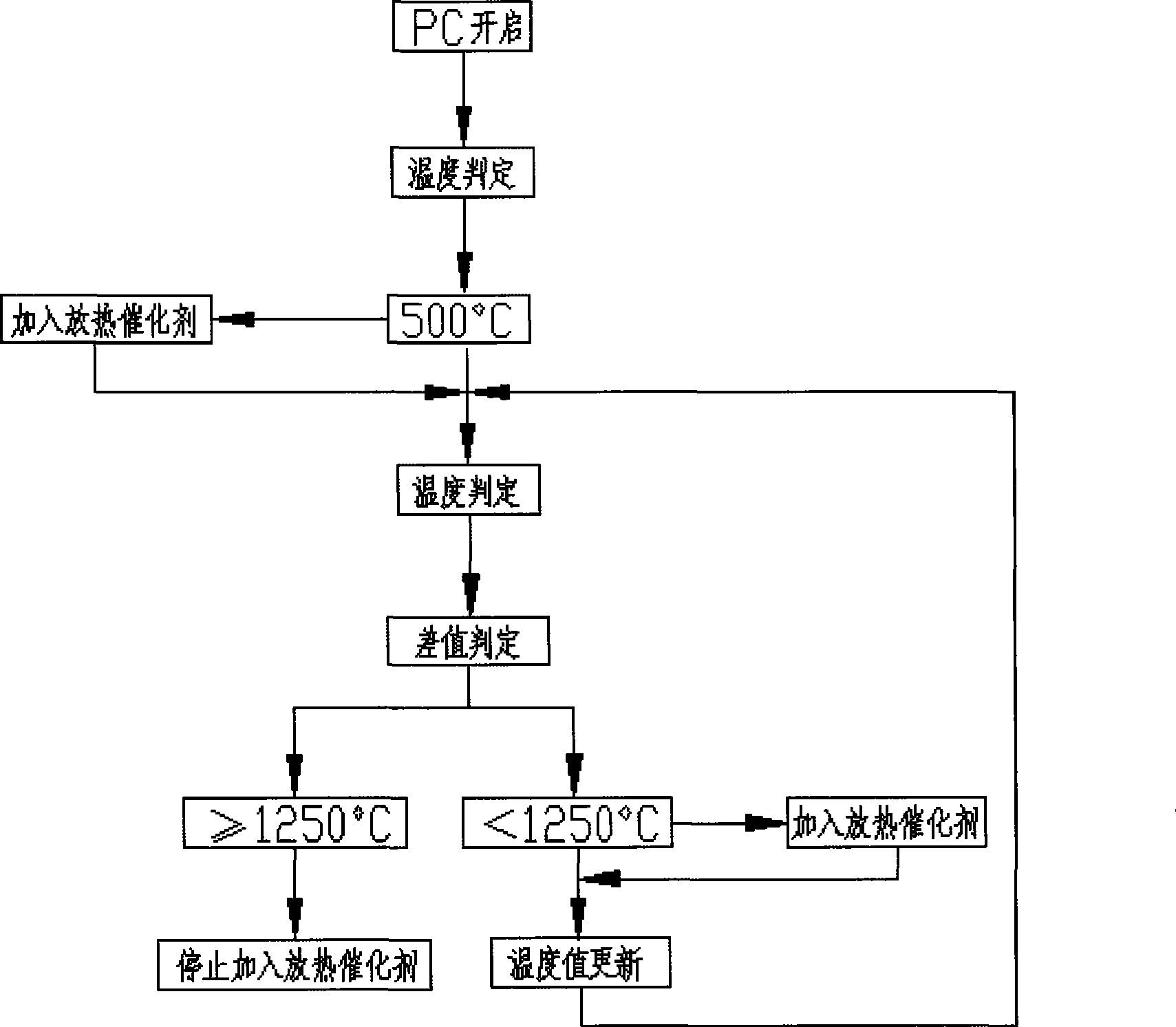

Exothermic catalytic combustion method for pyrolysis gasification submelting furnace under pure oxygen conditions

InactiveCN101520176AReduce lossEmission reductionCombustion using catalytic materialIncinerator apparatusInternal pressureCatalytic combustion

The invention provides an exothermic catalytic combustion method for a pyrolysis gasification submelting furnace under pure oxygen conditions, which is characterized in that pure oxygen is directly introduced into the pyrolysis gasification submelting furnace for pyrolysis after the ignition. During the pyrolysis, catalysts, namely magnesium powder, aluminum powder or a mixture of the magnesium powder and the aluminum powder is added from the furnace bottom, and the adding amount of the catalysts is between 0.1 and 1.0 kg for each ton of treated substance. During the pyrolysis gasification, the pressure in the furnace is adjusted by adjusting the opening degree of a rectification mechanism to ensure that the pressure inside the pyrolysis furnace is stable. The method has the advantages of low cost, energy conservation, and environmental protection.

Owner:SHANGHAI DISHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Preparation method of energy-saving waste salt ball for pyrolysis

ActiveCN112709990AIncrease pyrolysis rateReduce direct contactIncinerator apparatusPolymer adhesiveSlag

The invention discloses a preparation method of energy-saving waste salt balls for pyrolysis. The preparation method comprises the following steps of (a) drying waste salt slag at 50-60 DEG C, and controlling the water content of the waste salt slag below 10%; (b) stirring the dried the waste salt slag and biomass particles in a stirring device according to a mass ratio of (5-20): 1 to obtain pyrolysis inner core particles with a calorific value of more than 2500 kilocalories / kg; and (c) adding a polymer adhesive and an inorganic material rich in iron, aluminum and silicon and having a porous structure into the pyrolyzed inner core particles, and stirring and mixing until the inorganic material uniformly covers the surfaces of the pyrolyzed inner core particles to obtain the waste salt balls. The preparation method can effectively reduce the direct contact between waste salt and equipment, reduce the corrosion to the equipment, improve the pyrolysis rate of organic matters in the waste salt slag, and reduce the consumption of natural gas energy.

Owner:绍兴越信环保科技有限公司

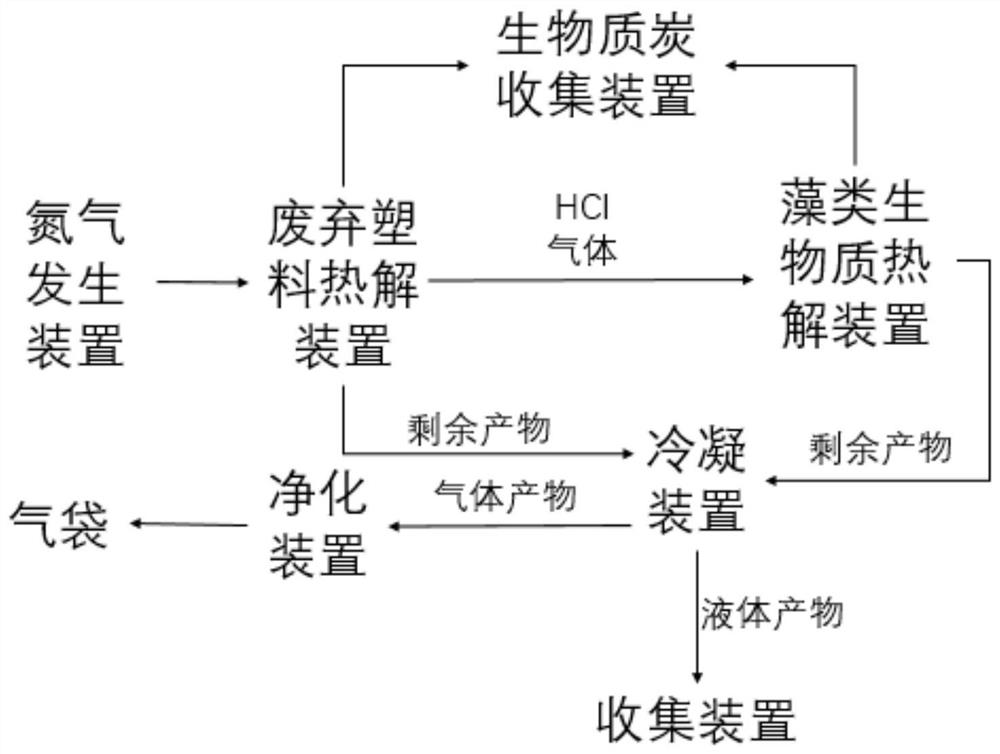

A method of pyrolyzing high-protein algae and waste plastics to produce carbon by gas-solid two-phase mixed chlorine removal

ActiveCN109609152BEfficient removalImprove qualityProductsReagentsEnvironmental engineeringHydrolysis

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Household garbage disposal system and method

PendingCN110894948AFully dryReduce energy consumptionIncinerator apparatusCombustion chamberThermodynamics

The invention discloses a household garbage disposal system and method. The system comprises a drying device which is provided with a first rotary feeding part, a household garbage inlet, a flue gas inlet, a dried household garbage outlet, and a tail gas outlet; a pyrolysis device with a pyrolysis chamber which is further provided with a second rotary feeding part, a dried household garbage inlet,a pyrolysis carbon outlet and a pyrolysis gas outlet; a shell provided with a pyrolysis gas combustor, a first combustion-supporting gas inlet, a post-combustion glue gas outlet and a first post-combustion ash outlet; and a flue gas re-combustion device divided by an internal partition plate into a re-combustion chamber and a separation chamber communicated with each other. A combustion chamber is formed between the shell and the outer wall of the pyrolysis chamber; and the pyrolysis gas combustor is connected with the pyrolysis gas outlet via a pipe. The re-combustion chamber is provided with a post-combustion flue gas inlet, a combustor and a second combustion-supporting gas inlet; the separation chamber is provided with a second post-combustion ash outlet, a post-re-combustion flue gasoutlet and a heat exchange piece; the post-re-combustion flue gas outlet is connected with the flue gas inlet; and the heat exchange piece is provided with a heat exchange medium inlet and a post-heat exchange medium outlet.

