Patents

Literature

43results about "Hydride purification/stabilisation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

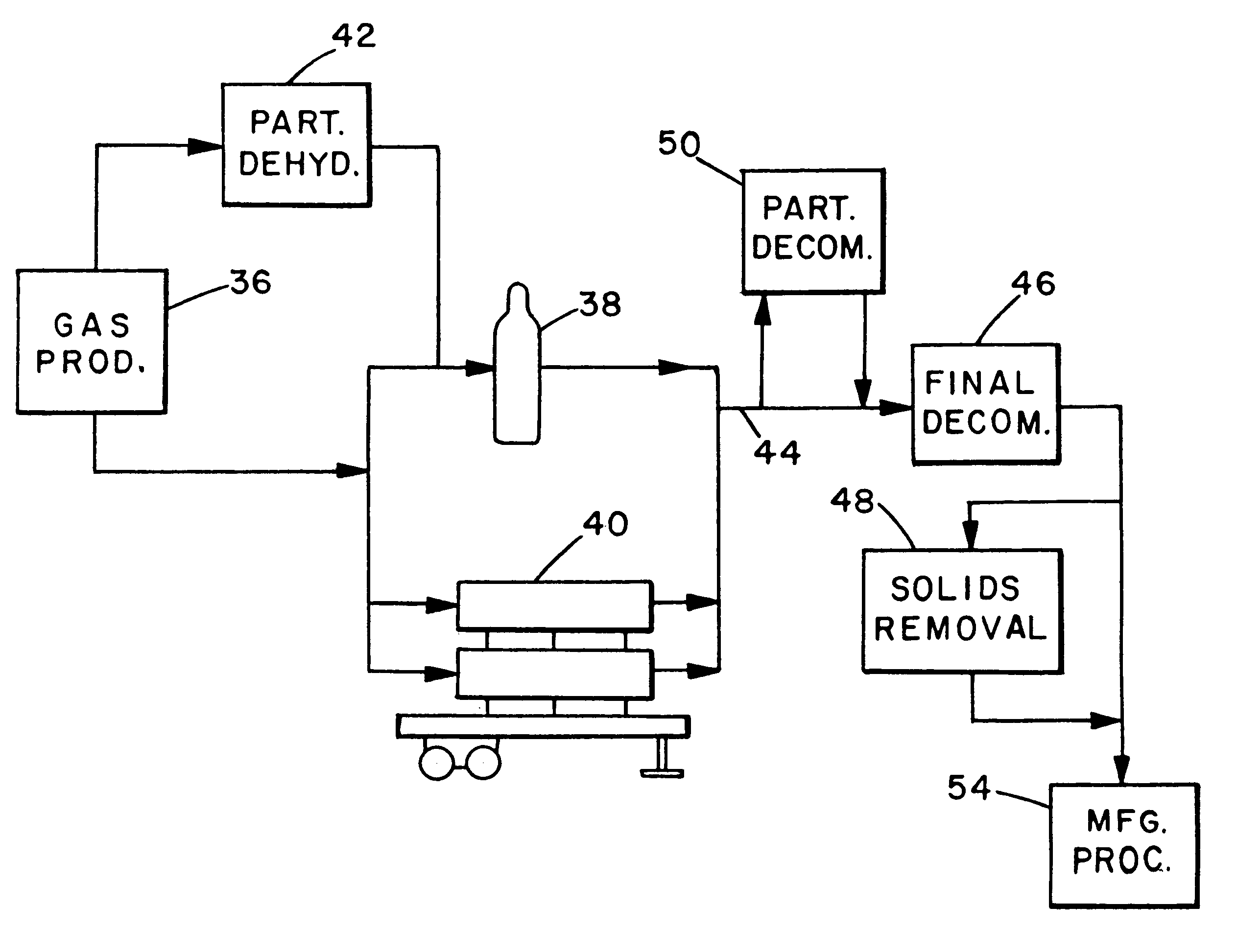

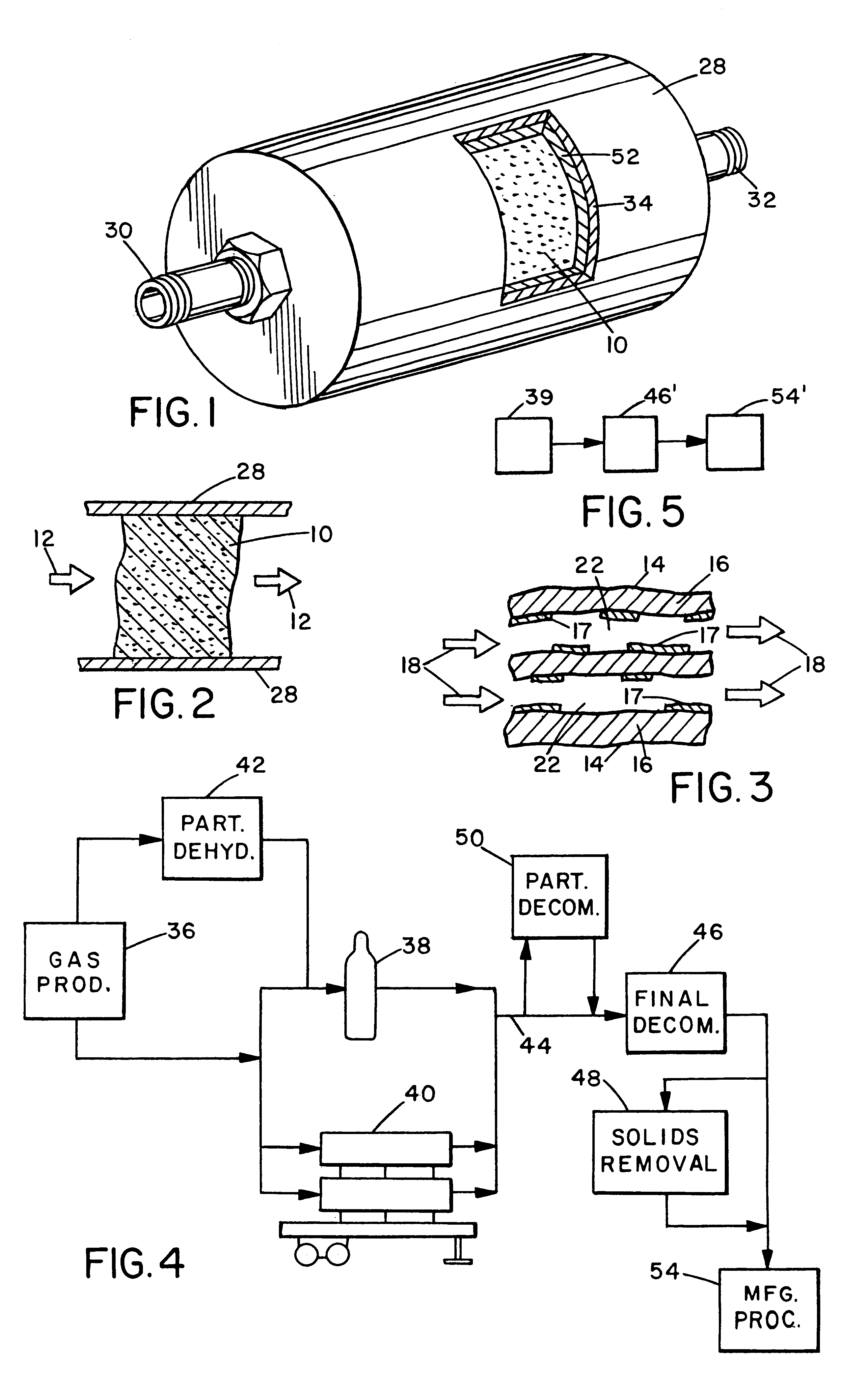

