Microwave pyrolysis equipment

A kind of equipment and pyrolysis technology, applied in the field of microwave pyrolysis equipment, can solve the problems of low processing efficiency, small capacity, low power, etc., and achieve the effects of uniform heating, simplified structure and guaranteed effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

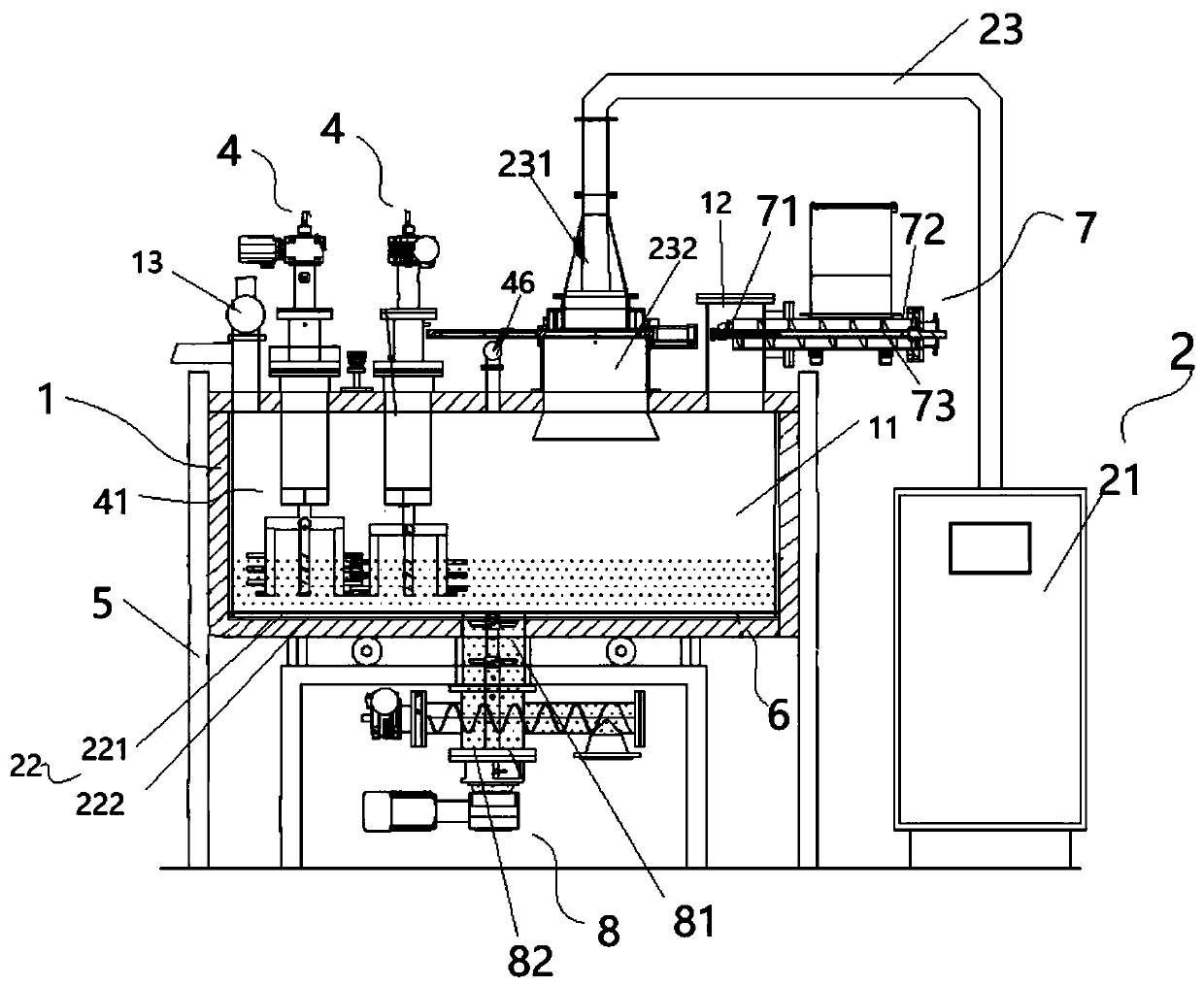

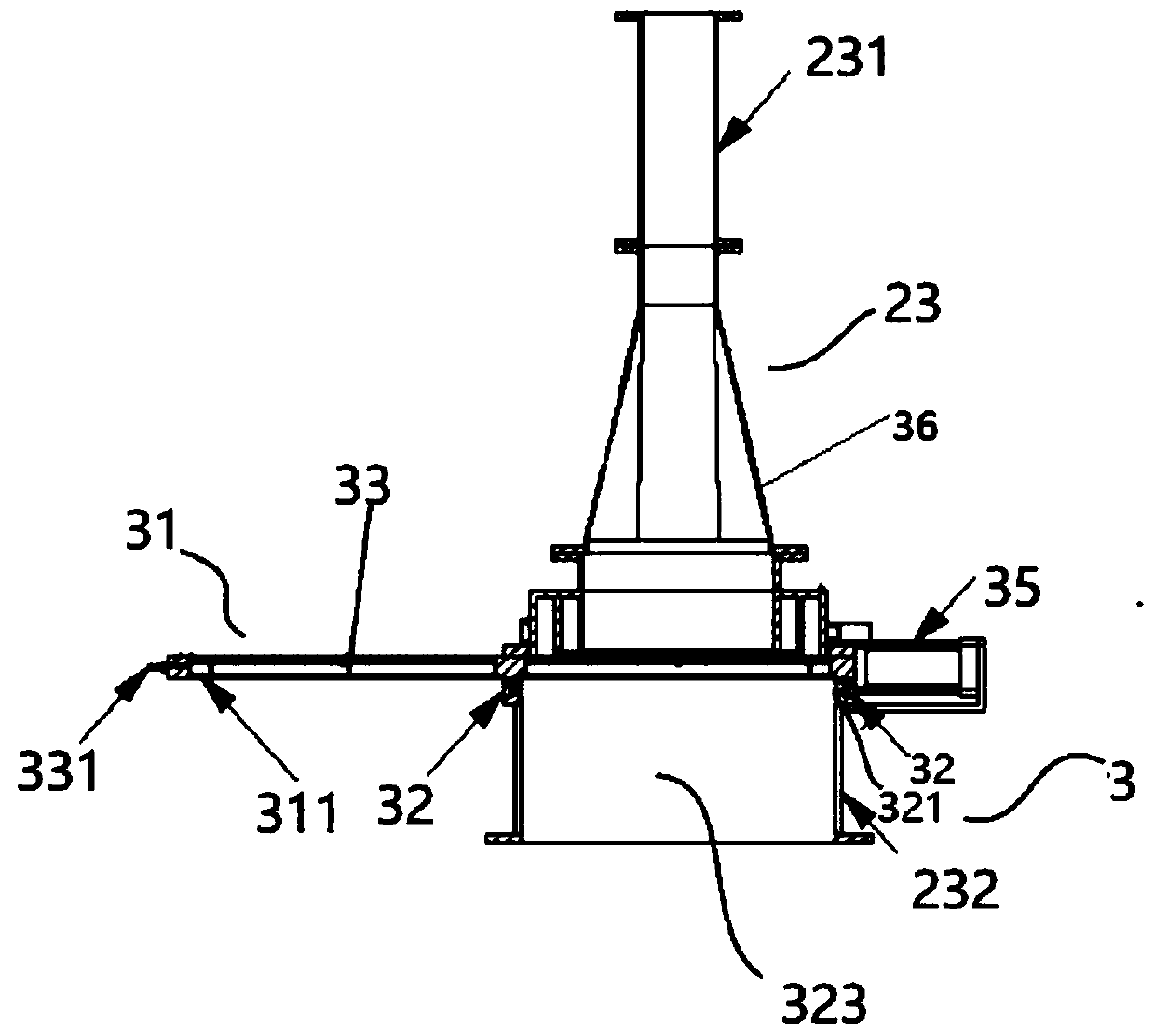

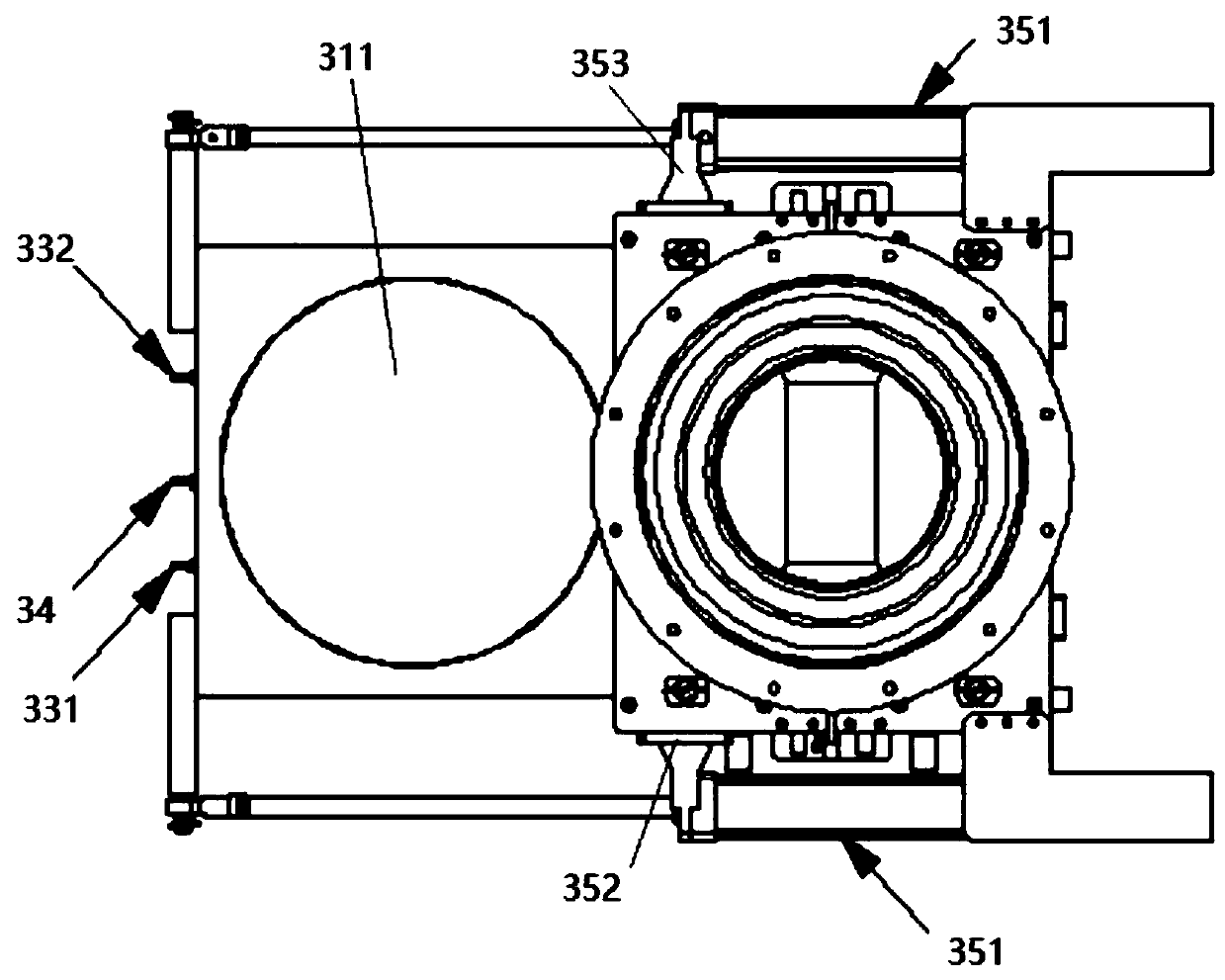

[0066] A kind of pyrolysis equipment is recorded in the embodiment of the present invention, and this pyrolysis equipment utilizes microwave heating to carry out pyrolysis treatment to material, as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the pyrolysis equipment includes a housing 1, a microwave generating device 2, a waveguide protection device 3, and a stirring device 4, wherein the housing 1 is arranged on a frame 5, and inside the housing 1 there is a The housing cavity 11 is also provided with a housing air inlet 12 on the housing 1 for introducing safety gas, and a housing gas outlet 13 for discharging waste gas or other gas mixtures generated after pyrolysis