Pyrolysis device for processing desulfurization waste liquid in partial oxidation environment

A technology for desulfurizing waste liquid and oxidizing environment, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. problems, to achieve the effect of realizing resource recycling, flexible operation, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

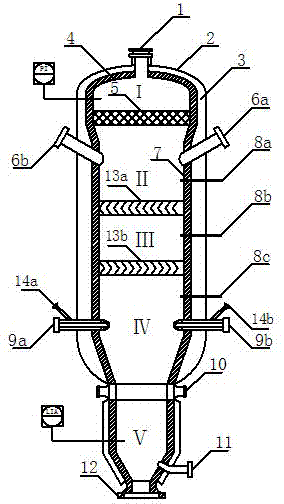

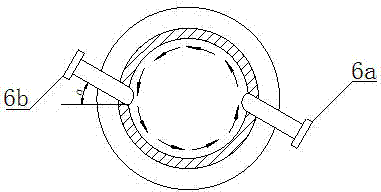

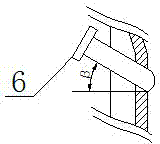

[0085] The sodium-containing desulfurization waste liquid (hereinafter referred to as waste liquid, the same below) is concentrated by 30% after heat exchange with the pyrolysis gas from the pyrolysis gas outlet 1, atomized by atomizing nozzles 6a and 6b, and enters downward along the tangent line of the inner wall In the atomization pyrolysis stage II, at about 600°C, the waste liquid is further evaporated and concentrated, and the aromatic compounds and other non-salt organic compounds in the waste liquid are decomposed. The decomposed gas, water vapor and pyrolysis gas from the lower section pass upward through the demister 5 and enter the gas separation section I, and are discharged after the temperature drops to about 350°C. By detecting the temperature of the temperature detection hole 8a, the flow rate of the waste liquid is adjusted to ensure that the temperature of the atomization pyrolysis section II is stable at about 600°C.

[0086] The waste liquid is concentrated...

Embodiment 2

[0099] The device and operation mode are the same as in Example 1, except that the air coefficient is 0.6, and the concentration of waste liquid is 50%. At this time, the temperature of the atomization pyrolysis section II is about 550°C, and the temperature of the mixed flow pyrolysis section III is 850°C. ℃, the temperature of inactive salt pyrolysis section IV is about 1100 ℃, the condensate produced by the concentration of waste liquid, and the condensate obtained from the gas-liquid separation of pyrolysis gas pass through the chiller 10 together, but are not sprayed into the pyrolysis salt quenching section V. Cool the pyrolysis salt together with the cooling medium in the jacket 3 to form solid particles, which can be used as a solid alkali source for gas desulfurization after being discharged through the solid outlet.

[0100] The pyrolysis gas and pyrolysis salt produced by the above two embodiments have the same composition, and the pyrolysis gas is mainly H 2 S, N ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractory | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com