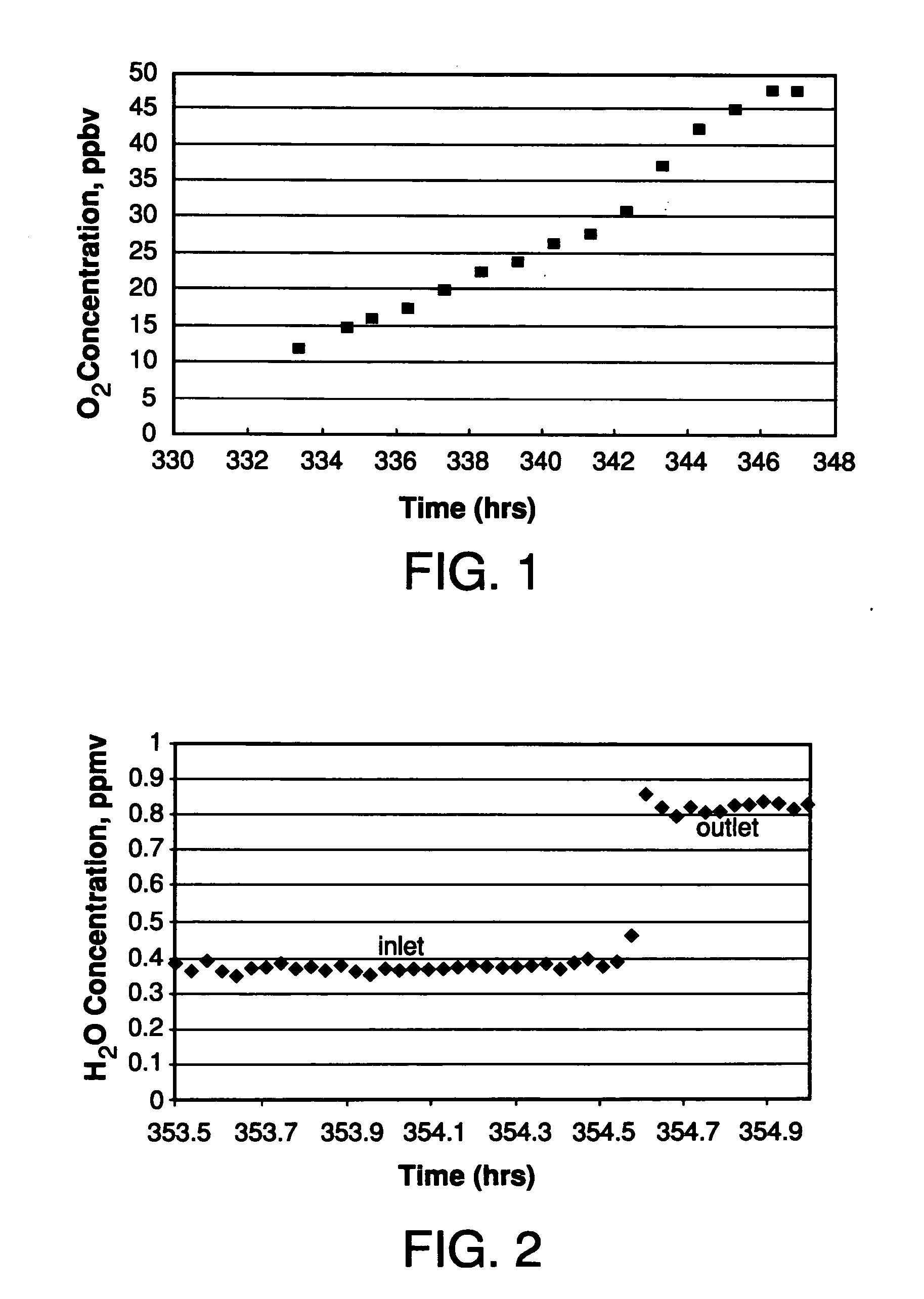

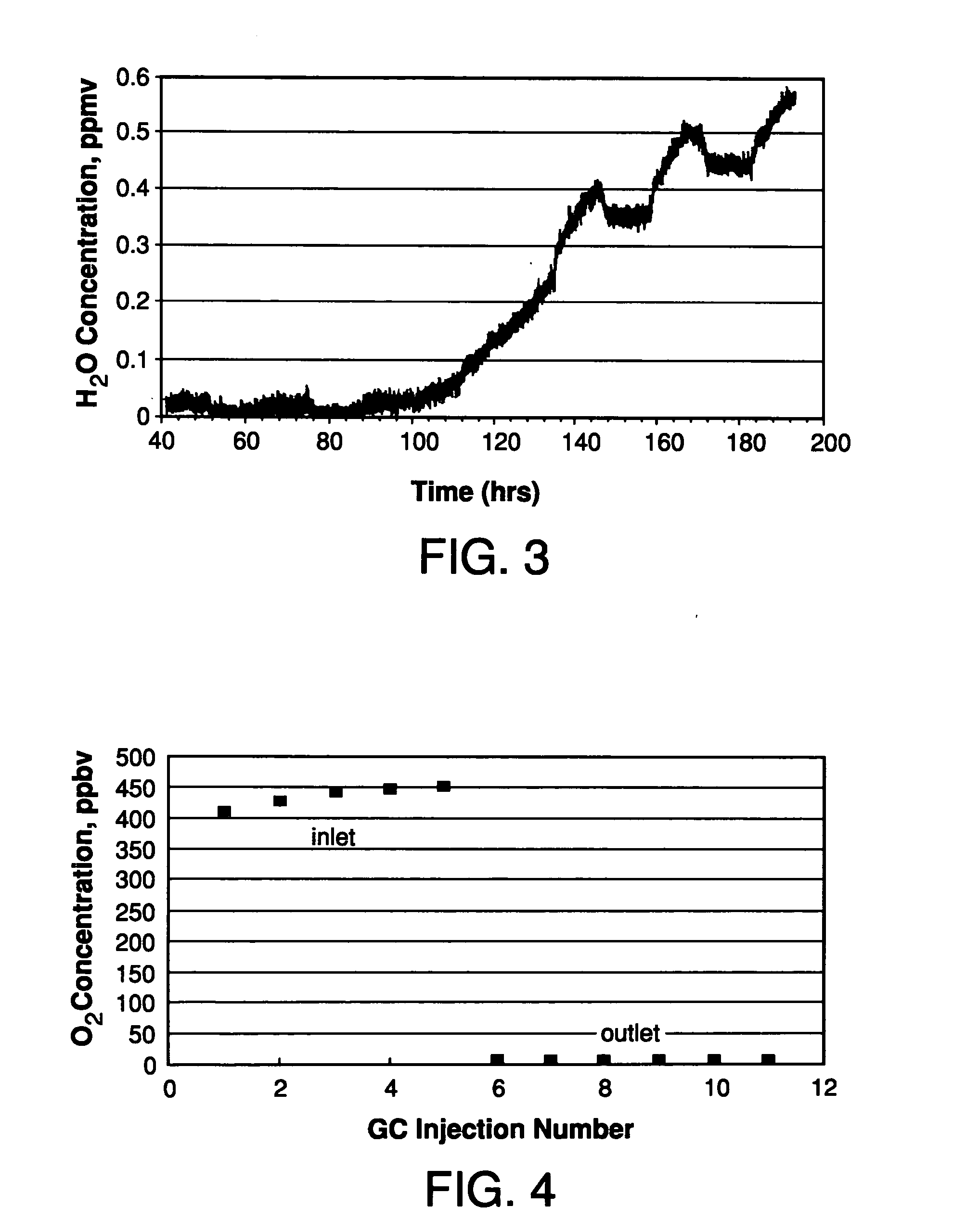

