Temperature control synthesis device

A synthesis device and drive device technology, applied in the direction of inorganic chemistry, non-metallic elements, metal hydrides, etc., can solve problems such as difficulty in ensuring the consistency of reaction vessel temperature, insufficient contact between solid and gas materials, and capacity expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiment of the present invention will be further described below by taking the synthesis of diborane as an example.

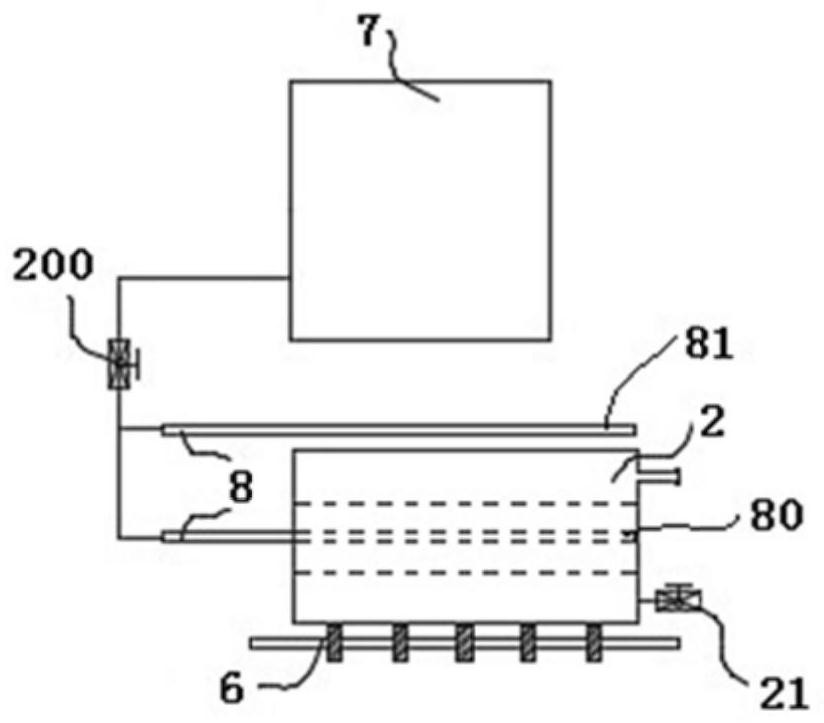

[0027] A specific embodiment of the temperature-controlled synthesis device of the present invention, the structural schematic diagram is as follows figure 1 As shown, it includes a diborane reaction tank 2, a temperature control system and a rolling machine 6. The temperature control system is a cooling system.

