Preparation method of energy-saving waste salt ball for pyrolysis

A technology of pyrolysis and waste salt residue, applied in the combustion method, lighting and heating equipment, combustion type and other directions, can solve the problems of serious equipment corrosion, unfavorable resource utilization, difficult to control, etc., to reduce equipment corrosion, reduce raw material consumption, Reduce the effect of direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing energy-saving waste salt pellets for pyrolysis, comprising the following steps:

[0028] (a) drying the waste salt slag at 55°C, and controlling the water content of the waste salt slag to be below 10%;

[0029] (b) placing the dried waste salt slag and rice husk particles in a stirring device at a mass ratio of 5:1 to obtain pyrolysis core particles with a calorific value greater than 2500 kcal / kg;

[0030] (c) Add polymer adhesive polymethyl acrylate and inorganic material fly ash rich in iron, aluminum, silicon and pore structure to the pyrolysis core particles, stir and mix until the inorganic materials evenly cover the surface of the pyrolysis core particles, Waste salt pellets were obtained, wherein the mass ratio of pyrolysis core particles to polymethylacrylate and fly ash was 1:0.3:2.

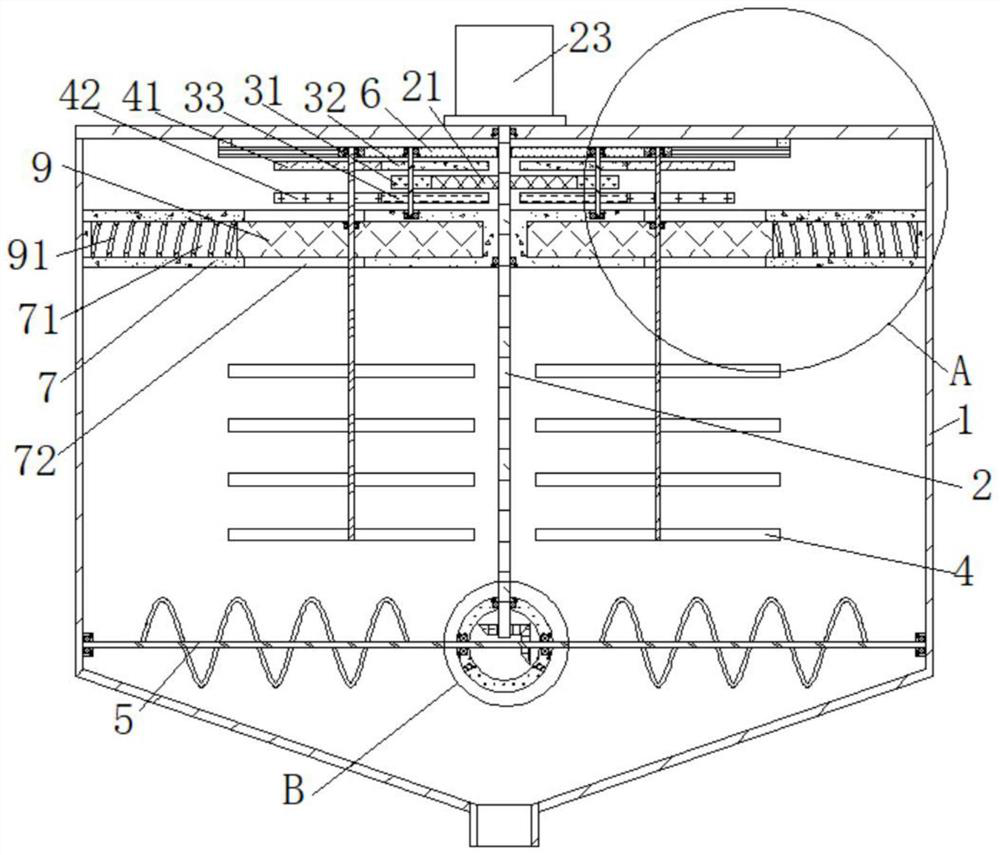

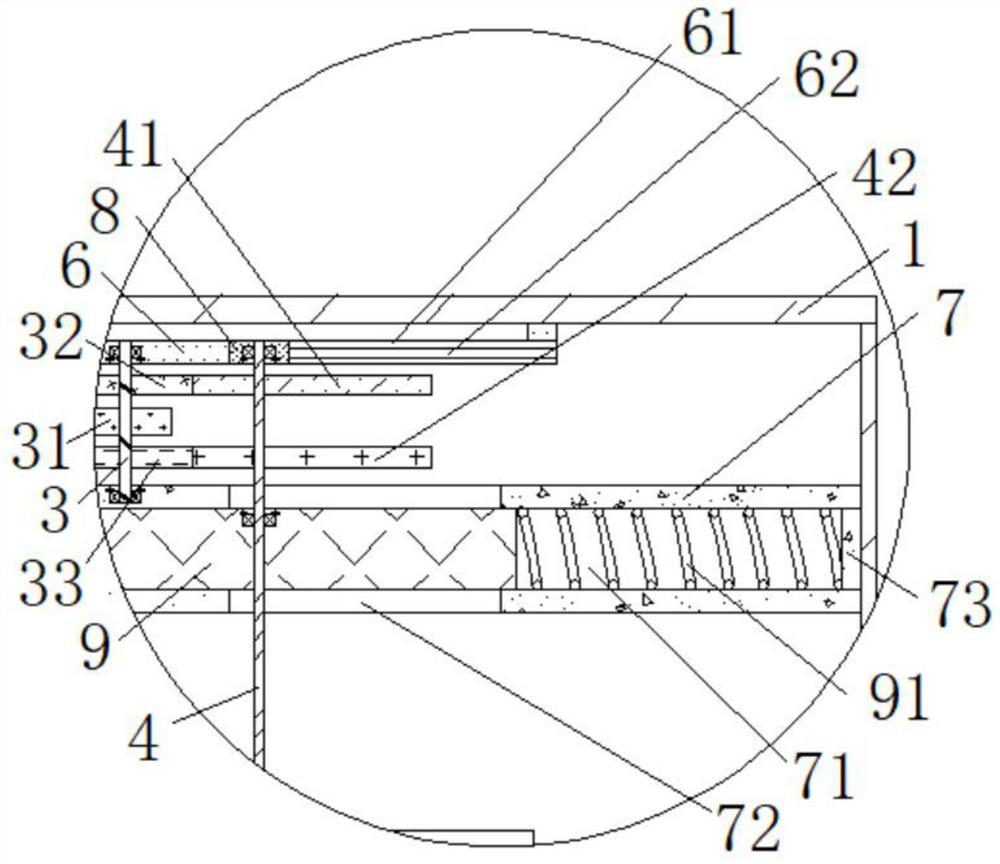

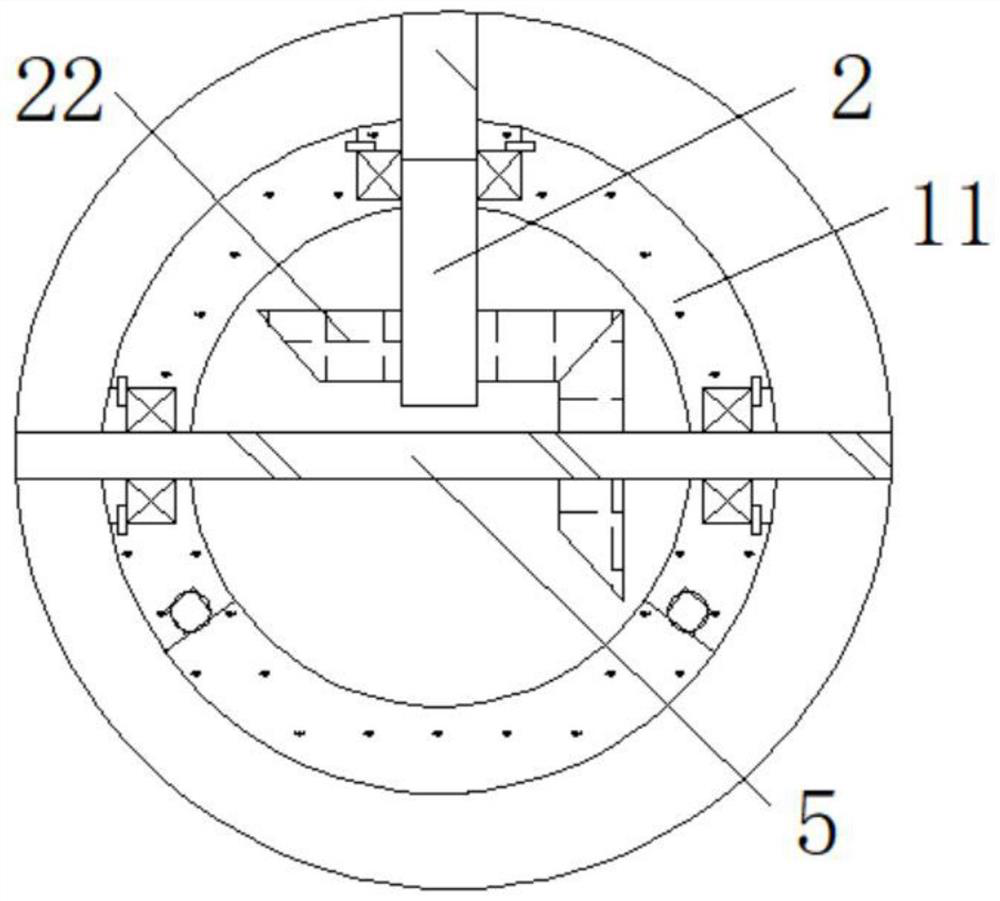

[0031] Such as Figure 1 to Figure 6 As shown, the stirring device includes a tank body 1, a central shaft 2 driven to rotate by a motor 23, a rotating ...

Embodiment 2

[0039] A method for preparing energy-saving waste salt pellets for pyrolysis, comprising the following steps:

[0040] (a) drying the waste salt slag at 50°C, and controlling the water content of the waste salt slag to be below 10%;

[0041] (b) placing the dried waste salt slag and straw particles in a stirring device at a mass ratio of 10:1 to obtain pyrolysis core particles with a calorific value greater than 2500 kcal / kg;

[0042] (c) Add polymer adhesive polymethacrylate and inorganic material incineration fly ash rich in iron, aluminum, silicon and pore structure to the pyrolysis core particles, stir and mix until the inorganic materials evenly cover the surface of the pyrolysis core particles , to obtain waste salt pellets, wherein the mass ratio of pyrolysis core particles to polymethacrylate and incineration fly ash is 1:0.5:3.

Embodiment 3

[0044] A method for preparing energy-saving waste salt pellets for pyrolysis, comprising the following steps:

[0045] (a) drying the waste salt slag at 60°C, and controlling the water content of the waste salt slag to be below 10%;

[0046] (b) placing the dried waste salt slag and corncob particles in a stirring device in a mass ratio of 20:1 to obtain pyrolysis core particles with a calorific value greater than 2500 kcal / kg;

[0047] (c) Add polymer adhesive polyvinyl acetate and inorganic material activated carbon rich in iron, aluminum, silicon and pore structure to the pyrolysis core particles, stir and mix until the inorganic materials evenly cover the surface of the pyrolysis core particles, and obtain waste Salt balls, wherein the mass ratio of pyrolysis core particles to polyvinyl acetate and activated carbon is 1:0.8:3.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com