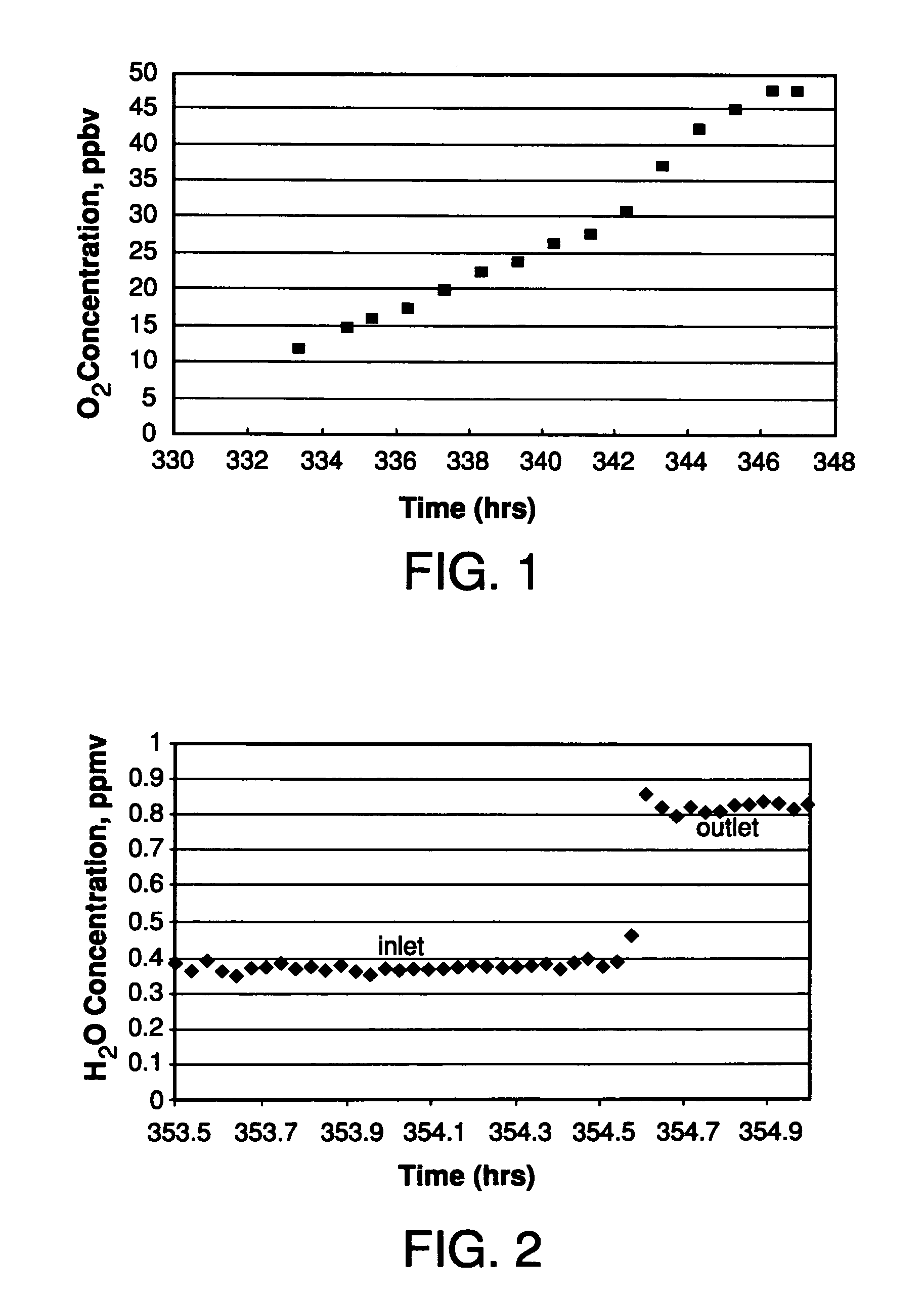

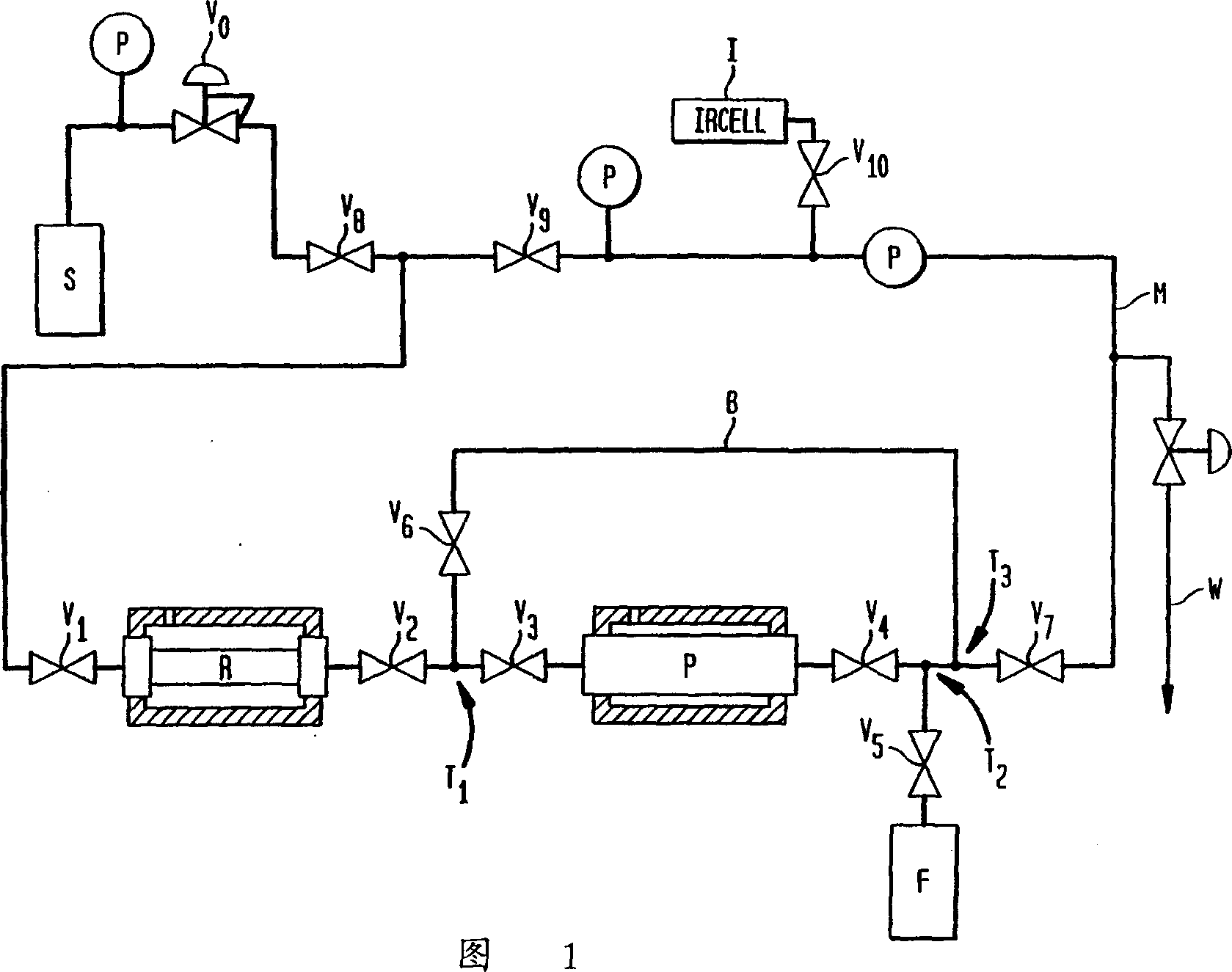