Owner:北京云水浩瑞环境科技有限公司

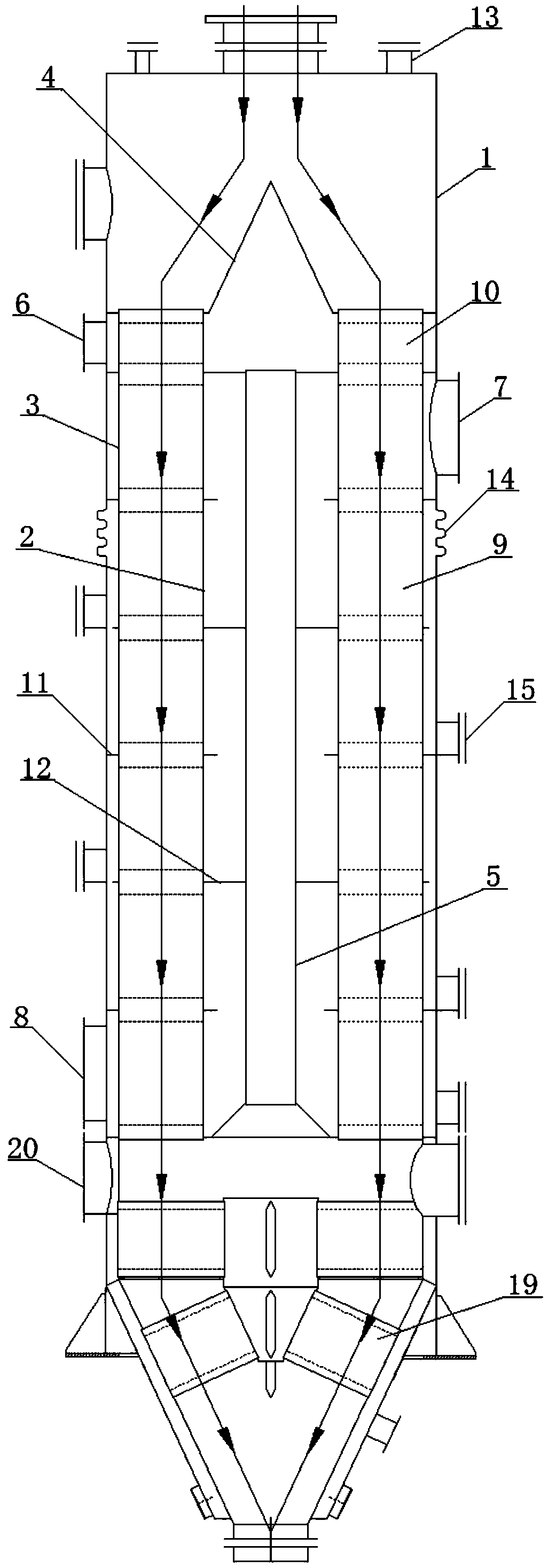

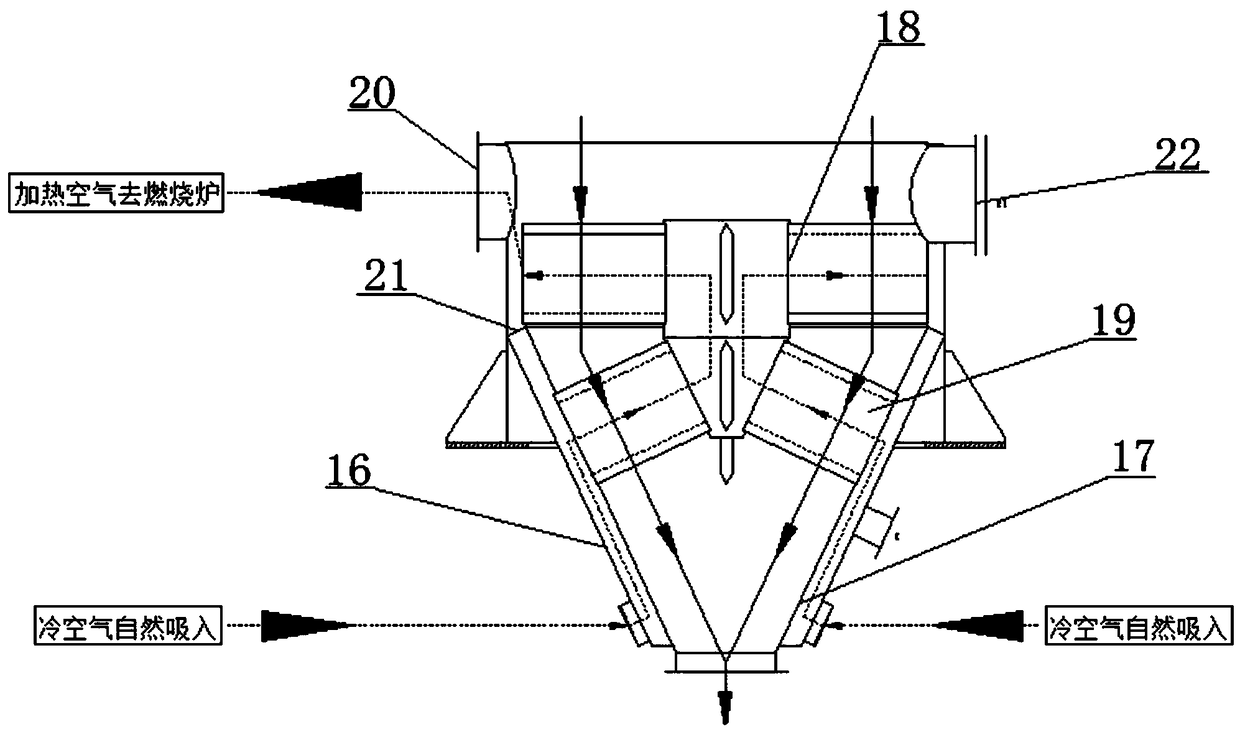

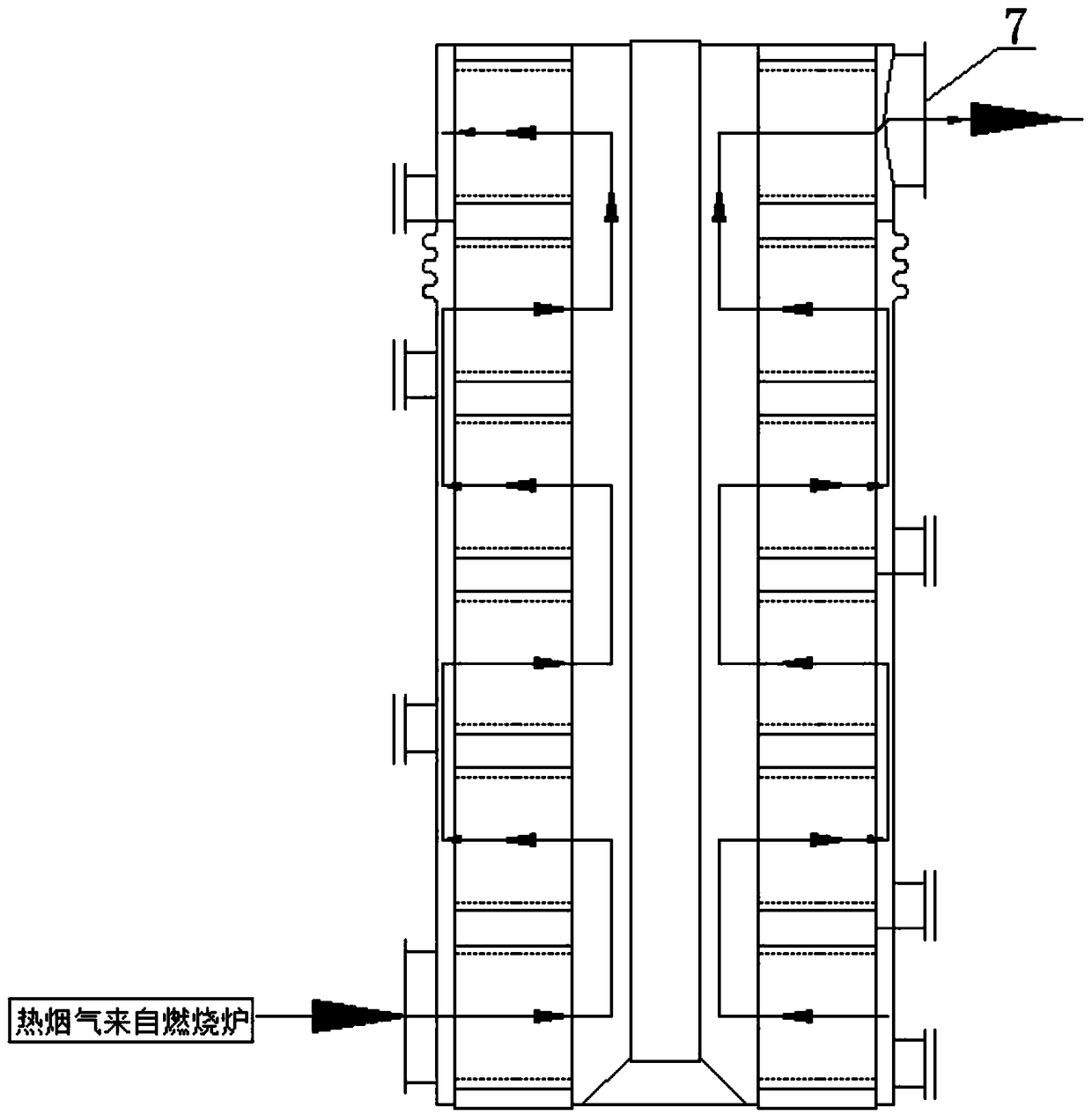

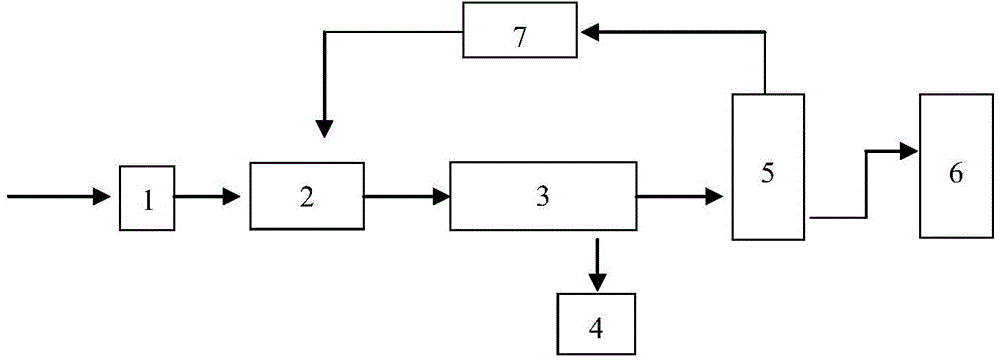

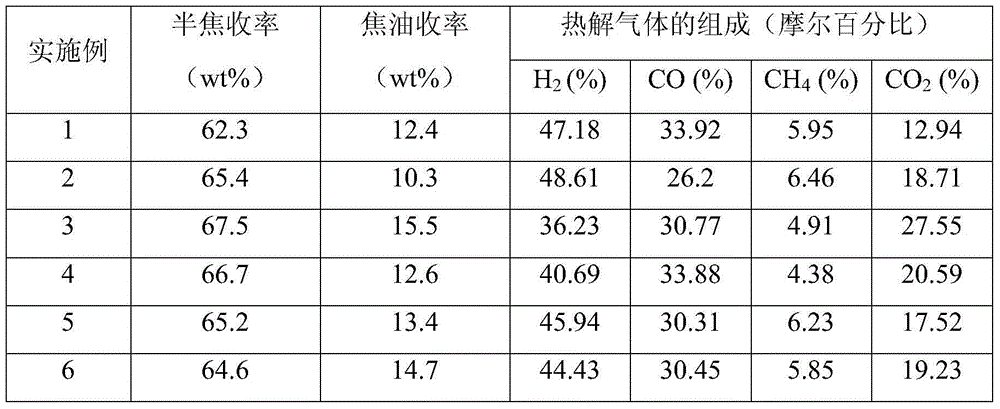

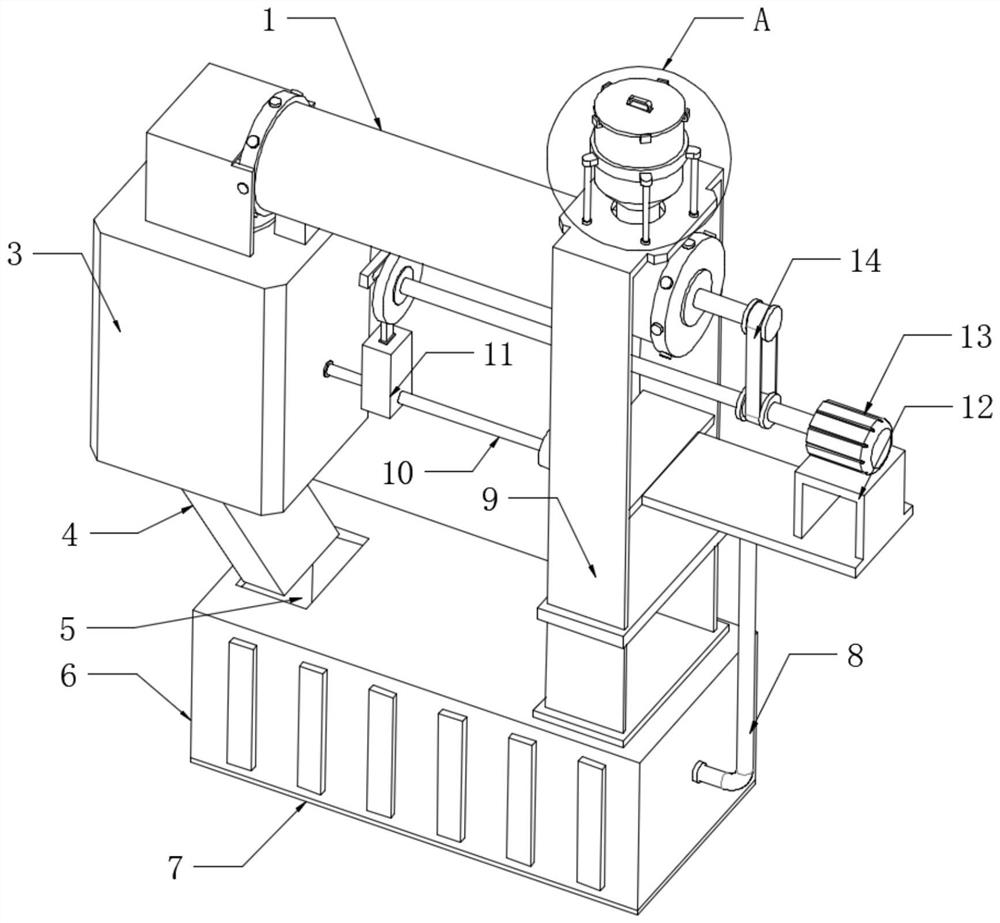

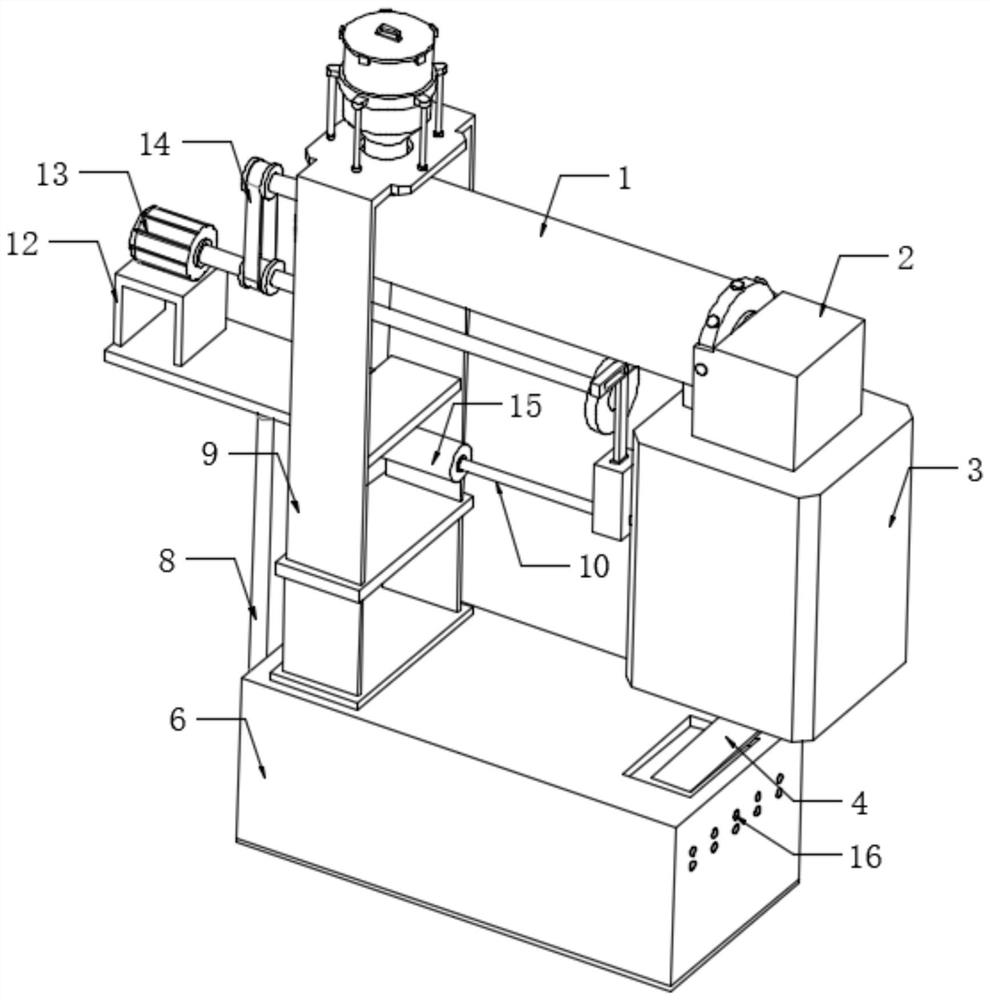

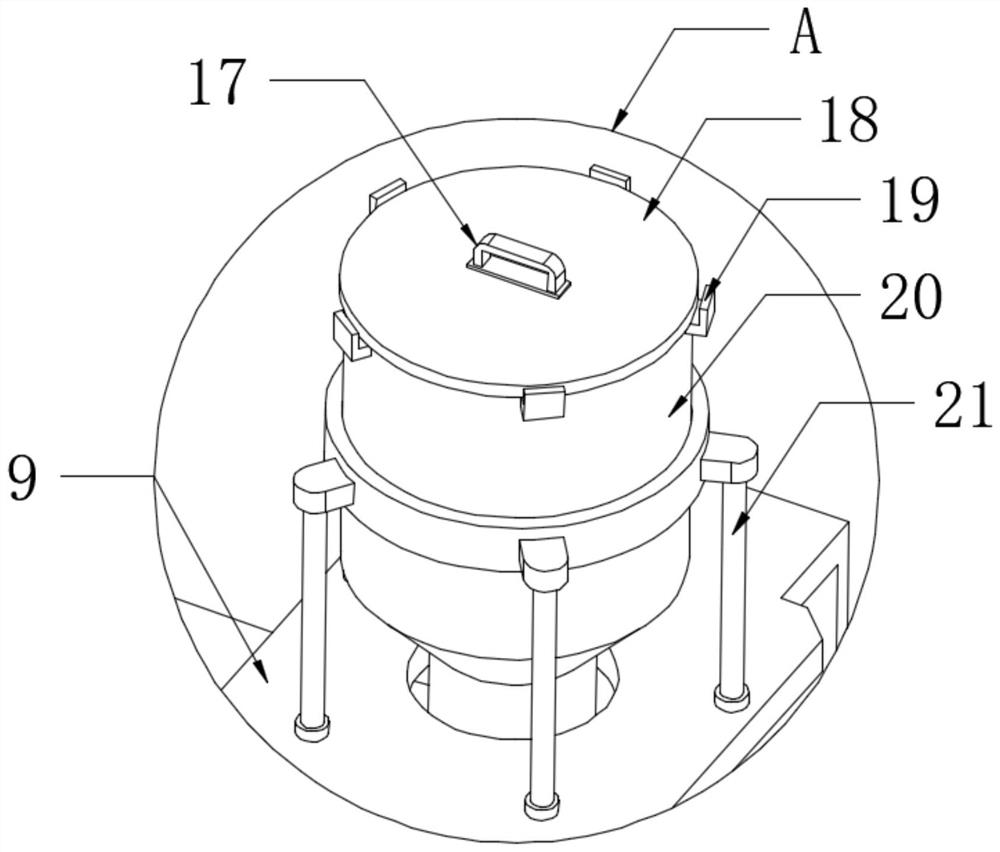

Self-weight spiral progressive type high-efficiency and energy-saving biomass pyrolysis furnace device

ActiveCN109022001ARealize continuous productionIncrease the heat exchange areaBiofuelsSpecial form destructive distillationEngineeringDistributor

A self-weight spiral progressive type high-efficiency and energy-saving biomass pyrolysis furnace device comprises a pyrolysis furnace and an air cooler, a closed cavity is formed between the outer box body (16) and the inner box body (17) of the air cooler, a closed cylindrical shell (18) is arranged in the inner box body (17), a plurality of layers of air cooling flow deflectors (19) are arranged between the inner box body (17) and the cylindrical shell (18), an opening at one end of every air cooling flow deflector (19) is communicated with the inner chamber of the cylindrical shell (18), and an opening at the other end of the air cooling flow deflector (19) is communicated with the cavity between the outer box body (16) and the inner box body (17); and an inner cylinder (2) and an outer cylinder (3)are arranged in the inner part of the furnace body (1) of the pyrolysis furnace, a conical distributor (4) is arranged at a position, corresponding