Method for preparing nitrogen-doped porous carbon nanomaterial by using carbon dioxide

A nitrogen-doped porous carbon and carbon dioxide technology, applied in chemical instruments and methods, nano-carbon, inorganic chemistry, etc., can solve problems such as harsh reaction conditions, and achieve low cost, large scalability, and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Passing excess carbon dioxide gas into an aqueous solution of hydrazine hydrate with a mass fraction of 98% carries out a chemical adsorption reaction, reaches adsorption equilibrium in 10 minutes, and obtains an aqueous solution of hydrazinoformate;

[0045] (2) Carbazate aqueous solution and magnesium powder are mixed according to a mass ratio of 4:1, and a complexation reaction occurs to form a uniform gel-like magnesium carbazate complex and magnesium powder mixture as a combustion precursor;

[0046] (3) Ignite the combustion precursor, a self-propagating combustion reaction occurs, and generate magnesium oxide and nitrogen-doped porous carbon nanomaterials; then wash the reaction product with 5mol / L hydrochloric acid aqueous solution to remove magnesium oxide impurities and obtain pure nitrogen-doped porous carbon carbon nanomaterials.

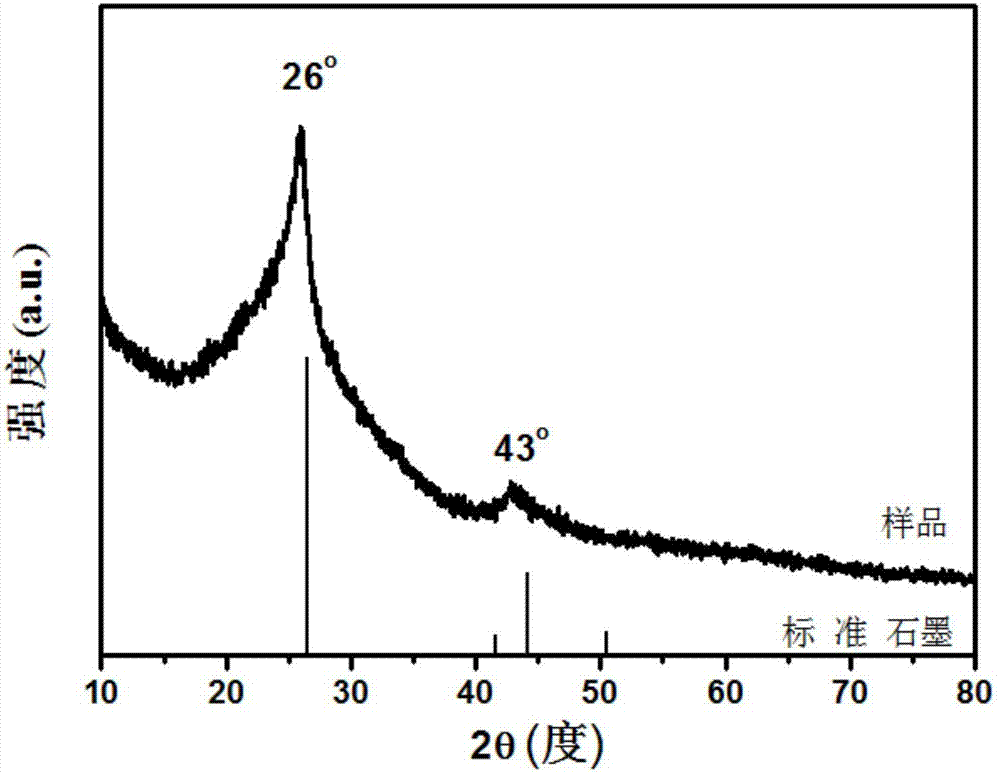

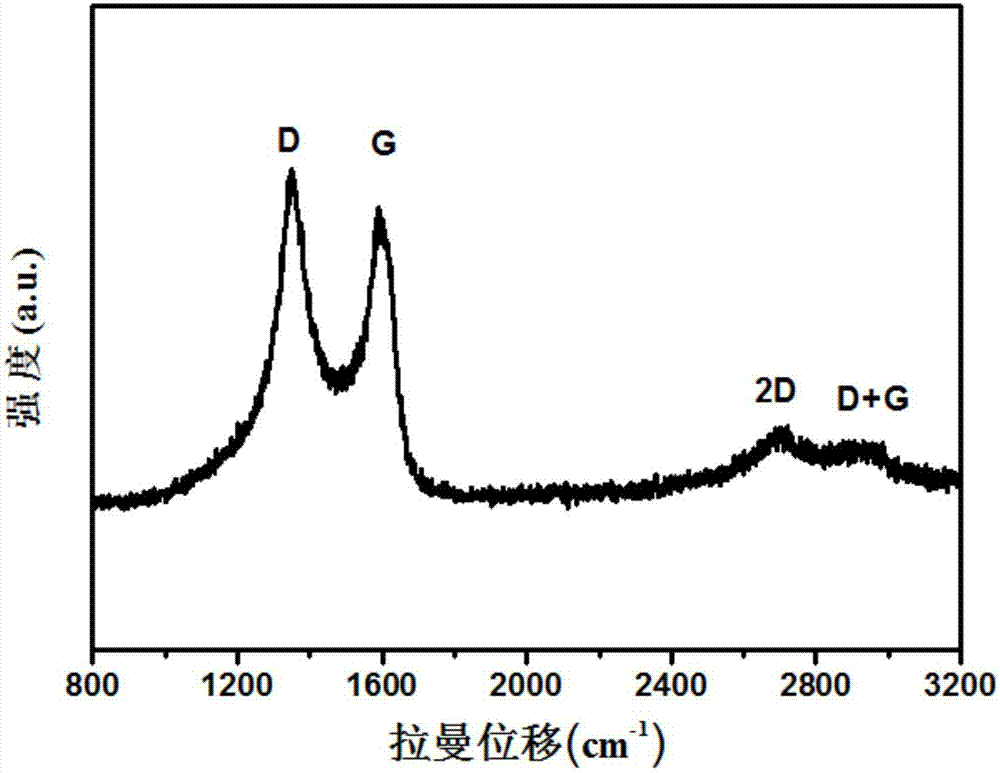

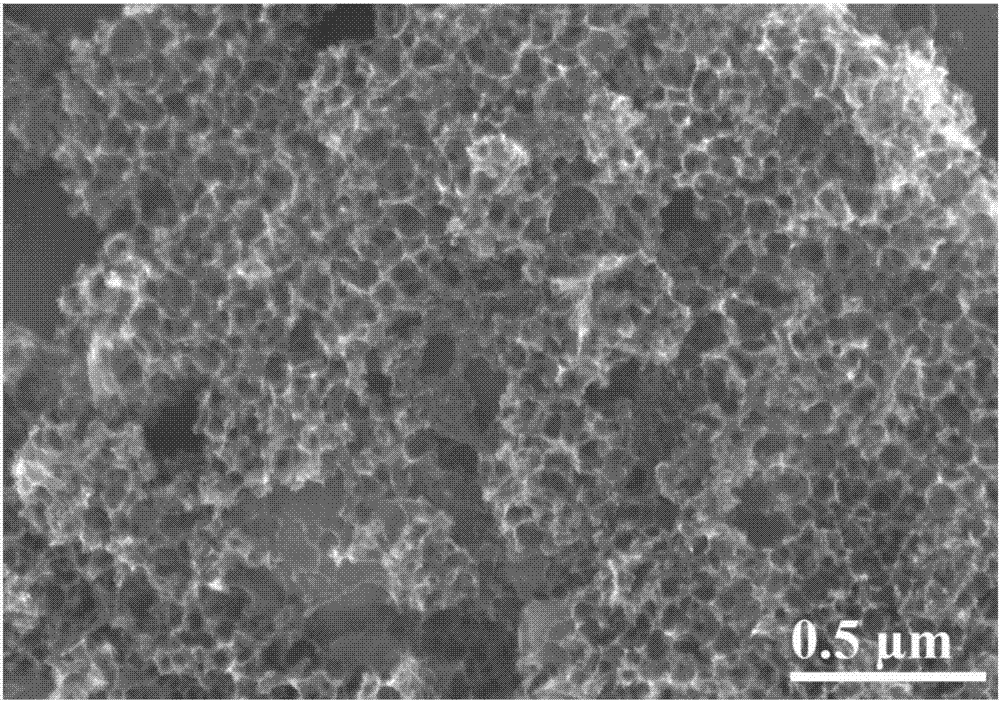

[0047] from figure 1 It can be seen from the XRD spectrum in the figure that the main peaks of the prepared carbon nanomate...

Embodiment 2

[0049] (1) passing excess carbon dioxide gas into an aqueous solution of hydrazine hydrate with a mass fraction of 60% to carry out a chemical adsorption reaction, reaching adsorption equilibrium in 10 minutes, and obtaining an aqueous solution of hydrazinoformate;