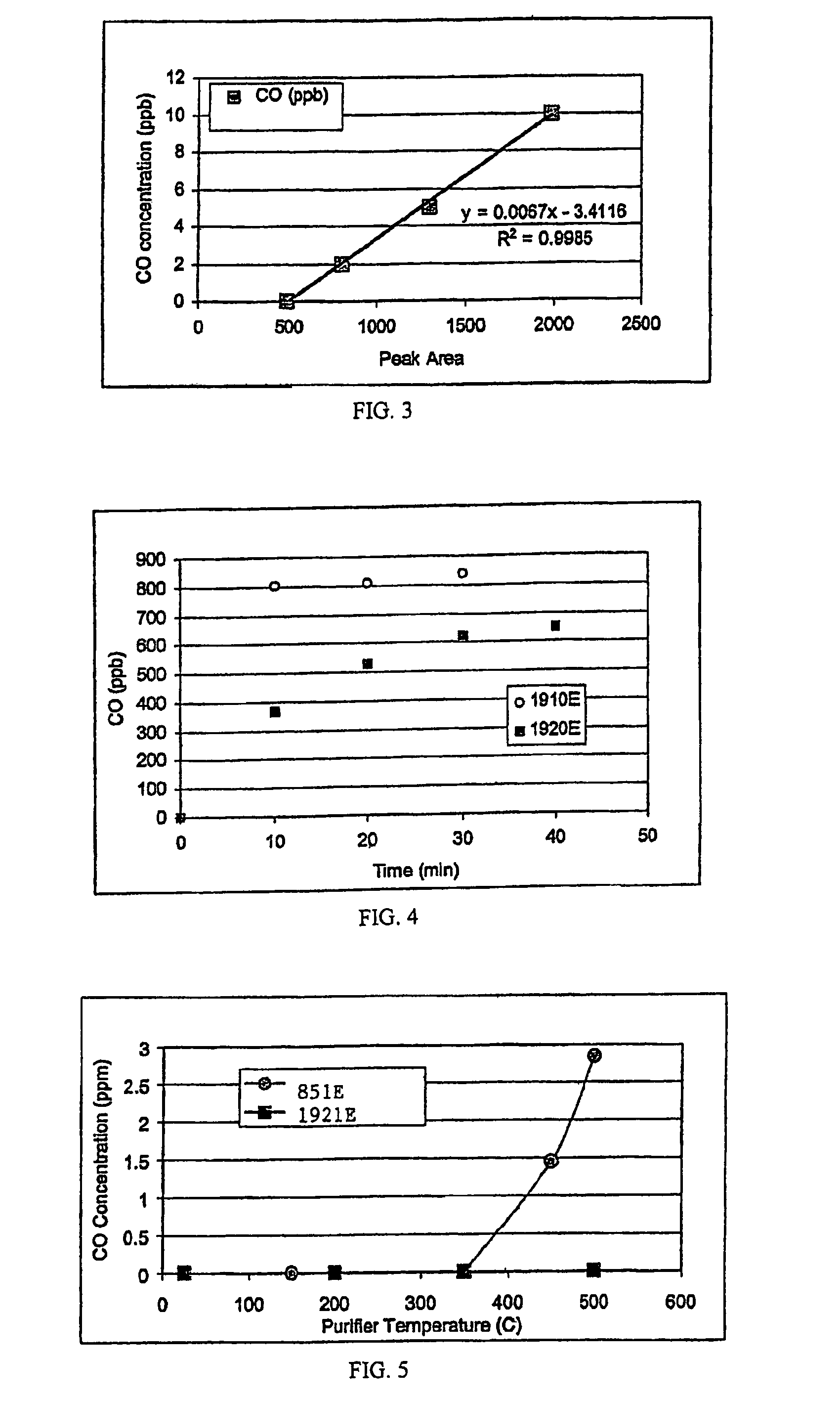

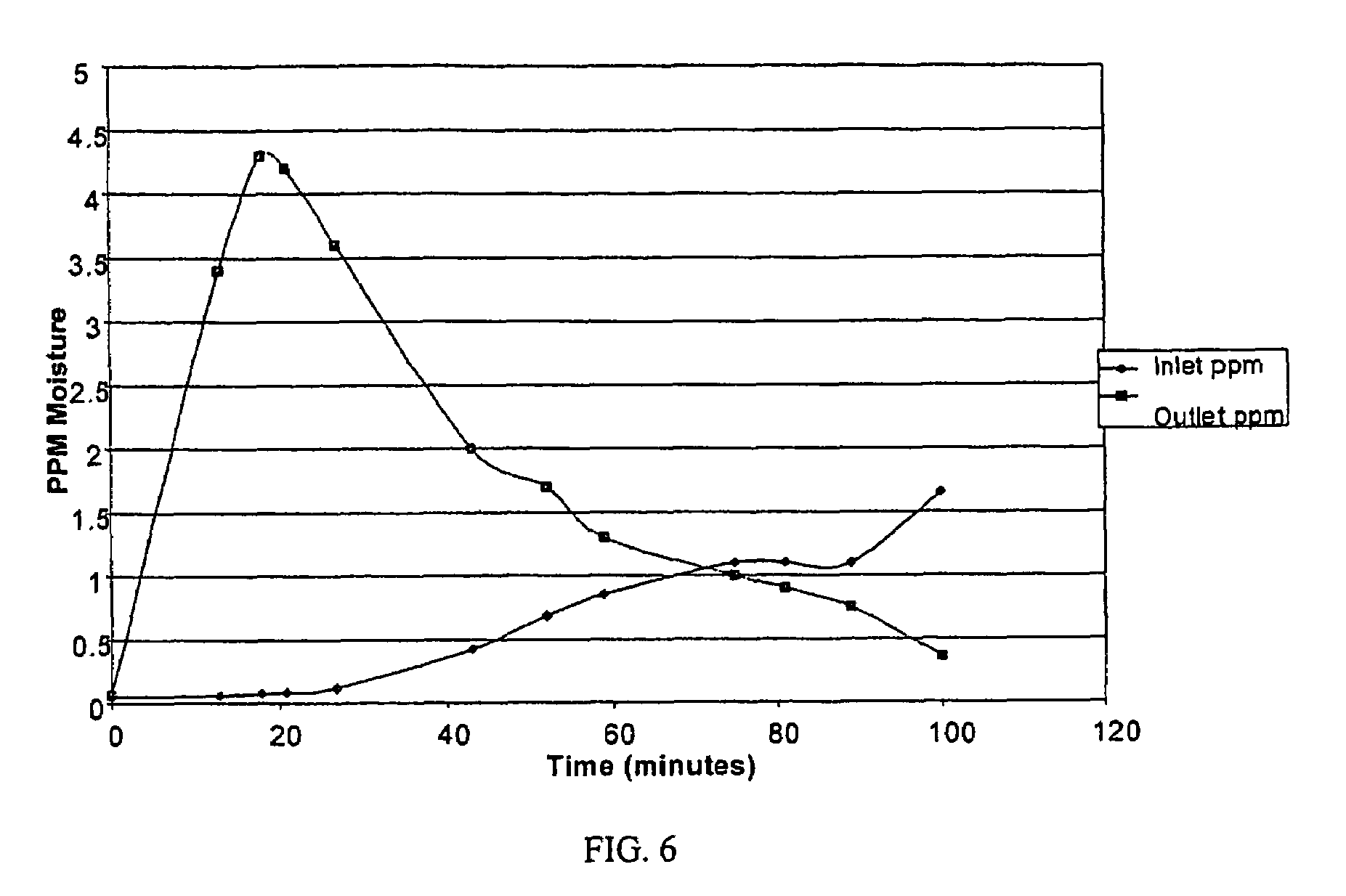