to the charging port of the furnace body (1), of the top of the inner cylinder (2), and a pyrolysis gas secondary pyrolysis tube (5) is arranged in the inner cylinder (2). The device has the advantages of heat transfer and interaction, high heat utilization efficiency, and realization of cascade utilization of energy.

Owner:HUBEI NORMAL UNIV

Method of Microwave Pyrolysis and Utilization of Lignite

ActiveCN103788975BIncrease pyrolysis rateImprove efficiencySpecial form destructive distillationCombustionMicrowave pyrolysis

The invention discloses a method for microwave pyrolysis utilization of lignite. The method comprises the steps of (1) smashing lignite to form powdered raw materials, and conveying the raw materials into a drying device for drying to obtain dried powdered raw materials; (2) heating the dried powdered raw materials in the step (1) to 400-600 DEG C by taking microwaves as a heat source, and preserving the heat for 20-60 minutes to obtain a semi-coked product and oil gas mixture; and (3) separating out tar and pyrolysis gas from the obtained oil gas mixture through a condenser, conveying the pyrolysis gas into a combustion device for combustion to generate flue gas, and conveying the flue gas into the drying device in the step (1) to be used as a drying medium. The method has the advantages of simple technology, high processing efficiency, short flow, easiness in operation and the like and can improve the comprehensive utilization efficiency of lignite.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +1

