A kind of preparation method of hydrogenated bisphenol A

A technology for hydrogenating bisphenol and bisphenol is applied in hydrogenation preparation, chemical instruments and methods, catalyst activation/preparation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

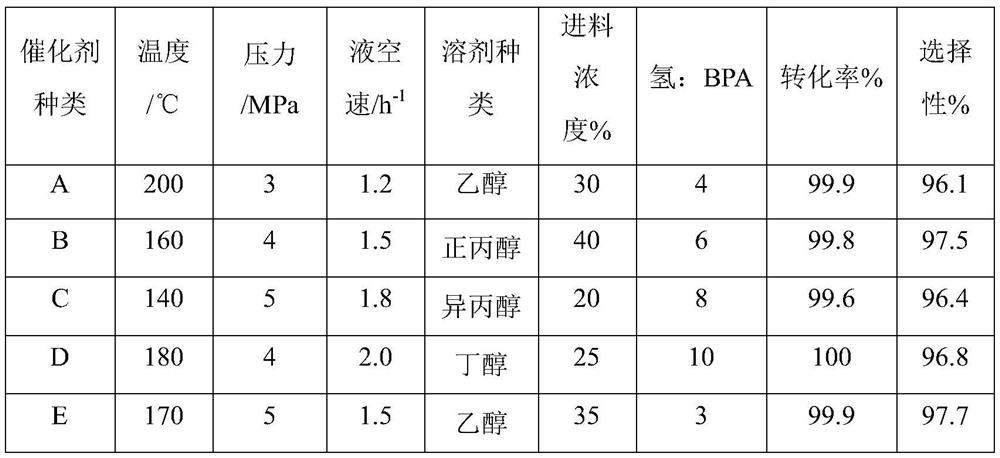

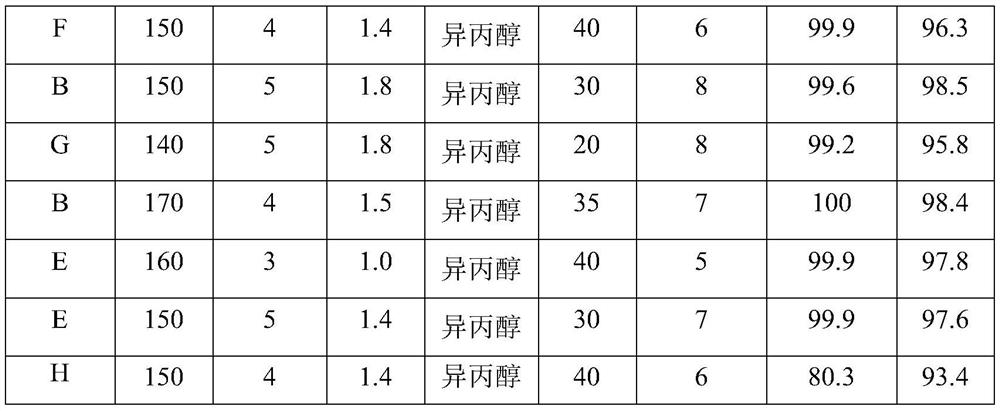

Examples

Embodiment 1

[0026] Add 500ml of water and 100g of microsphere silica carrier into a 1L autoclave successively. After sealing, the temperature is raised to 160°C for 3 hours. When the temperature drops below 50°C, the material is filtered, the filter cake is collected, and dried. required carrier. The catalyst preparation is carried out in a closed reaction vessel according to the following steps. ①Preparation of nickel-ammonia solution: Slowly add ammonia solution dropwise to 500ml of 2M nickel nitrate solution to make the pH value 8.5 to prepare a clear nickel-ammonia complex solution with a nickel content of 16%. ② Impregnation: Take 80 g of the above-mentioned carrier and add it to the nickel-ammine complex solution of ①, control the temperature at 65°C, and keep the impregnation for 4 hours under the condition of a stirring pressure of -0.06MPa, and the impregnation is completed. ③Separation, drying, and calcination at 350°C for 5 hours to obtain a semi-finished catalyst. ④ 100 mL o...

Embodiment 2

[0028] Add 500ml of water and 100g of microsphere silica carrier into a 1L autoclave successively, seal and heat up to 120°C for 4 hours, filter the material after the temperature drops below 50°C, collect the filter cake, and dry to obtain required carrier. The catalyst preparation is carried out in a closed reactor according to the following steps. ①Preparation of nickel-ammonia solution: slowly add the ammonia solution dropwise to 500ml of 4M nickel nitrate solution to make the pH value 9.0 to prepare a clear nickel-ammonia complex solution with a nickel content of 18%. ② Impregnation: 80 g of the above-mentioned carrier was added to the nickel ammine complex solution of ①, the temperature was controlled at 80°C, and the immersion was completed under a stirring pressure of -0.08 MPa for 6 hours. ③Separate, dry, and calcinate at 500°C for 3 hours to obtain a semi-finished catalyst. ④ 100 mL of 0.04M manganese nitrate solution was evenly sprayed on the above-mentioned semi-...

Embodiment 3

[0030]Add 500ml of water and 100g of microsphere silica carrier into a 1L autoclave successively. After sealing, the temperature is raised to 180°C for 2 hours. When the temperature drops below 50°C, the material is filtered and dried to obtain the desired carrier. The catalyst preparation is carried out in a closed reactor according to the following steps. ①Preparation of nickel-ammonia solution: Slowly add ammonia solution dropwise to 500ml 3M nickel nitrate solution to make the pH value 10.0 to prepare a clear nickel-ammine complex solution with a nickel content of 19.8%. ② Impregnation: 80 g of the above-mentioned carrier was added to the nickel ammine complex solution of ①, the temperature was controlled at 60°C, and the stirring pressure was -0.05MPa for 3 hours, and the impregnation was completed. ③Separate, dry, and bake at 500°C for 3 hours. ④ 100 mL of 0.4M cobalt nitrate solution was evenly sprayed on the above-mentioned semi-finished catalyst, dried, and calcined ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com