A hydrogenation method and hydrogenation device for a hydrogen-containing anthraquinone working liquid

A working fluid, hydroanthraquinone technology, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, inorganic chemistry, etc., can solve the problem of large investment and product production. High consumption, low production efficiency and other problems, to achieve the effect of speeding up the reaction rate and large investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

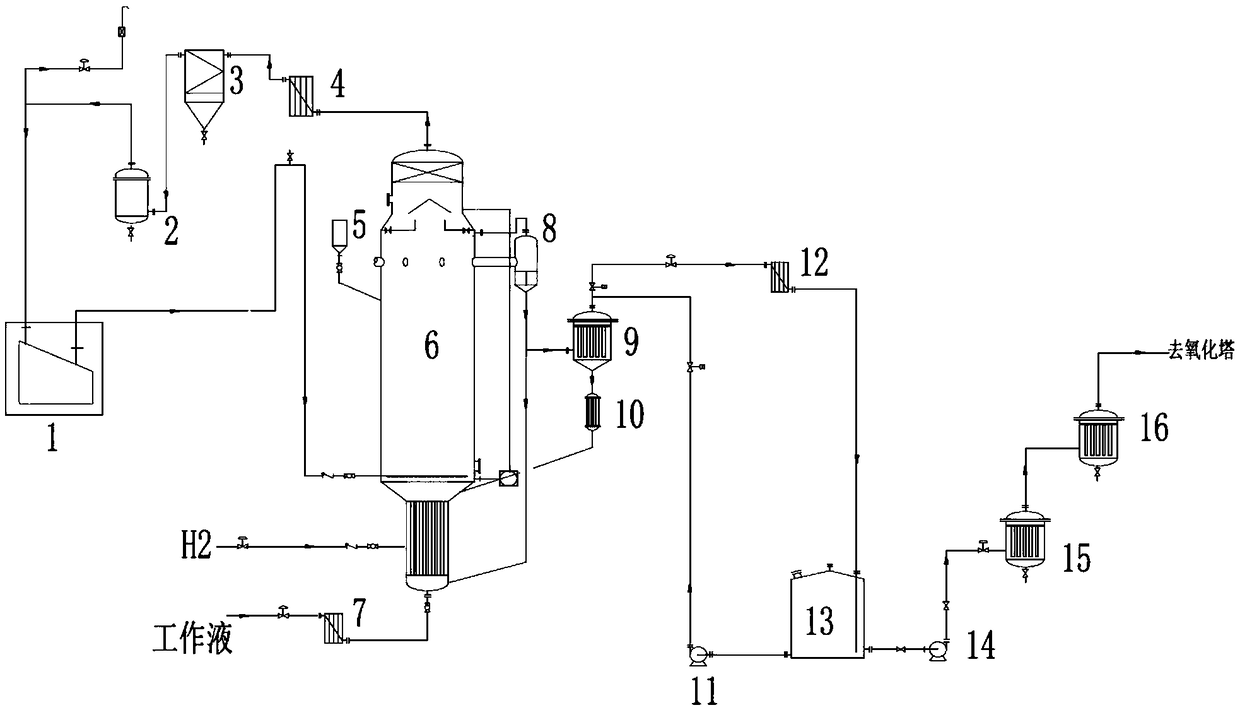

[0069] A hydrogenation method for a hydrogen-containing anthraquinone working solution, characterized in that it comprises the following steps:

