Electromagnetically inducing biomass pyrolyzing and liquefying reactor

An electromagnetic induction and biomass technology, which is applied in the fields of biomass electromagnetic induction pyrolysis liquefaction reactor, biomass pyrolysis, and solid fuel pyrolysis, can solve problems such as serious friction and wear, difficult sealing, and achieve low cost, The effect of fast pyrolysis and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below using the accompanying drawings and examples.

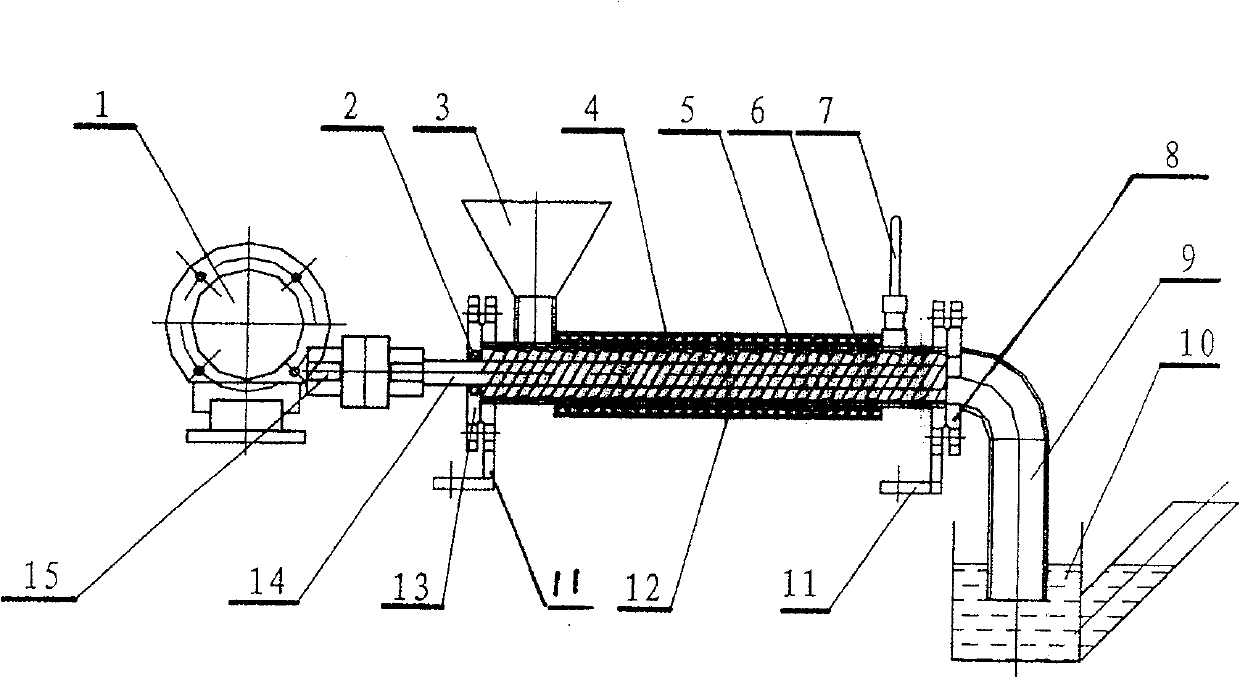

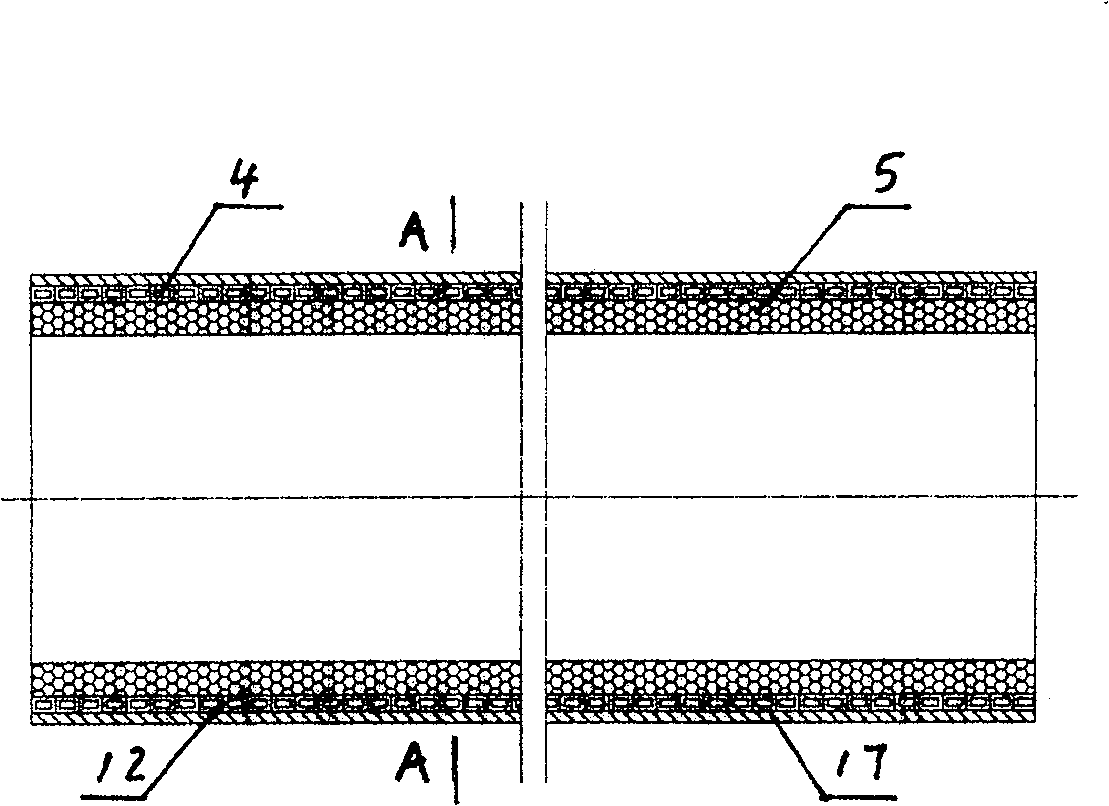

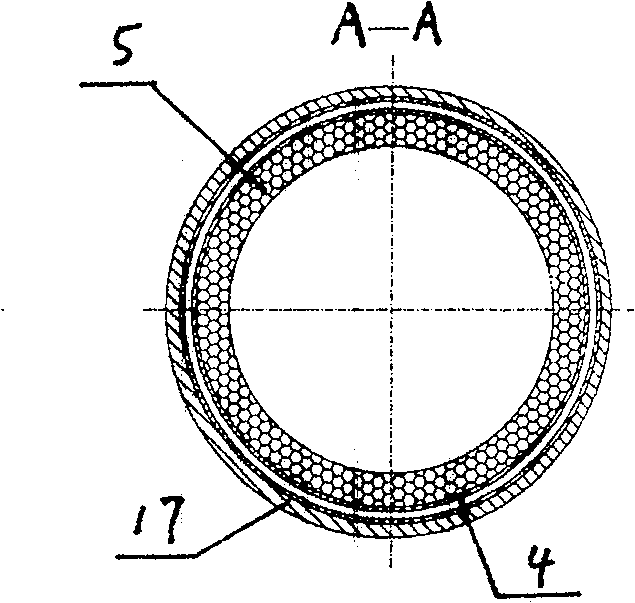

[0023] refer to Figure 1-4 , The biomass electromagnetic induction pyrolysis liquefaction reactor has a support frame 11, and a screw conveyor 6 is placed on the support frame 11. The structure of the screw conveyor 6 is that it has a housing 5 on which a feeding hopper 3 , an exhaust pipe 7 and a slag discharge pipe 9 are arranged, and a screw shaft 14 is built in the housing 5 . The casing 5 of the screw feeder 6 is fixedly connected with the support frame 11 . An inductance coil 12 is wound on the casing 5 of the screw conveyor 6 . The upper port of the slag discharge pipe 9 is provided with a pipe base 8, which is fixedly connected with the support frame 11 of the shell 5, and the lower port of the slag discharge pipe 9 is placed in a water seal tank 10. The screw shaft 14 of the screw conveyor 6 is connected with the reducer shaft 15 of the motor 1 . Motor 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com