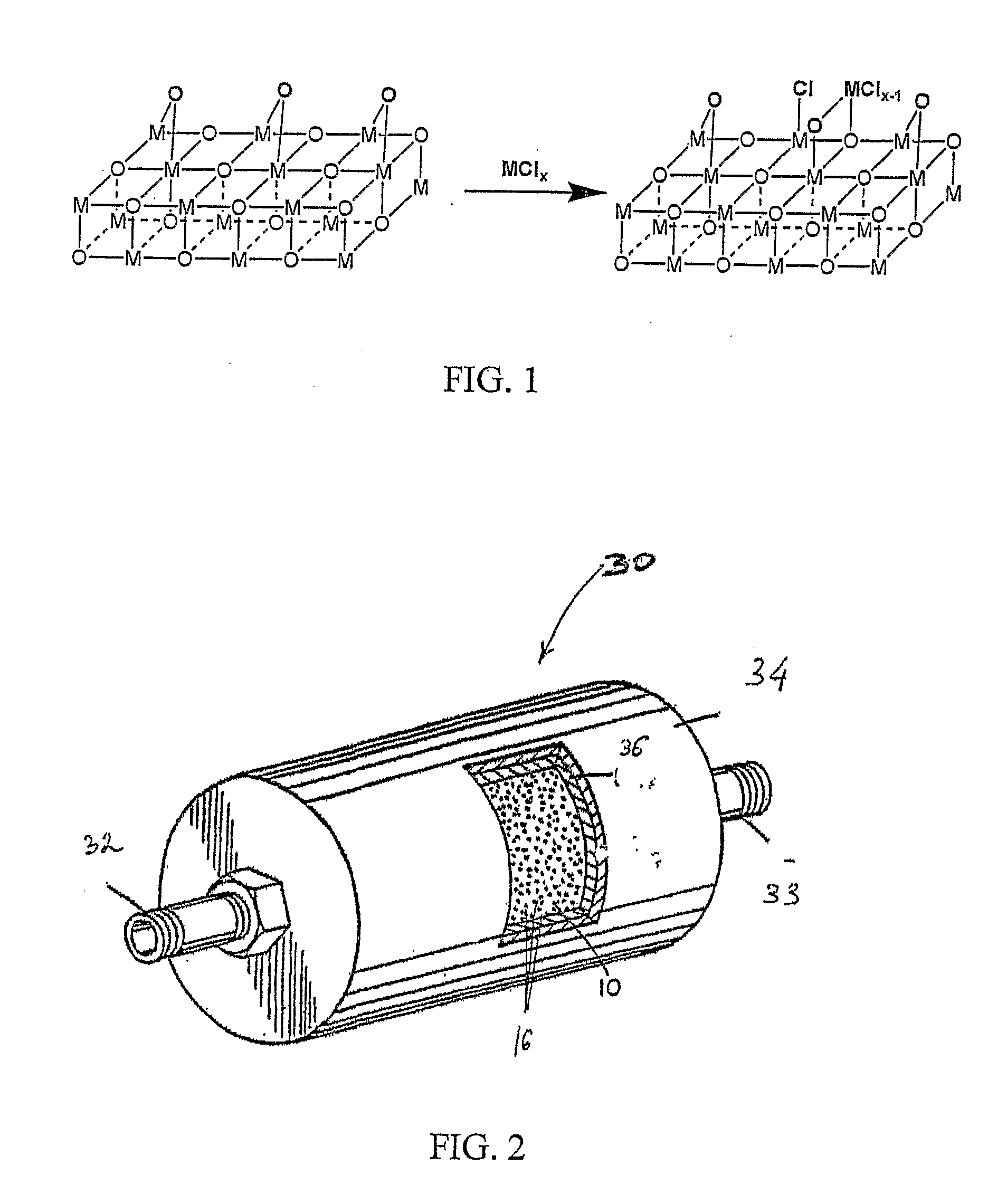

