Exothermic catalytic combustion method for pyrolysis gasification submelting furnace under pure oxygen conditions

A technology of pyrolysis gasification and catalytic combustion, which is applied in the direction of combustion methods, combustion using catalytic materials, incinerators, etc., can solve the problems of low production efficiency, large safety hazards, and high maintenance costs, so as to reduce waste, reduce pollution, Effect of reducing CO2 emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

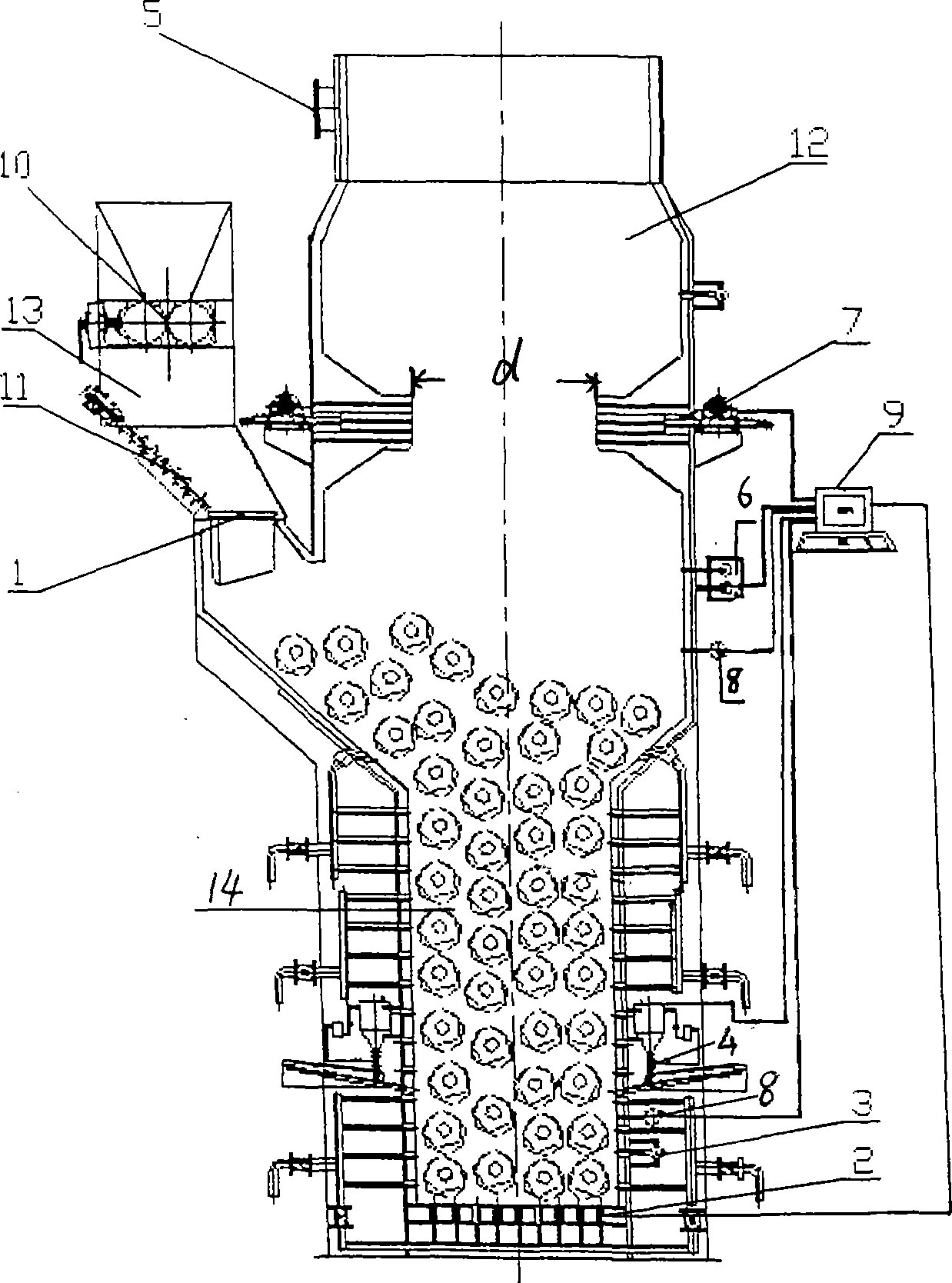

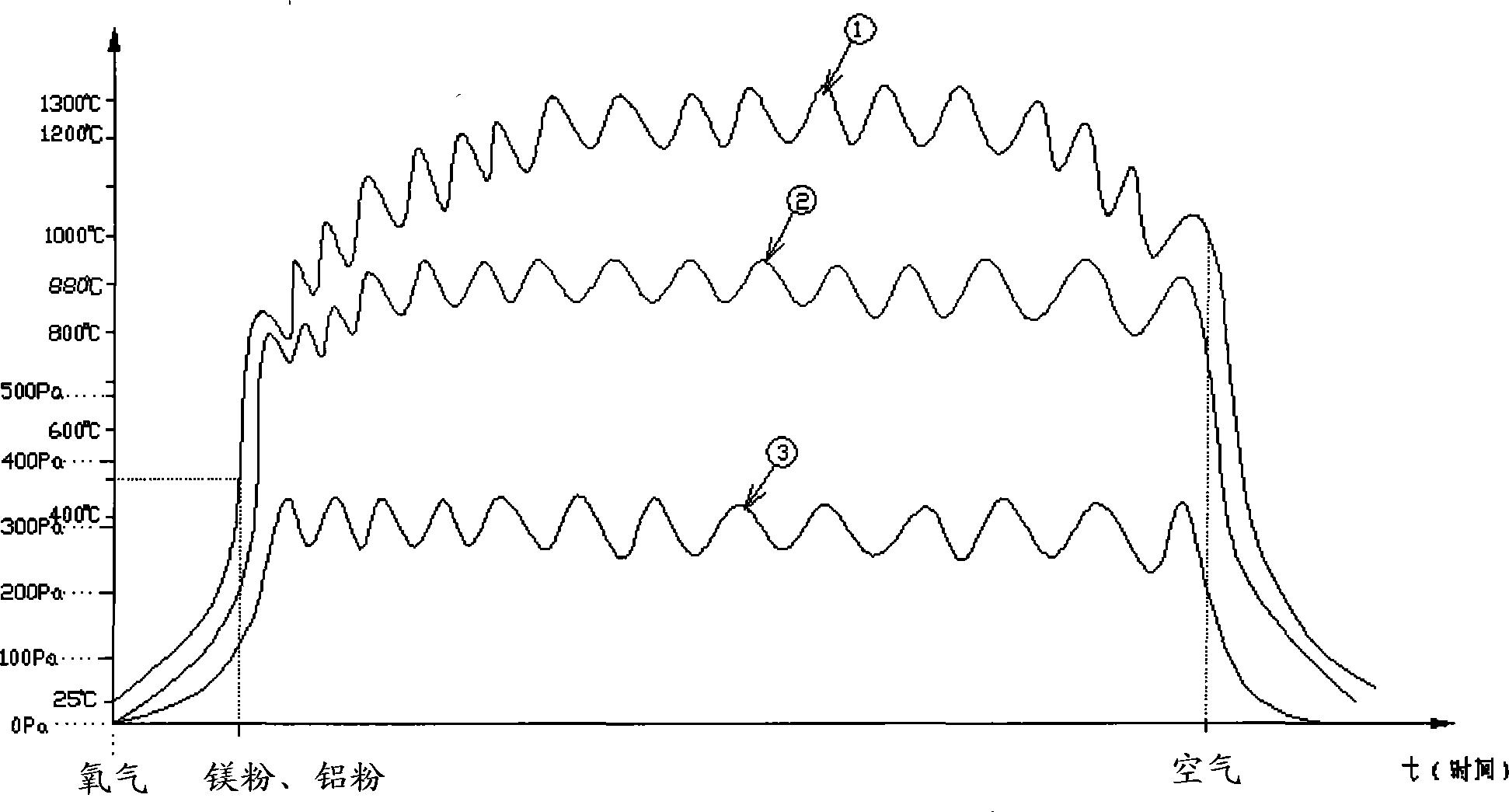

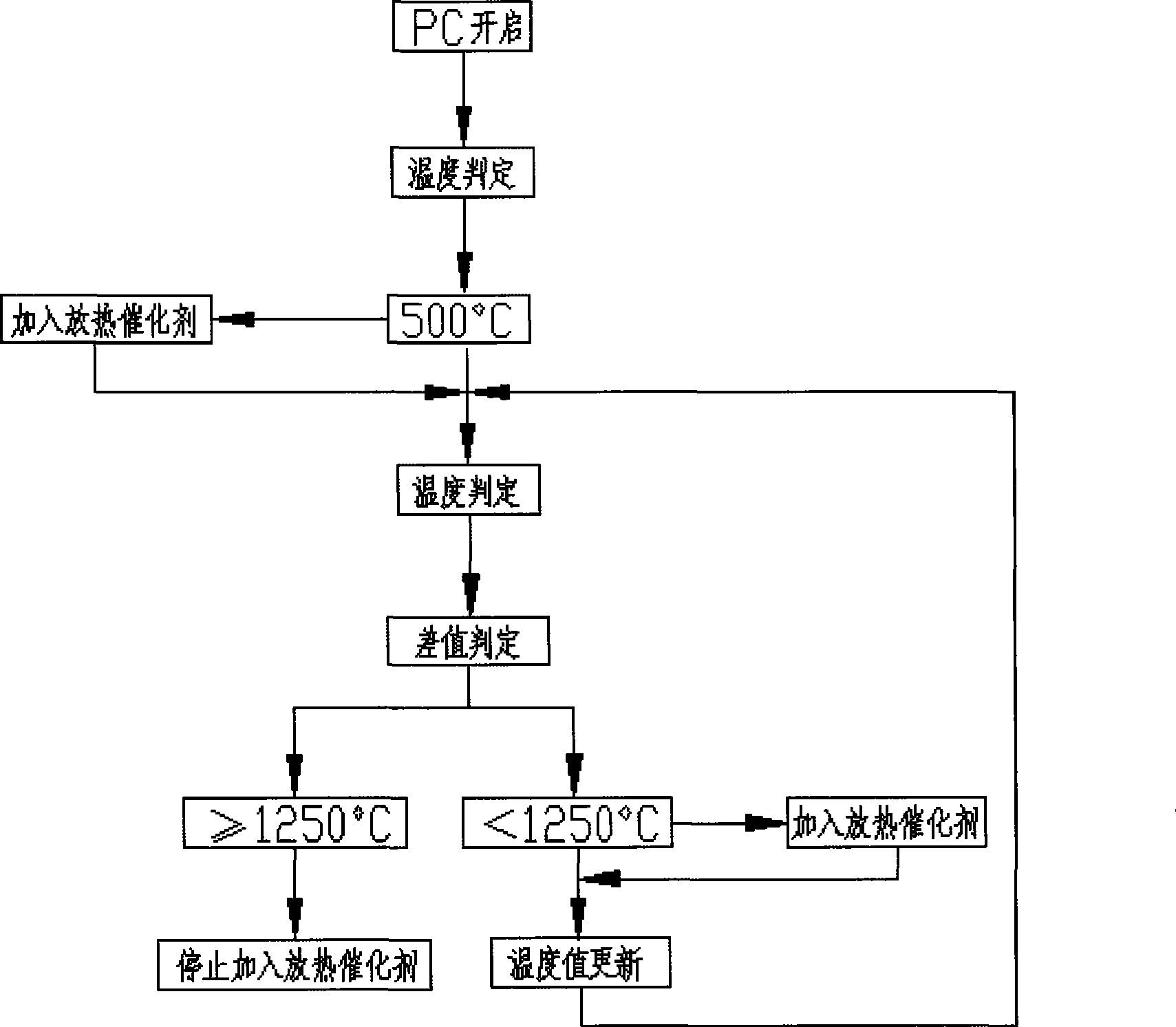

[0042] A method for exothermic catalytic combustion of a pyrolysis gasification sub-melting furnace under pure oxygen conditions. The specific steps are: put 5 tons of processed objects (garbage, waste) into a closed storage room 13 through a crushing feeder 10, and pass through The material of the quantitative pulverizer 10 is conveyed by the screw conveyor 11 through the feed door 1 to the pyrolysis furnace 14, and the low-temperature material entering the pyrolysis furnace 14 is automatically and quickly ignited by an array of igniters, and blows oxygen through the bottom and side