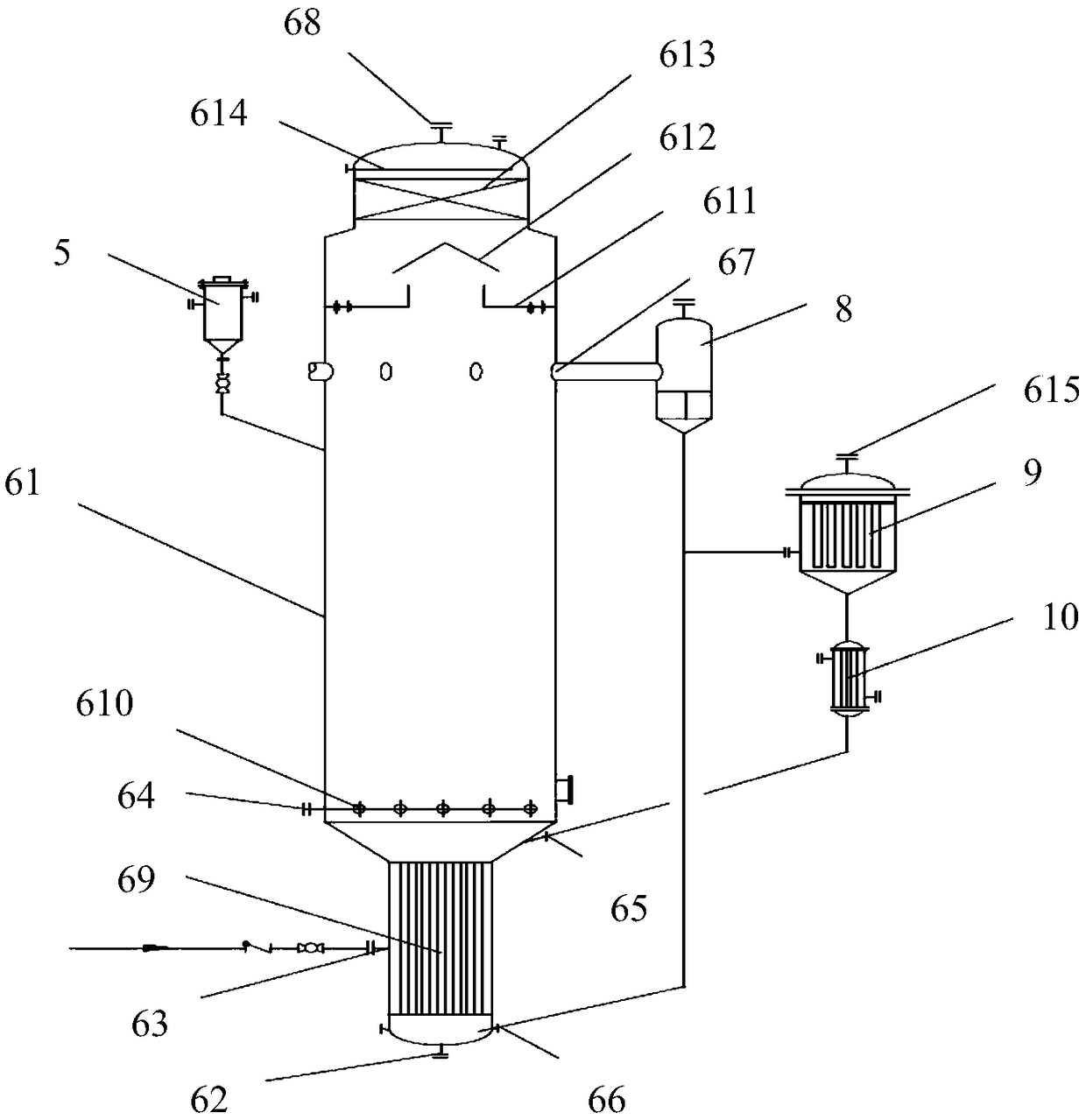

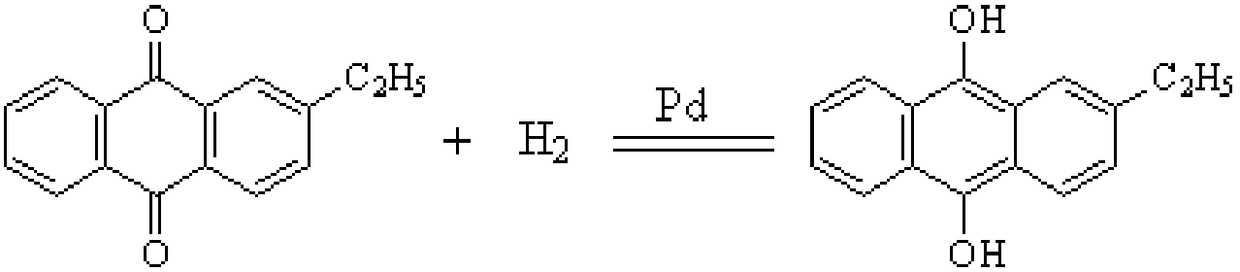

[0070] (1) Preparation of hydrogen-containing anthraquinone working solution: the hydrogen-containing gas and anthraquinone working solution are respectively passed into the fluidized bed 6, and the hydrogen-containing gas gas and anthraquinone working solution are mixed at the tubular membrane at the bottom of the fluidized bed Mix well in the container 69, and then the gas-liquid mixture enters the reaction section containing catalyst solid particles in the fluidized bed. Hydrogenation reaction is carried out under certain conditions to generate hydroanthraquinone working solution;

[0071] In the process of hydrogenation reaction, the gas-liquid-solid three items are maintained in a bubbling or turbulent state in the fluidized bed by the gas stripping effect of the circulating gas compressor 1, while the liquid-solid two items are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com