Acid leaching ore pulp liquid drying pyrolysis device

A technology of pyrolysis and pulp, applied in the direction of drying gas arrangement, drying solid materials, non-progressive dryers, etc., can solve the problems of difficult separation, low efficiency, complicated process, etc., and achieve increased pyrolysis rate, complete discharge, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the present invention will be further described in detail below in conjunction with the accompanying drawings:

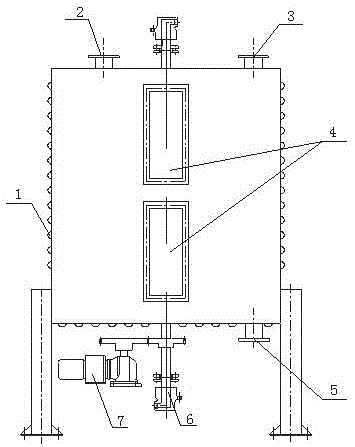

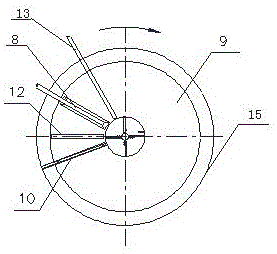

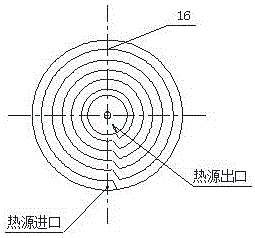

[0022] like figure 1 , figure 2 , image 3 , Figure 4 As shown, a kind of acid leaching ore slurry drying pyrolysis device comprises an outer casing 15, an external heating coil 1 is arranged on the outer side of the outer casing 15, and a detachable observation window 4 is provided on the outer casing 15, which is convenient for observation and easy to disassemble and feed Tube 13, scraper 12, steel brush 10 and suction device 8. The upper end of the outer casing 15 is provided with an exhaust port 3 and a temperature measuring port 2, and the exhaust port 3 of the outer casing is connected with a fan for extracting moisture, nitrogen oxides and other gases evaporated during the drying and pyrolysis process. A slag outlet 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com