Large-scale production method for preparing high purity gallium

A production method and high-purity technology, applied in the field of purification, can solve the problems of high energy consumption, high gallium consumption in the process, unstable quality, etc., and achieve the effects of low energy consumption, consistency, and high conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

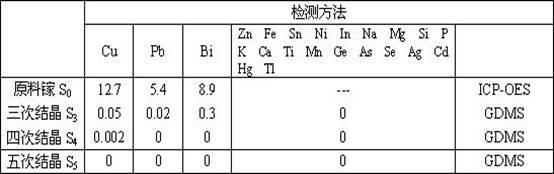

[0016] Example 1: Using the above process conditions, five partial crystallization operations were carried out, and the purification effect is shown in Table 1, wherein S 0 is the raw gallium, S 4 is the solid phase produced by the 4th partial crystallization, S 5 This is the solid phase produced by the 5th partial crystallization.

[0017] Table 1. Content of impurity elements

[0018]

[0019] Note: "---" means not detected; "0" means less than the detection limit

Embodiment 2

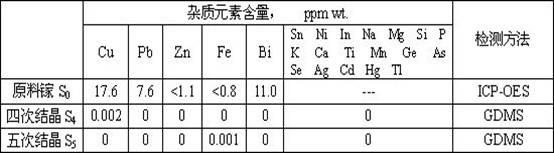

[0020] Embodiment 2: Adopt above-mentioned process condition, carry out five partial crystallization operations, wherein S 0 is the raw gallium, S 3 is the solid phase produced by the third partial crystallization, S 4 is the solid phase produced by the 4th partial crystallization, S 5 It is the solid phase produced by the fifth partial crystallization, and the purification effect is shown in Table 2.

[0021] Table 2. Content of impurity elements

[0022]

[0023] Note: "---" means not detected; "0" means less than the detection limit

Embodiment 3

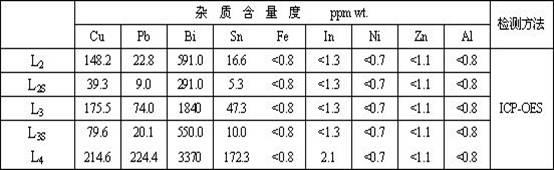

[0024] Example 3: Using the above process conditions, five partial crystallization operations were carried out, and the enrichment of impurities is shown in Table 3. where L 1 : represents the remaining liquid gallium after the first crystallization; L 2 : stands for L 1 Liquid gallium remaining after recrystallization; L 2S : stands for L 2 The solid phase produced after crystallization; L 3 : stands for L 2 Liquid gallium remaining after crystallization; L 3S : stands for L 3 The solid phase produced after crystallization; L 4 : stands for L 3 liquid gallium remaining after crystallization;

[0025] Table 3. Impurity enrichment content

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com