A process for preparing synthetic natural gas

A technology for synthesizing natural gas and coal-based syngas, which is applied in the petroleum industry, gas fuel, fuel, etc., can solve the problems of small scale and achieve the effects of reduced temperature rise, low impurity content, and high calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

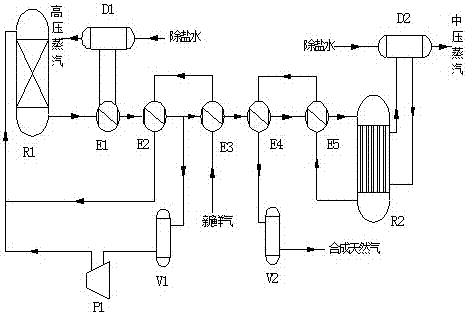

[0023] according to figure 1 As shown in the process flow, the pressure is 3.0MPa and the space velocity is 15000h -1 The composition (vol%) of the fresh coal-based syngas is: H 2 69.5, CH 4 8.21, CO 17.84, CO 2 1.95, H 2 O 2.0, N 20.5. The initial temperature of fresh coal-based syngas is 40°C, the temperature is 160°C after one-stage heat exchange (E3) with primary reaction product gas, and the temperature is 330°C after two-stage (E2) heat exchange, after mixing with circulating gas A reverse (R1) intake air is formed, the circulation ratio is 1.5, the gas inlet temperature is 270°C, and the temperature rises to 650°C after the reaction. After heat exchange through waste heat boiler one (E1), waste heat boiler one (E1) and steam drum ( D1) Heat exchange to generate high-pressure steam, the temperature of the product gas in the first reaction is 380°C, the product gas in the first reaction and the fresh gas undergo two heat exchanges (E2 and E3), the temperatures ar...

Embodiment 2

[0025] according to figure 1 As shown in the process flow, the pressure is 3.0MPa and the space velocity is 15000h -1 The composition (vol%) of the fresh coal-based syngas is: H 2 69.5, CH 4 8.21, CO 17.84, CO 2 1.95, H 2 O 2.0, N 2 0.5. The initial temperature of the fresh coal-based syngas is 40°C, the temperature is 160°C after one-stage heat exchange (E3) with the primary reaction product gas, and the temperature is 340°C after two-stage (E2) heat exchange, after mixing with the circulating gas A reverse (R1) intake air is formed, the circulation ratio is 1.4, the gas inlet temperature is 290°C, and the temperature rises to 665°C after the reaction. After heat exchange through waste heat boiler one (E1), waste heat boiler one (E1) and steam drum ( D1) Heat exchange to generate high-pressure steam. The temperature of the first reaction product gas is 390°C. The first reaction product gas and the fresh gas undergo two heat exchanges (E2 and E3), and the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com