Patents

Literature

32results about How to "Effective control of reaction temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

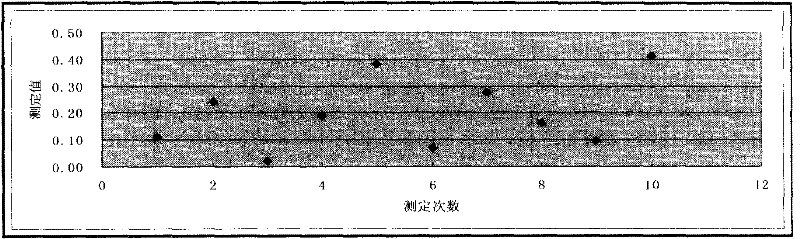

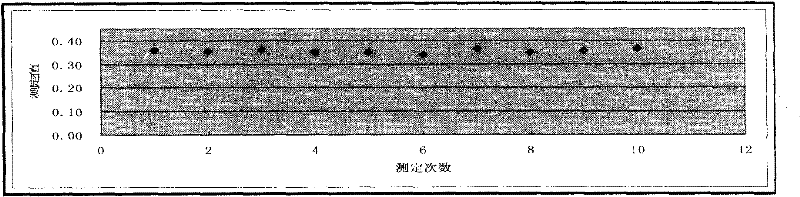

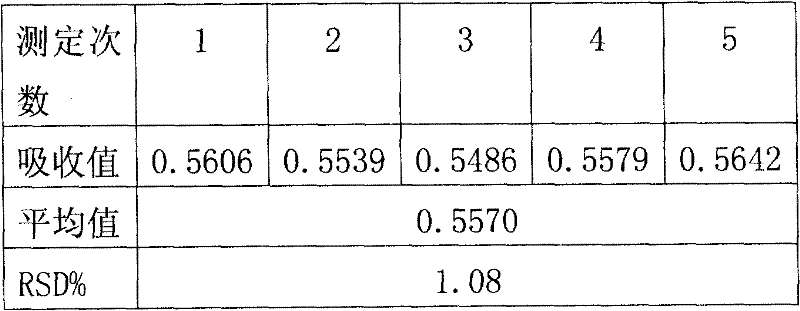

Method for measuring content of phospholipid in liposome

InactiveCN101692038AChromogenic reaction, stable colorImprove the display effectPreparing sample for investigationColor/spectral properties measurementsWater bathsPhospholipid

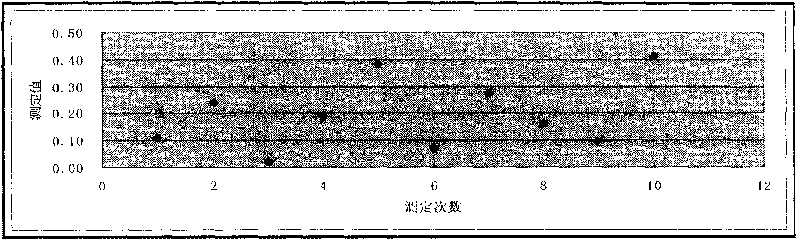

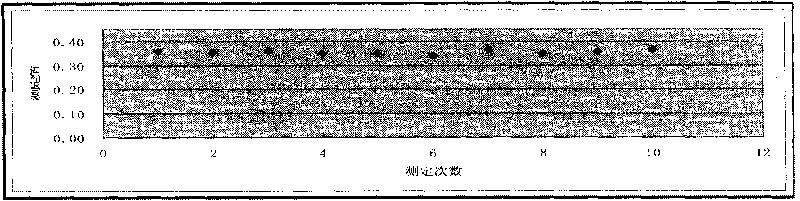

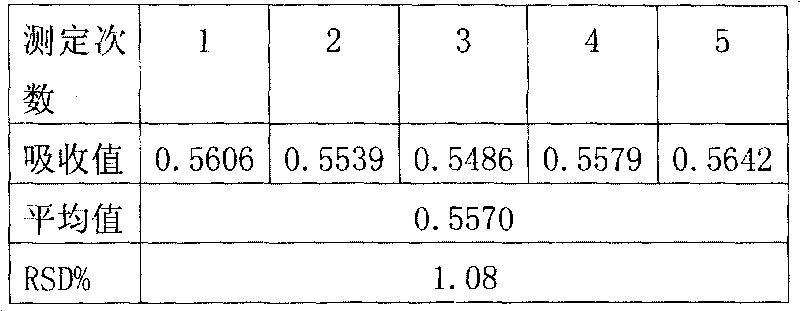

The invention discloses a method for measuring the content of phospholipid in liposome, which comprises the following steps: preparing a color development reagent A and a color development reagent B; preparing standard storage liquid; preparing a sample solution; drawing a standard curve; measuring the content of a sample: accurately sucking 0.5ml of the prepared liposome sample solution into 15*200mm test tubes, and sequentially adding 0.4ml of sulfuric acid with the concentration of 10N and 0.1ml of 30% hydrogen peroxide solution; heating for 60 minutes at a constant temperature of 170 DEG C; after cooling, adding 9ml of distilled water into each test tube, uniformly mixing and sucking 1.5ml of mixed solution into another test tube, then respectively adding 4.6ml of solution of the color development reagent A and 0.1ml of solution of the color development reagent B, and heating for 15 minutes in a water bath at 100 DEG C; after cooling, carrying out color comparison at the point with the wavelength of 822nm to measure the absorbance; and substituting the obtained absorbance value of the sample into a regression curve equation to calculate the content of phosphorus in the sample. The invention has simple and convenient method and easy operation, greatly improves the accuracy of the measuring result, and also improves the precision of the measuring result.

