A biochar blanking device used in biomass production

A technology of biomass charcoal and blanking device, which is applied in the fields of biofuels, carbonization furnaces, special forms of dry distillation, etc., can solve the problems of reducing the pyrolysis rate in the furnace, the drying speed of materials, affecting the output rate, etc., and achieve a reasonable overall structure and layout. , Speed up the drying speed, the effect of low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

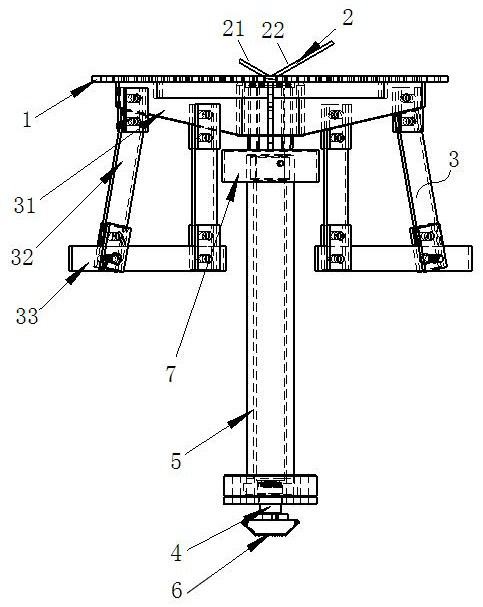

[0013] Such as figure 1 As shown, a kind of biomass charcoal blanking device used in biomass production includes a furnace pan 1 arranged in the furnace and connected to a transmission mechanism. A number of charcoal through holes are arranged in the pan body of the furnace pan 1. A disturbance arch breaking device 2 is installed, a charcoal scraping device 3 is installed under the furnace tray 1, and the transmission mechanism drives the furnace tray 1 to rotate, thereby driving the disturbance arch breaking device 2 to open the accumulation of biochar, and the biochar falls from the carbon falling through hole, and The biochar is transported to the next process through the carbon scraping device 3. A biochar blanking device is set in the furnace to open the accumulation of biochar, provide continuous pyrolysis time, make the biochar loose and fall, speed up the drying of the material, and transport the biochar to the next process.

[0014] The disturbance arch breaking devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com