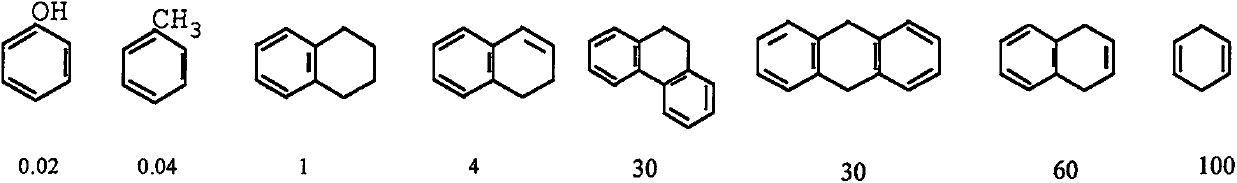

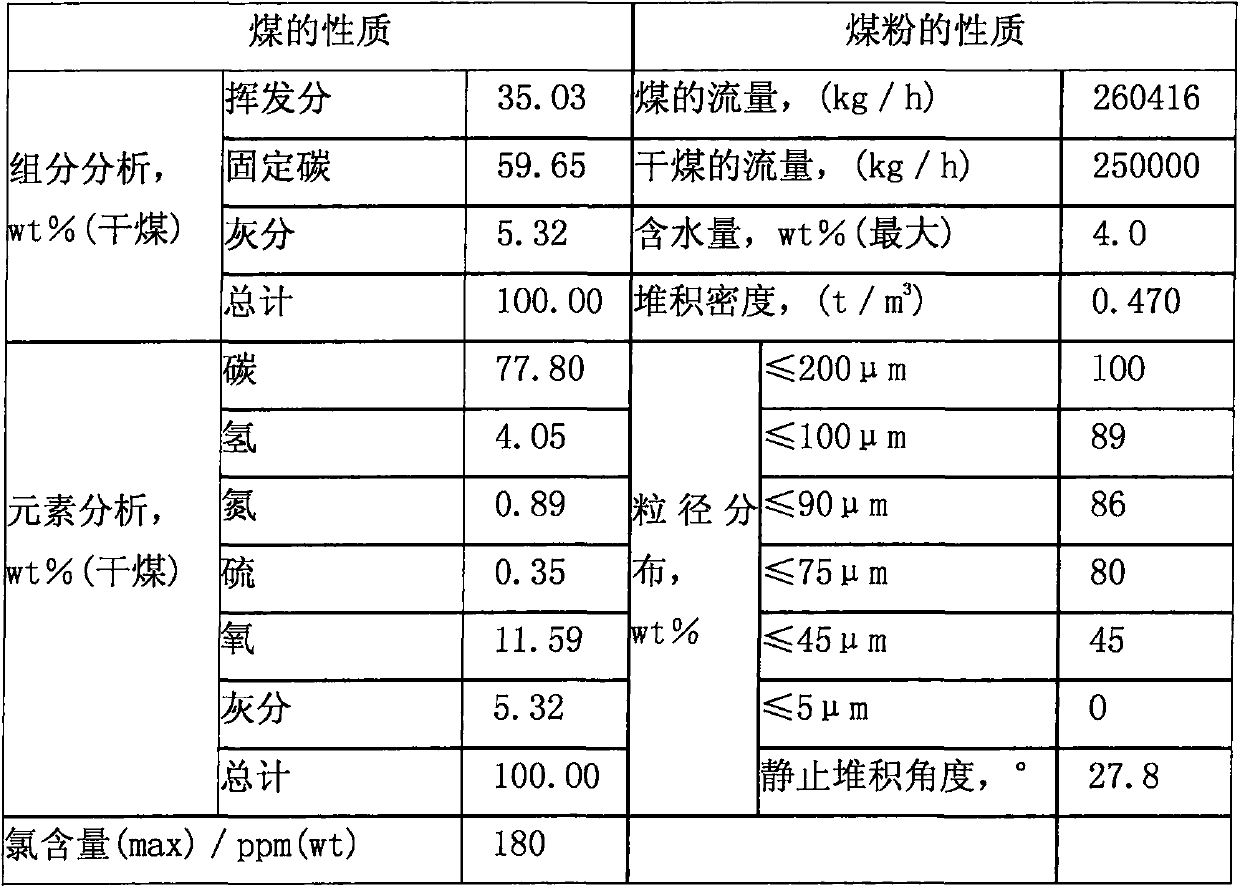

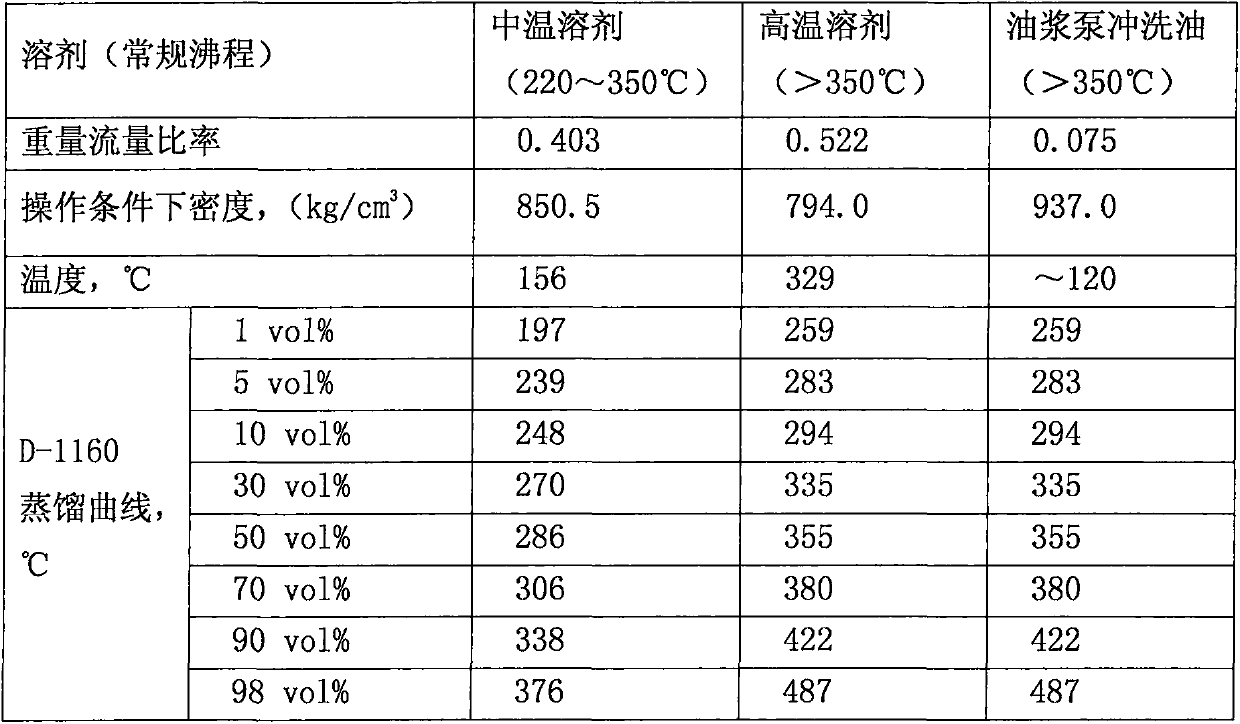

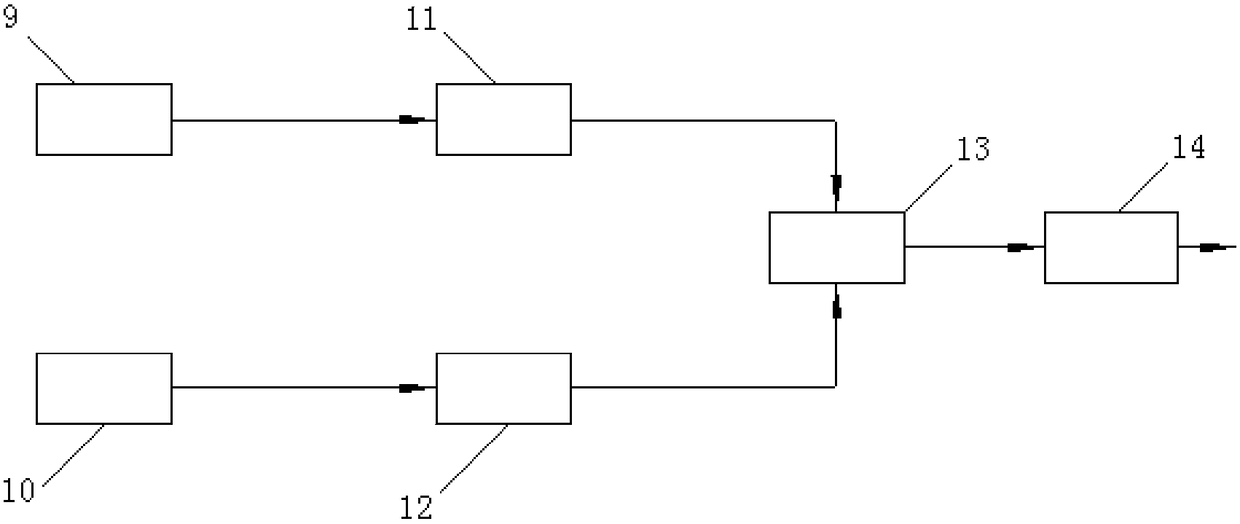

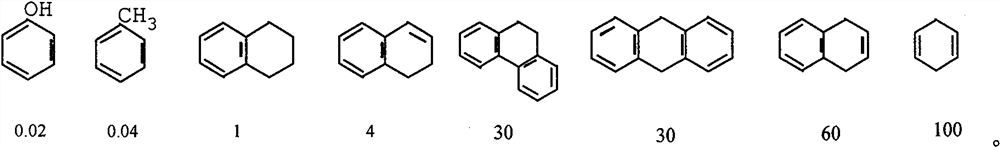

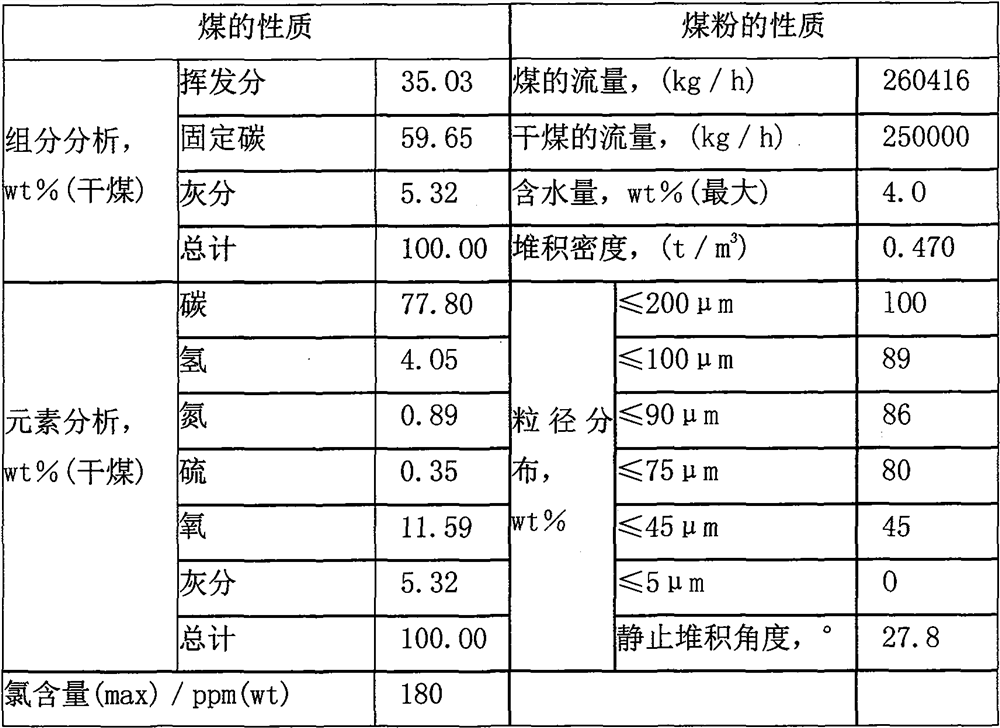

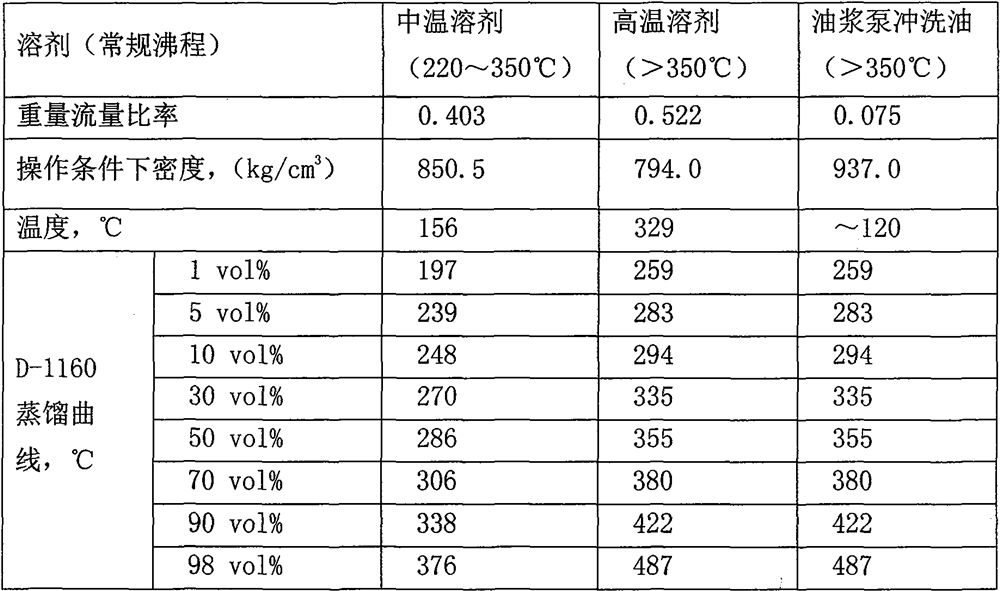

Feeding method of coal-oil slurry with different concentration in direct liquefaction of coal hydrogenation

ActiveCN109666502AIncrease pyrolysis rateLow viscosityLiquid hydrocarbon mixture productionHeat carrierHydrogen

The invention provides a feeding method of coal-oil slurry with different concentrations in direct liquefaction of coal hydrogenation. The feeding method of the coal-oil slurry with different concentrations in direct liquefaction of coal hydrogenation includes the steps of reducing the ratio of solvent oil to coal for coal blending slurry, completing the preparation of low-viscosity heated dilutecoal slurry LCF-LT1 that usually contains a hydrogen donor during swelling process, allowing the low-viscosity heated dilute coal slurry LCF-LT1 to act as a dilutant and a heat carrier in the first thick coal slurry mixing process M1, directly heating high pressure first thick coal slurry with HCF1-PF as the first mixing coal slurry M1P of a temperature M1TK, best making the temperature of HCF1-PFrapidly exceed a viscosity-temperature peak area caused by temperature rise, rising the temperature M1P to near AR reaction temperature of a reaction process, such as 330-450 DEG C in the first mixing coal slurry heating process M1P-HX, then entering the direct liquefaction process of coal hydrogenation AR to conduct the direct liquefaction process of coal hydrogenation, performing tandem repeatuse of the above-mention concepts, adding 2 or multi-channel thick coal slurry to hot dilute coal slurry step by step, and then forming a combined heating and conveying process of multi-channel high coal concentration oil coal slurry.