Owner:NORTH CHINA PHARMA COMPANY

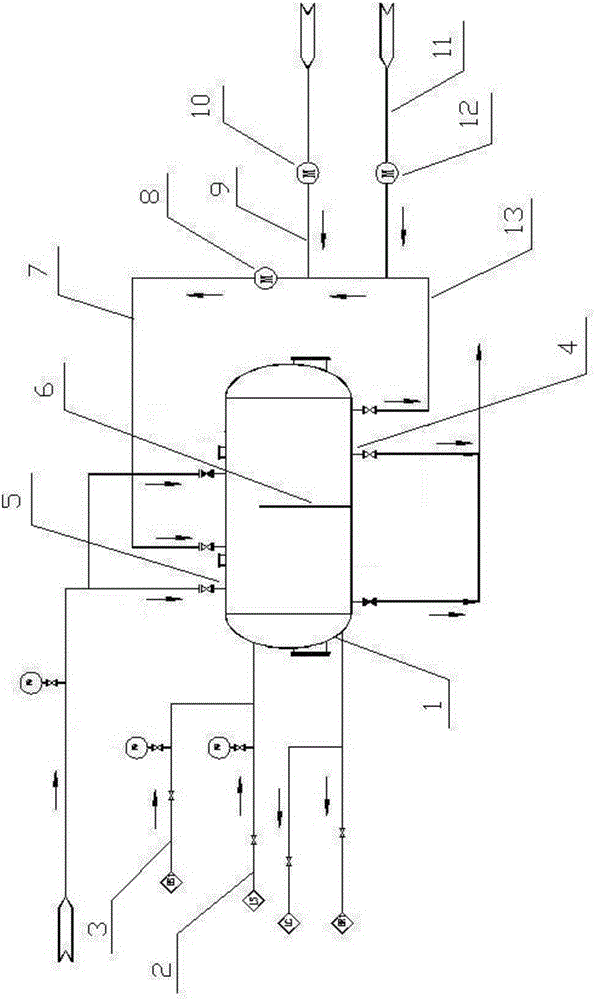

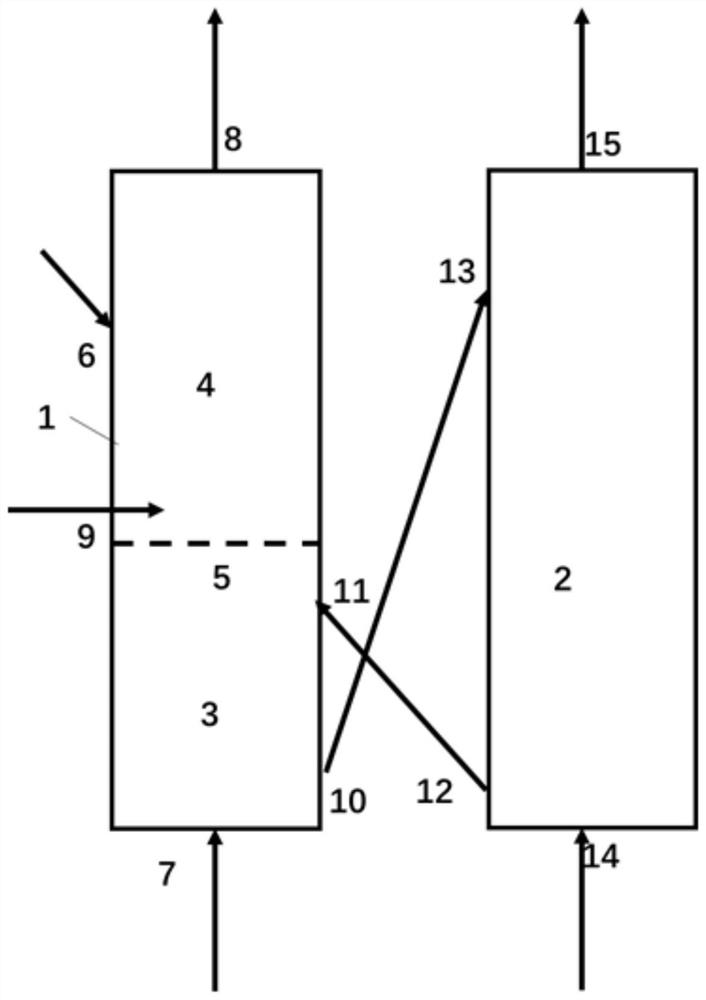

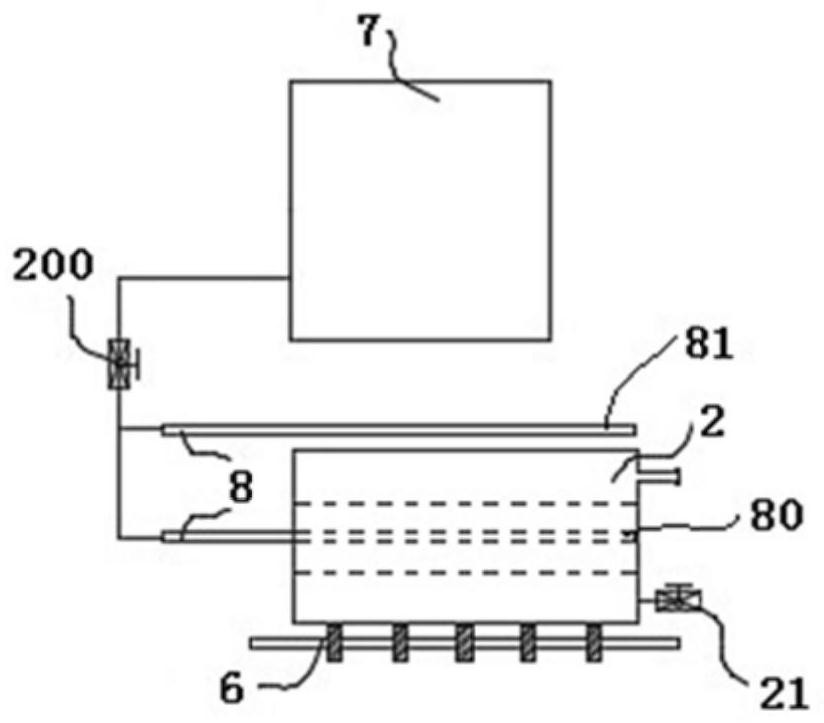

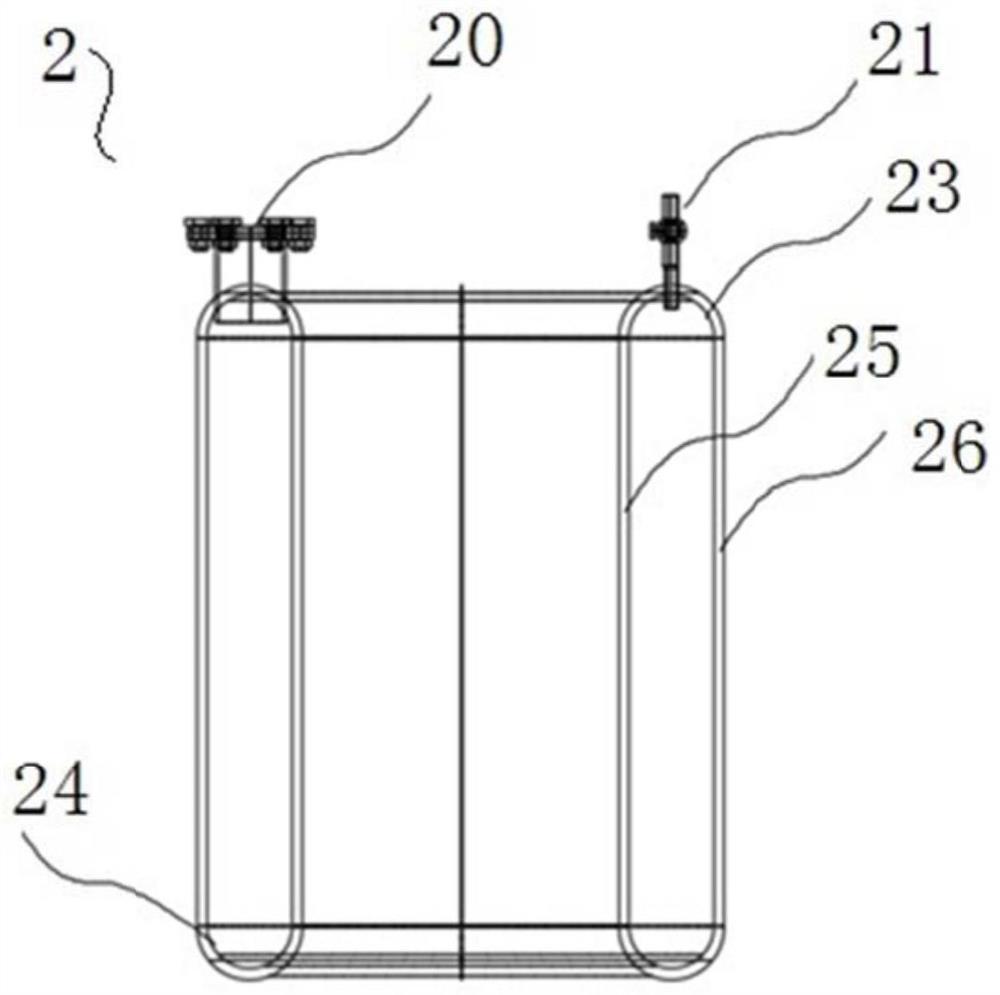

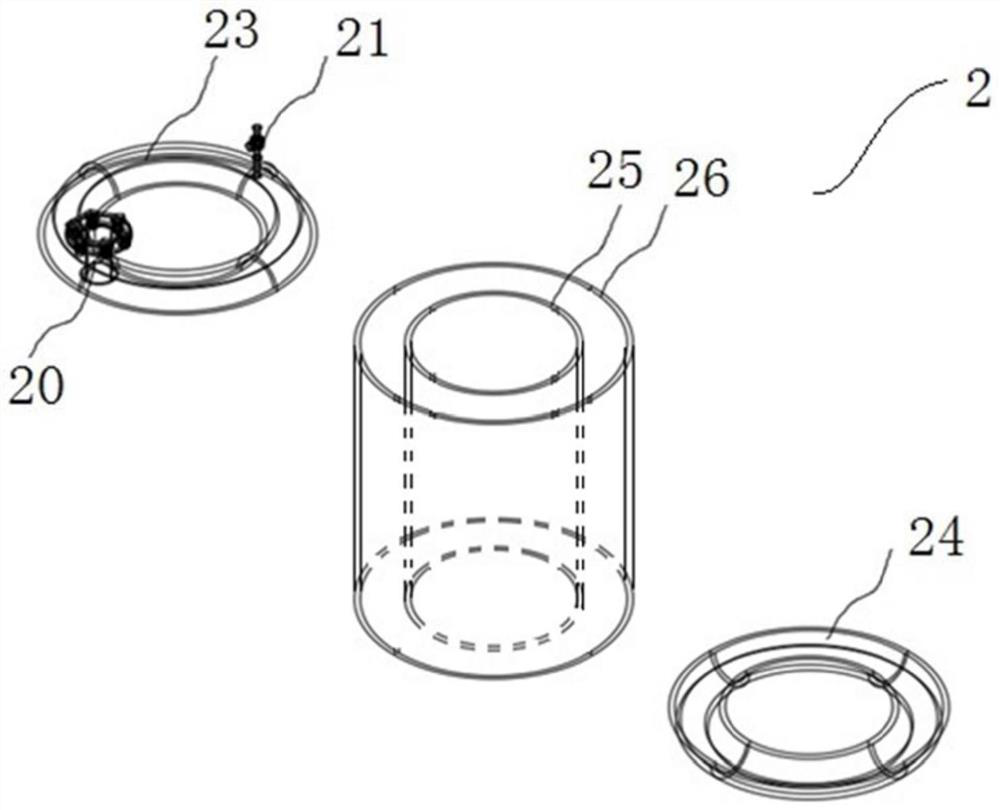

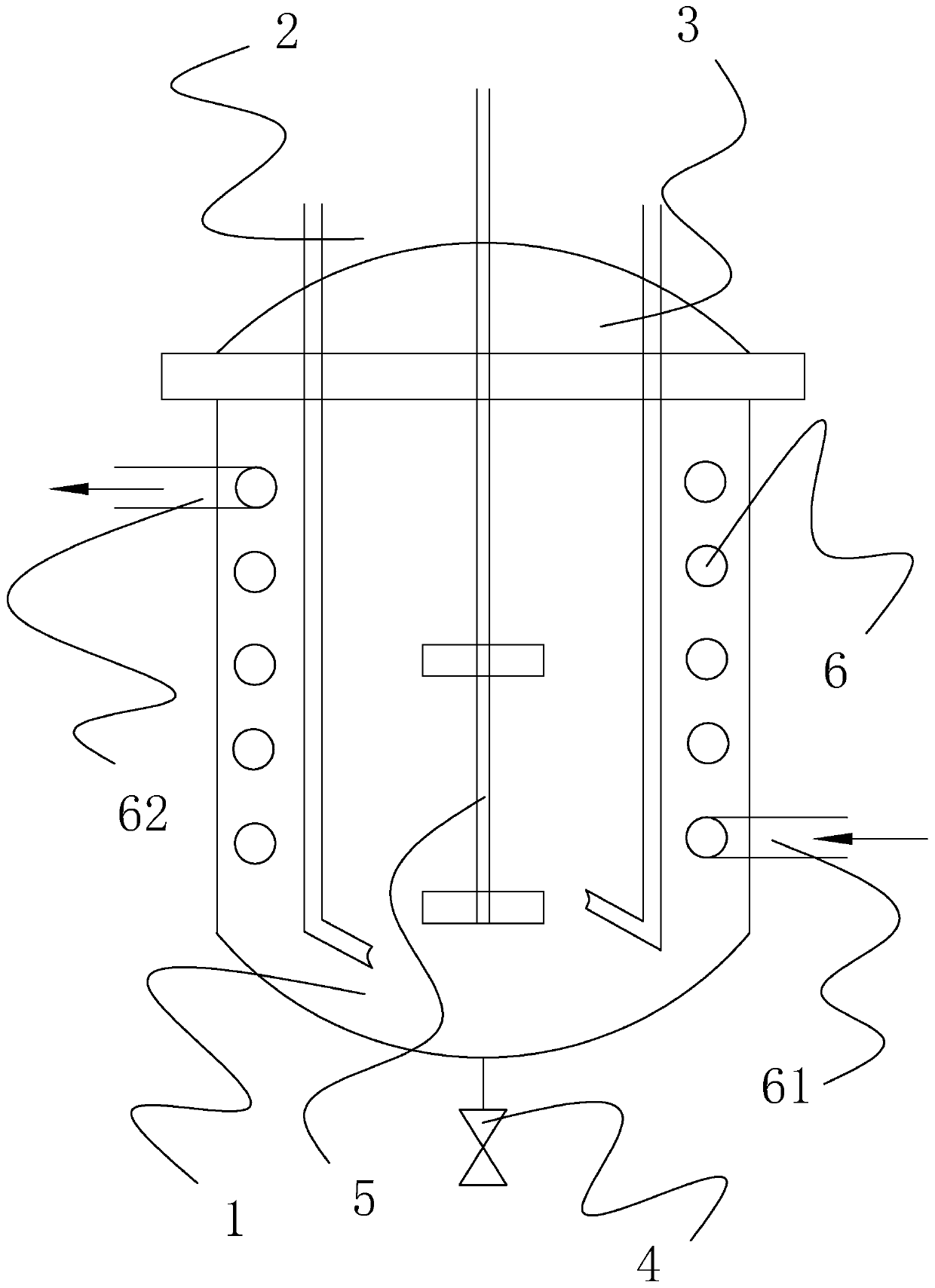

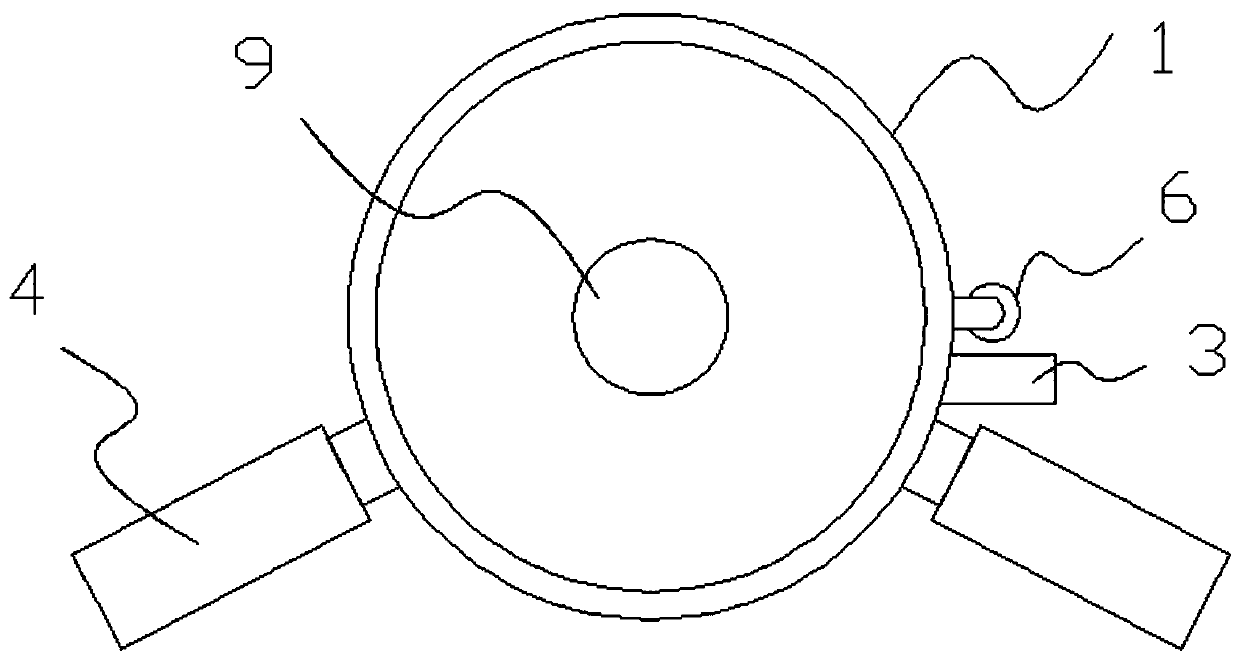

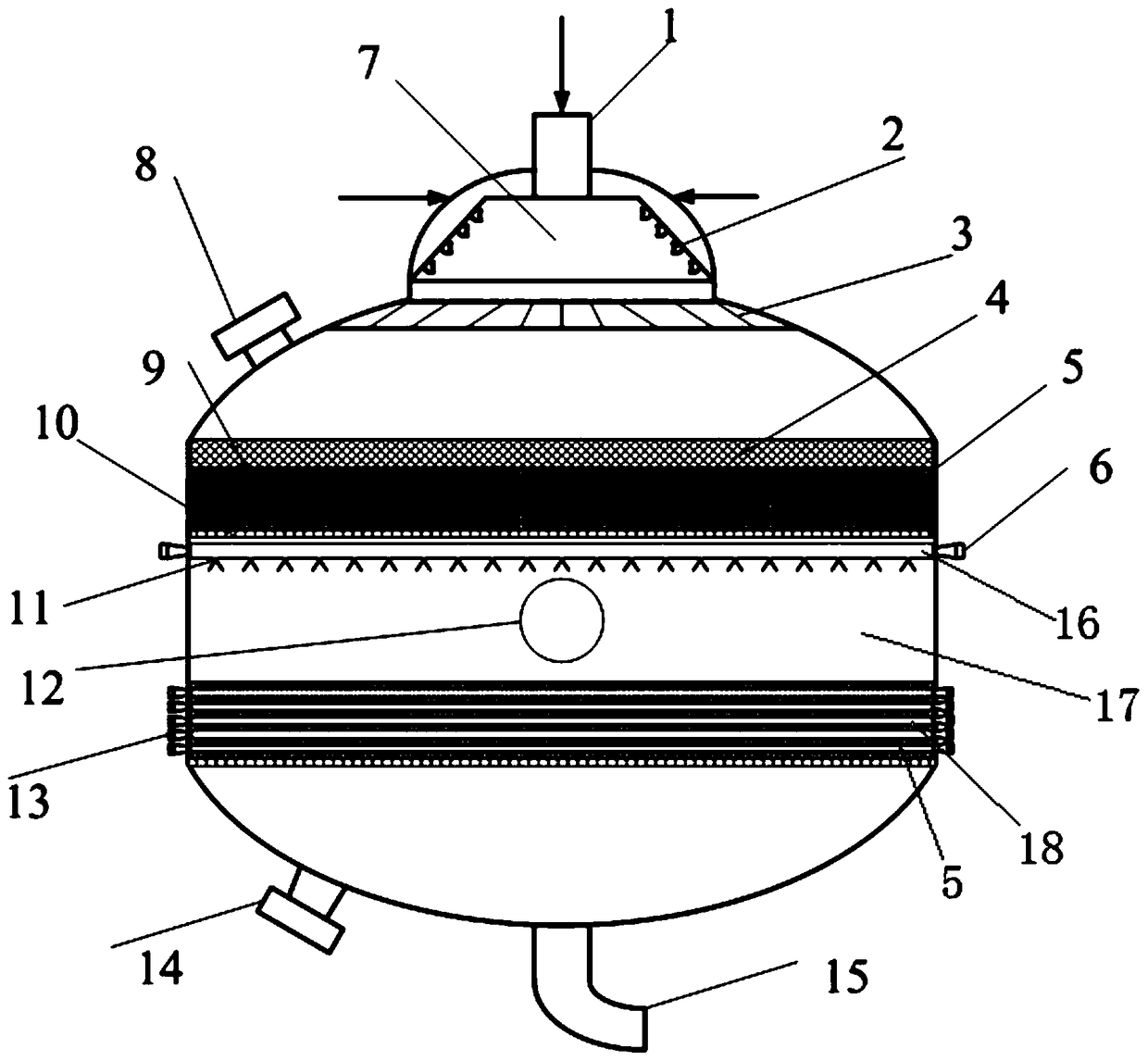

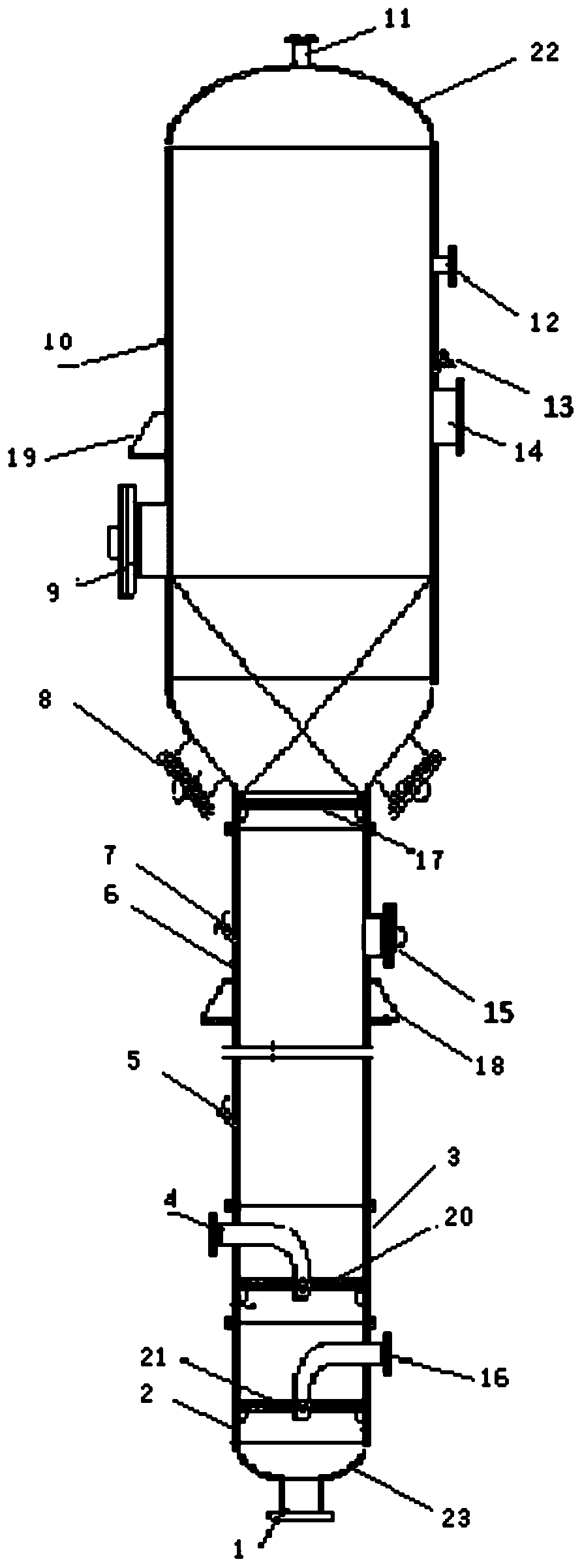

Acetonitrile production reactor and preparing method thereof

ActiveCN106362671AEffective control of reaction temperatureWell mixedProcess control/regulationChemical/physical/physico-chemical reactor detailsLine tubingEngineering

The invention discloses an acetonitrile production reactor and a preparing method thereof. The acetonitrile production reactor comprises a reaction kettle provided with a clamping sleeve. A vertically-arranged partition plate is arranged in the reaction kettle, and the reaction kettle is divided by the partition plate into a left cavity and a right cavity, wherein the upper portion of the left cavity and the upper portion of the right cavity are communicated; feeding inlets are formed in the tops of the cavities, and discharging openings are formed in the bottoms of the cavities; a material mixing pipe for being communicated with the two cavities is arranged on the reaction kettle, feeding pipes for feeding a sodium hydroxide solution and a formaldehyde solution are connected on the material mixing pipe, and a control mechanism for the feeding pipe is arranged on the reaction kettle. According to the acetonitrile production reactor and the preparing method thereof, the two cavities are formed in the reaction kettle, cross flowing of materials in the two cavities is achieved through the material mixing pipe, and all the materials are more fully and evenly mixed; as the sodium-hydroxide-solution feeding pipe and the formaldehyde-solution feeding pipe are additionally arranged on the material mixing pipe, pipe plugging can be conveniently treated.

Owner:JIANGSU SAILBOAT PETROCHEMICAL CO LTD

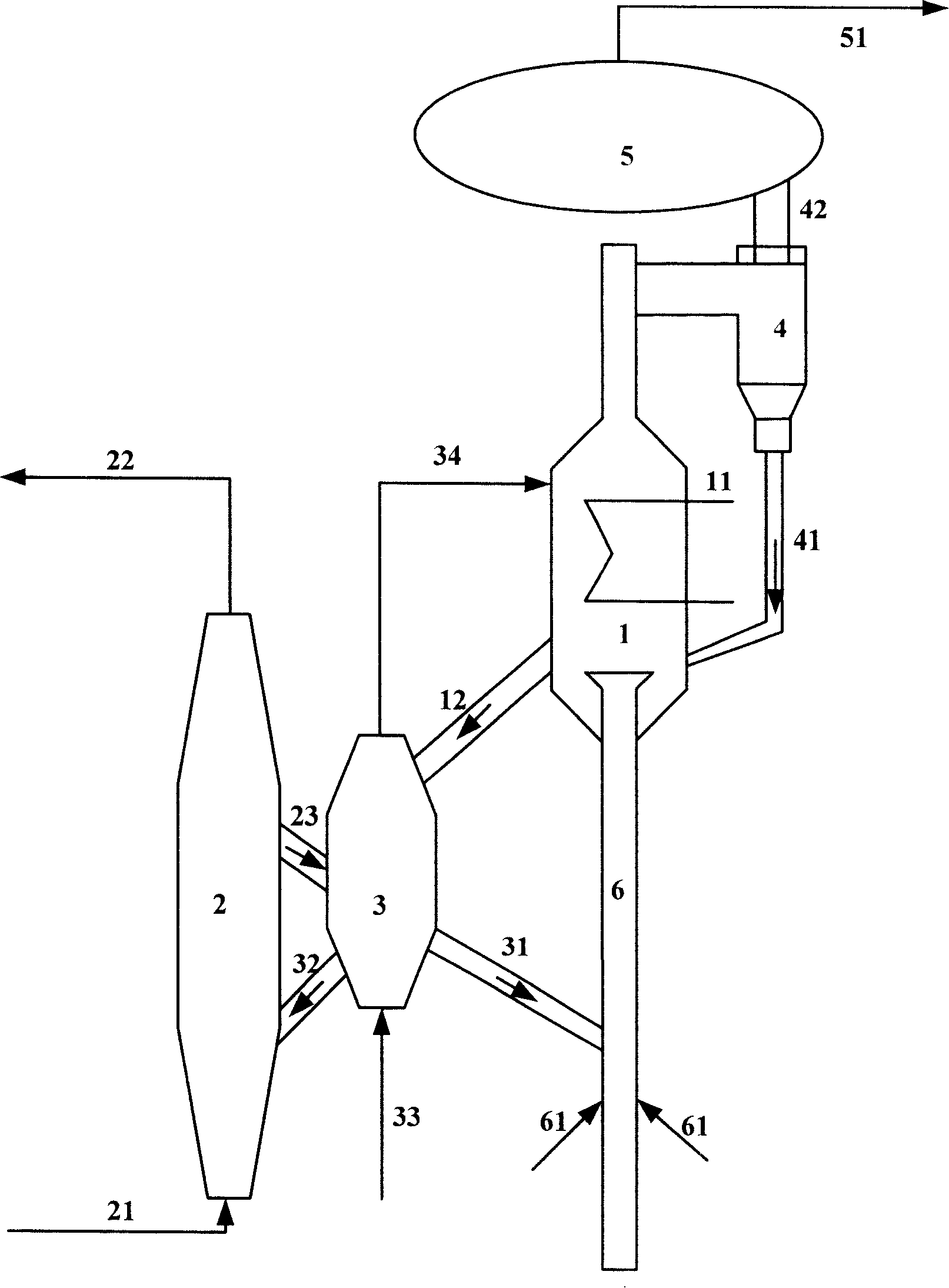

Method for producing dimethyl ether from methanol

InactiveCN101152999AContinuous conversionEffective control of reaction temperatureEther/acetal/ketal group formation/introductionChemical recyclingReaction temperatureCarbon deposit

The present invention provides a production method of dimethyl ether from methanol. The methanol material and catalyst containing Y-series zeolite contact and react in a reactor where the catalyst can be fluidized; the reaction materials are separated to get carbon deposit catalyst and target product dimethyl ether; part of or all of the carbon deposit catalyst enter a regenerator to be burnt and regenerated. The regenerated catalyst returns into the reactor to contact the methanol material. The method can effectively control the reaction temperature of bed layers, ensures the continuous transformation of methanol into dimethyl ether; the conversion rate of methanol is generally more than 80 per cent; the selectivity of dimethyl ether is more than 98 percent.

Owner:CHINA PETROLEUM & CHEM CORP +1

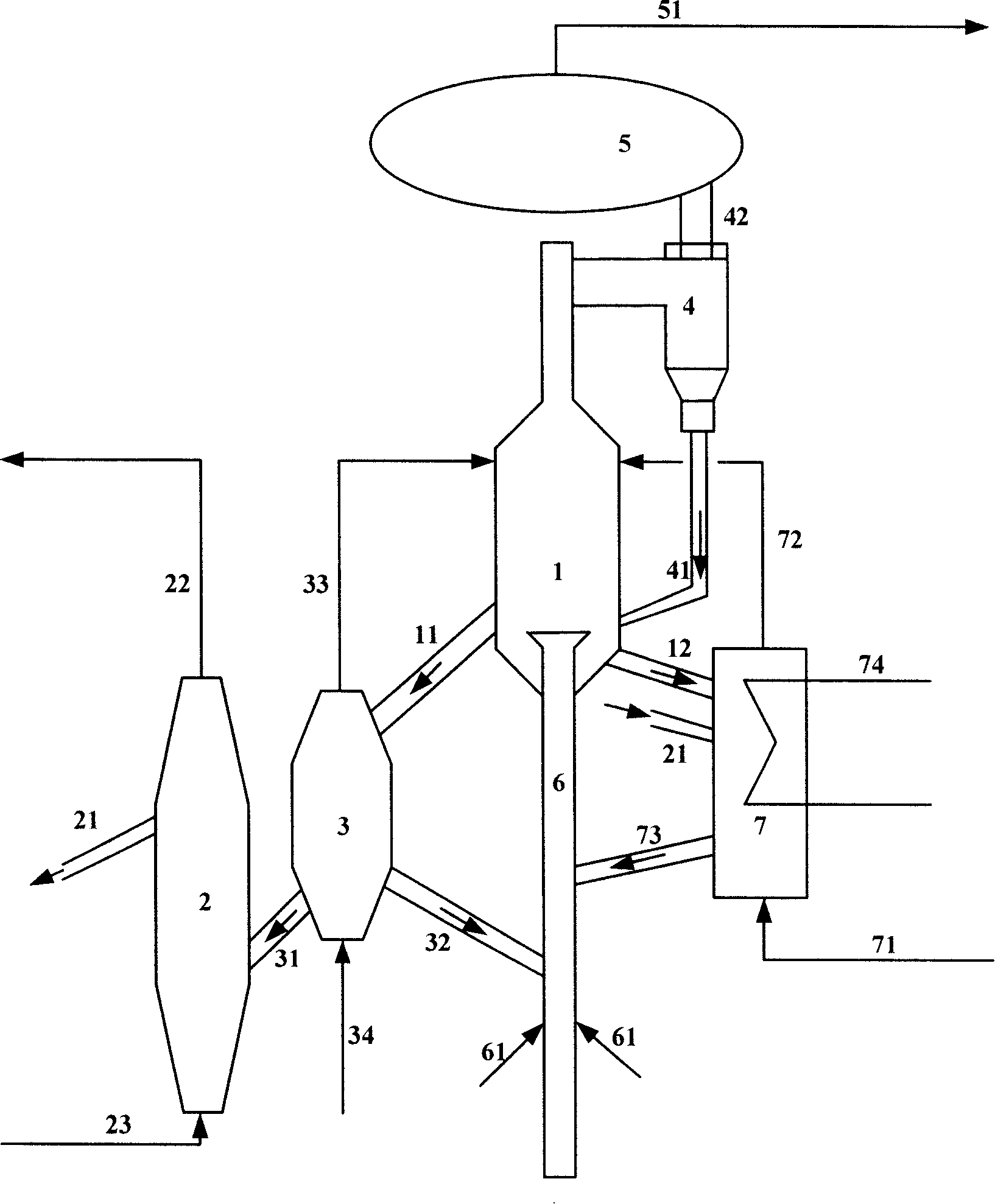

Method for producing dimethyl ether by fluidized catalytic gas-phase dehydration of methanol

ActiveCN101205172AContinuous conversionEffective control of reaction temperatureMolecular sieve catalystsChemical recyclingTime rangeGas phase

The invention relates to a method for producing a dimethyl ether by applying the fluidization, catalysis and gas phase dehydration to a methanol. The methanol serving as the raw materials contacts with the catalysts in which the Y series is contained in a reactor provided with a riser and a fluidized bed and the reaction between the methanol and the catalysts is carried out on the conditions that the temperature ranges from 150 to 350 DEG C, the weight ratio of the catalysts to the methanol raw materials ranges from 0.001 to 50, the reaction time ranges from 0.1 to 20 seconds and the pressure ranges from 1 to 1000kPa; the bed temperature of the fluidized bed reactor is controlled to be below 350 DEG C and the reactants are separated so as to obtain the coked catalysts and the target products, dimethyl ether; the coked catalysts separated out from a cyclone separator are circulated back to the fluidized bed and part or all of the coked catalysts in the fluidized bed are enter a generator to be subject to the coke burning regeneration with or without being stripped; the regenerated catalysts go back into the reactor so as to contact with the methanol raw materials. The method effectively controls the bed reaction temperature and ensures that the methanol is continuously converted into the dimethyl ether, the conversion rate of the methanol is usually higher than 80 per cent and the selectivity of the dimethyl ether is more than 98 per cent.

