Method of Microwave Pyrolysis and Utilization of Lignite

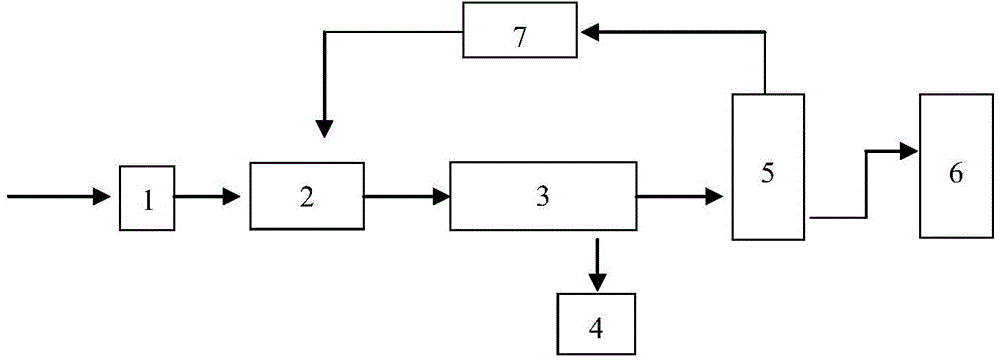

A lignite and microwave technology, used in special forms of dry distillation, petroleum industry, coke ovens, etc., can solve the problems of high temperature, low utilization rate, large energy consumption, etc., and achieve the effects of short production cycle, reduced emissions, and safe and reliable system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

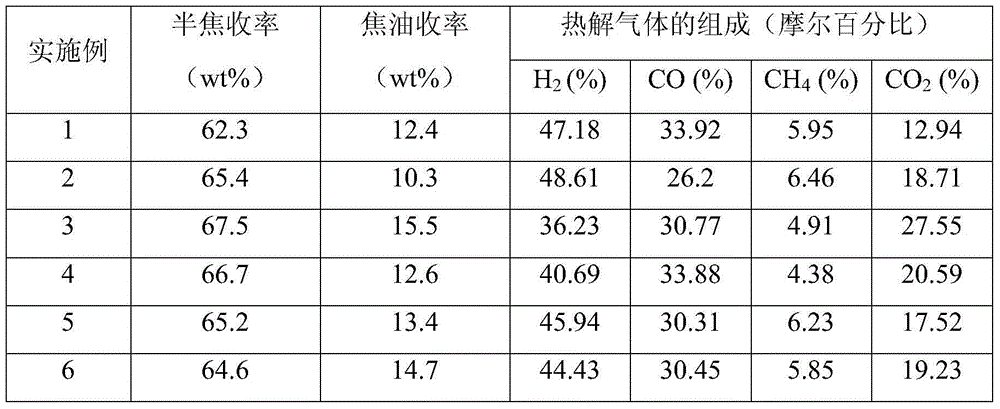

[0028] After pulverizing the lignite with a water content of 20% (weight percentage) into 0.5mm powder, it is transported to the dryer 2 and dried to a moisture content of 5% (weight percentage). Using microwave as a heat source, the lignite is heated to 600°C, After keeping it for 20 minutes, it is cooled to obtain a semi-coke product and a mixture of oil and gas. The oil and gas mixture is condensed by condenser 5 to separate tar products and pyrolysis gas. The composition of the pyrolysis gas was detected by gas chromatography (Shimadzu 2014C, TCD detector, Ar as carrier gas, TDX-1 packed column, oven temperature at 100°C).

[0029] The results of the pyrolysis of lignite are shown in Table 1.

Embodiment 2

[0031] After pulverizing the lignite with a moisture content of 30% into 1.5mm powder, it is transported to the dryer 2 and dried to a moisture content of 1%. Using the microwave as the heat source, the lignite is heated to 500℃, kept for 30 minutes, and then cooled to obtain semi-coke Product and oil-gas mixture. The oil and gas mixture is condensed by condenser 5 to separate tar products and pyrolysis gas. The composition of the pyrolysis gas was detected by gas chromatography (Shimadzu 2014C, TCD detector, Ar as carrier gas, TDX-1 packed column, oven temperature at 100°C).

[0032] The results of the pyrolysis of lignite are shown in Table 1.

Embodiment 3

[0034] The lignite with a moisture content of 40% is pulverized into a 2.0mm powder and transported to the dryer 2, dried to a moisture content of 10%. Using microwave as a heat source, the lignite is heated to 400°C, kept for 60 minutes, and cooled to obtain a semi-coke product And oil and gas mixture. The oil and gas mixture is condensed by condenser 5 to separate tar products and pyrolysis gas. The composition of the pyrolysis gas was detected by gas chromatography (Shimadzu 2014C, TCD detector, Ar as carrier gas, TDX-1 packed column, oven temperature at 100°C).

[0035] The results of the pyrolysis of lignite are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com