Pouring structure for pouring electrochromic liquid into electrochromic rearview mirror

An electrochromic, rear-view mirror technology, applied in optics, instruments, optical observation devices, etc., can solve the problems of inconvenient injection operation and high environmental vacuum requirements, and is suitable for assembly operations and large-scale production, with excellent perfusion effect. , create convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

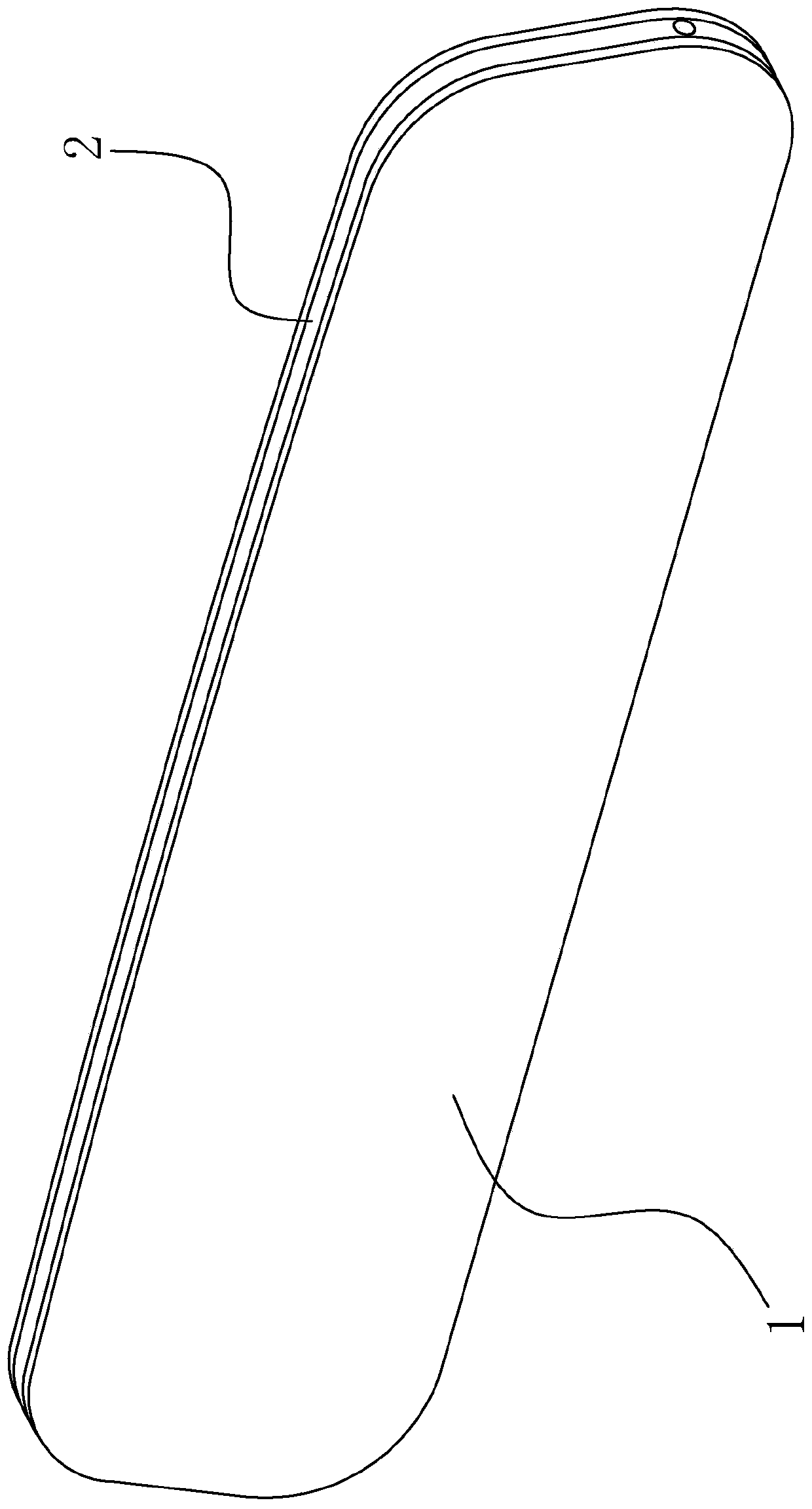

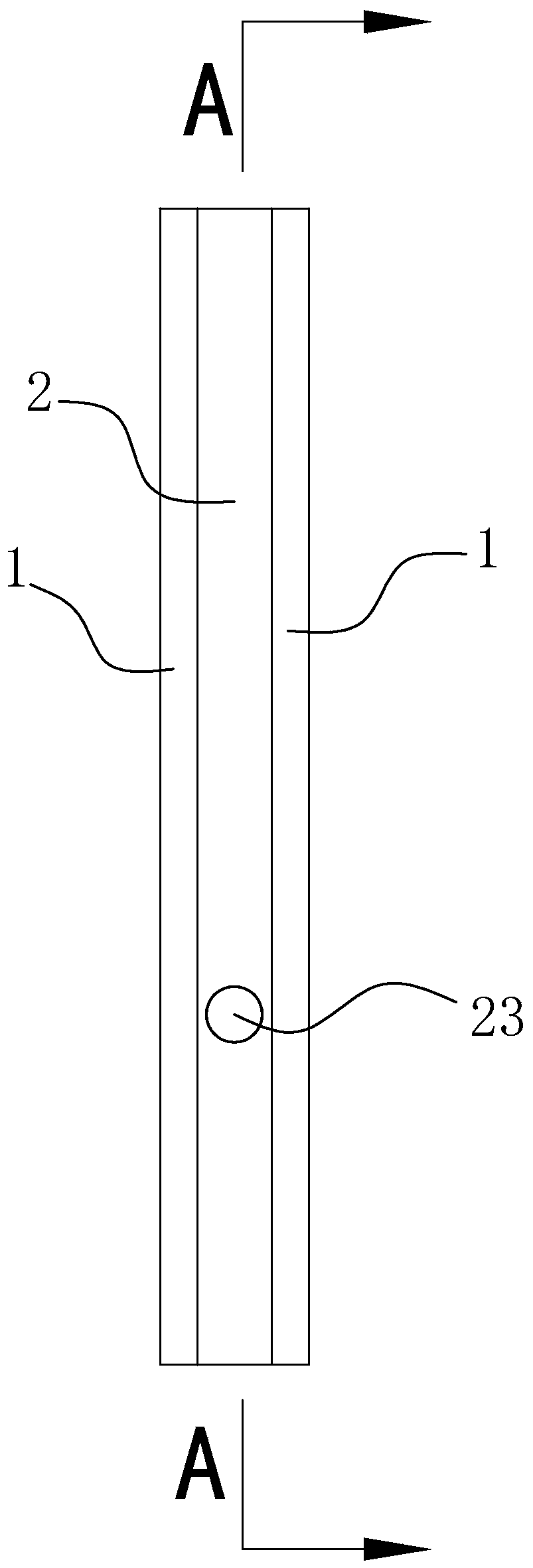

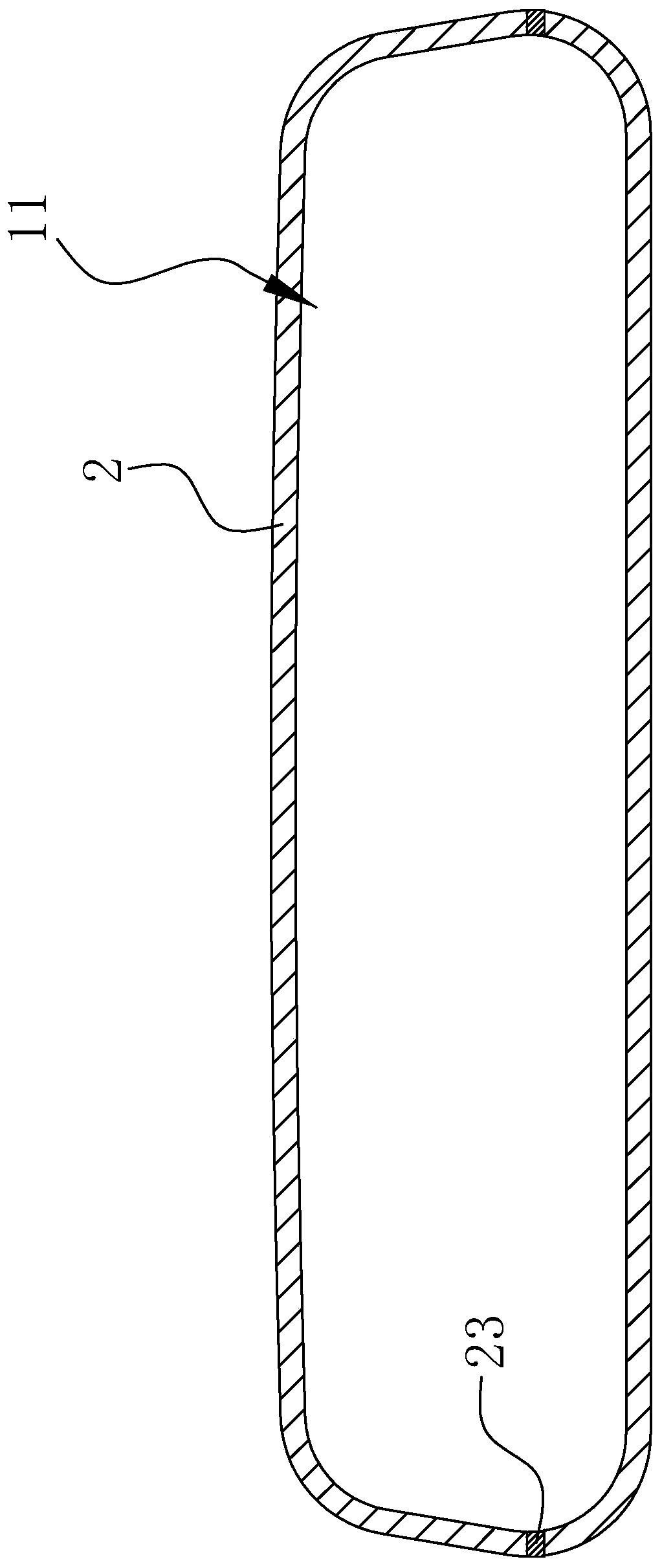

[0022] like Figure 1 to Figure 4 As shown, the perfusion structure for filling the electrochromic liquid in the electrochromic rearview mirror of this embodiment includes a glass shell that can be filled with the electrochromic liquid in the electrochromic rearview mirror, and the glass shell It is formed by bonding two front and rear glass substrates 1 through epoxy resin glue 2 on the periphery of the front and rear two glass substrates. The enclosed cavity is sealed by epoxy resin glue bonded to the periphery of the front and rear two glass substrates 1, and an opening capable of filling the electrochromic liquid is provided at the epoxy resin glue on the periphery of the front and rear two glass substrates. , one end of the glass housing is provided with a liquid inlet opening 21 through which the electrochromic liquid enters the inner ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com