Precise temperature control system and method for micro reaction experiments

A temperature control system and micro-reaction technology, applied in control/regulation systems, temperature control, non-electric variable control, etc., can solve problems such as low reaction efficiency, large temperature or pressure fluctuations, and reactions that fail to meet design requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

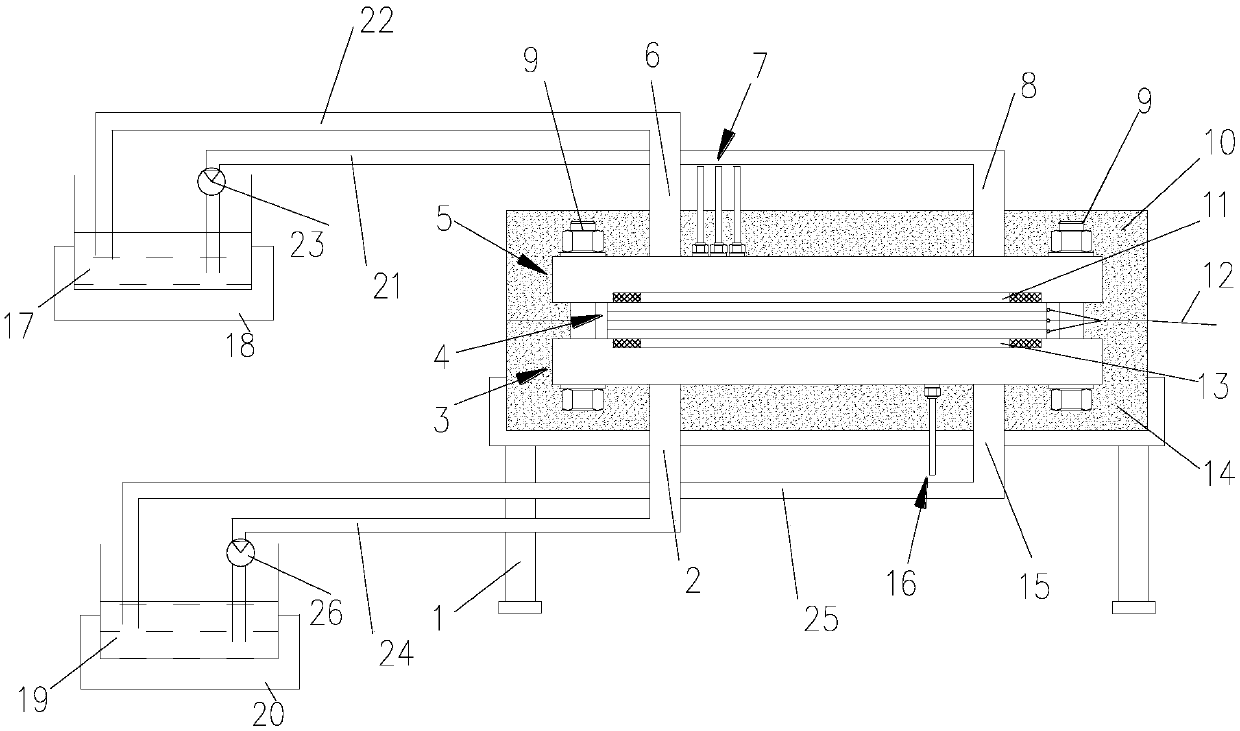

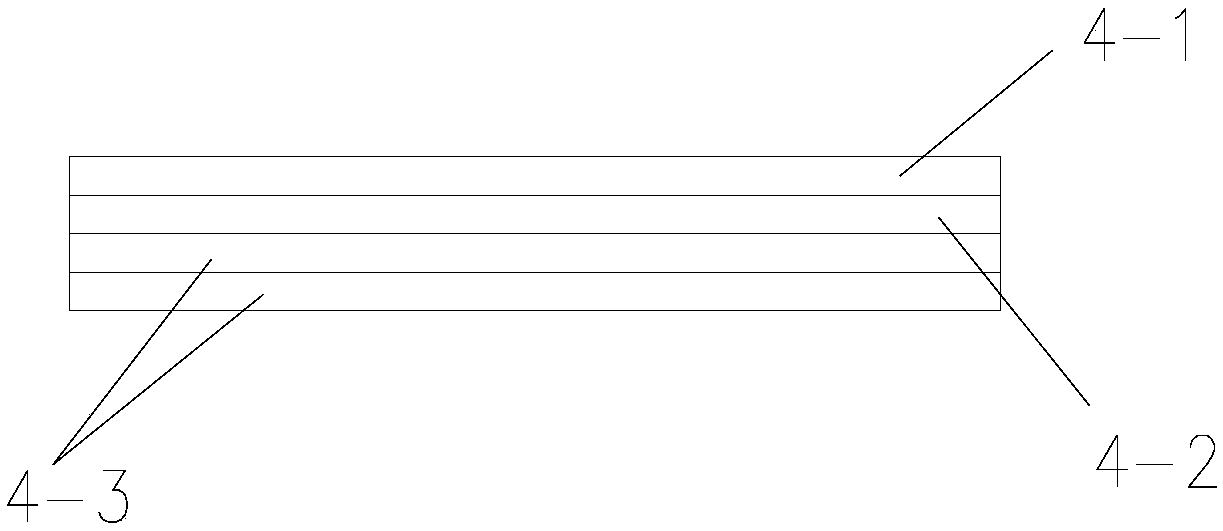

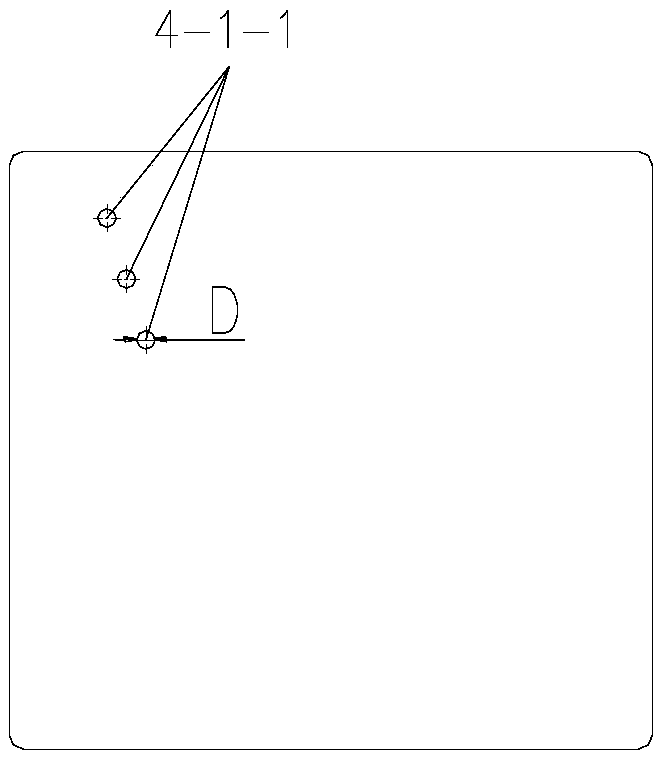

[0084] like Figure 1 to Figure 16 As shown, the present invention includes a microreactor and a temperature control system installed on an operating platform and connected to the microreactor, and the microreactor includes a lower insulation board 3, which is horizontally arranged on the support 1 from bottom to top, Microchannel reactor 4 and upper insulation plate 5, described microchannel reactor 4 comprises reaction material input plate 4-1, reaction material mixing plate 4-2 and mixed material output plate 4-3 fixedly connected successively from top to bottom ; The edge position of the reaction material input plate 4-1, the edge position of the reaction material mixing plate 4-2 and the edge position of the mixture output plate 4-3 are all provided with four temperature measuring thermocouples 12;

[0085]The reaction material mixing plate 4-2 is provided with an introduction channel 4-2-3 and a reaction flow channel 4-2-5, and one end of the introduction channel 4-2-3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com