Owner:CHINA PETROLEUM & CHEM CORP +1

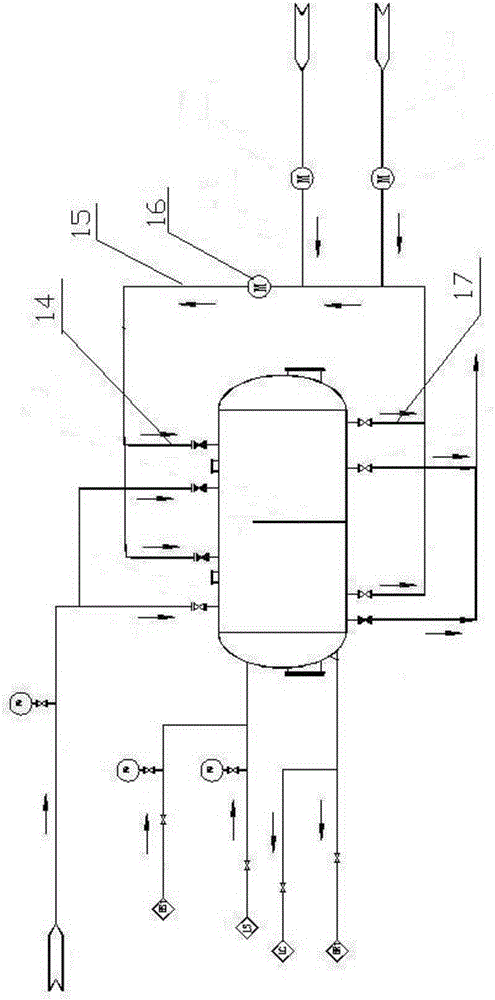

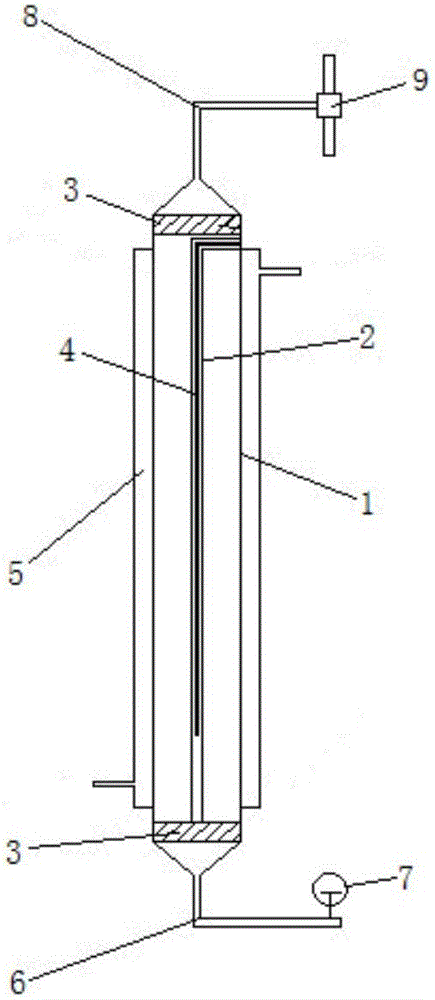

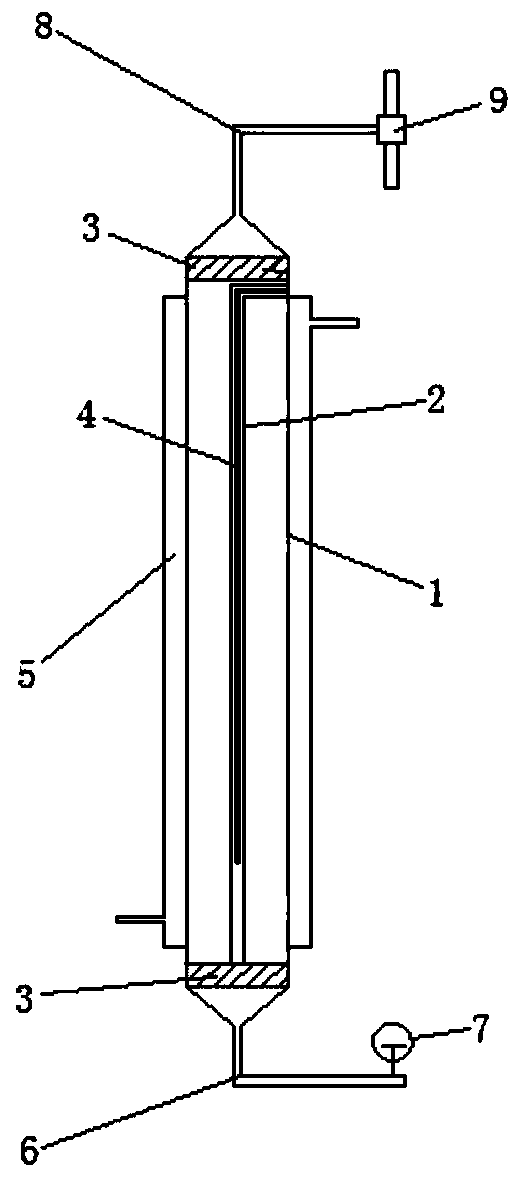

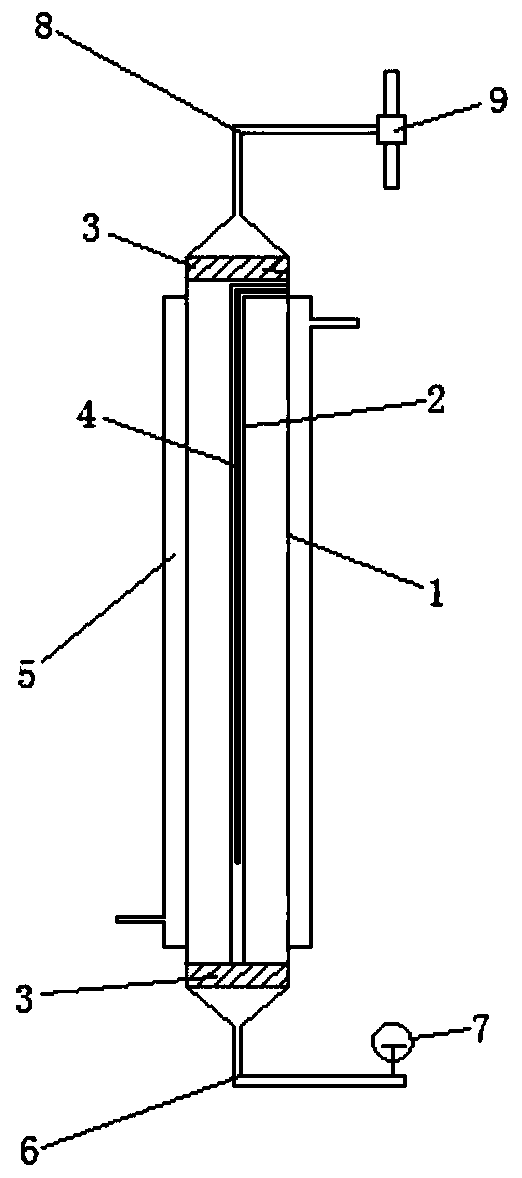

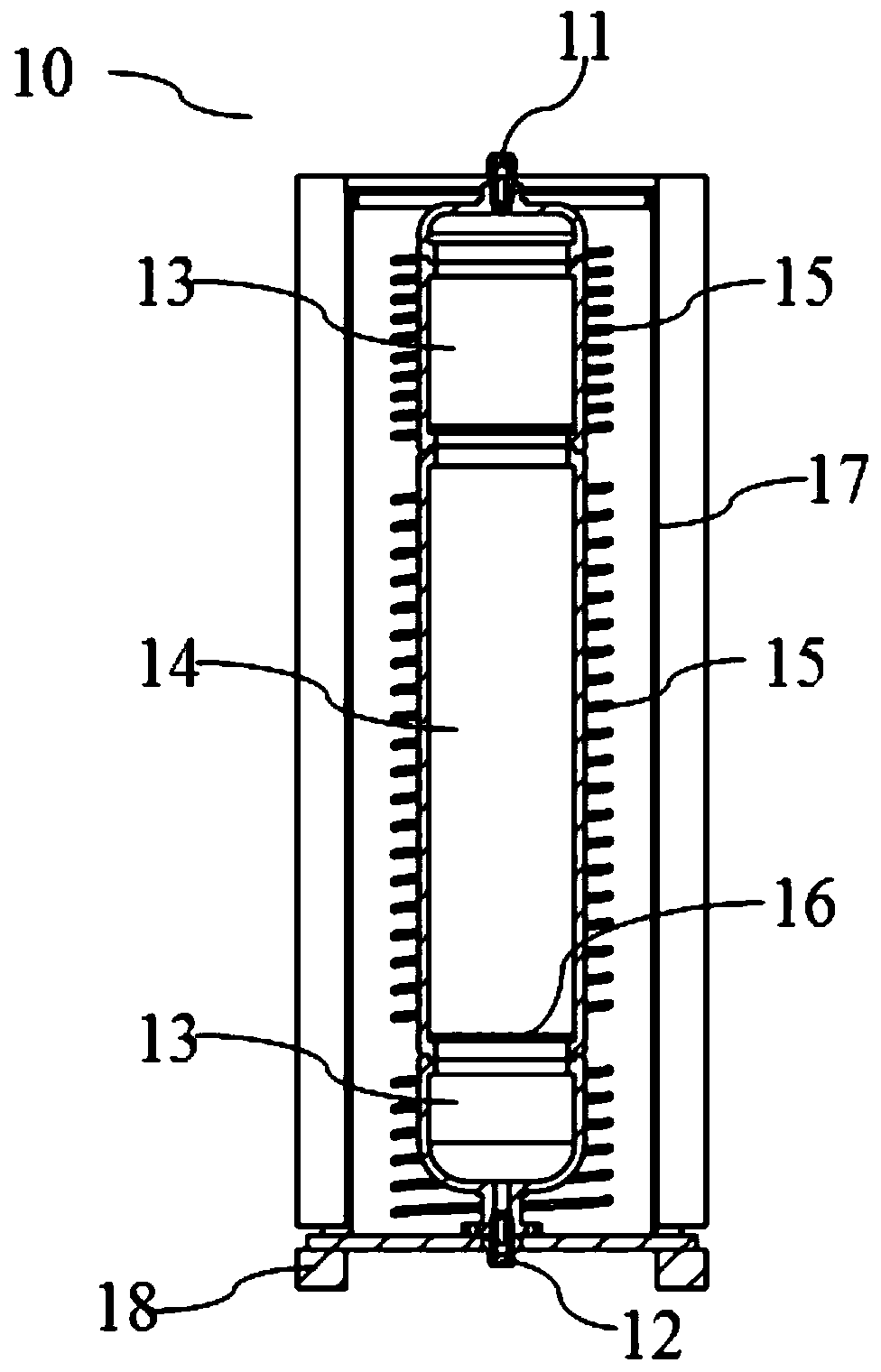

Catalytic device for preparing U(IV) solution

ActiveCN106311092AFully contactedLarge adjustment flexibilityChemical/physical processesMaterials scienceReaction conditions

The invention discloses a catalytic device for preparing a U(IV) solution. The device comprises an outer pipe, an inner pipe, a jacket, sintered stainless steel plates, a feeding hole and a discharging hole, wherein an annular structure is formed by the inner pipe in the outer pipe; the sintered stainless steel plates are arranged at the upper and lower ends of the outer pipe; the jacket is arranged on the exterior of the outer pipe; the feeding hole is formed in the bottom of the sintered stainless steel plate at the lower end; the discharging hole is formed in the top of the sintered stainless steel plate at the upper end. The catalytic device for preparing the U(IV) solution provided by the invention has the advantages of simple structure, mild catalytic reaction condition, easily controlled process, safety, reliability, easiness in continuous production and capability of continuously running in long period.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

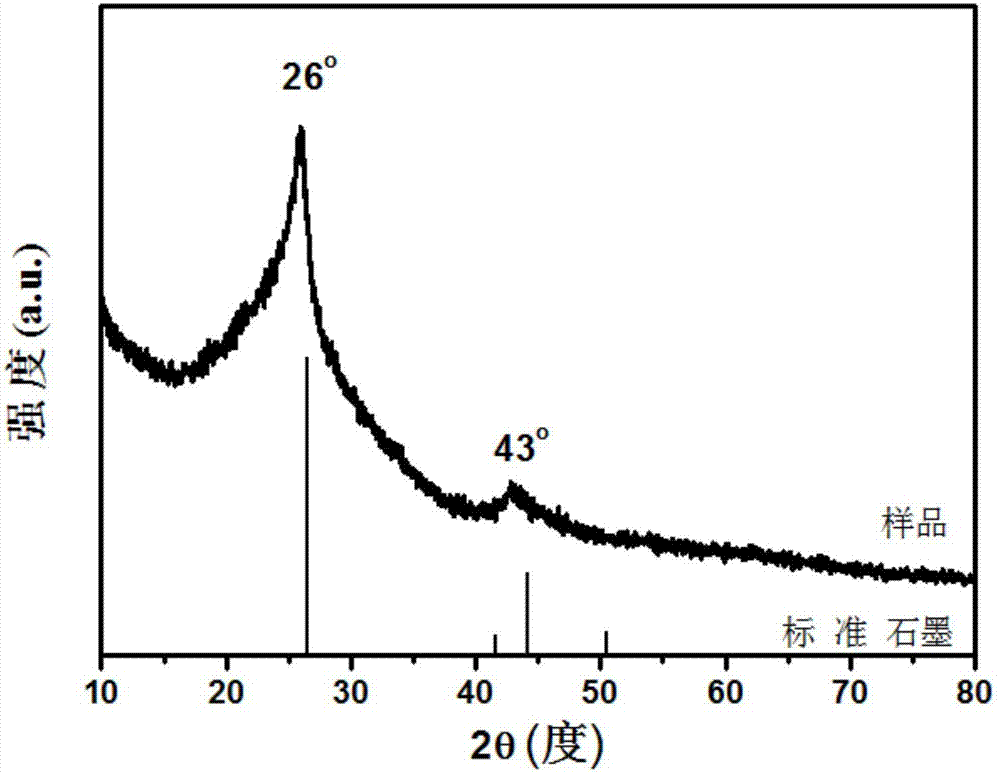

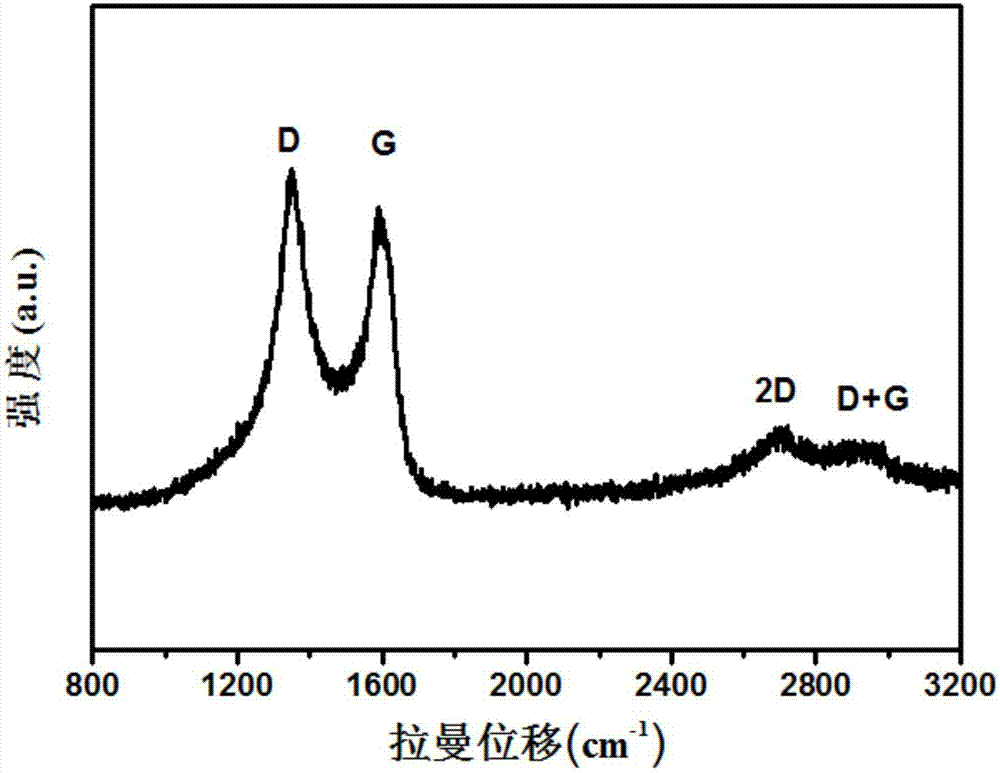

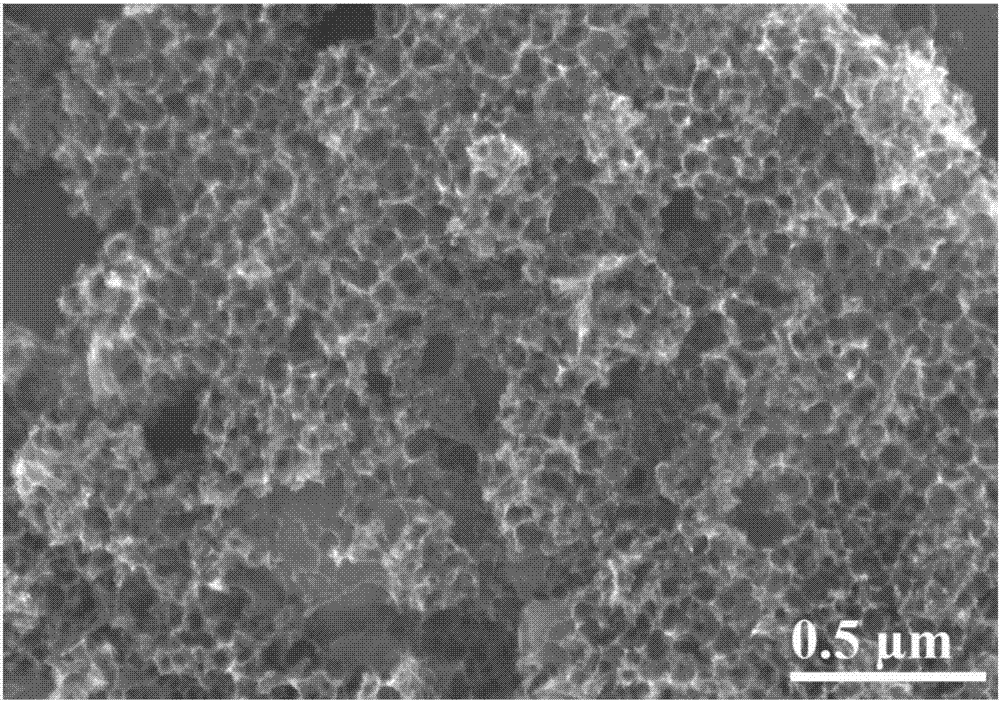

Method for preparing nitrogen-doped porous carbon nanomaterial by using carbon dioxide

ActiveCN107416819AWide range of choicesIncrease industrial outputCell electrodesGrapheneCombustionPorous carbon

The invention relates to a method for preparing a nitrogen-doped porous carbon nanomaterial by using carbon dioxide and belongs to the technical field of novel materials. The method comprises the steps of firstly carrying out chemical adsorption reaction on carbon dioxide and a flammable alkaline solution; adding magnesium powder for complexing reaction to obtain a combustion precursor; and lighting the combustion precursor, carrying out self-propagating combustion reaction and pickling a reaction product to obtain the nitrogen-doped porous carbon nanomaterial. The method is low in cost, energy is saved, the technological process and the property of the product are controllable, the reaction can be completed within a very short period of time, the prepared product has a good porous structure, specific surface area and electrochemical performance.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

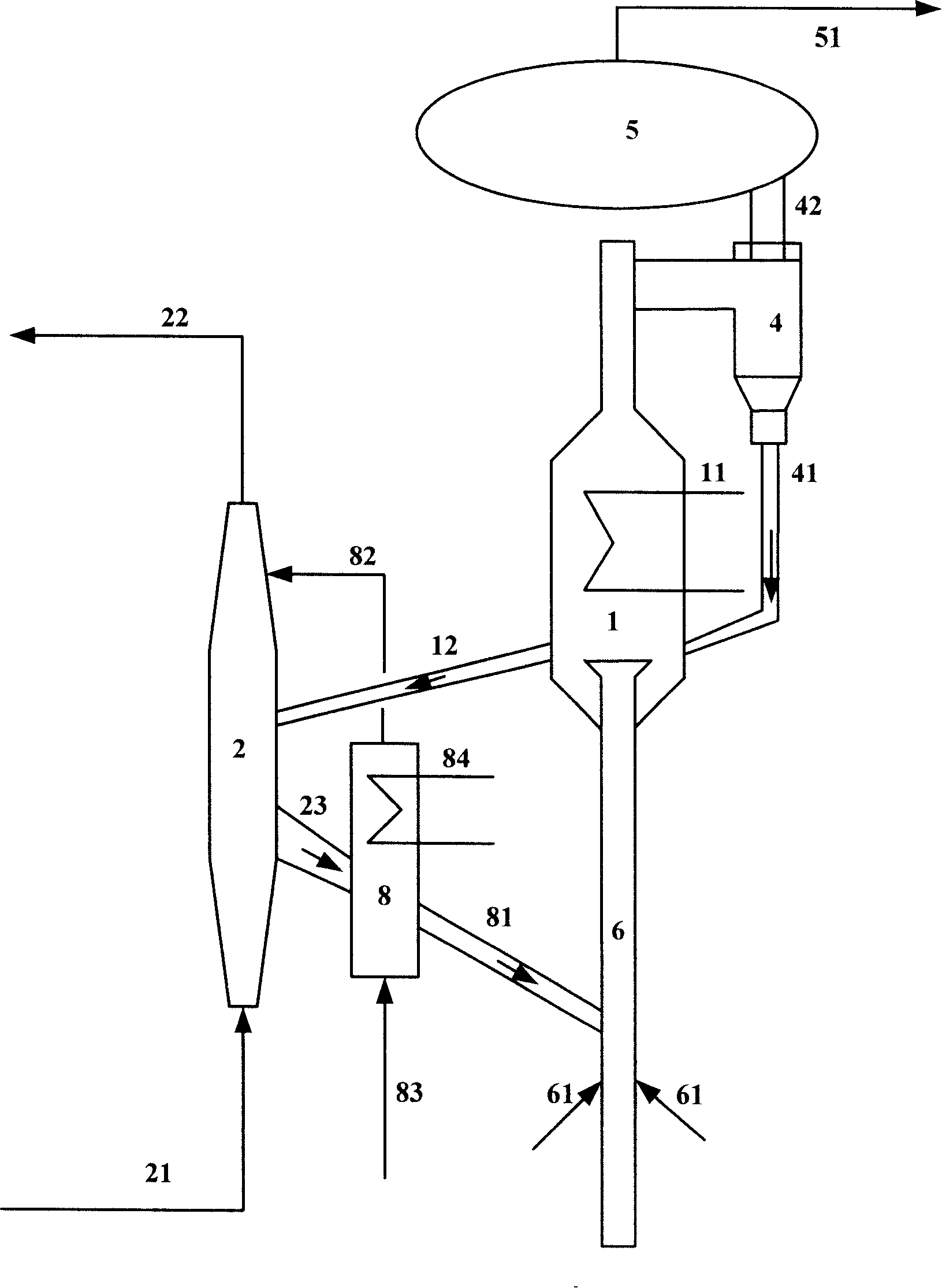

Fluidized bed continuous reaction regeneration system and method for converting C3-C9 alkane into aromatic hydrocarbon

ActiveCN114130313ASimple structureLow manufacturing costCatalyst regeneration/reactivationHydrocarbonsBenzeneAlkene

The invention discloses a fluidized bed continuous reaction regeneration system and method based on C3-C9 alkane to aromatic hydrocarbon in the technical field of chemical process and equipment, and the system comprises a two-section fluidized bed for C3-C9 alkane to aromatic hydrocarbon (from bottom to top, the two-section fluidized bed has a first reaction zone and a second reaction zone for respectively controlling the temperature so as to complete the functions of high-temperature light hydrocarbon aromatization and medium-temperature olefin aromatization; meanwhile, a liquid aromatic hydrocarbon (benzene or / and toluene) feeding hole is formed in the lower part of the second reaction area, and the temperature of the second reaction area is controlled through liquid vaporization). The connection relationship between the two fluidized beds is that after the catalyst in the two fluidized beds is inactivated, the catalyst enters the catalyst regeneration fluidized bed from the first reaction zone, is regenerated and then returns to the first reaction zone of the two fluidized beds; the system and the method have the characteristics of high alkane conversion rate, high aromatic hydrocarbon yield and simple temperature control.

