A large axial multi-stage mixed heat exchange butene oxidative dehydrogenation reactor

A mixed heat exchange and oxidative dehydrogenation technology, which is applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve the problems of limited capacity of a single unit and large pressure drop of distributors, and achieve easy large-scale and overall The effect of reducing the drop and increasing the productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

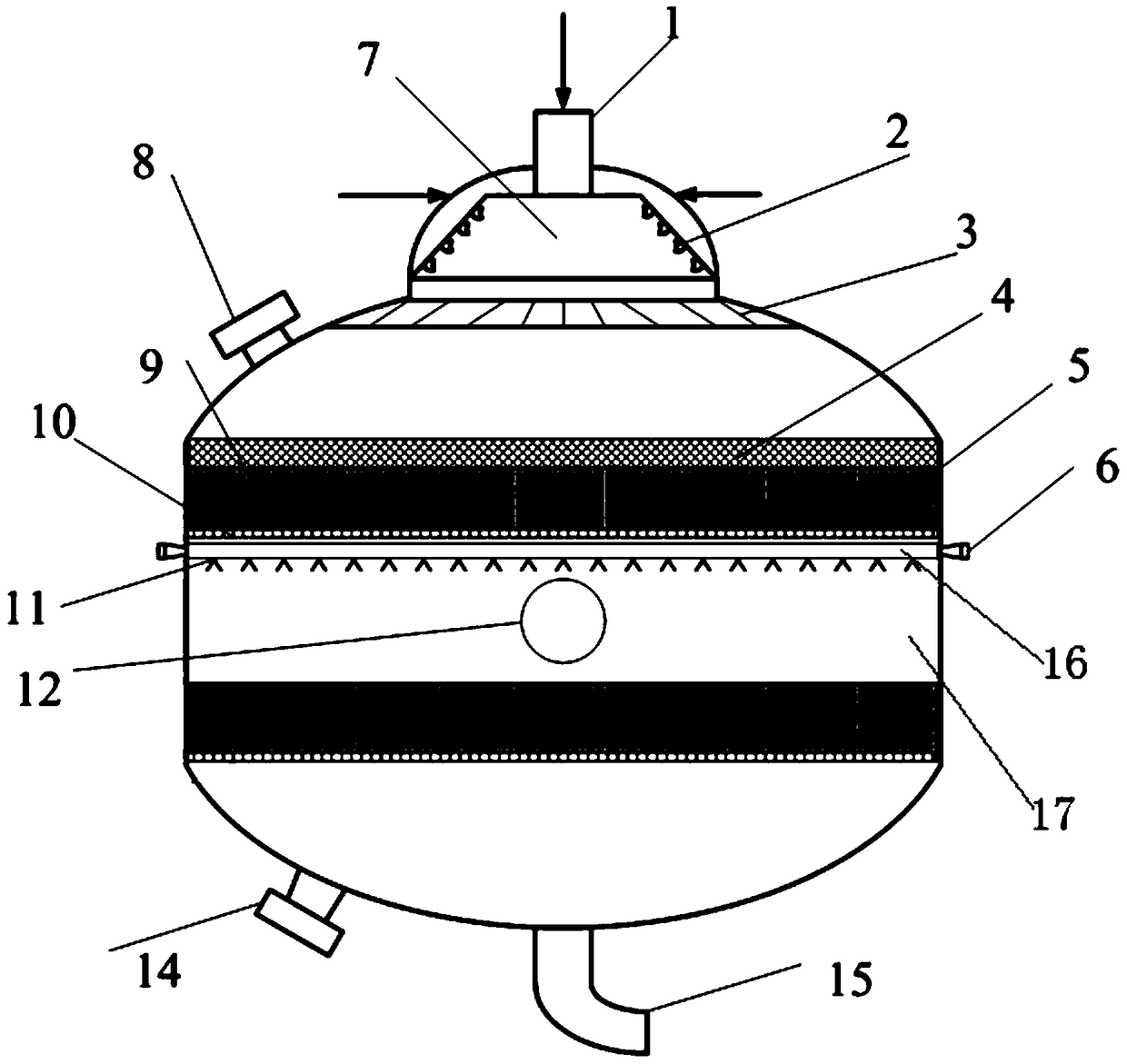

[0044] like figure 1 As shown, it is a large-scale axial multi-stage mixed heat-exchange butene oxidative dehydrogenation reactor with a direct heat exchange section. The upper part of the reactor shell is provided with a mixing device, and the reactor shell is provided with two axial catalyst beds. , contains a direct heat exchange section; the direct heat exchange section is located between the two axial catalyst beds, and the cold shock stream passes into the cooling shock material distribution pipe in the reactor shell, and then passes through the cooling shock nozzle and the upper axial catalyst. The outlet material after the bed layer reaction is uniformly distributed through the gas distributor. The hot and cold streams are mixed in the mixing space of the direct heat exchange section and directly heat exchanged, and then enter the axial catalyst bed below it for reaction. The specific structure of the reactor as follows:

[0045] The mixing device includes a straight ...

