Device and method for catalyst-regenerable high-temperature catalytic pyrolysis of domestic garbage and hydrogen filtering

A technology for domestic waste and high-temperature catalysis, which is used in special forms of dry distillation, petroleum industry, coke ovens, etc. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

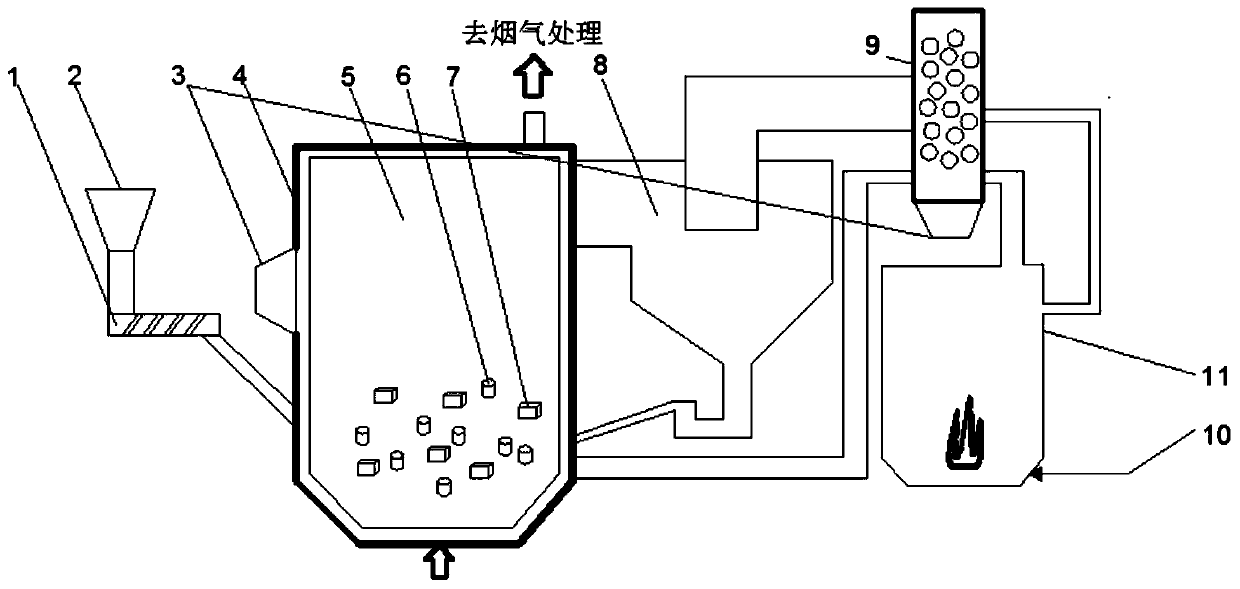

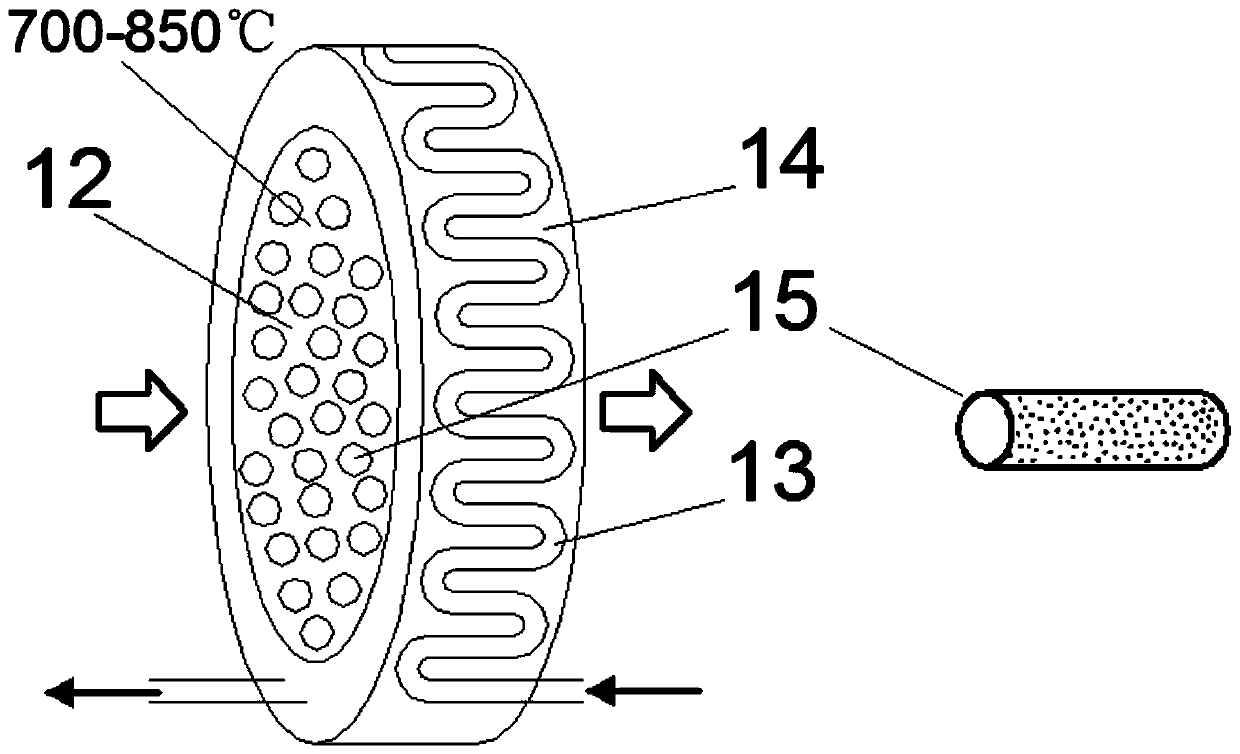

[0035] like figure 1 As shown, a device for producing hydrogen by high-temperature catalytic pyrolysis of household garbage with regenerable catalysts, including a fluidized bed pyrolysis furnace 5, a microwave generator 3, a regenerable catalyst bed 9, a combustion furnace 11 and a cyclone separator 8 The gas inlet is arranged at the bottom of the fluidized bed pyrolysis furnace 5, and the bed material 7 is arranged inside, and the microwave generator 3 is arranged on the side wall of the fluidized bed pyrolysis furnace 5 and the bottom or the side wall of the catalyst bed 9 where the catalyst can be regenerated, and the cyclone The inlet of the separator 8 is connected to the pyrolysis gas outlet of the fluidized bed pyrolysis furnace 5, the bottom of the cyclone separator 5 is connected to the lower part of the fluidized bed pyrolysis furnace 5, and the gas outlet of the cyclone separator 5 is connected to the catalyst regenerable The catalyst bed 9, the gas outlet of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com