Owner:洛阳瑞华新能源技术发展有限公司

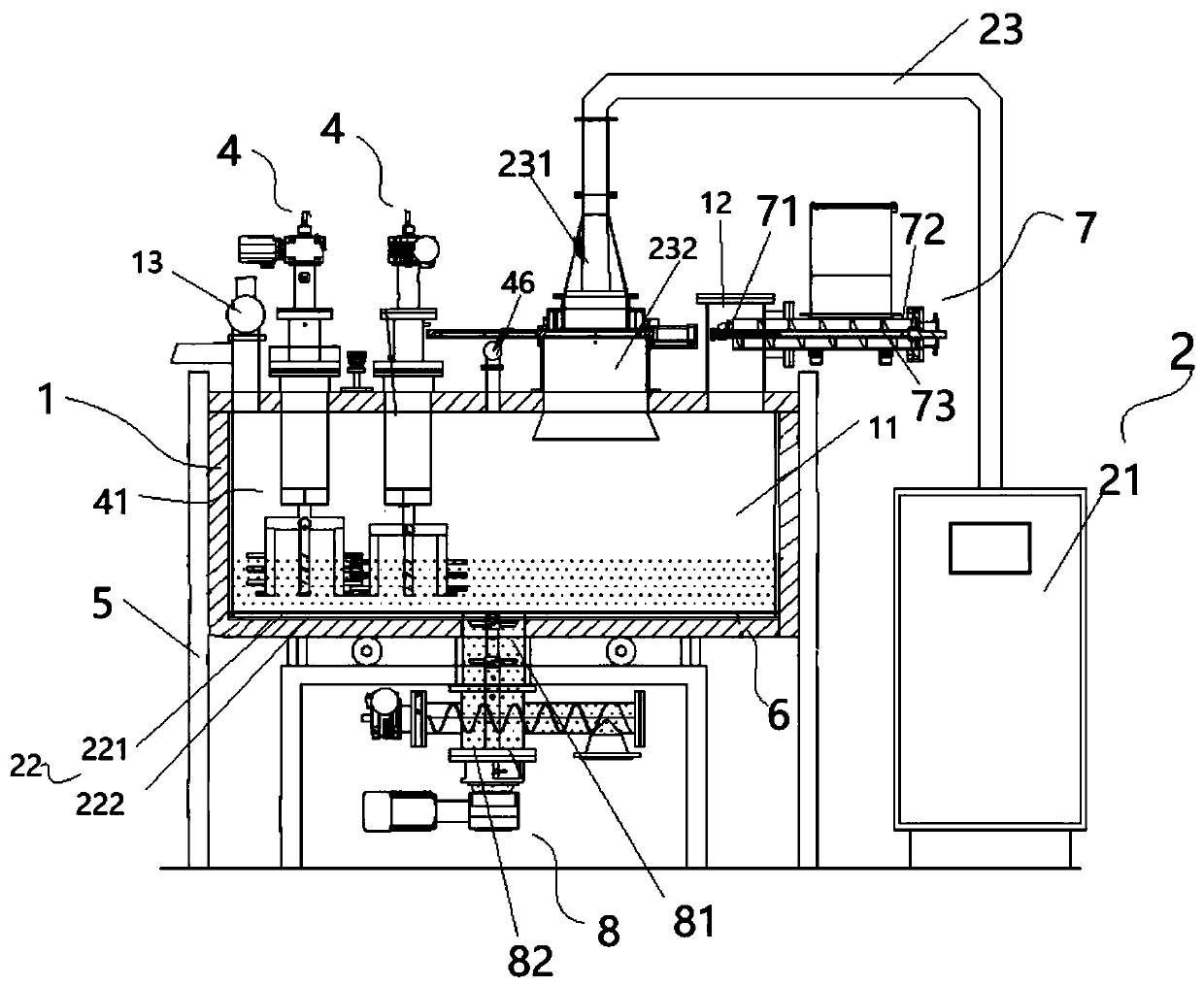

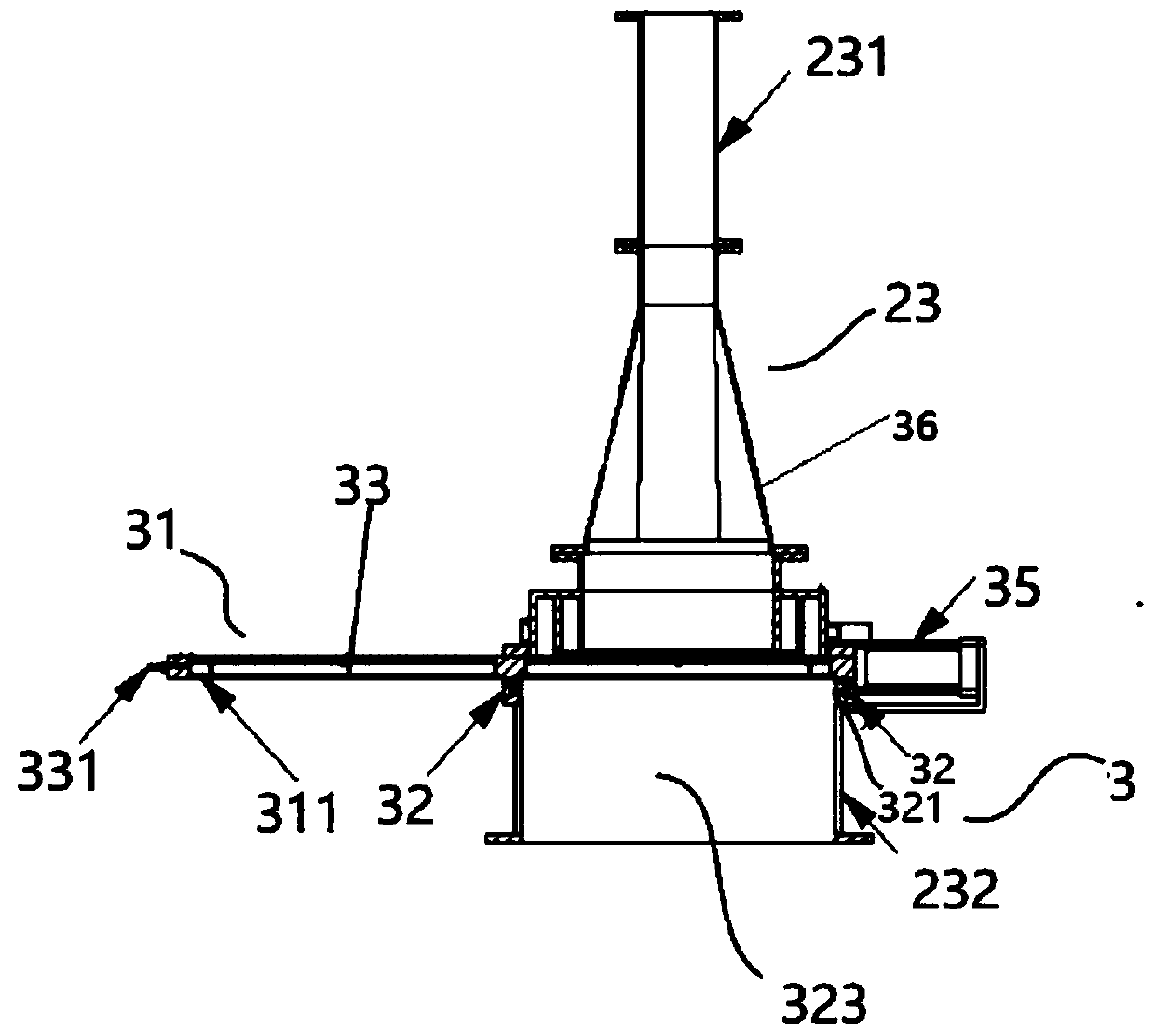

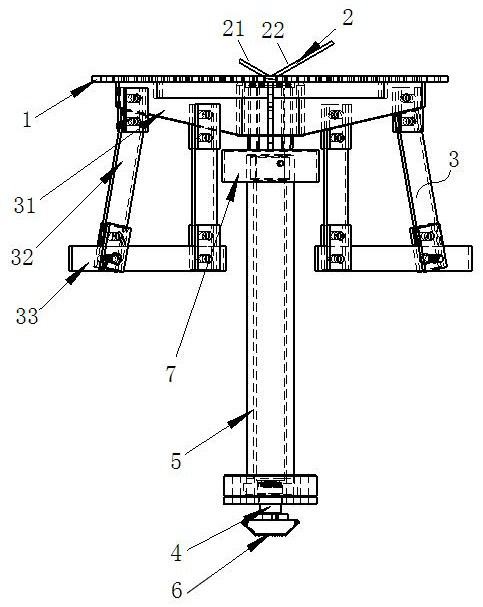

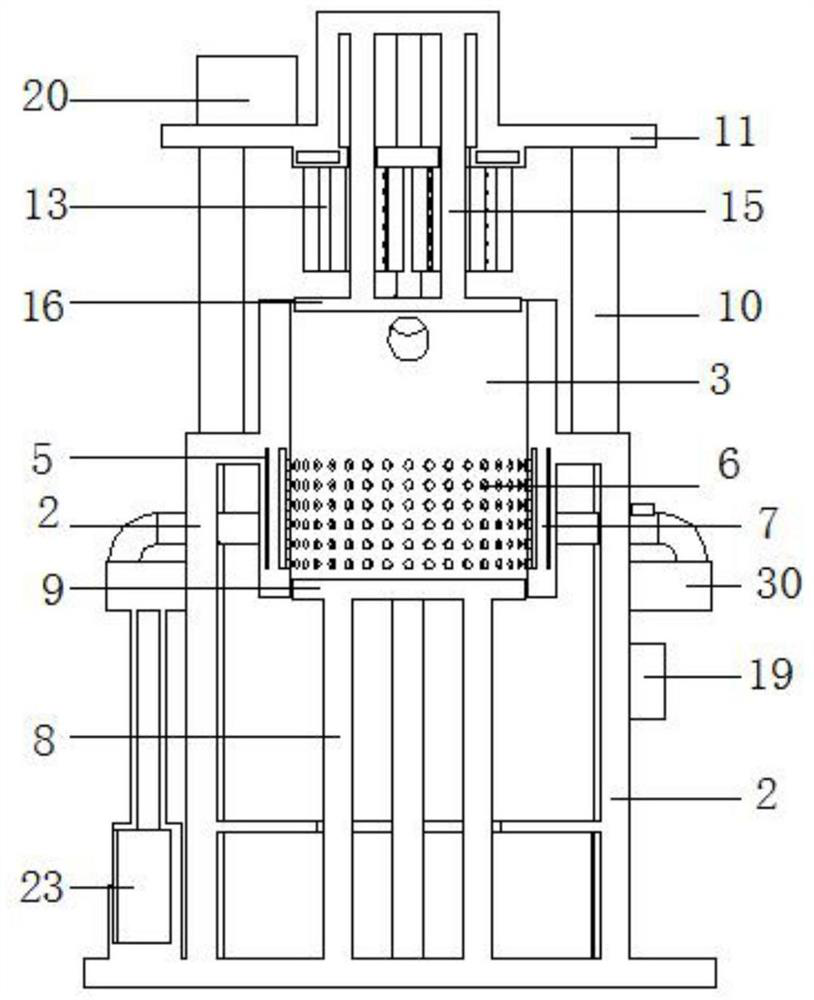

Microwave pyrolysis equipment

PendingCN111139099AImprove daily throughputOvercome the defects that need to be processed in batches and batchesProductsReagentsMicrowave pyrolysisWaveguide

The invention relates to the technical field of pyrolysis, and provides pyrolysis equipment. The equipment comprises a machine frame, a shell, a microwave generating device, a waveguide protection device and a stirring device, wherein the shell is arranged on the machine frame, and a containing cavity used for containing materials is formed in the machine frame; the microwave generating device comprises at least one microwave generator and a wave absorbing assembly, the microwave generator is communicated with the containing cavity through a waveguide, and the wave absorbing assembly is arranged in the containing cavity; the waveguide protection device is arranged on the waveguide, and a dielectric protection layer is formed between the containing cavity and the waveguide; the stirring device is arranged on the shell, and one end of the stirring device extends into the containing cavity and is inserted into the material for stirring. The pyrolysis equipment is reasonable in structuraldesign, pyrolysis treatment can be carried out on a large batch of materials, all the devices operate independently, maintenance is convenient, the treatment efficiency is high, and the defect that the large batch of materials need to be treated in batches is overcome.