oxygen blowing ports 2 , pyrolysis, carbonization, the pyrolysis gas enters the combustion chamber 12 for combustion, and is discharged through the flue gas outlet 5, and is discharged after recovering heat energy, neutralization, and dust removal. After the automatic igniter 3 is ignited, oxygen is directly fed into the pyrolysis gasification sub-melting furnace, and the opening of the valve on th...

Embodiment 2

[0044] A method for exothermic catalytic combustion of a pyrolysis gasification sub-melting furnace under the condition of pure oxygen, the specific steps are: put 50 tons of processed objects (garbage, waste) into a closed storage room 13 through a crushing feeder 10, and pass through The material of the quantitative pulverizer 10 is conveyed by the screw conveyor 11 through the feed door 1 to the pyrolysis furnace 14, and coal or coke is put into the pyrolysis furnace 14. The low-temperature material entering the pyrolysis furnace 14 is automatically and quickly ignited by an array of igniters, and blown through the bottom and side. The oxygen port 2 blows oxygen, pyrolyzes, and carbonizes. The pyrolysis gas enters the combustion chamber 12 for combustion, and is discharged through the flue gas outlet 5. It is discharged after recovering heat energy, neutralization, and dust removal. After the automatic igniter 3 is ignited, oxygen is directly fed into the pyrolysis gasificat...

Embodiment 3

[0046] A method for exothermic catalytic combustion of a pyrolysis gasification sub-melting furnace under pure oxygen conditions. The specific steps are as follows: 30 tons of processed objects (garbage, waste) enter the airtight storage chamber 13 through the crushing feeder 10, and pass through The material of the quantitative pulverizer 10 is conveyed by the screw conveyor 11 through the feed door 1 to the pyrolysis furnace 14, and the low-temperature material entering the pyrolysis furnace 14 is automatically and rapidly ignited by an array of igniters, and oxygen is blown through the bottom and side oxygen blowing ports 2 , pyrolysis, carbonization, the pyrolysis gas enters the combustion chamber 12 for combustion, and is discharged through the flue gas outlet 5, and is discharged after recovering heat energy, neutralization, and dust removal. After the automatic igniter 3 is ignited, oxygen is directly fed into the pyrolysis gasification sub-melting furnace, and the openi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com