Owner:TSINGHUA UNIV

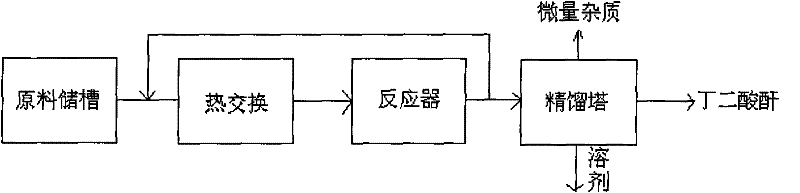

Process for continuously producing succinic anhydride through hydrogenation of maleic anhydride

ActiveCN101735182BHigh purityHigh yieldOrganic chemistryChemical/physical processesSolventSuccinic anhydride

The invention provides a process for continuously producing succinic anhydride through hydrogenation of maleic anhydride, which comprises the following steps of: shunting solution of maleic anhydride in a split ratio of 1 / 5-1 / 2 after hydrogenation is performed on the solution of maleic anhydride through a trickle bed reactor; rectifying partial shunted reaction liquid into a rectifying tower to obtain finished products succinic anhydride and a solvent, and recycling the solvent; mixing the other liquid with the solution of maleic anhydride; and returning to the reactor after eliminating heat through a heat exchanger. The process successfully solves the problem of exothermic effect in the process of preparing the succinic anhydride through the hydrogenation of the maleic anhydride, meanwhile realizes continuous production of the succinic anhydride, and greatly improves the production capacity of the succinic anhydride with above 97.5 percent of the yield of the succinic anhydride; the process has the advantages of simple flow, high utilization rate of devices and good quality of products; the solvent can be recycled, and the operation cost is low; and the process is suitable for clean production and has good environmental benefit.

Owner:SHANXI UNIV

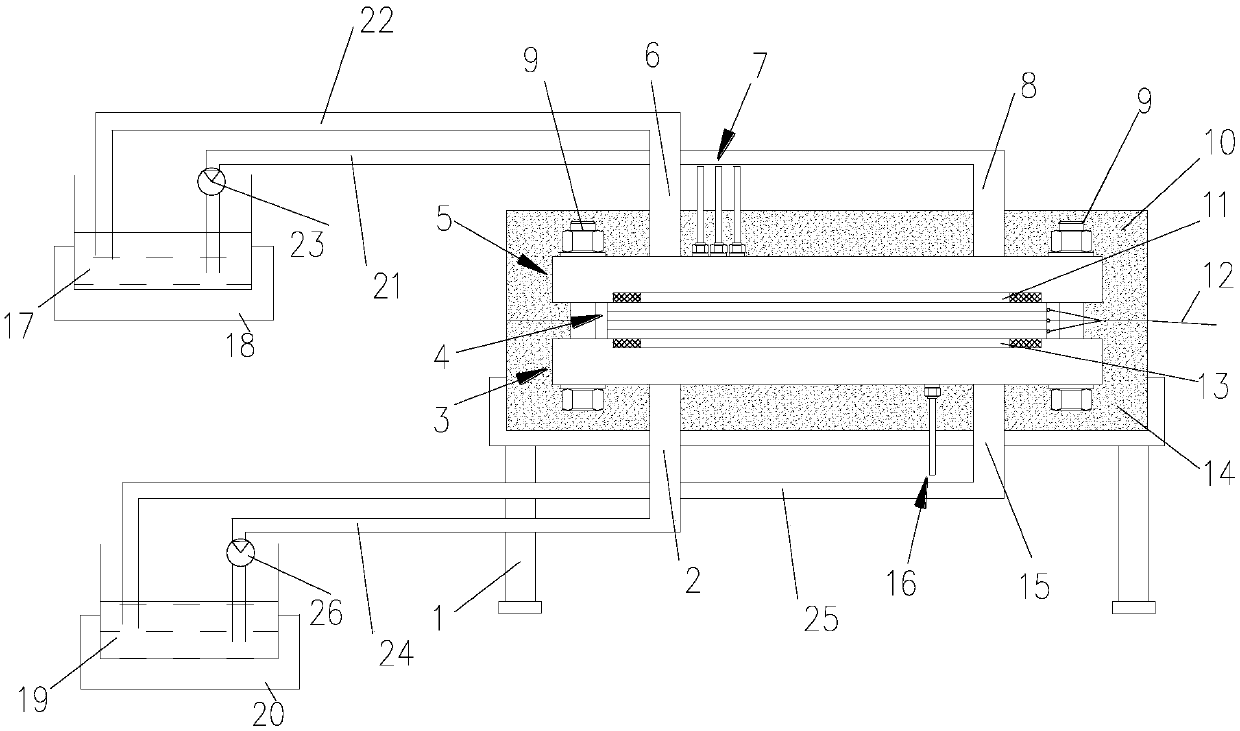

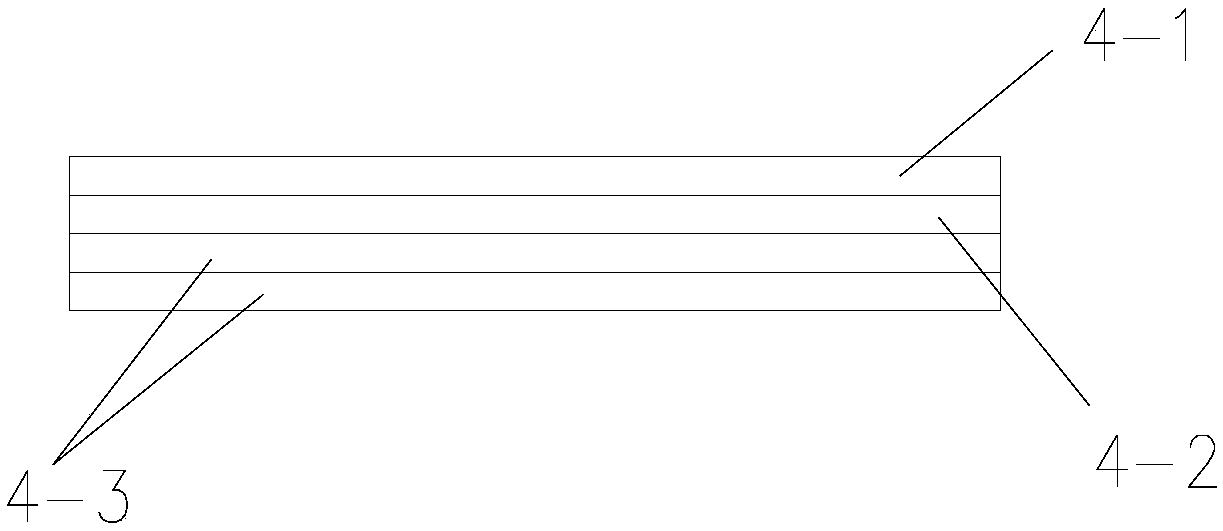

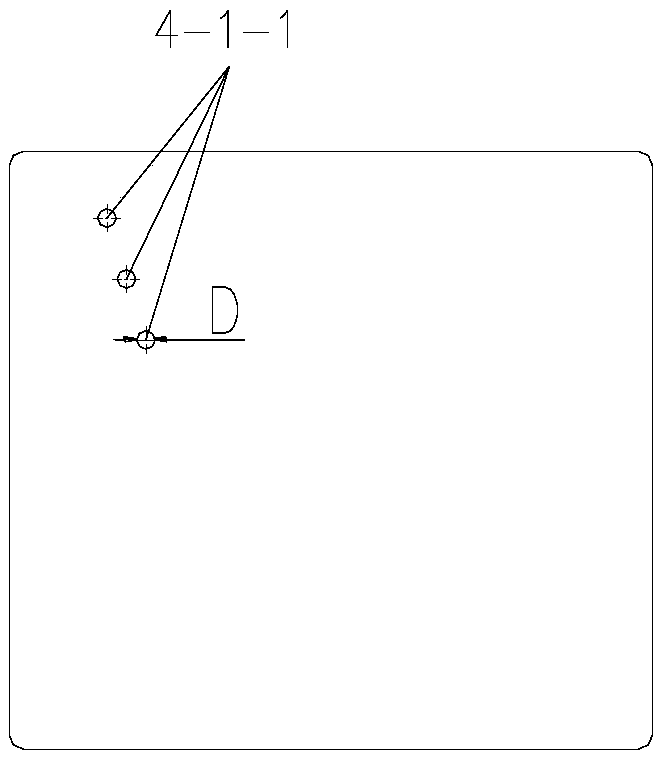

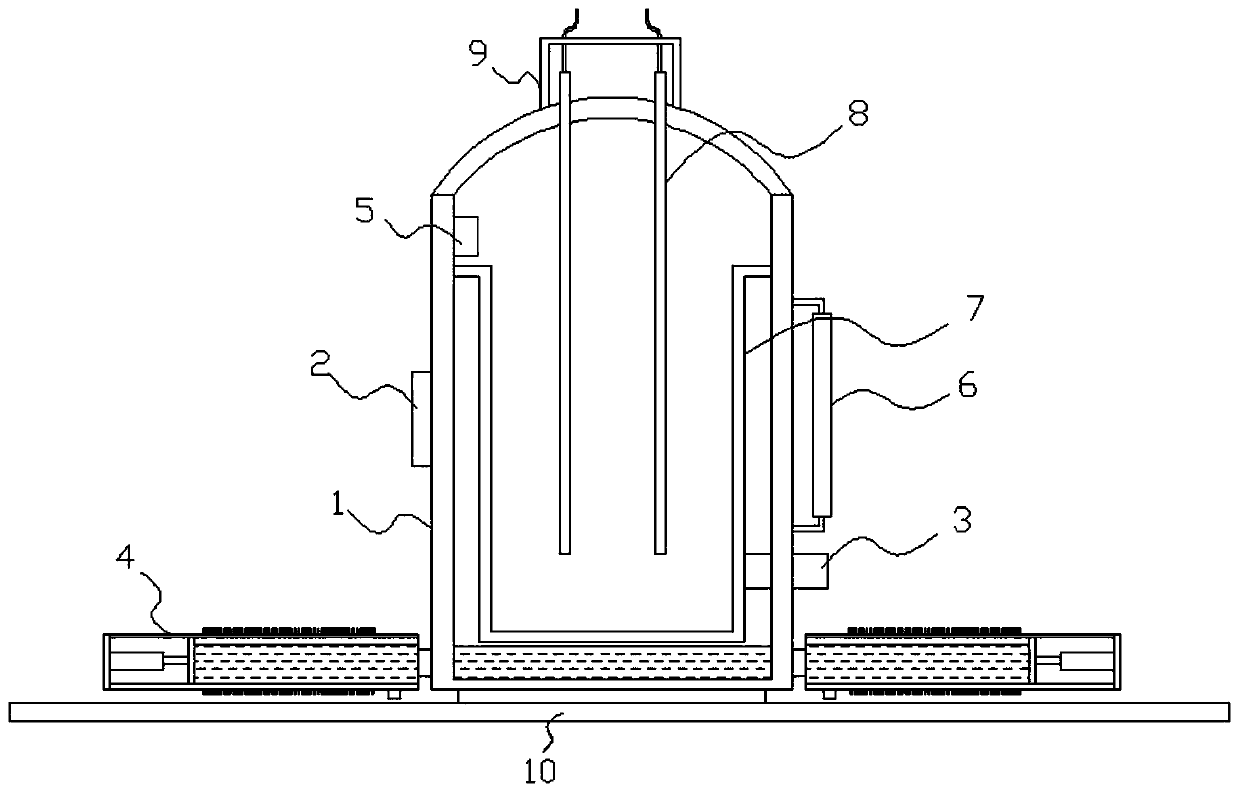

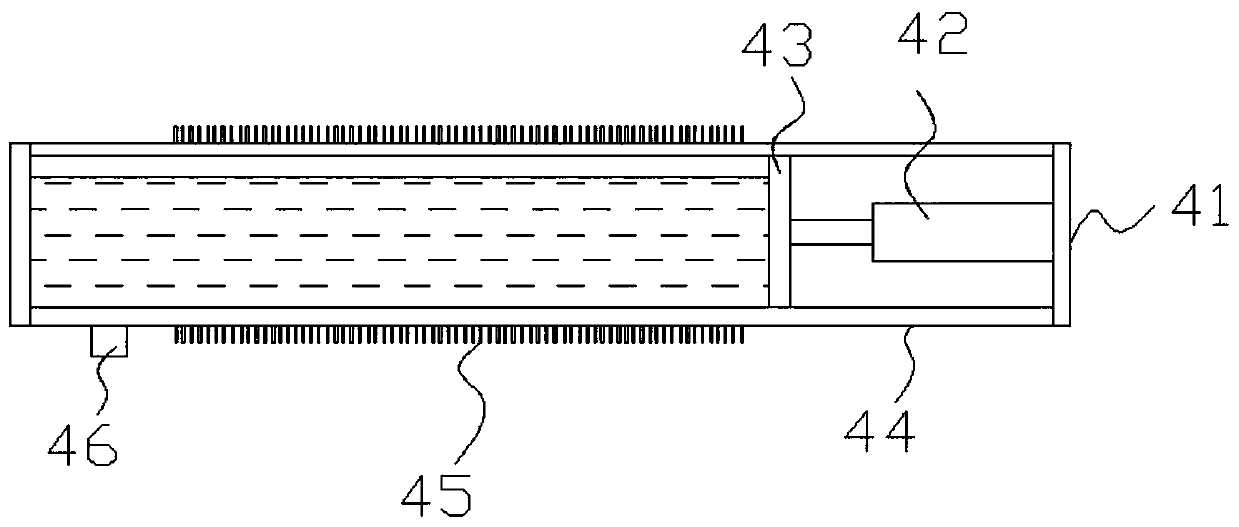

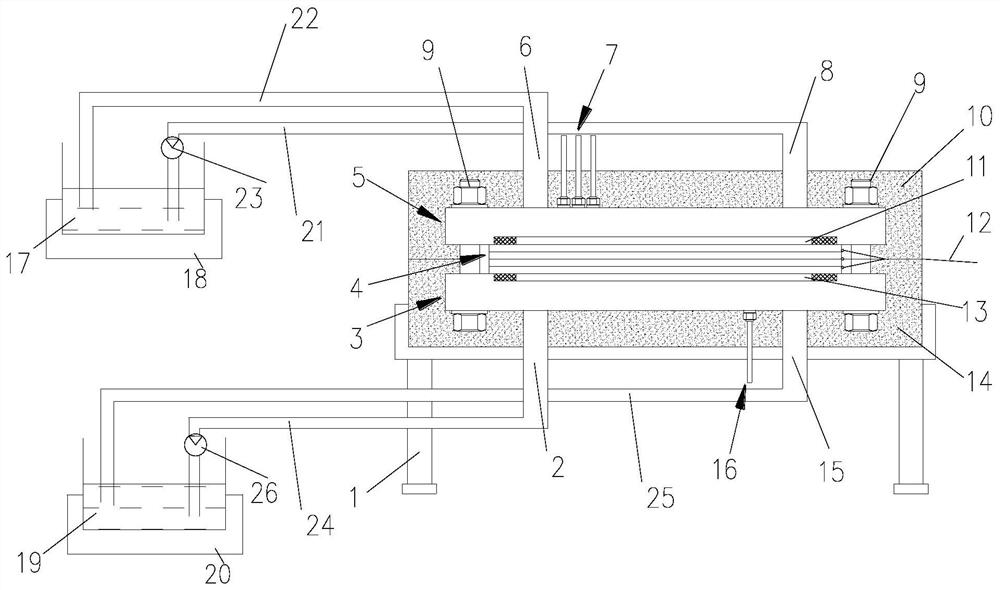

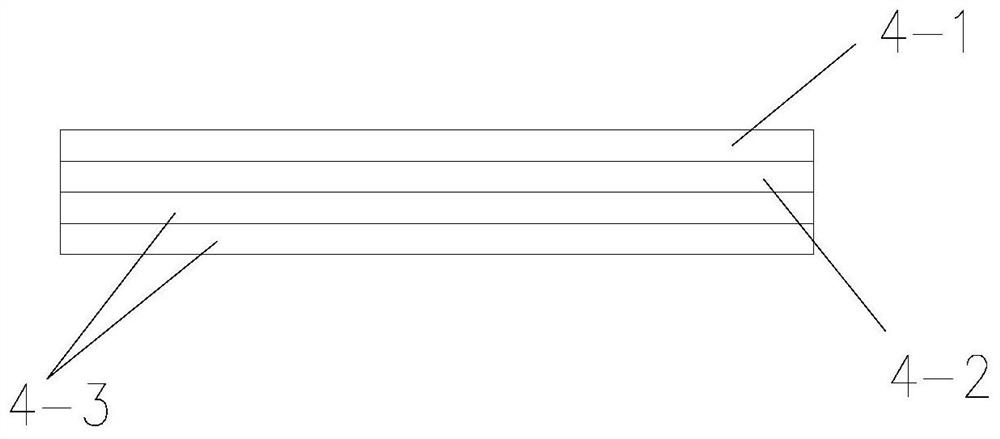

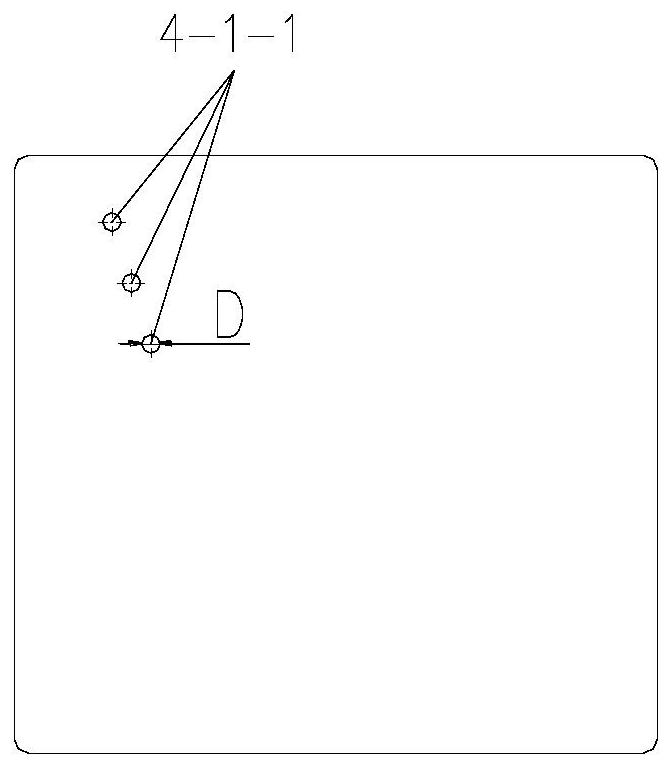

Precise temperature control system and method for micro reaction experiments

ActiveCN109634321AAdjustable temperatureEasy to useTemperatue controlTemperature controlMicroreactor

The invention discloses a precise temperature control system and method for micro reaction experiments. The system comprises a micro reactor and a temperature control system. The method comprises thesteps: step one, determining the temperature of a micro-reaction experiment; step two, setting the temperature of heat-preserving liquid; step three, leading reaction liquid; step four, collecting a temperature value of a micro-channel reactor; step five, determining whether the actual measurement temperature of a reaction material mixing plate is equal to the set temperature of the micro-reactionexperiment; step six, maintaining the heat-preserving liquid to be unchanged; step seven, determining whether the actually measured temperature of the reaction material mixing plate is greater than the set temperature of the micro-reaction experiment; step eight, determining whether the actually measured temperature of a reaction material input plate is greater than the set temperature of the micro-reaction experiment; step nine, determining whether the actually measured temperature of the reaction material input plate is lower than the set temperature of the micro-reaction experiment; step ten, reducing the temperature of the reaction material input plate; step eleven, reducing the temperature of the mixing material output plate; step twelve, increasing the temperature of the reaction material input plate; and step thirteen, increasing the temperature of the mixing material output plate. Therefore, the reaction temperature in the micro-reaction process can be controlled effectively and accurately.