Owner:北京诺芯环境科技有限公司

A high-efficiency and environmentally friendly waste pyrolysis process

ActiveCN109737424BIncrease pyrolysis rateEfficient combustionIncinerator apparatusEnvironmental engineeringPlastic film

The invention belongs to the technical field of garbage treatment, and particularly relates to a high-efficiency environment-friendly garbage pyrolysis process. A garbage pyrolysis device comprises anincineration chamber, a hot air chamber, a smoke discharge pipe, a slag collecting box, a garbage water recycling tank, an air conveying channel, an air conveying pipe, a partition plate, a combustion-supporting mechanism, a filter screen and a feeding port with a sealing cover; the hot air chamber is arranged on the outer side of the incineration chamber, a gas conveying pipeline is arranged onthe hot air chamber; the air conveying channel is used for conveying hot air for pyrolysis to the hot air chamber; the waste is compressed, punched and inserted into the sodium; the garbage pyrolysisdevice can tear the plastic film on the sodium when the waste pyrolysis device works, so that the sodium is in contact with the water in the garbage, a large amount of hydrogen is released, the hydrogen enables the garbage blocks to be opened, and hydrogen is ignited in the pyrolysis device, so that the interior and the exterior of the rubbish block are simultaneously combusted, so that the rubbish pyrolysis speed is greatly increased.

Owner:JINGMEN TUODA TECH CO LTD

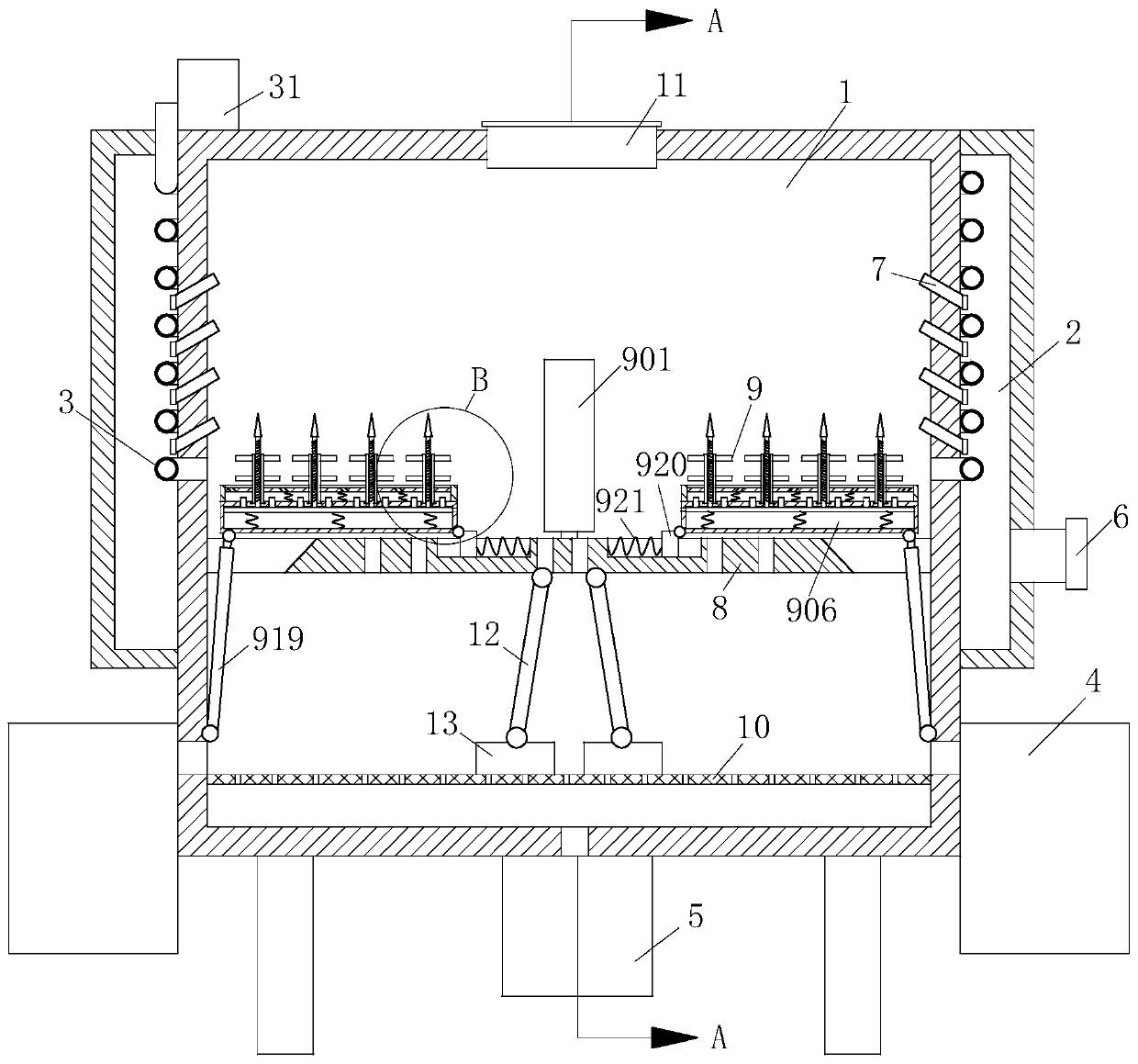

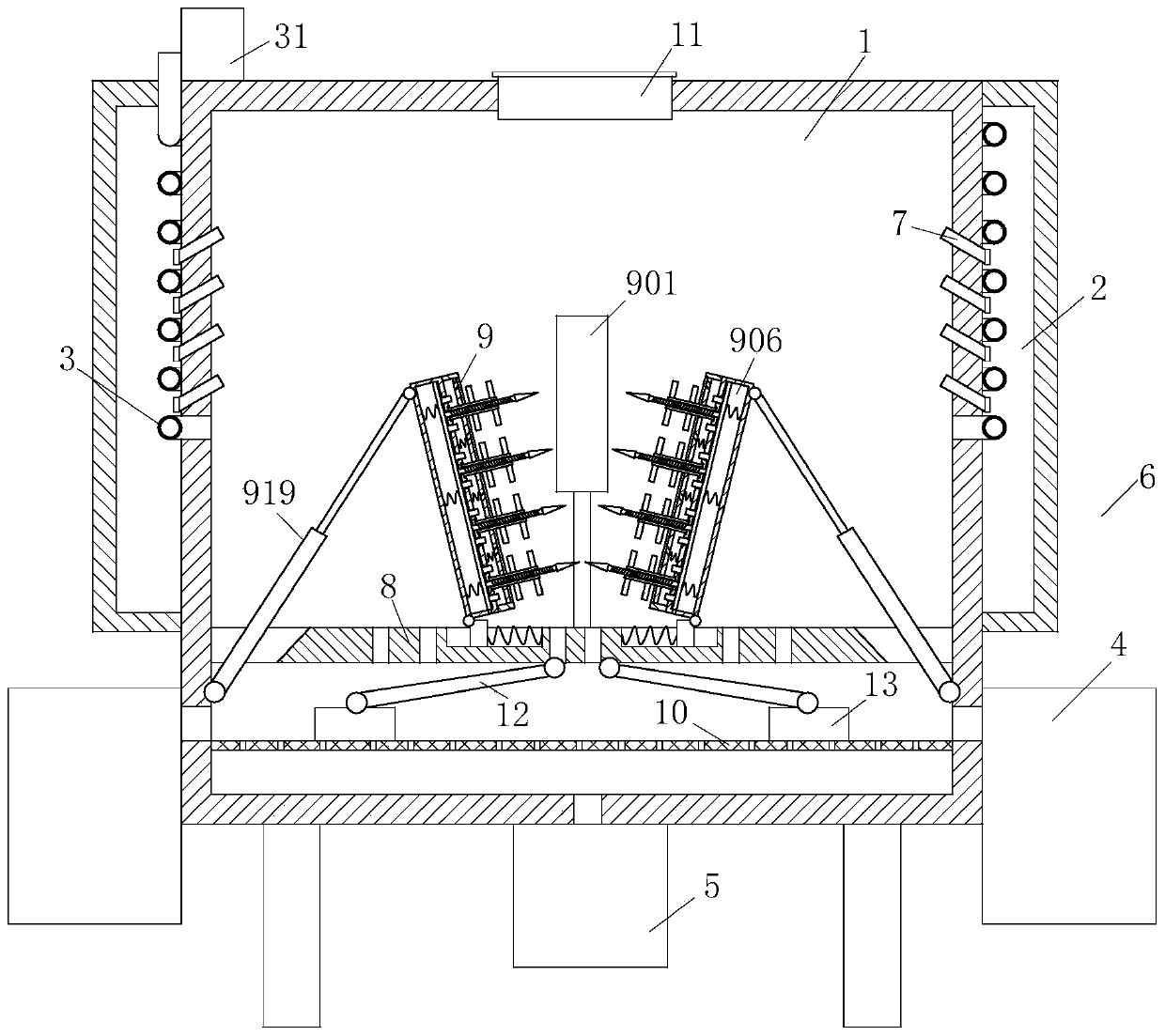

Device and method for catalyst-regenerable high-temperature catalytic pyrolysis of domestic garbage and hydrogen filtering

PendingCN110437857AEmission reductionReduce deteriorationSpecial form destructive distillationCatalytic pyrolysisExternal energy

The invention discloses a device and method for catalyst-regenerable high-temperature catalytic pyrolysis of domestic garbage and hydrogen filtering. The device includes a fluidized bed pyrolysis furnace, microwave generators, a catalyst regenerable catalyst bed, a combustion furnace and a cyclone separator. The bottom of the fluidized bed pyrolysis furnace is provided with a gas inlet. The microwave generators are arranged on the side wall of the fluidized bed pyrolysis furnace and the bottom or the side wall of the catalyst regenerable catalyst bed. An inlet of the cyclone separator is connected to a pyrolysis gas outlet of the fluidized bed pyrolysis furnace, the bottom of the cyclone separator is connected to the lower part of the fluidized bed pyrolysis furnace, and a gas outlet of the cyclone separator is connected to the catalyst bed. A gas outlet of the catalyst bed is connected to the combustion furnace. Through the device and the method, microwave-assisted high-temperature pyrolysis of domestic garbage, catalyst regeneration and hydrogen filtration can be achieved, the catalytic pyrolysis efficiency can be increased, external energy supply cab be reduced, energy is savedwhile achieving resource utilization of domestic garbage, the service lifetime of the device can be effectively prolonged, and the device and the method are economical and environmentally friendly.

