Gas purification reactor and gas purification method

A gas purification and reactor technology, applied in chemical instruments and methods, inert gas compounds, specific gas purification/separation, etc., can solve problems such as high cost and complex structure, achieve simple structure, improve purification effect, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

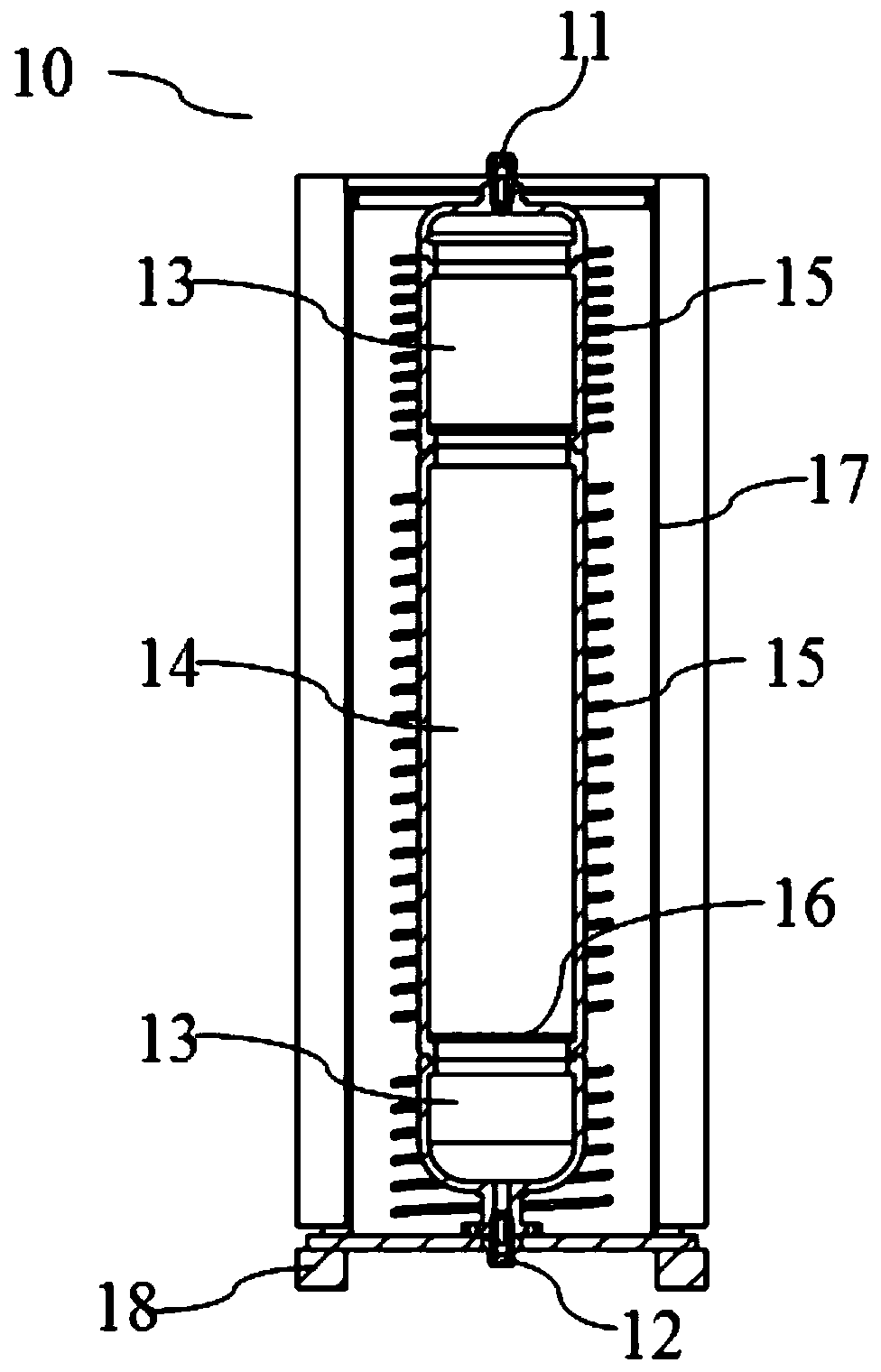

[0026] In the gas purification reactor 10 provided by the present invention, an air inlet 11 and an air outlet 12 are respectively arranged at both ends, the air inlet 11 is connected with the furnace body pipeline, receives used inert gas for crystal growth containing impurities, and the air outlet 12 Connect with other reactors or gas pipelines. The gas purification reactor 10 is filled with gas purification materials. In this embodiment, the gas purification materials can be iron-based, copper-based, nickel-based or composite oxygen carrier materials, preferably with a small amount of catalyst. The gas purification material catalyzes the oxidation of carbon-containing gas and / or hydrogen-containing gas in the inert gas, and absorbs impurities in the gas.

[0027] The gas purification reactor 10 includes at least one gas buffer chamber 13 and at least one gas purification chamber 14 . One end or two ends of the gas purification chamber 14 are connected to a gas buffer chamb...

Embodiment 2

[0035] This embodiment provides a gas purification method using the gas purification reactor 10 as described above, comprising the following steps:

[0036] filling the gas purification chamber 14 of the gas purification reactor 10 with gas purification material;

[0037] Heating the gas purification chamber to the corresponding temperature T 1 , Heating the gas buffer chamber to the corresponding temperature T 2 ;

[0038] The gas enters from the gas inlet 11 of the gas purification reactor 10 and is discharged from the gas outlet 12 .

[0039] Of course, a plurality of gas purification reactors 10 can also be connected to each other, for example, a plurality of gas purification reactors 10 are connected in series through an inlet 11 and a gas outlet 12, or a plurality of gas purification reactors 10 are connected in series through an inlet 11. The gas outlet 12 and the gas pipeline are connected in parallel with each other.

[0040] The gas inlet 11 and the gas outlet 12 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com