Owner:XIAN UNITED PRESSURE VESSEL CO LTD

A catalytic device for preparing u(iv) solution

ActiveCN106311092BFully contactedLarge adjustment flexibilityChemical/physical processesStructural engineeringMaterials science

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

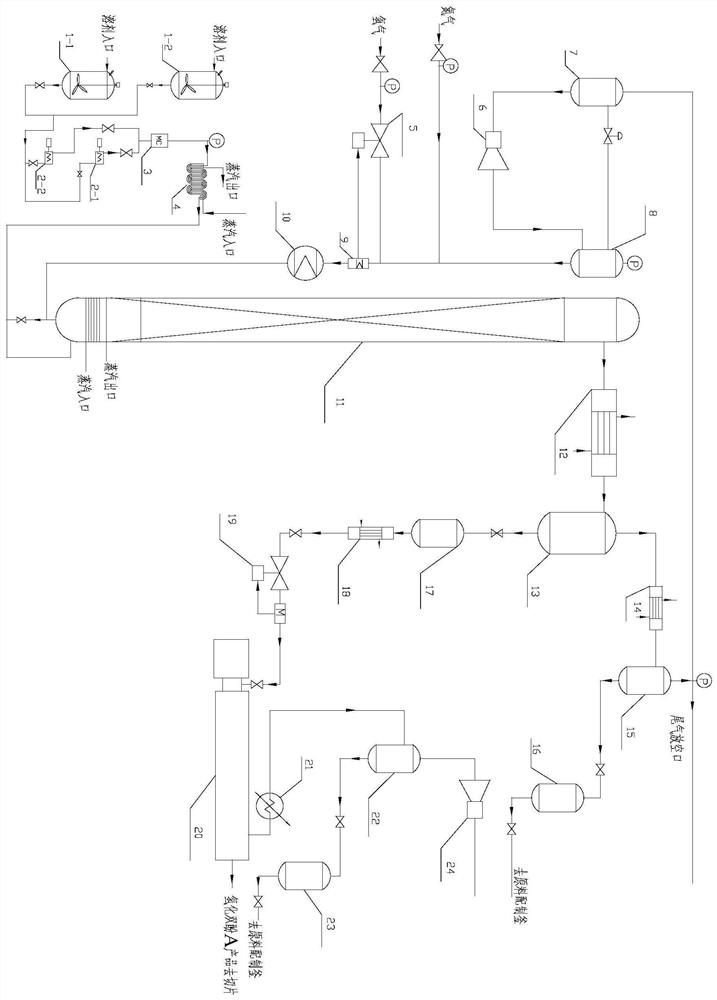

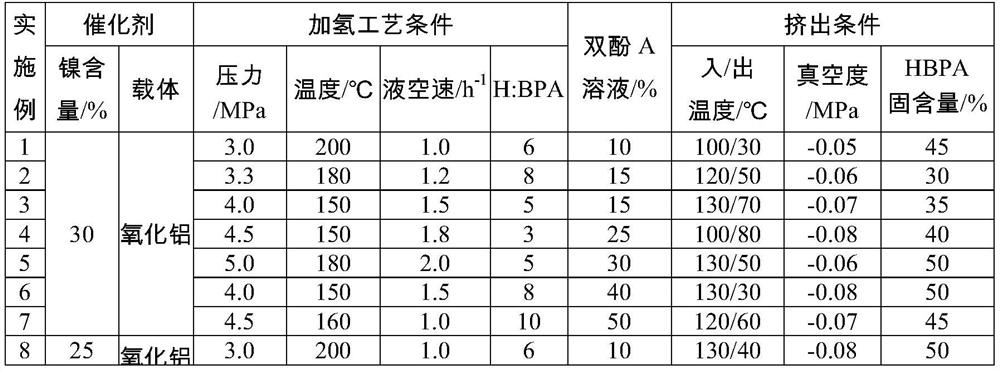

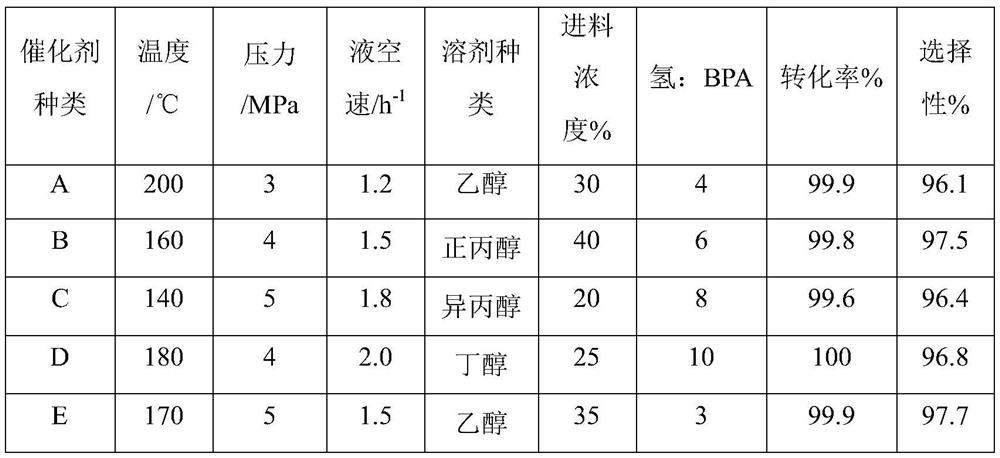

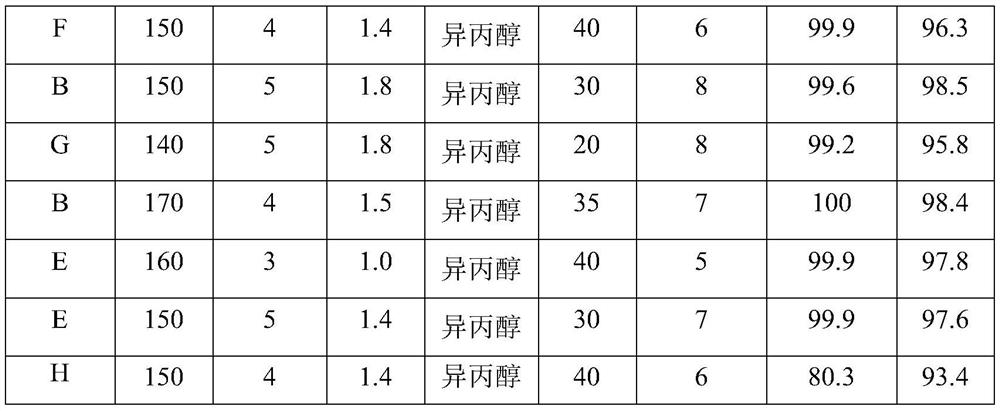

Equipment for continuous preparation of hydrogenated bisphenol a and continuous preparation method of hydrogenated bisphenol a

ActiveCN109678661BExtended stayRaise the ratioPreparation by hydrogenationHydroxy compound separation/purificationPtru catalystHydrogenation reaction

Owner:CHANGZHOU UNIV

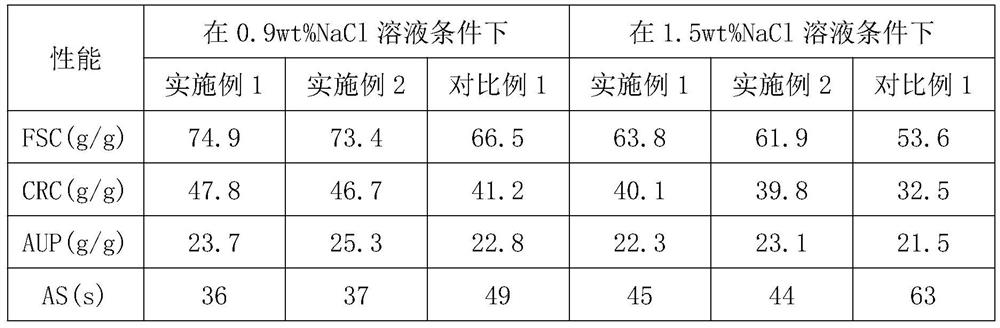

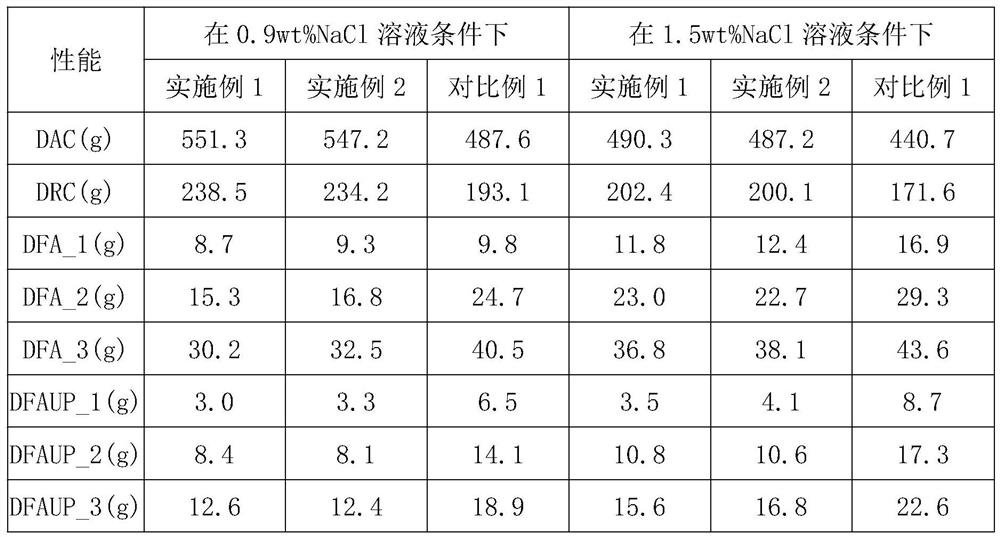

Preparation method of super absorbent resin under high salt concentration

ActiveCN112480301AIncrease the proportionFast absorptionAbsorbent padsBandagesSalt waterSuper absorbent

The invention discloses a preparation method of super absorbent resin under high salt concentration. The method comprises the following steps: a) preparing a monomer solution with neutralization degree of 70-80mol% by using acrylic acid, alkali and deionized water as raw materials; b) adding 3wt%-45wt% of an acidic nanoscale silicon dioxide solution and a composite internal crosslinking agent intothe monomer solution obtained in the step a), and fully stirring and uniformly mixing to obtain a reaction solution; c) heating the reaction solution in the step b), adding a foaming medium, and thenadding a thermal initiator for polymerization to obtain gel; and d) sequentially carrying out drying, crushing and surface treatment on the gel obtained in the step c) to obtain the high-absorbability resin with excellent performance under high salt water concentration. The super absorbent resin with high salt concentration has excellent performance under high salt concentration, improves the liquid absorption and liquid retention capacity of adult incontinence diapers and patient nursing mattresses, and can effectively ensure the dryness of nursing products.

Owner:浙江卫星新材料科技有限公司

Temperature control synthesis device

PendingCN111892021AEffective control of reaction temperatureGood for laying flatHydride purification/stabilisationTemperature controlSprayer

The invention relates to a temperature control synthesis device. The temperature control synthesis device comprises: a cylindrical tank body, which is provided with a middle cavity and a sealed annular inner cavity surrounding the middle cavity, wherein the sealed annular inner cavity is used for accommodating a reaction material; a driving device, which is in transmission connection with the cylindrical tank body and can drive the cylindrical tank body to rotate around the axis of the cylindrical tank body, wherein the axis of the cylindrical tank body is arranged in a horizontal or inclinedstate; a temperature control system, which comprises a heat exchange medium source and a sprayer connected with the heat exchange medium source, wherein the sprayer comprises an inner sprayer corresponding to the middle cavity and spraying towards the cavity wall of the middle cavity and an outer sprayer located on the outer side of the cylindrical tank body and spraying towards the outer side face of the cylindrical tank body. Reaction raw materials are in full contact through rotation of the tank body, in the rotating process, the materials are mainly scattered on the cavity wall face of theannular inner cavity, the reaction temperature can be effectively controlled by spraying temperature control over the interior and the exterior of the cylindrical tank body, and the device can be used for synthesizing diborane and other substances sensitive to the reaction temperature.

Owner:HENAN UNIV OF SCI & TECH

A fully automatic production process for fireproof glass

ActiveCN111233348BStrong adhesionReduce risk of leakageLiquid surface applicatorsCoatingsProcess engineeringFire prevention