reaction, The material undergoes a pyrolysis reaction inside the containing cavity 11, and the microwave generating device 2 transmits microwaves to the inside of the containing cavity 11. Specifically, the microwave generating device 2 includes at least one microwave generato...

Embodiment 2

[0091]This embodiment provides a microwave pyrolysis device. Compared with the microwave pyrolysis device provided in Embodiment 1, the difference is that in this embodiment, the barrier assembly 31 includes two layers of barriers 311, a sealed cavity 33 is formed between the two layers of barriers 311, the first barrier 311 connected to the waveguide cavity in the second waveguide 232 is provided with at least one through hole, and the two layers of barriers 311 The gap between them is the import channel 32, and the through hole is used as the import outlet port 321, and the protection medium is passed into the inside of the sealed cavity 33, and the protection medium is input to the waveguide along the through hole on the first barrier member 311 as an outlet. Inside the chamber, by changing the way the protective medium is fed into the dielectric protection layer 323, the oxidation reaction with the carbon-containing mixture in the dielectric protection layer 323 and the car...

Embodiment 3

[0095] This embodiment provides a microwave pyrolysis device, which differs from the microwave pyrolysis devices provided in Embodiment 1 and Embodiment 2 in that, in this embodiment, it can be placed inside the body of the housing 1 An insulating layer 6 is provided, and an insulating material is filled into the insulating layer 6, so that when the material in the containing cavity 11 undergoes a pyrolysis reaction, the heat exchange between the containing cavity 11 and the outside can be reduced, and the pyrolysis reaction can be ensured to proceed smoothly , in this embodiment, the insulation material material can be thermal insulation cotton, of course, it can also be insulation material of other materials, as long as it can withstand high temperature, does not absorb microwaves, is non-flammable, and has good thermal insulation performance, so as to reduce the occurrence of material in the cavity and the outside. Just heat exchange.

[0096] In this embodiment, a galvaniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com