Embodiment 2

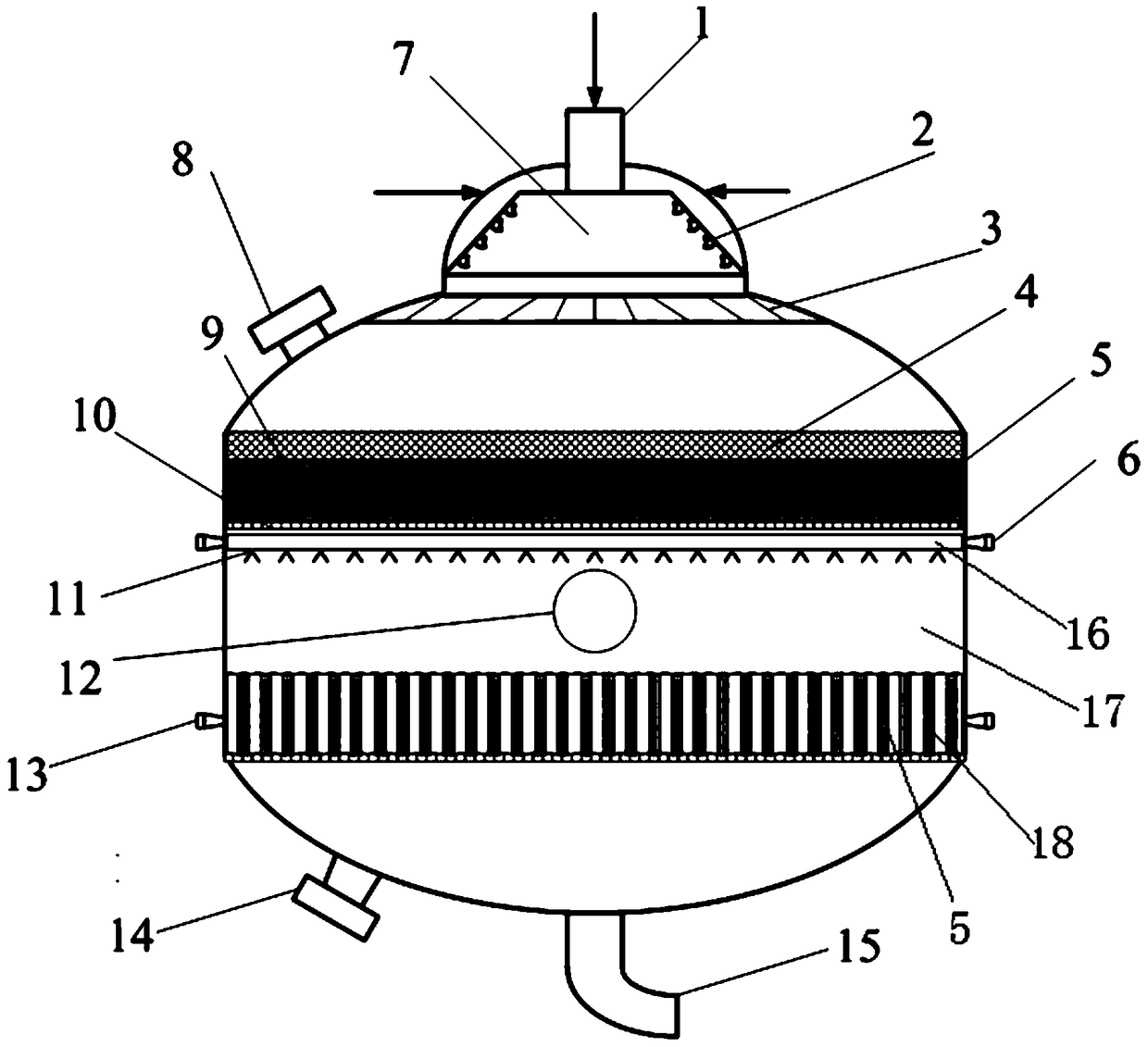

[0051] like figure 2 As shown, the upper part is provided with a direct heat exchange section, and the lower part is provided with a large-scale axial multi-stage mixed heat exchange type butene oxidative dehydrogenation reactor in which the catalyst is installed in the indirect heat exchange section in the tube, and adopts a structure similar to that of Example 1. , but the second section of the axial catalyst bed is a catalyst bed containing indirect heat exchange, and the catalyst bed containing indirect heat exchange includes heat exchange tube 18, catalyst 5 and heat exchange system, heat exchange tube 18 and axial catalyst bed The layers are arranged in a vertical manner, wherein the catalyst is packed in the heat exchange tube 18, and the outside of the heat exchange tube 18 communicates with the cooling medium, forming a heat exchange system in which the outside of the tube communicates with the heat exchange medium.