[0050] (2) The aqueous solution of carbazinate and magnesium powder are mixed according to a mass ratio of 6:1, and a complexation reaction occurs to form a mixture of a uniform gel-like magnesium carbazate complex and magnesium powder as a combustion precursor;

[0051] (3) Ignite the combustion precursor, a self-propagating combustion reaction occurs, and generate magnesium oxide and nitrogen-doped porous carbon nanomaterials; then wash the reaction product with 2mol / L hydrochloric acid aqueous solution to remove magnesium oxide impurities, and obtain pure nitrogen-doped porous carbon nanomaterials carbon nanomaterials.

[0052] The XRD results show that the main peaks of the prepared carbon nanomaterials are co...

Embodiment 3

[0054] (1) passing excess carbon dioxide gas into an ethanolamine aqueous solution with a mass fraction of 98% to carry out a chemical adsorption reaction, reaching adsorption equilibrium in 10 minutes, and obtaining a carbamate aqueous solution;

[0055] (2) The carbamate aqueous solution and magnesium powder are mixed according to the mass ratio of 5:1, and placed in an electric furnace at 90°C for 10 minutes, and a complexation reaction occurs to form a uniform gel-like magnesium carbamate complex and Magnesium powder mixture as a combustion precursor;

[0056] (3) Ignite the combustion precursor, a self-propagating combustion reaction occurs, and generate magnesium oxide and nitrogen-doped porous carbon nanomaterials; then wash the reaction product with 4mol / L hydrochloric acid aqueous solution to remove magnesium oxide impurities and obtain pure nitrogen-doped porous carbon carbon nanomaterials.

[0057] The XRD results show that the main peaks of the prepared carbon nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com