Owner:SUZHOU POLIMA MACROMOLECULE MATERIAL CO LTD

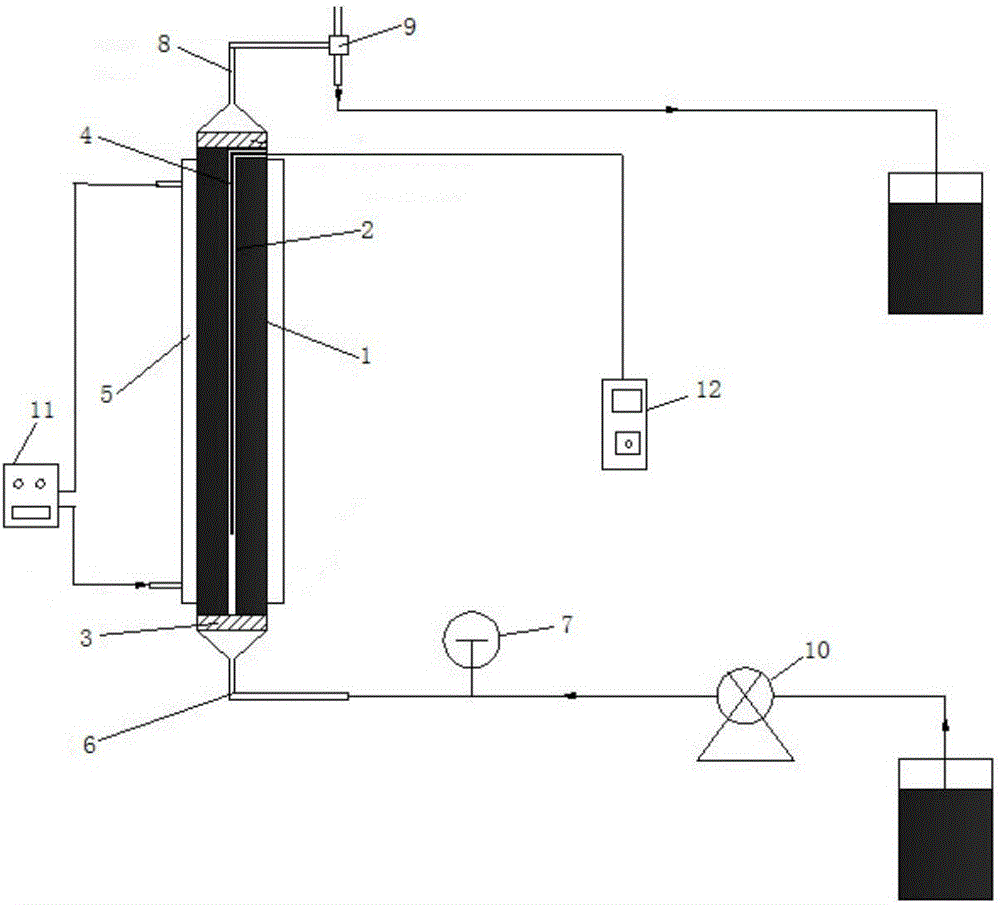

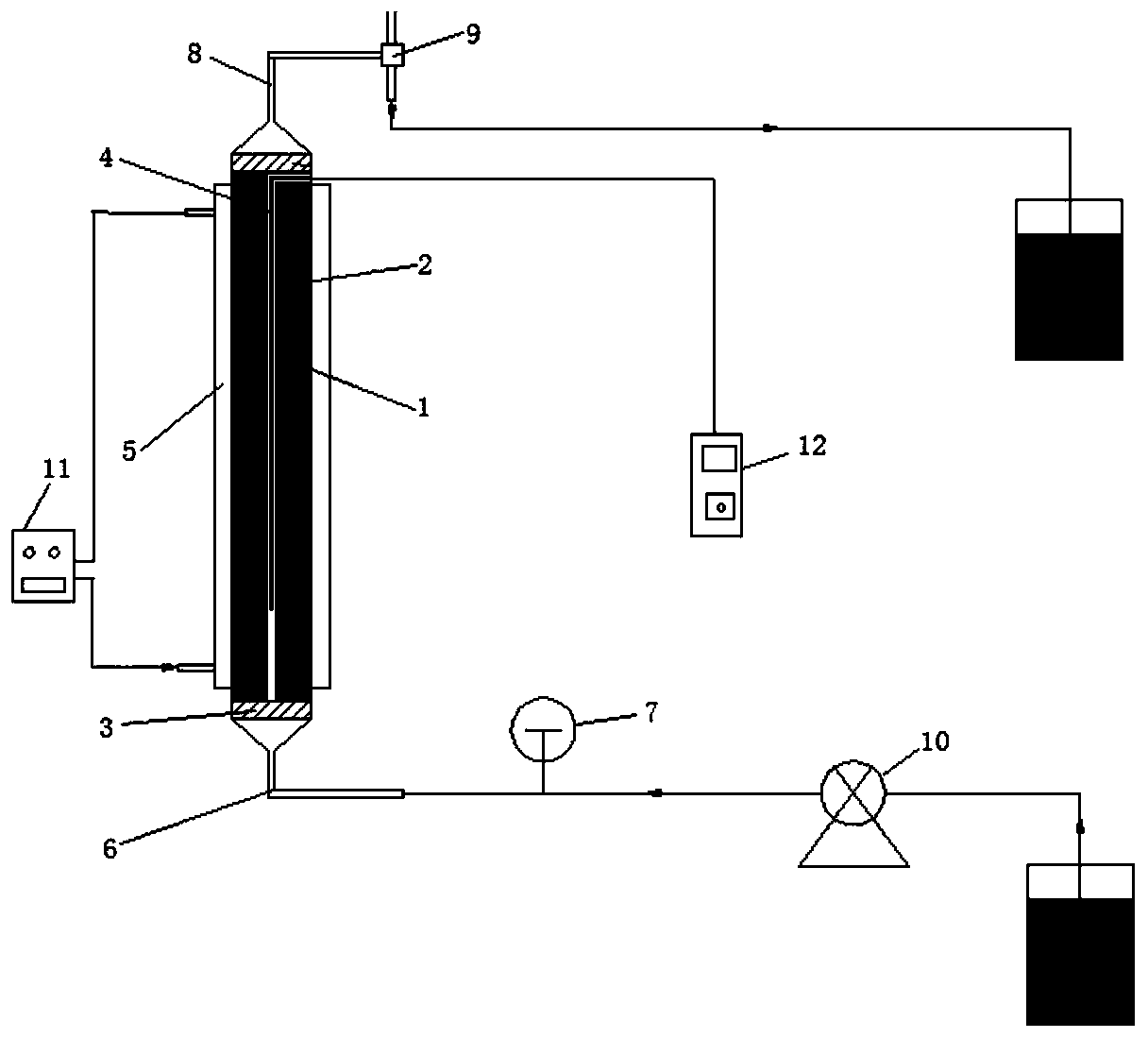

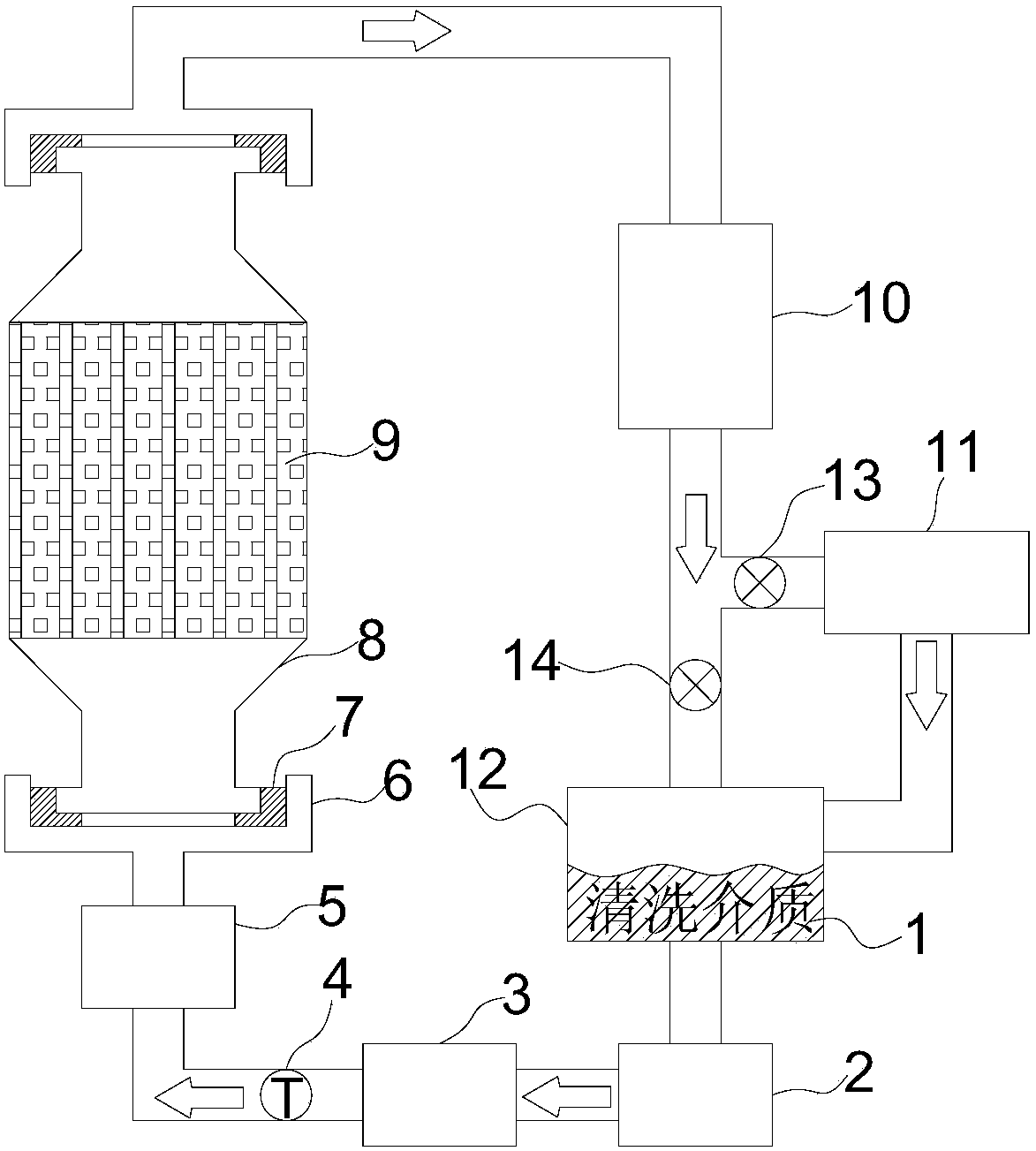

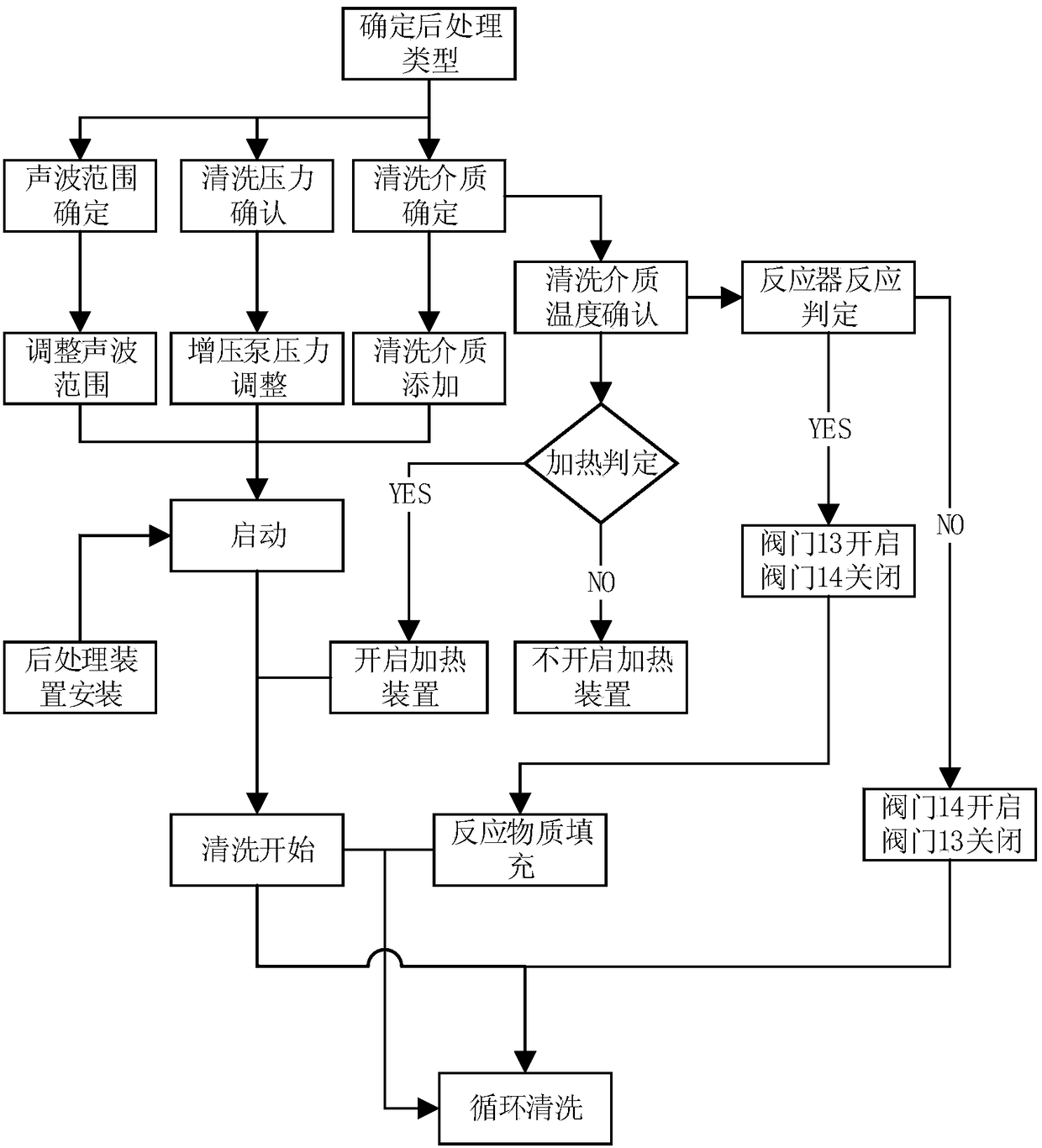

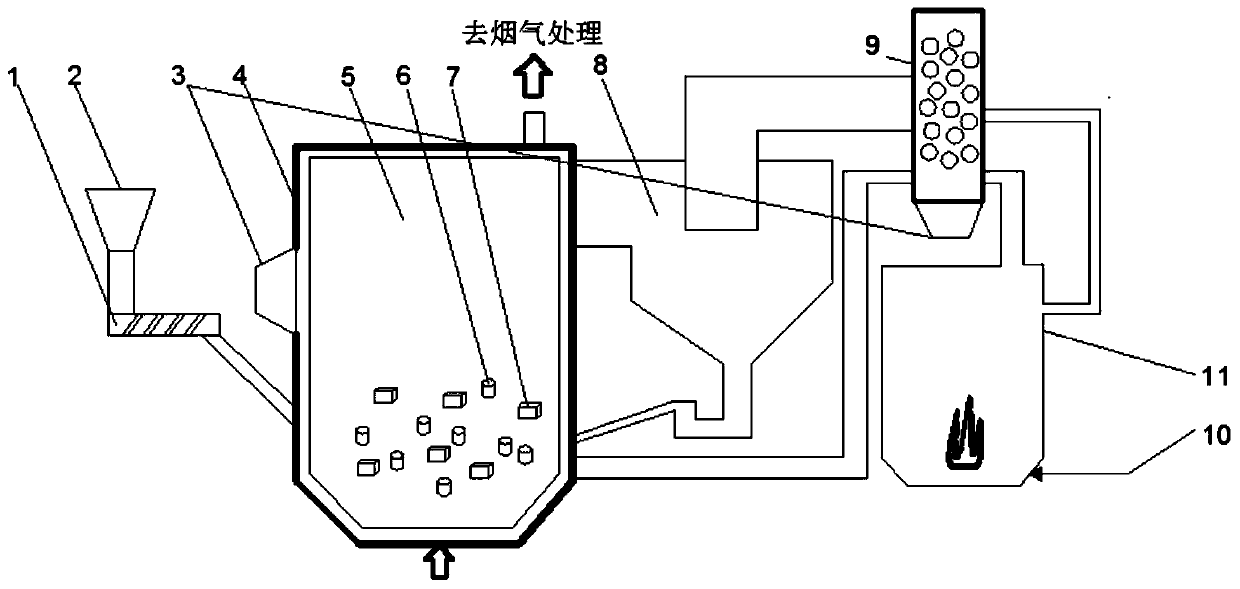

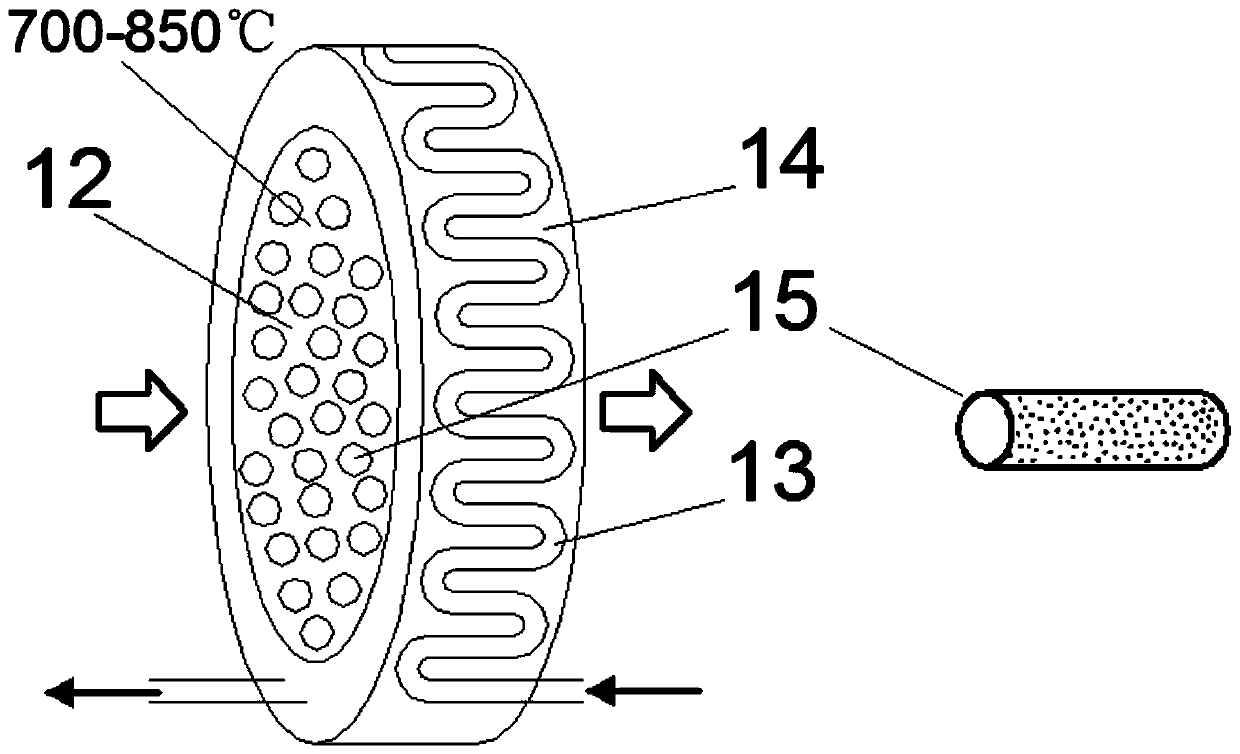

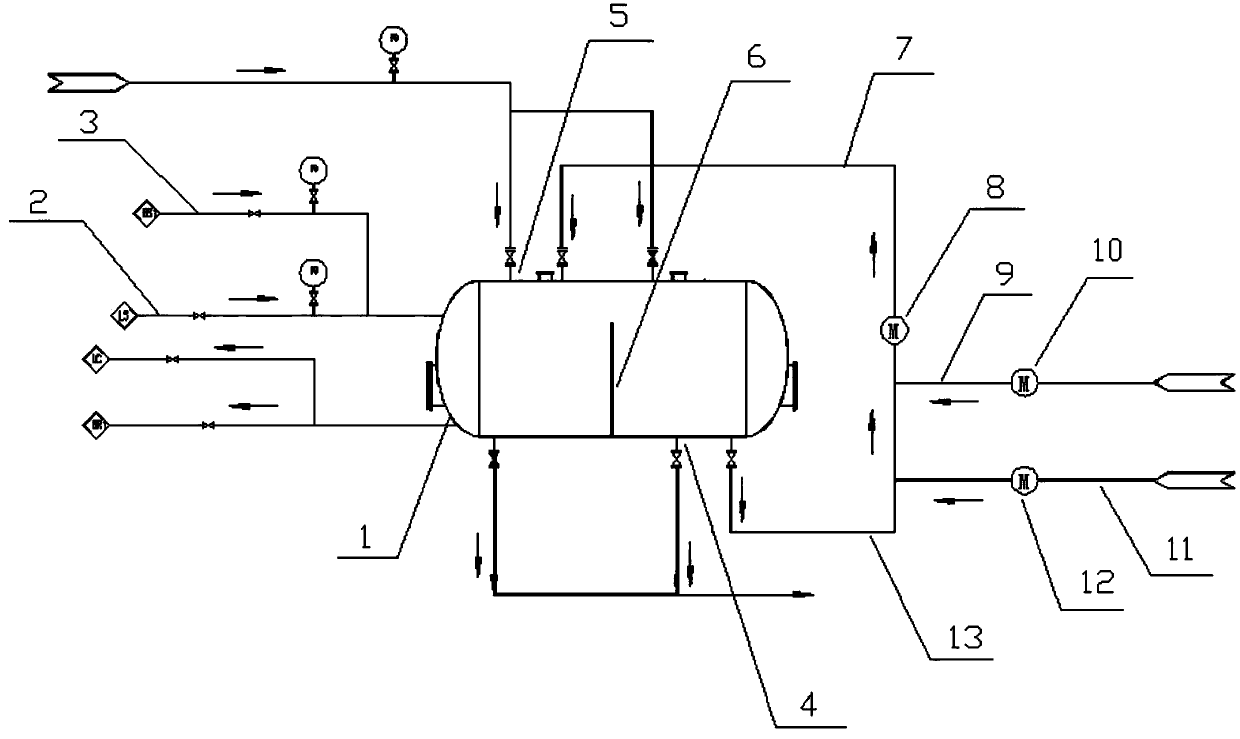

Cleaning device for carrier in engine exhaust aftertreatment system and control method thereof

ActiveCN105880211BEfficient removalPrevent reattachmentGas treatmentDispersed particle separationAfter treatmentTwo step

The invention relates to a cleaning device for a carrier in an engine exhaust gas after-treatment system. The cleaning device comprises a cleaning medium (1), a pressurization pump (2), a heater (3), a temperature sensor (4), a sound wave emitter (5), an after-treatment fixing device (6), a sealing gasket (7), a filter device (10), a reactor (11) and a storage tank (12). The cleaning device is characterized in that the pressurization pump (2), the heater (3), the sound wave emitter (5), the after-treatment device (8), the filter device (10), the cleaning medium (11) and the storage tank (12) are connected through pipelines to form a closed circulating cleaning system; and the device can complete cleaning in two steps, ash removal is conducted firstly, the cleaning medium is then replaced, device parameters are adjusted, the catalyst activity reduction is conducted, and therefore the cleaning device for the engine exhaust gas after-treatment system has the beneficial effect of being wide in application range.

Owner:WUHAN HUAWEI SECIAL PURPOSE AUTOMOBILE DETECTION

Device and method for catalyst-regenerable high-temperature catalytic pyrolysis of domestic garbage and hydrogen filtering

PendingCN110437857AEmission reductionReduce deteriorationSpecial form destructive distillationCatalytic pyrolysisExternal energy

The invention discloses a device and method for catalyst-regenerable high-temperature catalytic pyrolysis of domestic garbage and hydrogen filtering. The device includes a fluidized bed pyrolysis furnace, microwave generators, a catalyst regenerable catalyst bed, a combustion furnace and a cyclone separator. The bottom of the fluidized bed pyrolysis furnace is provided with a gas inlet. The microwave generators are arranged on the side wall of the fluidized bed pyrolysis furnace and the bottom or the side wall of the catalyst regenerable catalyst bed. An inlet of the cyclone separator is connected to a pyrolysis gas outlet of the fluidized bed pyrolysis furnace, the bottom of the cyclone separator is connected to the lower part of the fluidized bed pyrolysis furnace, and a gas outlet of the cyclone separator is connected to the catalyst bed. A gas outlet of the catalyst bed is connected to the combustion furnace. Through the device and the method, microwave-assisted high-temperature pyrolysis of domestic garbage, catalyst regeneration and hydrogen filtration can be achieved, the catalytic pyrolysis efficiency can be increased, external energy supply cab be reduced, energy is savedwhile achieving resource utilization of domestic garbage, the service lifetime of the device can be effectively prolonged, and the device and the method are economical and environmentally friendly.

Owner:SOUTH CHINA UNIV OF TECH

An environment-friendly neutralization reactor

ActiveCN106693871BReduce volatile lossReduce productionChemical/physical/physico-chemical stationary reactorsNiobiumReaction temperature

The invention discloses an environmental-friendly neutralization reaction kettle. The environmental-friendly neutralization reaction kettle comprises a reaction kettle body, a feeding pipe, an ammonia inlet pipe, a discharge hole and a stirring device. The feeding pipe and the ammonia inlet pipe are arranged on the upper portion of the reaction kettle body, the discharge hole is formed below the bottom of the reaction kettle body, the stirring device is arranged in the reaction kettle body, and a cooling coil is also arranged in the reaction kettle body. According to the environmental-friendly neutralization reaction kettle disclosed by the invention, heat generated by the neutralization reaction is fully used to heat cold water in a cooling coil, so that the water temperature at the outlet of the cooling coil reaches 40-50 DEG C, and hot water at the outlet can be used for washing fluorine ions adsorbed by niobium (tantalum) hydroxide. Meanwhile, the cooling coil is arranged in the reaction kettle body to effectively control the reaction temperature, so that the neutralization temperature is lower than 50 DEG C, the volatilization loss of ammonia in the neutralization reaction process is reduced, the production cost is lowered, and the waste gas generating amount is reduced, and therefore, and environmental-friendly and energy-saving effects are achieved.

Owner:稀美资源(广东)有限公司

Gas purification reactor and gas purification method

PendingCN110759323AImprove the purification effectEffective control of reaction temperatureNoble gas compoundsSpecific gas purification/separationPurification methodsPhysical chemistry

The invention discloses a gas purification reactor. The gas purification reactor is used for absorbing impurities in gas, and comprises at least one gas purification chamber, wherein the gas purification chamber is of a tubular structure, and is filled with a gas purifying material, and the temperature T1 of the gas purification chamber is not smaller than 300 DEG C and not larger than 600 DEG C.A gas purification method comprises the steps: filling the gas purification chamber of the gas purification reactor with the gas purifying material, heating the gas purification chamber to a corresponding temperature T1, heating a gas buffer chamber to a corresponding temperature T2, introducing gas into a gas inlet of the gas purification reactor, and performing discharge from a gas outlet. Through arrangement of a reasonable temperature range for the gas purification chamber, the activity of the gas purifying material can be adjusted, and the purification effect is improved; through arrangement of the gas buffer chamber, the gas flow rate is buffered, and the gas is preheated; through arrangement of a partition plate between the gas buffer chamber and the gas purification chamber, gas flow is dispersed, the gas flow rate is reduced, the gas flow is prevented from driving the gas purifying material to flow, and the purifying material is prevented from getting out of the partition plate under the impact action of the gas flow.

Owner:LONGI GREEN ENERGY TECH CO LTD +1

Full-automatic production process of fireproof glass

ActiveCN111233348AStrong adhesionReduce risk of leakageLiquid surface applicatorsCoatingsProcess engineeringIndustrial engineering

The invention discloses a full-automatic production process of fireproof glass. The full-automatic production process mainly comprises the following steps of automatic sheet feeding, automatic cleaning, transition, positioning, gluing, transition, automatic sheet combining, transition, hot pressing, automatic overturning, automatic gluing, automatic material mixing, automatic filling, curing and automatic sheet discharging. In this way, the problems that existing fireproof glass is low in production efficiency and poor in quality can be solved.

Owner:SUZHOU POLIMA MACROMOLECULE MATERIAL CO LTD

A kind of preparation method of hydrogenated bisphenol A

ActiveCN109232188BHigh selectivityImprove conversion ratePreparation by hydrogenationCatalyst activation/preparationPtru catalystHydrogenation reaction