Owner:SOUTH CHINA UNIV OF TECH

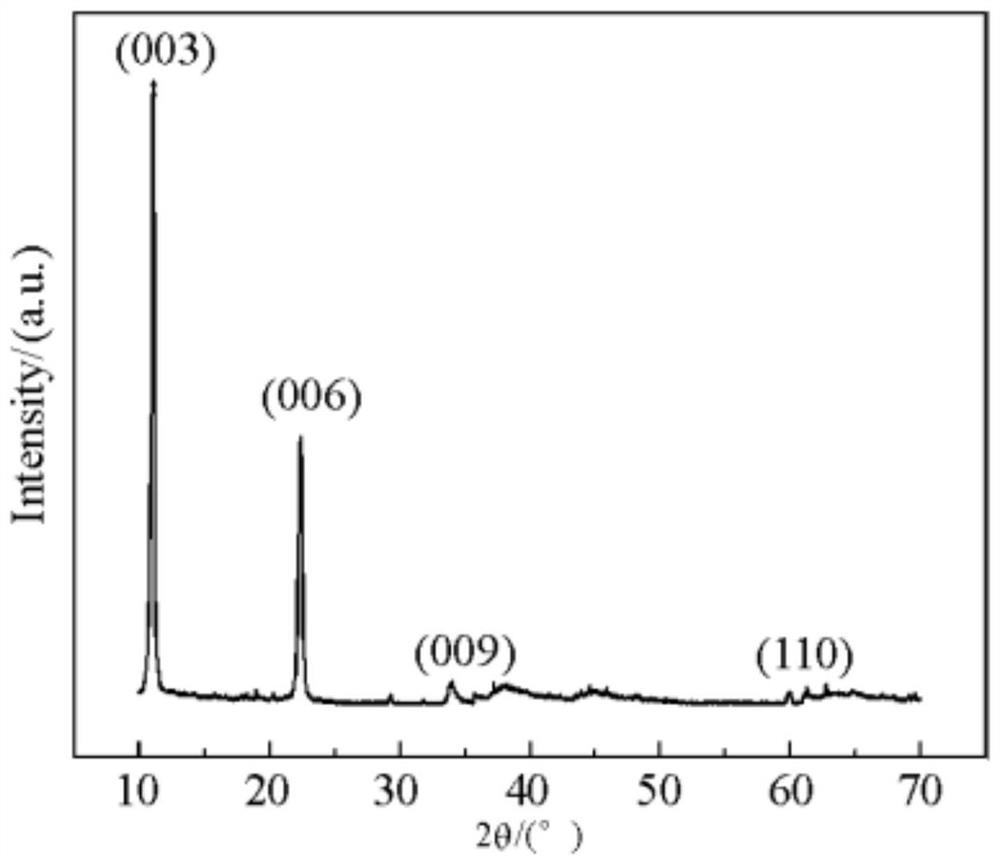

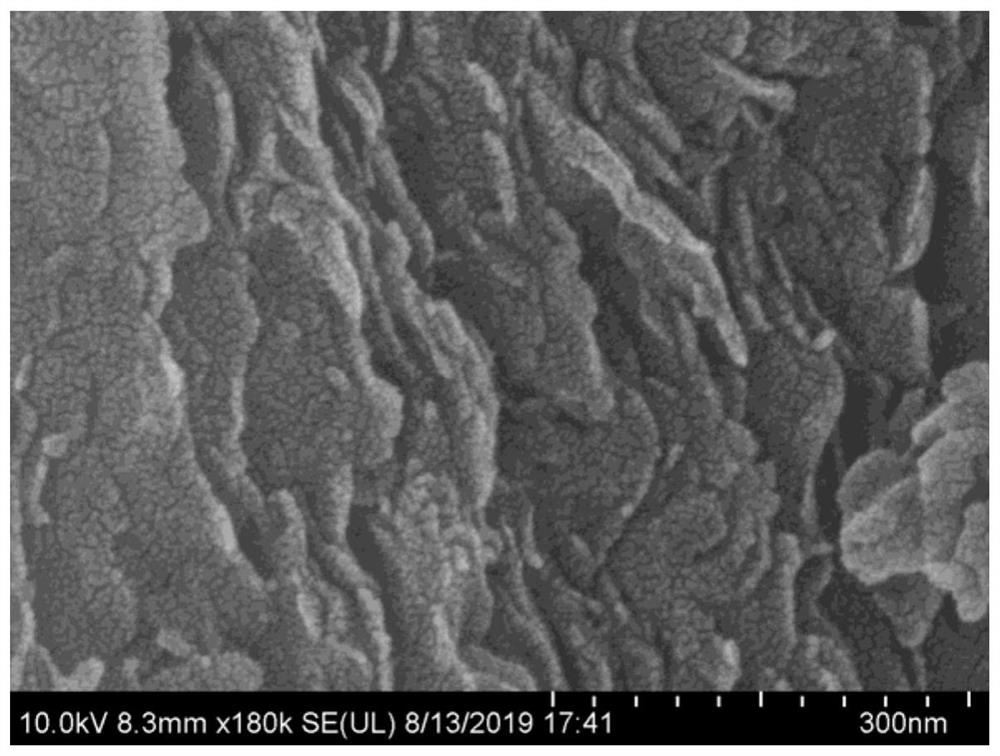

Method for catalyzing oriented conversion of cellulose into composite carbon source by using nickel-doped copper-aluminum hydrotalcite catalyst

ActiveCN113042056ALarge specific surface areaImprove stabilityHeterogenous catalyst chemical elementsBiofuelsCellulosePtru catalyst

The invention provides a method for catalyzing oriented conversion of cellulose into a composite carbon source by using a nickel-doped copper-aluminum hydrotalcite catalyst. The catalyst is a three-metal mixed oxide catalyst, copper-aluminum hydrotalcite is used as a skeleton, nickel atoms are located on a specific copper-aluminum laminate structure, and the catalyst has rich acidic and alkaline catalytic sites. The nickel-doped copper-aluminum hydrotalcite catalyst can be used for catalyzing oriented conversion of cellulose into the composite carbon source (wherein crude methanol, levoglucosenone and carboxylic acid are recovered). The nickel-doped copper-aluminum hydrotalcite catalyst provided by the invention is simple in preparation process and beneficial to industrialization, and has the advantages of complete crystal phase structure, multiple acid-base catalysis sites, high catalysis efficiency, strong anti-coking performance and good stability; and when the catalyst is used for catalyzing pyrolysis of the cellulose, a function of directionally converting the cellulose into the composite carbon source can be realized, and the yield and the product value of the composite carbon source are improved.

Owner:北京神舟茂华环保科技有限公司

Self-heating vertical axial flow roller ablation pyrolytic reaction device

ActiveCN113025354AReduce moistureReduce oxygen contentBiofuelsEnergy inputThermodynamicsHeat carrier

The invention relates to a self-heating vertical axial flow roller ablation pyrolytic reaction device, and belongs to the technical field of renewable energy utilization. The device comprises a shell and a reaction cylinder arranged in the shell, a rotating shaft is arranged in the reaction cylinder, the upper end of the rotating shaft is connected with a variable frequency motor through a belt, the rotating speed of the rotating shaft can be adjusted, a first-stage spiral feeder and a second-stage spiral feeder are arranged outside the shell, the discharging end of the first-stage spiral feeder is communicated with the feeding end of the second-stage spiral feeder, and the discharging end of the second-stage spiral feeder is communicated with the upper part of the reaction cylinder. The device has the beneficial effects that the pyrolysis efficiency is improved, pushing of carrier gas and heating of a heat carrier are not needed in the reaction process, and the heating and cooling loads of the carrier gas are greatly reduced. Self-heating in the pyrolysis process is achieved, and effective utilization of energy is fully achieved. Different taper angles can adapt to the change of the size of the material, powdery, granular and other biomass raw materials can be pyrolyzed, and gas-solid separation and biomass pyrolysis can be better achieved.

Owner:SHANDONG UNIV OF TECH

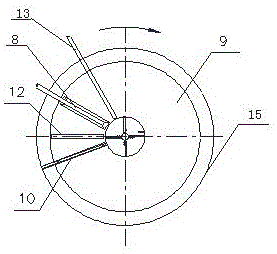

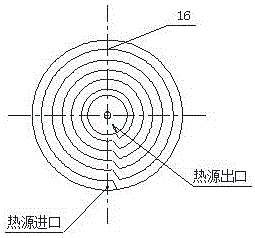

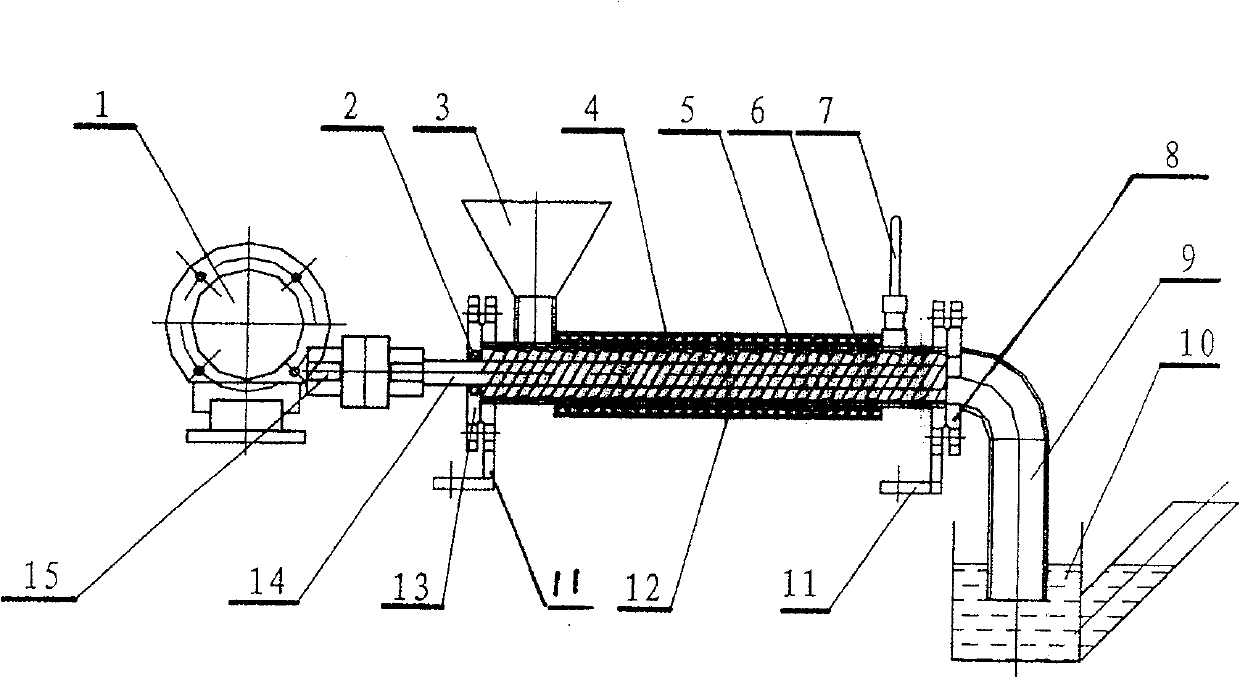

Electromagnetically inducing biomass pyrolyzing and liquefying reactor

InactiveCN100516174CImprove heating uniformityGuaranteed uptimeLiquid hydrocarbon mixture productionReduction driveSlag

The invention relates to the field of pyrolysis of carbon-containing materials, and is a biomass electromagnetic induction pyrolysis and liquefaction reactor, which is characterized in that: it comprises a screw feeder arranged on a support frame, and the screw feeder is composed of a shell and is The feeding hopper, the exhaust pipe and the slag discharge pipe arranged on the casing are composed of a screw shaft arranged in the casing; an inductive coil is wound on the casing; The core tube, the hollow core of the hollow core tube is the cooling liquid flow channel; the lower port of the slag pipe is placed in the water seal groove; the screw shaft is connected with the reducer shaft of the motor; there is an exhaust groove on the axial direction of the screw shaft mouth. It has the advantages of simple structure, convenient operation, continuous operation, uniform heating, fast pyrolysis speed, good quality, cleanliness, environmental protection, low cost and long service life. It is especially suitable for the pyrolysis of fuelwood, crop straw, aquatic plants and other biomass, and also suitable for the pyrolysis of solid fuels such as coal, oil shale and municipal waste.