Embodiment 3

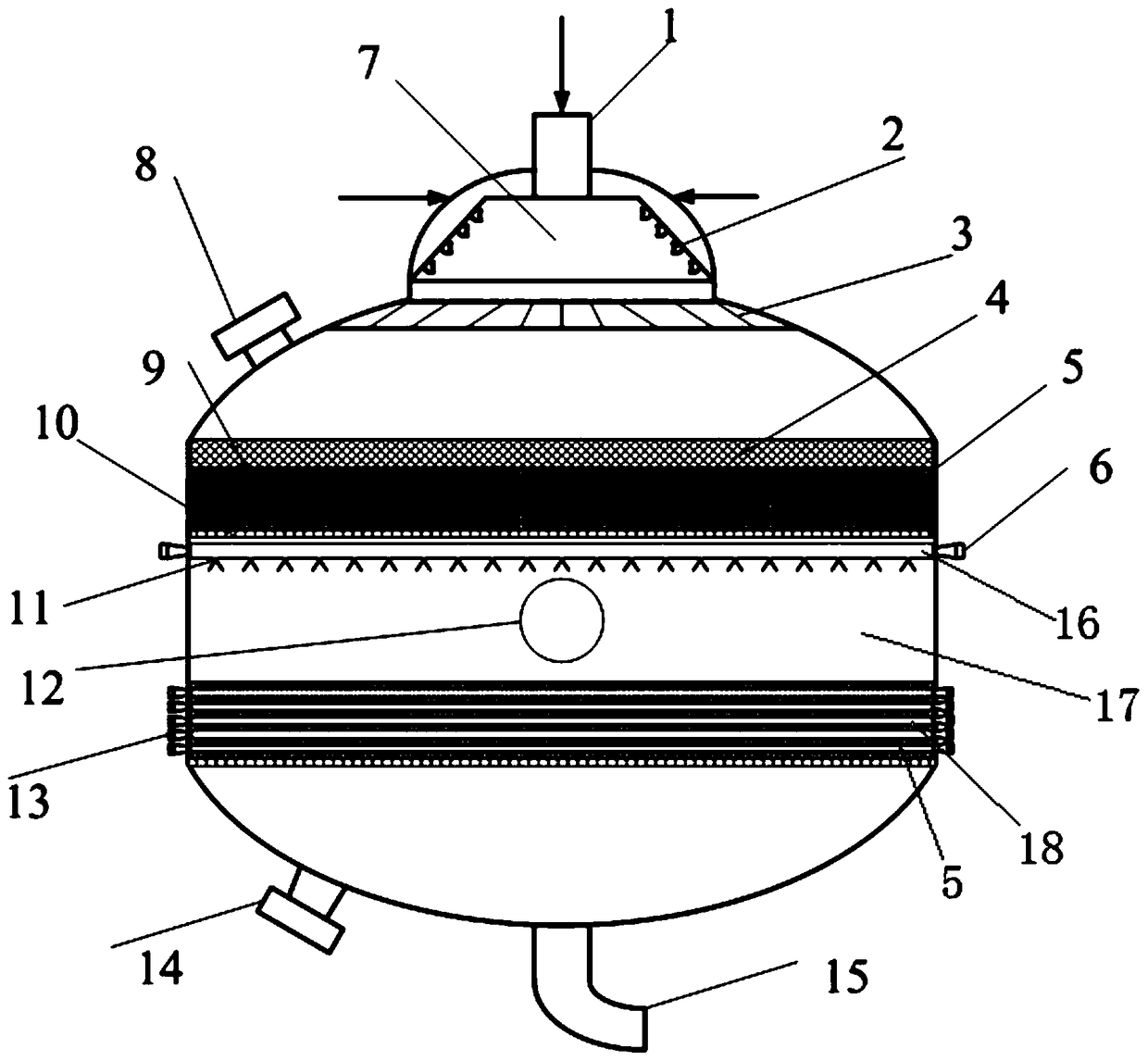

[0053] like image 3 As shown, the upper part is provided with a direct heat exchange section, and the lower part is provided with a large-scale axial multi-stage mixed heat exchange type butene oxidative dehydrogenation reactor in which the catalyst is installed in the indirect heat exchange section between the tubes. structure, but the second section of the axial catalyst bed is a catalyst bed containing indirect heat exchange, and the catalyst bed containing indirect heat exchange includes heat exchange tubes 18, catalyst 5 and heat exchange system, heat exchange tubes 18 and axial catalyst bed The layers are arranged in a parallel manner, wherein the catalyst is packed between the heat exchange tubes 18, and the cooling medium is passed through the heat exchange tubes 18 to form a heat exchange system in which the heat exchange medium passes through the tubes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com