Owner:CHANGZHOU UNIV

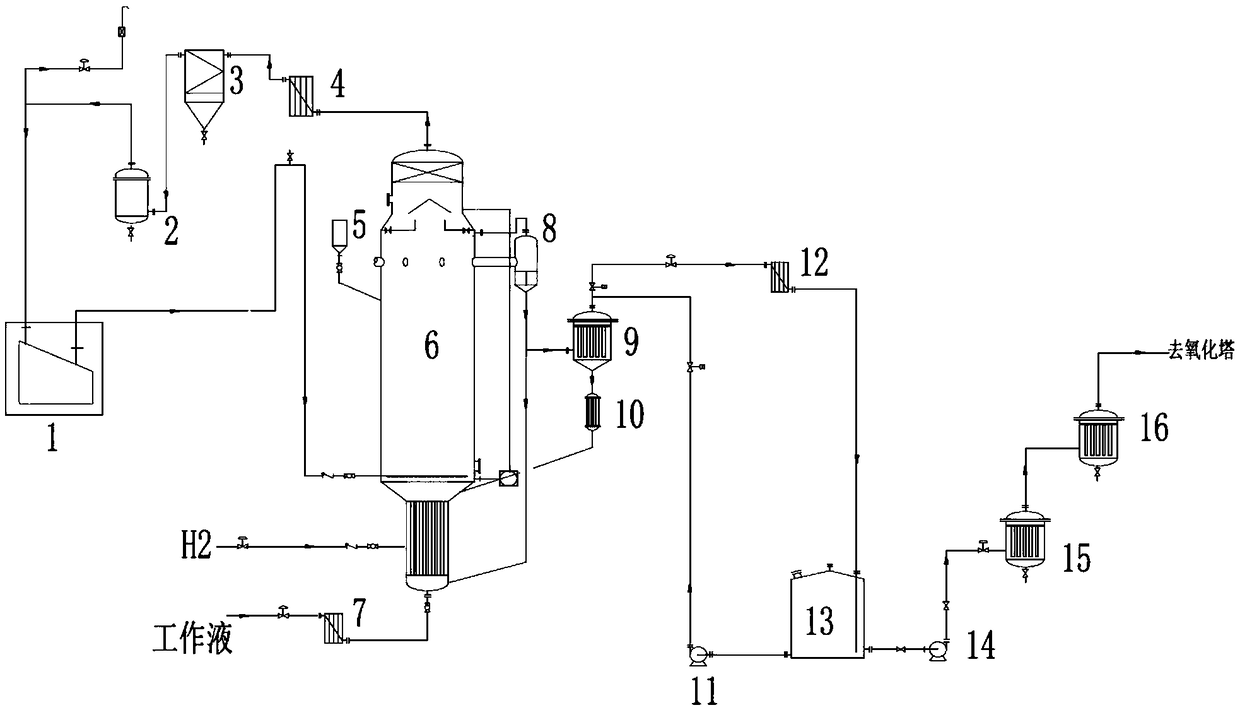

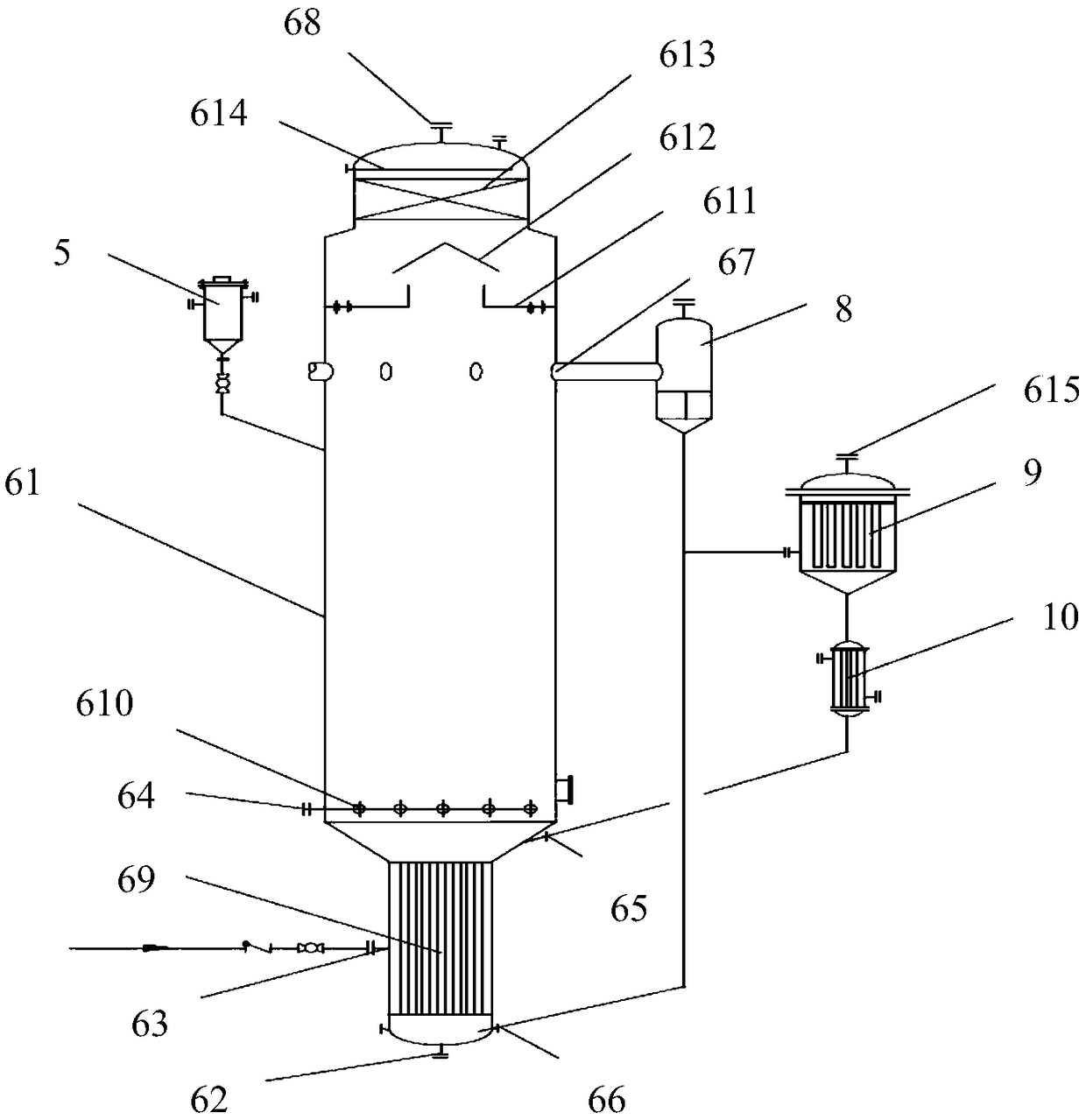

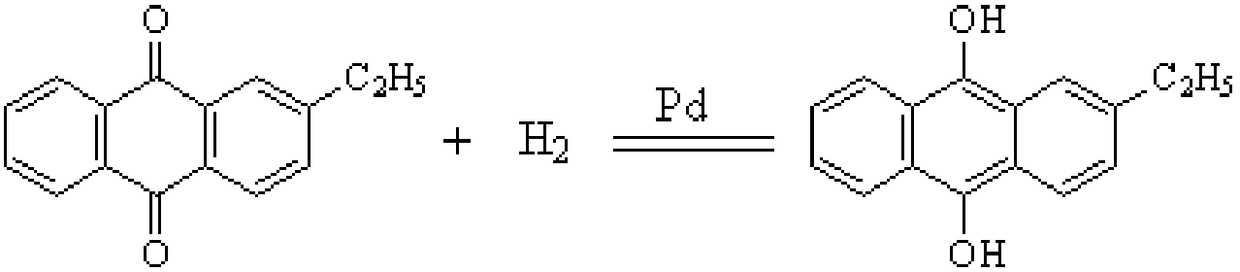

A hydrogenation method and hydrogenation device for a hydrogen-containing anthraquinone working liquid

ActiveCN106629622BAvoid risk factorsIncrease reaction ratePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical recyclingHydrogenation reactionFixed bed

The present invention disclosed a hydrogenation method and hydrogenation device for hydrogen -containing work liquid: hydrogen -containing gas and pyrine work liquid under the catalyst catalyst to generate hydrogen -containing hydrogen -containing work liquid;The generated tail gas is used after condensation, separation, filtering, and pressurizing; the generated hydrogen -containing work liquid, part of which removes the catalyst after filtering, and then performs subsequent oxidation reactions after cooling, filtering, and security filtering. Most of them are mostly.Hydrogen -containing work liquid re -hydrogenation reactions.After the industrialization of this process, the production efficiency can be improved by 40 % on the basis of the existing domestic fixed bed hydrogenation process, and the risk factors in production in the essence of production principles and processes can increase the product concentration from 30 % by more than 40 % or moreAnd the main indicators of product quality, such as organic carbon content, and not volatile contents, etc., are better than the products produced by fixed bed processes.It has an epoch -making promotion significance for the development of hydrogen peroxide in my country.

Owner:CHINA CATALYST HLDG CO LTD

Industrial water treatment sodium hypochlorite generation equipment convenient for temperature adjusting

InactiveCN109706470AAvoid temperature riseEffective control of reaction temperatureElectrolysis componentsElectrolysisBiochemical engineering

The invention discloses industrial water treatment sodium hypochlorite generation equipment convenient for temperature adjusting. According to the industrial water treatment sodium hypochlorite generation equipment convenient for temperature adjusting, an electrolysis box is suspended in an external box; a cooling chamber is formed between the housing of the electrolysis box and the housing of theexternal box; the top of the housing of electrodes is connected with the internal wall of the external box in sealing manner; a heat dispersion assembly comprises liquid feeding mechanisms, a PLC controller, and a temperature sensor; each liquid feeding mechanism comprises end plates, an oil cylinder, a push plate, a liquid storage cylinder, and a liquid inlet pipe; the liquid storage cylinders are horizontally arranged on a bottom plate; each liquid storage cylinder is provided with a corresponding liquid inlet pipe; the two ends of each liquid storage cylinder are provided with openings; each opening is provided with an end plate; each oil cylinder is arranged in one side of a corresponding liquid storage cylinder, and is fixedly connected with one end plate; an output shaft of each oilcylinder is connected with a corresponding push plate; each push plate is arranged in a corresponding liquid storage cylinder in a coaxial manner; the temperature sensor is arranged in the external box; the PLC controller is arranged outside the external box; the temperature sensor is connected with a signal input terminal of the PLC controller through a signal wire; a signal output terminal of the PLC controller is connected with the oil cylinders. The industrial water treatment sodium hypochlorite generation equipment is excellent in temperature reducing effect, and is convenient to use.

Owner:合肥茗满天下茶叶有限公司

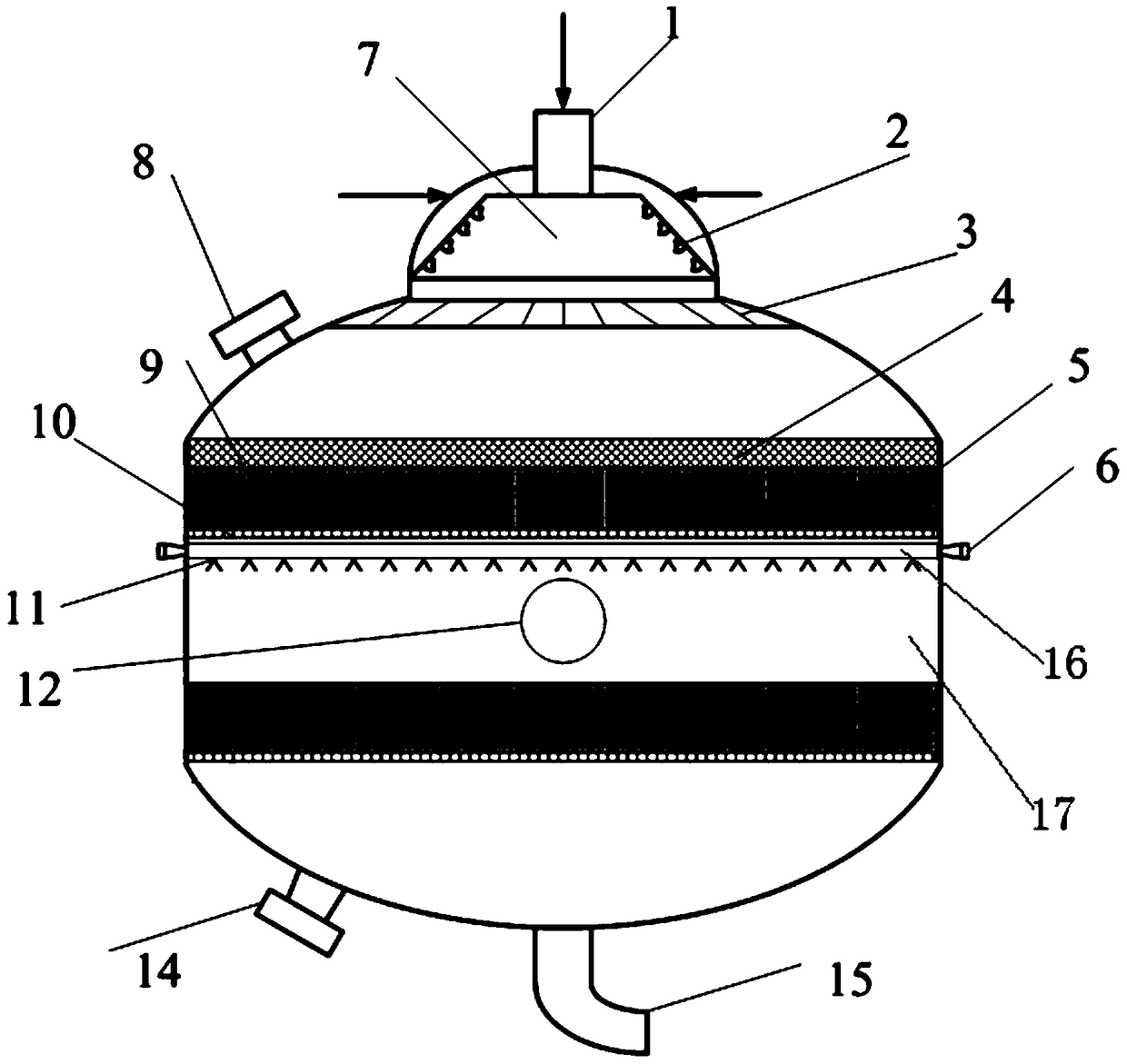

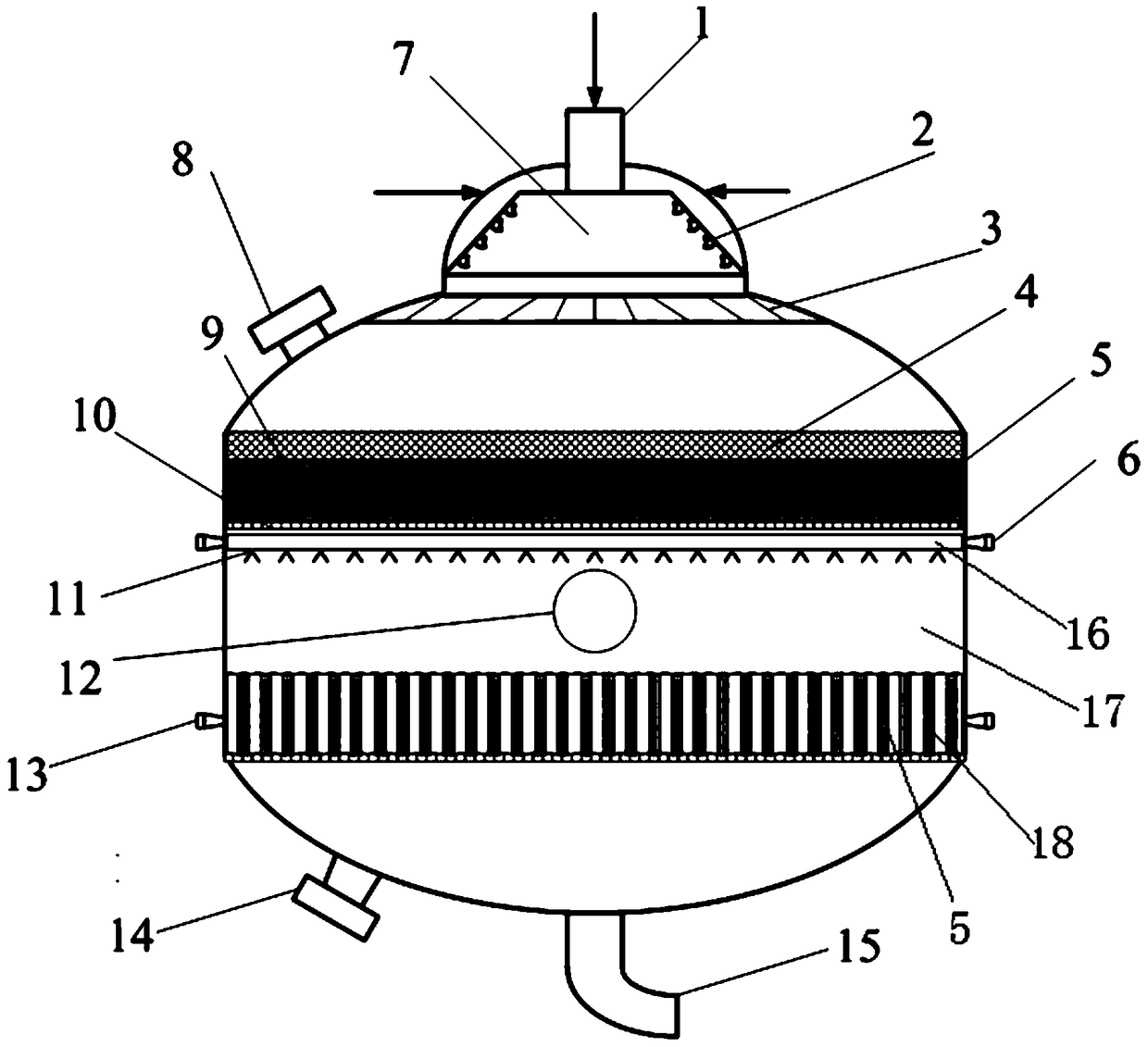

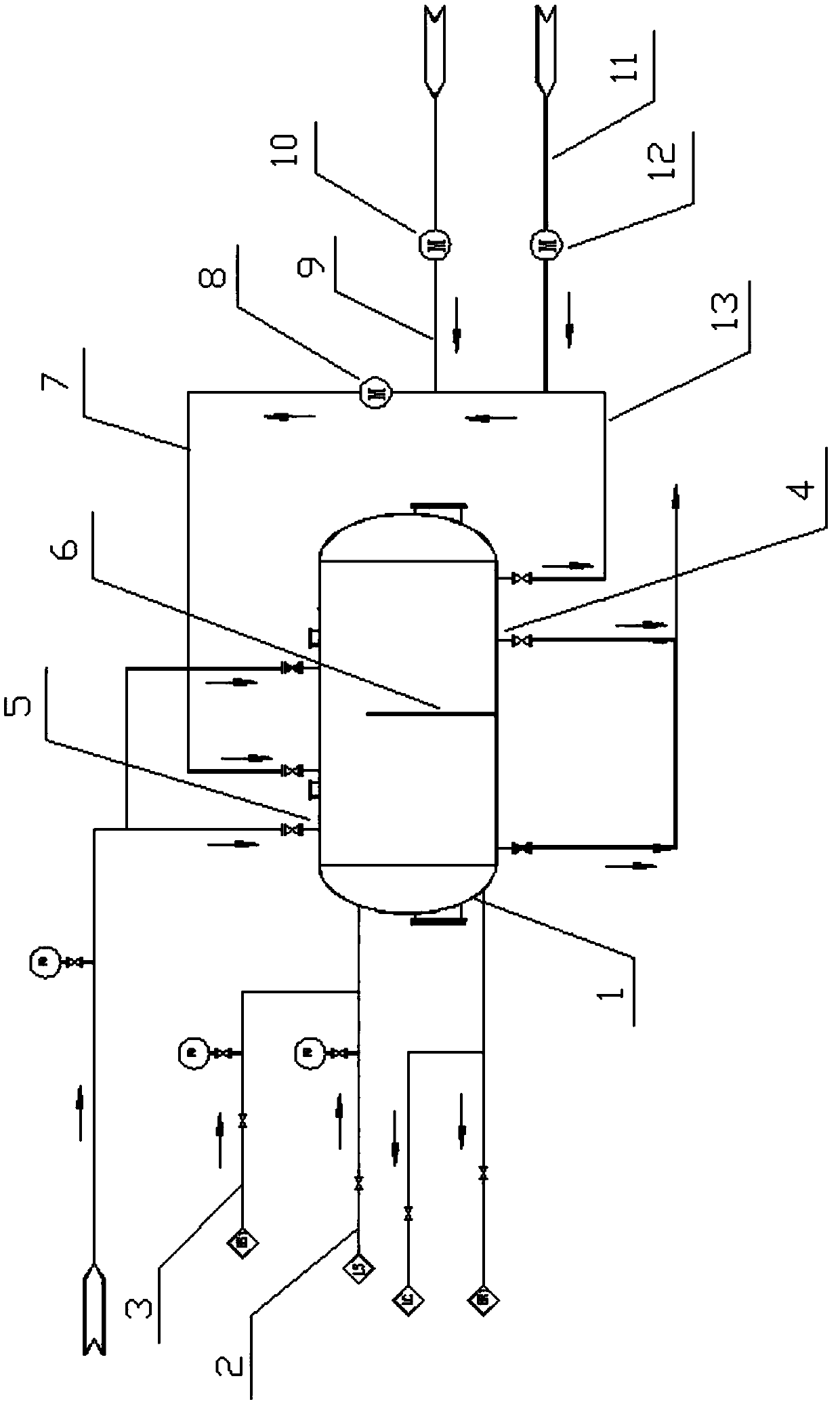

A large axial multi-stage mixed heat exchange butene oxidative dehydrogenation reactor

ActiveCN105536654BReduce stressIncrease production capacityHydrocarbonsChemical/physical processesButeneHigh energy

The invention relates to a large-scale axial multistage-mixing heat exchange type oxydehydrogenation reactor for butylene. The reactor comprises a reactor housing, a mixing arrangement which is arranged at the upper part of the reactor housing, at least two axial catalyst bed layers in the reactor housing, and at least one direct heat exchange segment; the direct heat exchange segment is located between the two axial catalyst bed layers, a cold torrent is introduced into the direct heat exchange segment in the reactor casing, the cold torrent and outlet materials which are reacted with the axial catalyst bed layer above the direct heat exchange segment are mixed for direct heat exchange, and a mixture enters the axial catalyst bed layer below the direct heat exchange segment for carrying out a reaction. Compared with the prior art, the reactor has the advantages of large-scale, effective control of reaction temperature, reduced bed layer pressure, high energy utilization rate, and good production capacity.

Owner:WISON ENG

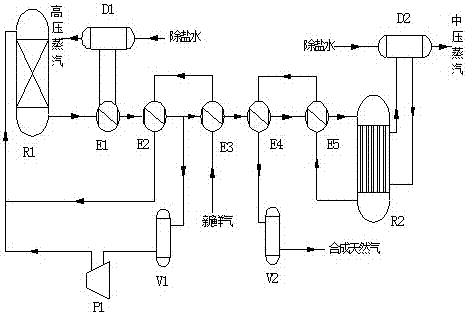

A process for preparing synthetic natural gas

The invention discloses a process for preparing synthetic natural gas, which belongs to the technical field of new energy utilization. After the fresh coal-based synthesis gas exchanges heat with the primary reaction product gas from the first methanation reactor, it is mixed with the recycle gas and enters the first methanation reactor for methanation reaction. The primary reaction product gas is separated into Two parts: one part circulates into the first methanation reactor through the circulating compressor, and the other part enters the second methanation reactor after heat exchange with fresh coal-based synthesis gas, and then with the second reaction product gas for two-stage heat exchange. In the methanation reaction, the product gas of the second reaction is exchanged with the product gas of the first reaction, and then condensed and separated to obtain synthetic natural gas containing more than 95% of methane. The invention has the advantages of low investment and high energy utilization rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