Owner:NORTHEAST DIANLI UNIVERSITY

Waste plastic pyrolysis carbonization system

PendingCN114350394AIncrease in sizeHigh hardnessProductsReagentsEnvironmental engineeringPyrolytic carbon

The invention discloses a waste plastic pyrolysis carbonization system, and relates to the technical field of waste plastic treatment equipment.The waste plastic pyrolysis carbonization system comprises an incinerator body and further comprises a crushing assembly, the crushing assembly comprises a feeding mechanism arranged at the top of the incinerator body and crushing boxes, multiple groups of crushing mechanisms are arranged between the crushing boxes, the feeding mechanism is connected with the crushing boxes, and the crushing boxes are connected with the crushing mechanisms; the crushing mechanism is used for conveying waste plastics to be pyrolyzed and incinerated into the crushing box and crushing the waste plastics through the crushing mechanism, the incinerator body is used for incinerating the crushed waste plastics, and the dust removal assembly is used for adsorbing and filtering dust generated during crushing in the crushing box; the waste plastics subjected to preliminary crushing in the crushing box fall into the incinerator body under the action of gravity to be subjected to incineration pyrolysis treatment, compared with traditional waste plastic pyrolysis equipment, the waste plastics are subjected to pre-crushing treatment before pyrolysis, and then the waste plastics with the large size and the high hardness are refined so that pyrolysis can be conveniently carried out, and the waste plastic pyrolysis efficiency can be improved. And the pyrolysis rate is improved.

Owner:WUXI TAIXIN ENVIRONMENTAL PROTECTION TECH

Pyrolysis device for processing desulfurization waste liquid in partial oxidation environment

InactiveCN103951131BRestricted accessReduce generationMultistage water/sewage treatmentLiquid wastePartial oxidation

The invention discloses a pyrolysis device for processing desulfurization waste liquid in a partial oxidation environment. The pyrolysis device comprises a pressure-bearing housing, a jacket, an insulating layer and a refractory brick which are arranged from outside to inside and connected together, and a gas separation section I, a spray pyrolysis section II, a mixed flow pyrolysis section III, an inactive salt pyrolysis section IV and a pyrolysis salt chilling section V are communicated from top to bottom to treat the desulfurization waste liquid in the partial oxidation environment. The device adopts a segmental treatment mode, so that decomposition of aromatic compounds and organic matters in the desulfurization waste liquid is ensured in the partial oxidation environment, COD and sulfides in the generated wastewater are reduced, meanwhile, pyrolysis of the inactive salt in the desulfurization waste liquid in the reducing atmosphere is ensured; therefore, the pollution problem of the desulfurization waste liquid is thoroughly solved and effective components in the desulfurization waste liquid can be recycled.

Owner:TAIYUAN UNIV OF TECH

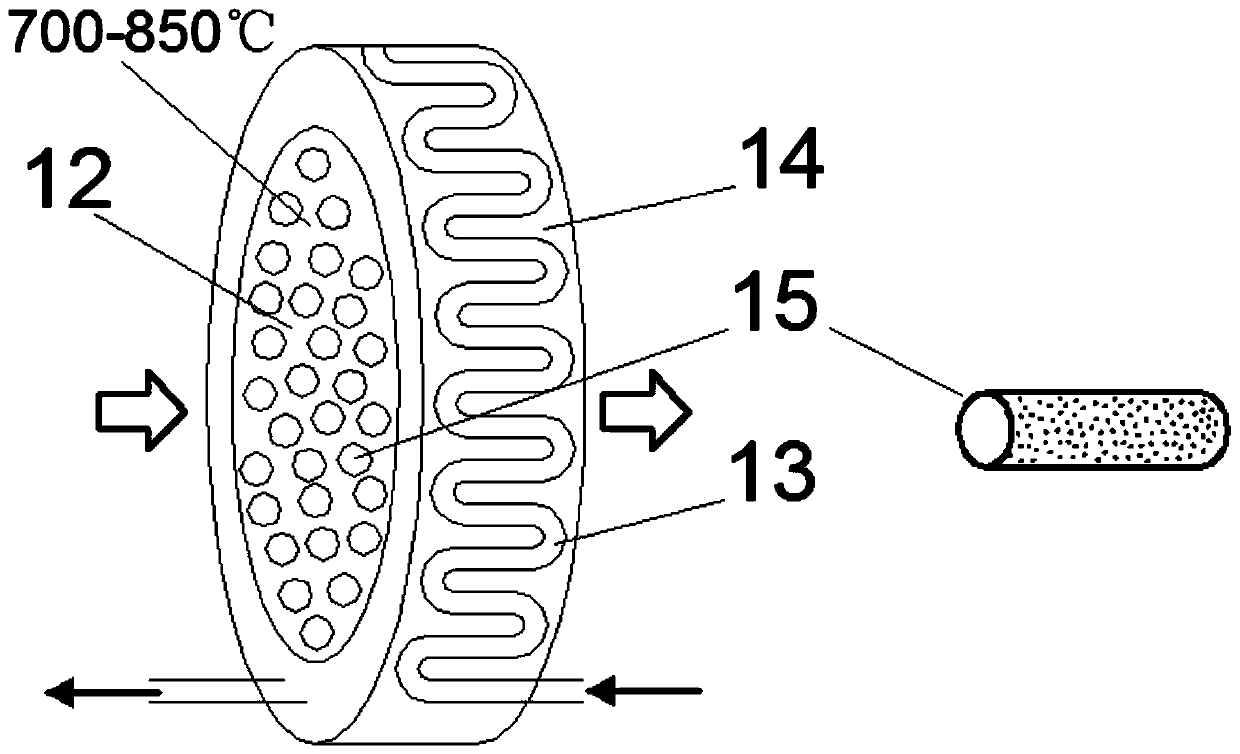

Radiant Tube Heated Rotary Hearth Furnace

ActiveCN105910428BImprove heat transfer effectIncrease pyrolysis rateFurnace typesMetallurgyConvection

The invention discloses a radiant tube-heated rotary hearth furnace. The rotary hearth furnace comprises a furnace body, a radiant tube and a heat transfer enhancement device. The furnace body comprises a hollow annular cavity. A hearth space is defined in the hollow annular cavity. Rotatable furnace bottoms are arranged at the bottom of the hollow annular cavity. The furnace bottoms adopt hollow annular structures. A furnace bottom space is defined between the furnace bottoms. The furnace bottom space communicates with the hearth space by virtue of a plurality of communicating holes. The radiant tube is arranged in the hearth space. The heat transfer enhancement device is arranged on the furnace body to enable airflow in the furnace body to pass through materials placed on one furnace bottom by virtue of the communicating holes to flow from the hearth space to the furnace bottom space or from the furnace bottom space to the hearth space. According to the rotary hearth furnace, the airflow in the furnace body can pass through the materials on the furnace bottom upwards and downwards alternately, and the heat convection between gas in the furnace body and the materials is enhanced, so that the heat exchange capability of the rotary hearth furnace is improved, and the pyrolysis rate of the materials is increased.

Owner:SHENWU TECH GRP CO LTD

Feeding method of oil-coal slurry with different concentrations in the direct liquefaction process of coal hydrogenation

ActiveCN109666502BIncrease pyrolysis rateLow viscosityLiquid hydrocarbon mixture productionHeat carrierDiluent

The feeding method of different concentrations of oil-coal slurry in the direct liquefaction process of coal hydrogenation can reduce the solvent oil-coal ratio of coal blending slurry, and complete the swelling process of low-viscosity heated thin coal slurry LCF usually containing hydrogen-donating agent ‑LT1, in the first thick coal slurry mixing process M1, acts as a diluent and heat carrier, directly heats the first high pressure thick coal slurry HCF1‑PF to be the first mixed coal slurry M1P whose temperature is M1TK, preferably HCF1‑PF The temperature quickly crosses the viscous temperature peak area caused by the temperature rise; then in the first mixed coal slurry heating process M1P‑HX, M1P is heated to a temperature close to the reaction temperature of the AR reaction temperature, such as 330-450 °C, and then enters the coal hydrogenation direct liquefaction reaction The process AR carries out the direct liquefaction reaction of coal hydrogenation; the concept of the present invention is used repeatedly in series, and two or more thick coal slurries are added step by step to the hot thin coal slurry to form a combination of multiple high-coal concentration oil-coal slurries for temperature rise delivery process.

Owner:洛阳瑞华新能源技术发展有限公司

A Method of Microwave Hydrothermal Carbon Decoupling Chemical Looping Gasification for Controlling the Quality of Syngas

ActiveCN111484877BSpeed up the hydrothermal reaction rateImprove conversion rateGasification processes detailsPyrolysis reactionsSyngasBiomass feedstock

The present invention provides a microwave hydrothermal charcoal decoupling chemical chain gasification method for controlling the quality of synthesis gas. The operation steps are as follows: A. Particle manufacturing: the user selects biomass raw material in advance, and then the user puts the biomass raw material into the reactor , and inject equal proportions of water into the reactor, and then the user uses a booster pump to pressurize the reactor, so that the biomass raw material and water undergo a hydrothermal reaction in the reactor to form hydrothermal charcoal particles. The present invention can regulate the product components of microwave hydrothermal charcoal gasification in a directional way through the process cooperation of particle manufacturing, oxygen carrier gasification reaction domain, reaction kinetics, reactor construction, interactive influence system and amplification law, thereby realizing microwave hydrothermal carbon gasification. The full conversion effect of thermally coupled chemical looping gasification technology to high value-added HMF and syngas reveals the directional reorganization mechanism of oxygen, carbon and hydrogen in the gasification reaction, and finally improves the oxygen, carbon and hydrogen in the hydrothermal char gasification reaction. Hydrogen regulation of synthesis gas quality.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

A biochar blanking device used in biomass production

ActiveCN107573953BFluidityReduce resistanceBiofuelsRetortsEnvironmental engineeringMechanical engineering

The invention discloses a biomass charcoal discharge device used in biomass production. The biomass charcoal discharge device comprises a furnace disc, wherein the furnace disc is arranged inside a hearth and is connected with a transmission mechanism; a plurality of charcoal discharge through holes are formed in the body of the furnace disc; a disturbance bridging breaking device is arranged on the furnace disc; a charcoal scraping device is arranged below the furnace disc; the furnace disc is driven to rotate by the transmission mechanism, and then the disturbance bridging breaking device isdriven to break accumulation of biomass charcoal; the biomass charcoal is dropped down from the charcoal discharge through holes and is conveyed to next procedures through the charcoal scraping device. Due to the arranged disturbance bridging breaking device on the furnace disc, the charcoal device below the furnace disc and the charcoal discharge through holes in the furnace disc, the biomass charcoal is always at a loosened state and is good in flowability and small in resistance, the pyrolysis velocity inside a furnace is increased, and the drying speed of materials inside an area is increased; a spindle casing and a dustproof cover are compactly connected, and the overall structure is reasonable in arrangement, convenient to maintain and long in service life.

Owner:合肥吉干原科技有限公司

A biomass pyrolysis carbonization furnace

The invention discloses a biomass pyrolysis carbonization furnace including a bottom plate. A reaction tube is connected to the surface of the bottom plate through a support frame. A mounting groove is installed in the lower part of an inner chamber of the reaction tube and is communicated with the inner chamber of the reaction tube through a communication hole. An electric heating tube is arranged in the mounting groove. A feeding inlet is arranged on the upper part of one side of the reaction tube. A top plate is connected to a position, corresponding to the bottom end of the reaction tube,on the surface of the bottom plate via a first electric telescopic rod. In the biomass pyrolysis carbonization furnace, the material is pyrolyzed with hot air flow at high speed in total, wherein thehot air can be reutilized, so that pyrolytic efficiency is guaranteed and heat energy utilization rate is increased too. Meanwhile, by adjustment on the distance between the top plate and a pressing plate, the pyrolyzed materials can be pressed to shape the materials in the same structure, so that the material can be stored conveniently, which has convenience in transportation in later period.

Owner:张海楠 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com