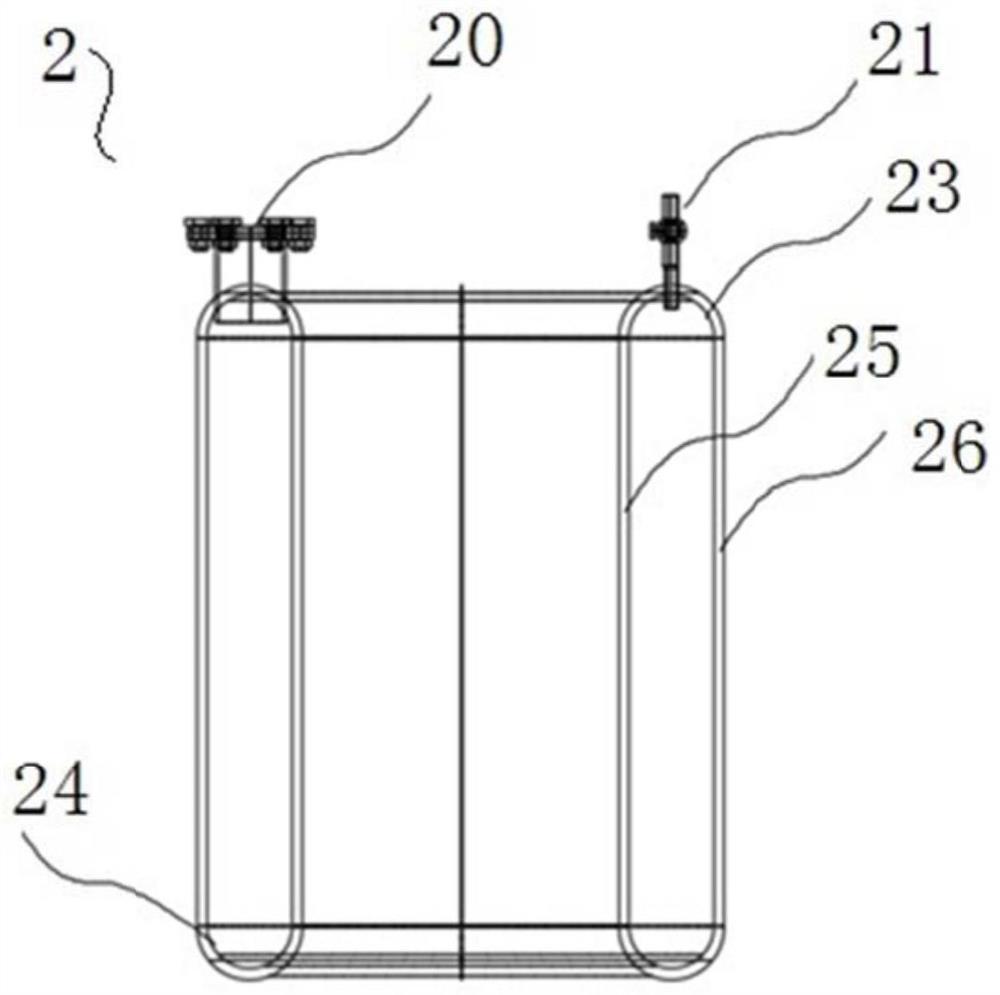

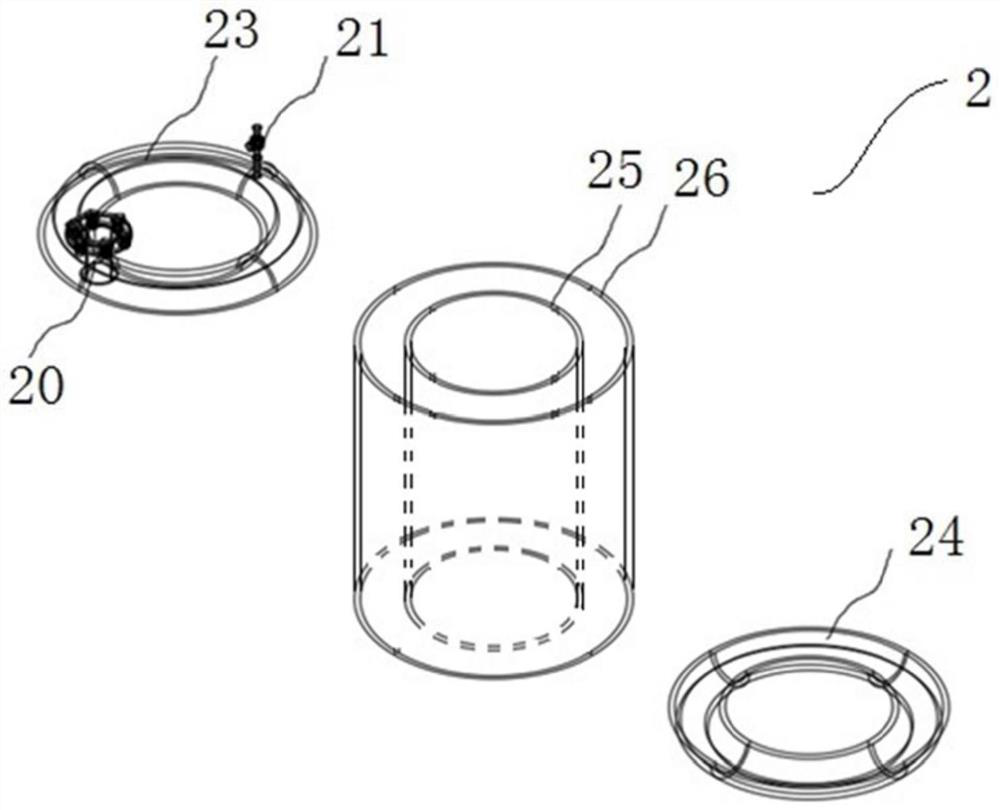

[0028] The structural representation of diborane reaction tank 2 is as figure 2 with image 3 As shown, it is a cylindrical tank with open ends, with a central cavity 201 and a sealed annular cavity 202 surrounding the central cavity 201. The sealed annular cavity 202 is composed of an inner cylinder 25 and an outer cylinder 26 arranged in parallel with each other. It is surrounded by the upper end cover 23 and the lower end cover 24, and the two ends of the inner cylinder are open. The upper end cover 23 and the lower end cover 24 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com