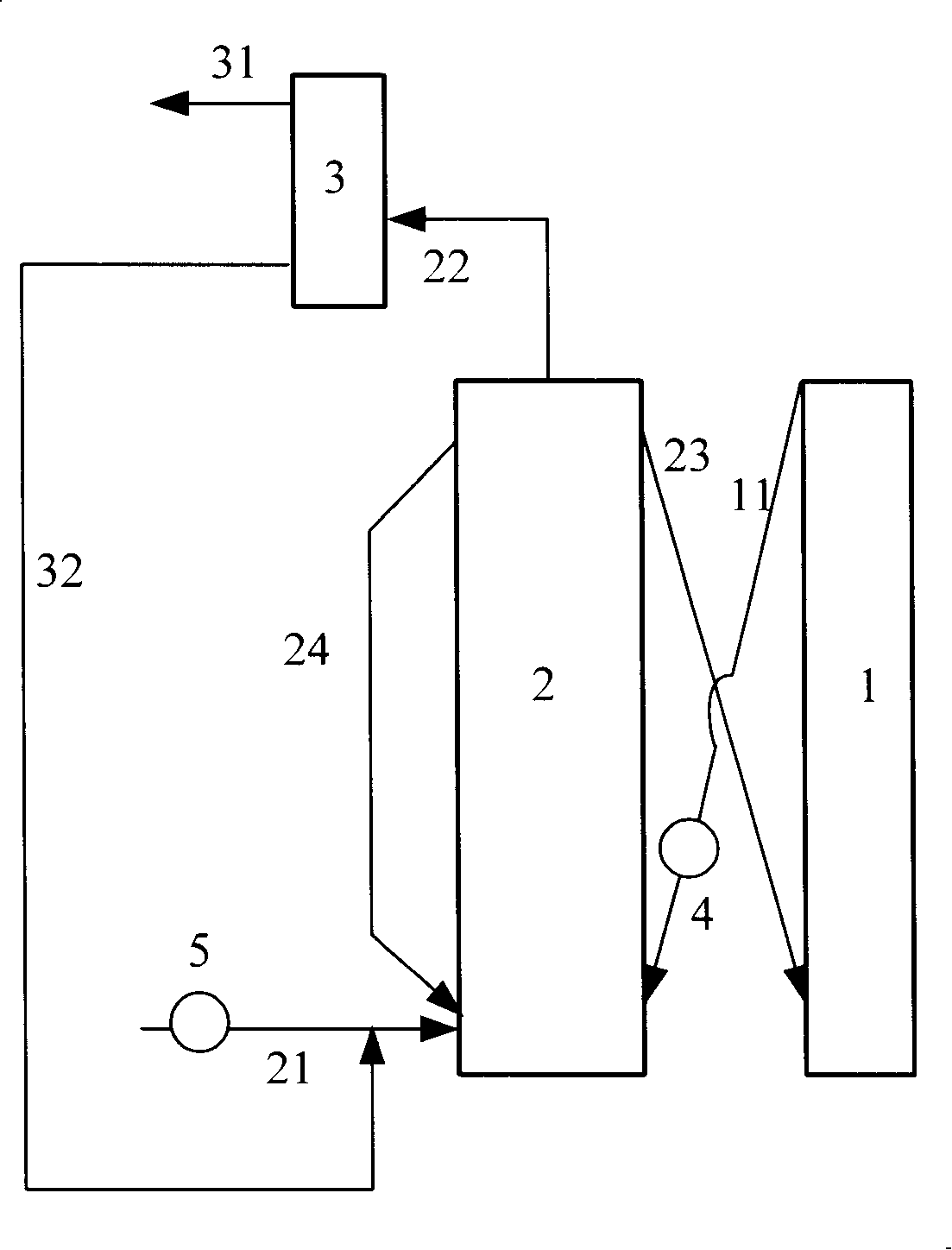

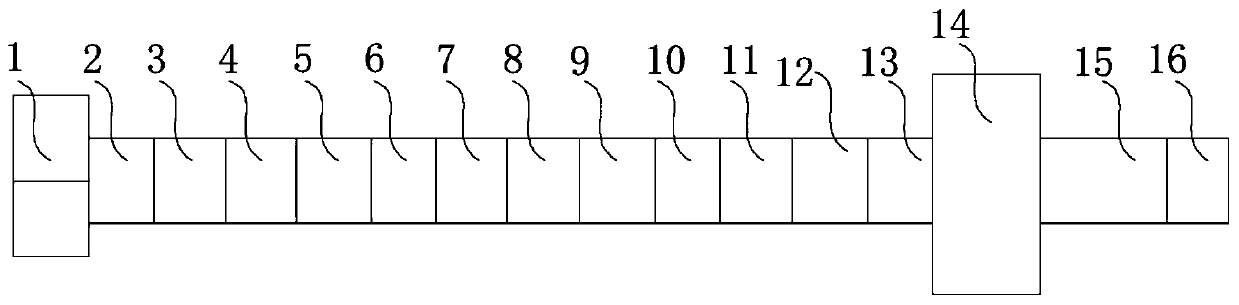

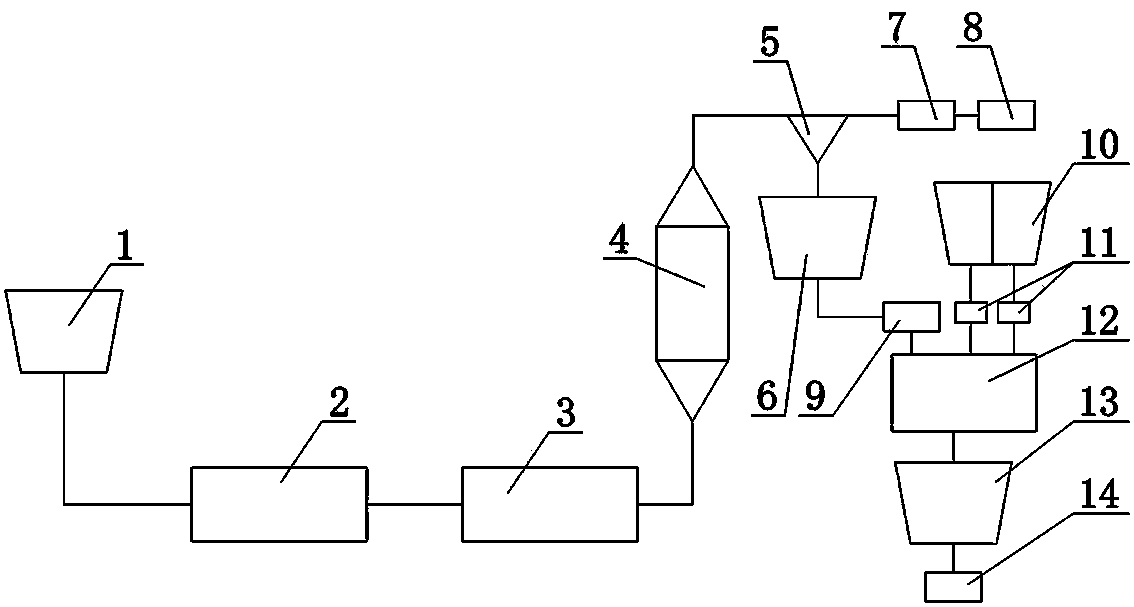

Powder material multistage dry-method modification system

InactiveCN102935348BEliminate pollutionGuaranteed drynessChemical/physical/physico-chemical processesEngineeringHigh pressure

The invention discloses a powder material multistage dry-method modification system comprising a powder material storage tank (1), a high-pressure fan (2), a heater (3), a boiling drying tower (4), a cyclone separator (5), a dry powder storage tank (6), a powder material metering feeder (9), a modifying agent storage tank (10), a modifying agent metering feeder (11), a modification machine (12), and a finished product storage tank (13). The powder material storage tank (1) is sequentially connected to the high-pressure fan (2), the heater (3), and the boiling drying tower (4). The boiling drying tower (4) is connected with the dry powder storage tank (6) through the cyclone separator (5). The dry powder storage tank (6) and the modifying agent storage tank (10) are respectively connected to the feeding port of the modification machine (12). The system provided by the invention has the advantages that: with the system, pollution to the environment caused by powder material modification processing is eliminated; operator labor intensity is reduced; processing quality is stable and homogeneous; and modification is continuous modification, such that production efficiency is improved.

Owner:SICHUAN HAIYA POWDER TECH CO LTD

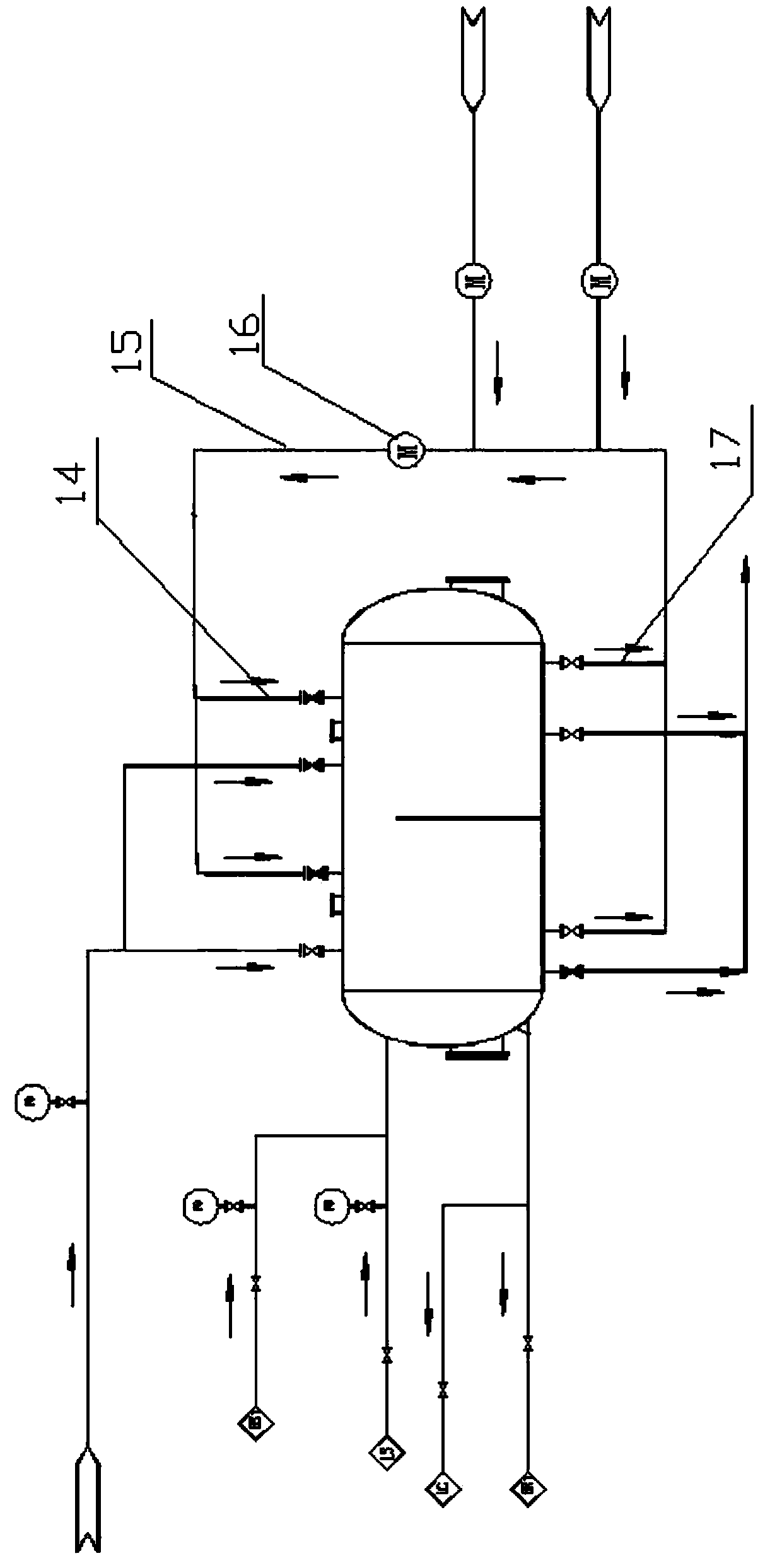

A kind of acetonitrile production reactor and preparation method thereof

ActiveCN106362671BEffective control of reaction temperatureWell mixedProcess control/regulationChemical/physical/physico-chemical reactor detailsProcess engineeringAcetonitrile

The invention discloses an acetonitrile production reactor and a preparing method thereof. The acetonitrile production reactor comprises a reaction kettle provided with a clamping sleeve. A vertically-arranged partition plate is arranged in the reaction kettle, and the reaction kettle is divided by the partition plate into a left cavity and a right cavity, wherein the upper portion of the left cavity and the upper portion of the right cavity are communicated; feeding inlets are formed in the tops of the cavities, and discharging openings are formed in the bottoms of the cavities; a material mixing pipe for being communicated with the two cavities is arranged on the reaction kettle, feeding pipes for feeding a sodium hydroxide solution and a formaldehyde solution are connected on the material mixing pipe, and a control mechanism for the feeding pipe is arranged on the reaction kettle. According to the acetonitrile production reactor and the preparing method thereof, the two cavities are formed in the reaction kettle, cross flowing of materials in the two cavities is achieved through the material mixing pipe, and all the materials are more fully and evenly mixed; as the sodium-hydroxide-solution feeding pipe and the formaldehyde-solution feeding pipe are additionally arranged on the material mixing pipe, pipe plugging can be conveniently treated.

Owner:JIANGSU SAILBOAT PETROCHEMICAL CO LTD

Method for measuring content of phospholipid in liposome

InactiveCN101692038BChromogenic reaction, stable colorImprove the display effectPreparing sample for investigationColor/spectral properties measurementsPhospholipinDistilled water

The invention discloses a method for measuring the content of phospholipid in liposome, which comprises the following steps: preparing a color development reagent A and a color development reagent B; preparing standard storage liquid; preparing a sample solution; drawing a standard curve; measuring the content of a sample: accurately sucking 0.5ml of the prepared liposome sample solution into 15*200mm test tubes, and sequentially adding 0.4ml of sulfuric acid with the concentration of 10N and 0.1ml of 30% hydrogen peroxide solution; heating for 60 minutes at a constant temperature of 170 DEG C; after cooling, adding 9ml of distilled water into each test tube, uniformly mixing and sucking 1.5ml of mixed solution into another test tube, then respectively adding 4.6ml of solution of the color development reagent A and 0.1ml of solution of the color development reagent B, and heating for 15 minutes in a water bath at 100 DEG C; after cooling, carrying out color comparison at the point with the wavelength of 822nm to measure the absorbance; and substituting the obtained absorbance value of the sample into a regression curve equation to calculate the content of phosphorus in the sample.The invention has simple and convenient method and easy operation, greatly improves the accuracy of the measuring result, and also improves the precision of the measuring result.

Owner:NORTH CHINA PHARMA COMPANY

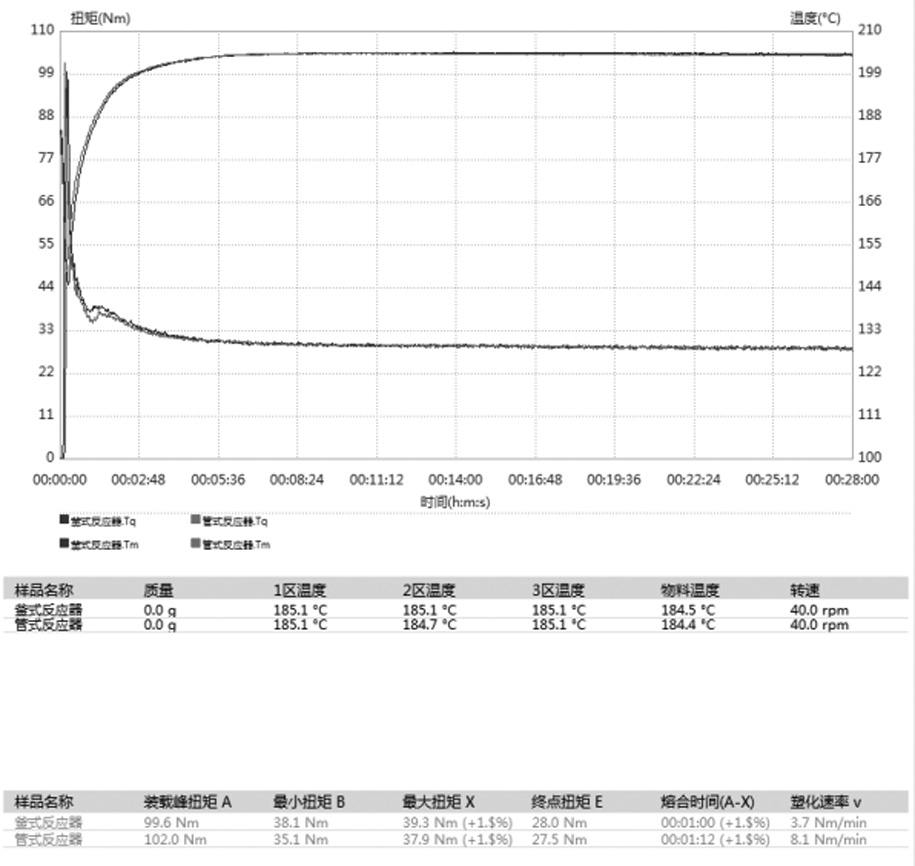

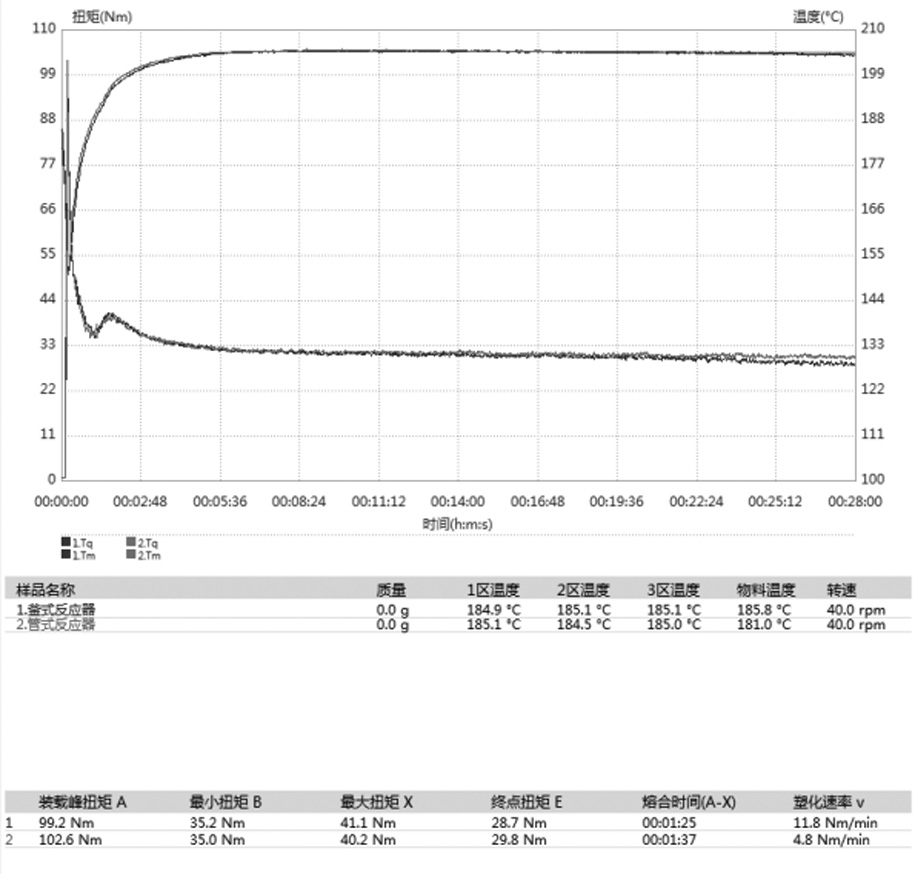

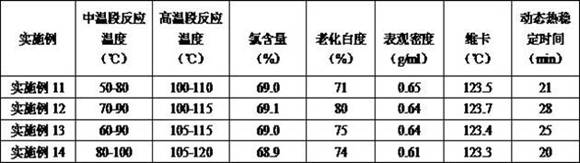

A kind of method for preparing chlorinated polyvinyl chloride resin based on tubular reactor

ActiveCN109485756BImprove the uniformity of chlorinationImprove thermal stabilityCarbide siliconChlorinated polyvinyl chloride

The invention discloses a method for preparing chlorinated polyvinyl chloride resin based on a tubular reactor. The method includes a batching step, a chlorination step, and a post-treatment step. The chlorination step is divided into a medium-temperature reaction stage and a high-temperature reaction stage; The reaction stage is carried out in the first reactor; the high temperature reaction stage is carried out in the second reactor; the first reactor and the second reactor are tubular reactors. Compared with the prior art, it can effectively prevent the bonding between the resin particles, improve the chlorination uniformity of the chlorinated polyvinyl chloride resin, improve the thermal stability of the chlorinated polyvinyl chloride resin, and effectively control the reaction temperature. The heat released by the chemical substitution reaction can be exported in time to achieve strict temperature control; at the same time, the tubular reactor is made of silicon carbide, which is durable and not easy to damage, and the equipment occupies a small area. reduce manufacturing cost.

Owner:山东高信化学股份有限公司

1,1,2-trichloroethane reactor and method thereof

PendingCN110511110AEasy to adjust the positionSimple structureChemical/physical/physico-chemical stationary reactorsPreparation by halogen addition1,1,2-TrichloroethanePulp and paper industry

The invention discloses a 1,1,2-trichloroethane reactor, which comprises a vertically installed cylinder body, wherein the cylinder body comprises a lower sealing head, a first cylinder body, a secondcylinder body, a third cylinder body, a fourth cylinder body and an upper sealing head which are sequentially connected from bottom to top, the bottom of the lower sealing head is provided with a circulating liquid inlet, a vinyl chloride distributor is arranged in the first cylinder body, the first cylinder body is provided with a vinyl chloride inlet, and the vinyl chloride inlet is connected with the vinyl chloride distributor. A chlorine distributor is arranged in the second cylinder body, a chlorine inlet is arranged on the second cylinder body, the chlorine inlet is connected with the chlorine distributor, a lower temperature measuring port and a middle temperature measuring port are arranged on the third cylinder body, a grid plate is arranged between the third cylinder body and the fourth cylinder body, a circulating liquid outlet, an overflow port and an upper temperature measuring port are arranged on the fourth cylinder body, and an exhaust port is arranged on the top of the upper sealing head. The invention also discloses a method for producing 1,1,2-trichloroethane by using the reactor. The1,1,2-trichloroethane reactor has the advantages of simple structure, large operation elasticity, good gas-liquid mass transfer effect and safe and controllable reaction process.

Owner:ZHEJIANG QUZHOU JUSU CHEM IND CO LTD +1

Precise temperature control system and method suitable for micro-reaction experiments

ActiveCN109634321BAdjustable temperatureEasy to useTemperatue controlMicroreactorTemperature control

The invention discloses a precise temperature control system and method for micro reaction experiments. The system comprises a micro reactor and a temperature control system. The method comprises thesteps: step one, determining the temperature of a micro-reaction experiment; step two, setting the temperature of heat-preserving liquid; step three, leading reaction liquid; step four, collecting a temperature value of a micro-channel reactor; step five, determining whether the actual measurement temperature of a reaction material mixing plate is equal to the set temperature of the micro-reactionexperiment; step six, maintaining the heat-preserving liquid to be unchanged; step seven, determining whether the actually measured temperature of the reaction material mixing plate is greater than the set temperature of the micro-reaction experiment; step eight, determining whether the actually measured temperature of a reaction material input plate is greater than the set temperature of the micro-reaction experiment; step nine, determining whether the actually measured temperature of the reaction material input plate is lower than the set temperature of the micro-reaction experiment; step ten, reducing the temperature of the reaction material input plate; step eleven, reducing the temperature of the mixing material output plate; step twelve, increasing the temperature of the reaction material input plate; and step thirteen, increasing the temperature of the mixing material output plate. Therefore, the reaction temperature in the micro-reaction process can be controlled effectively and accurately.

Owner:XIAN UNITED PRESSURE VESSEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com