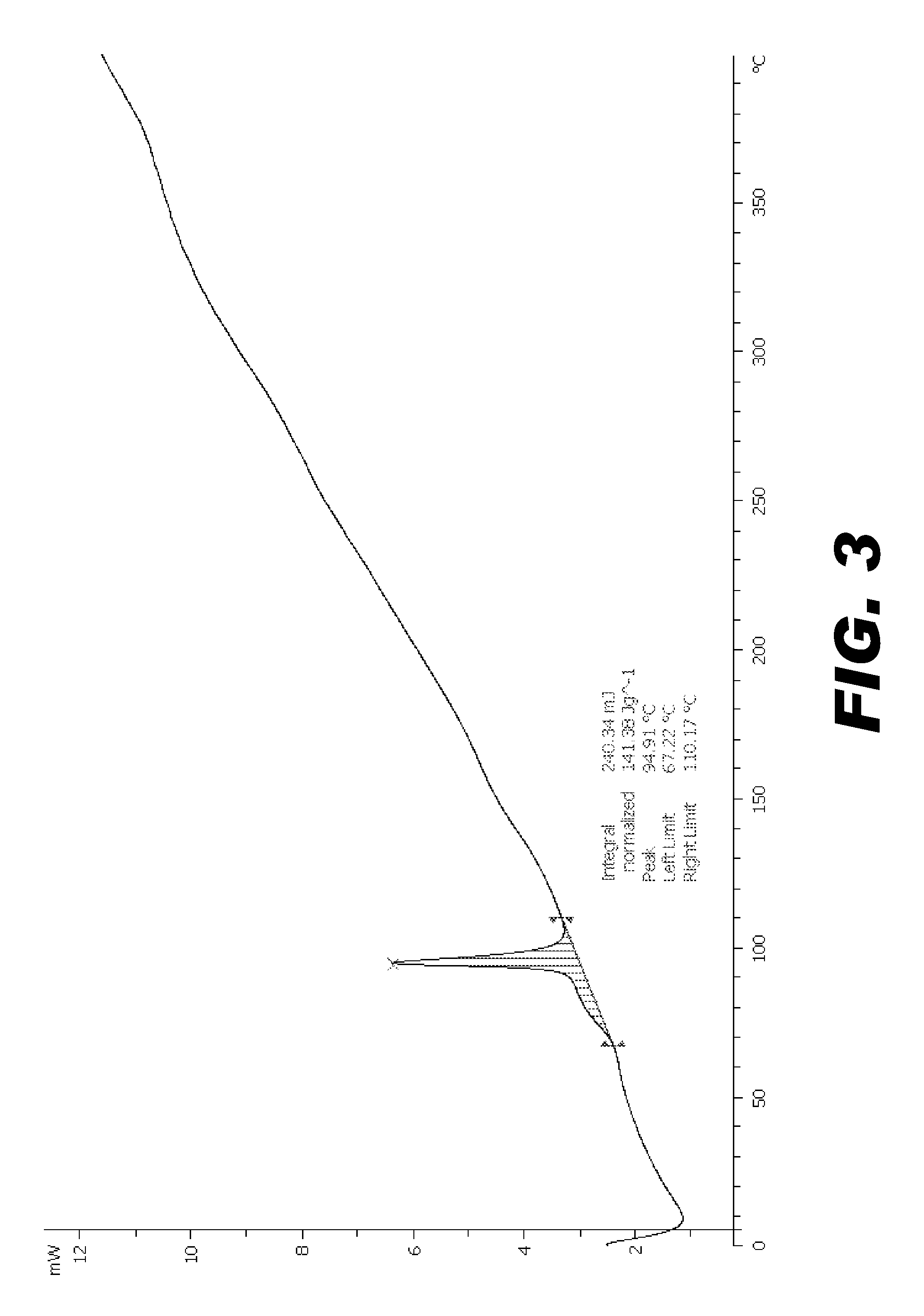

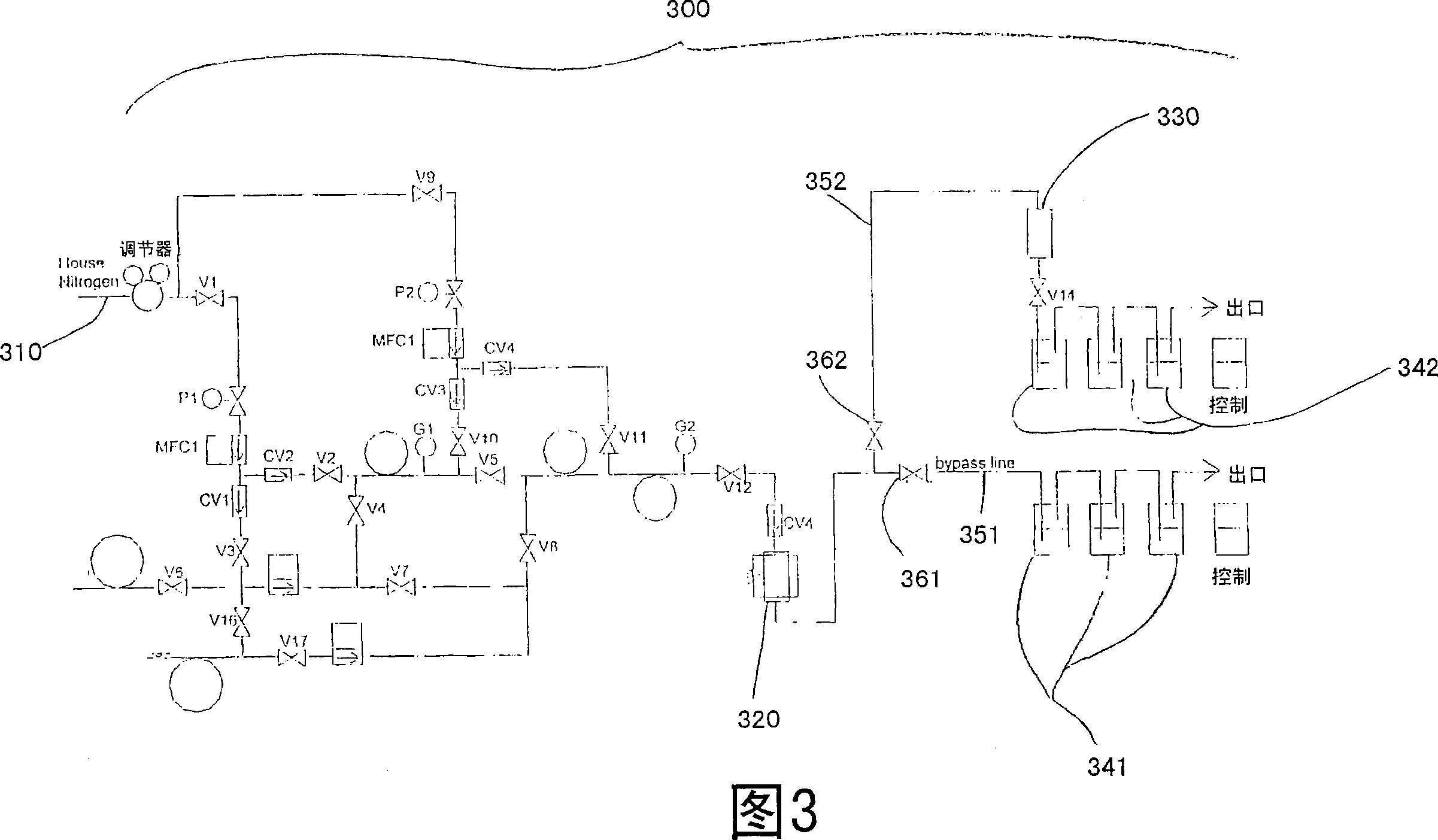

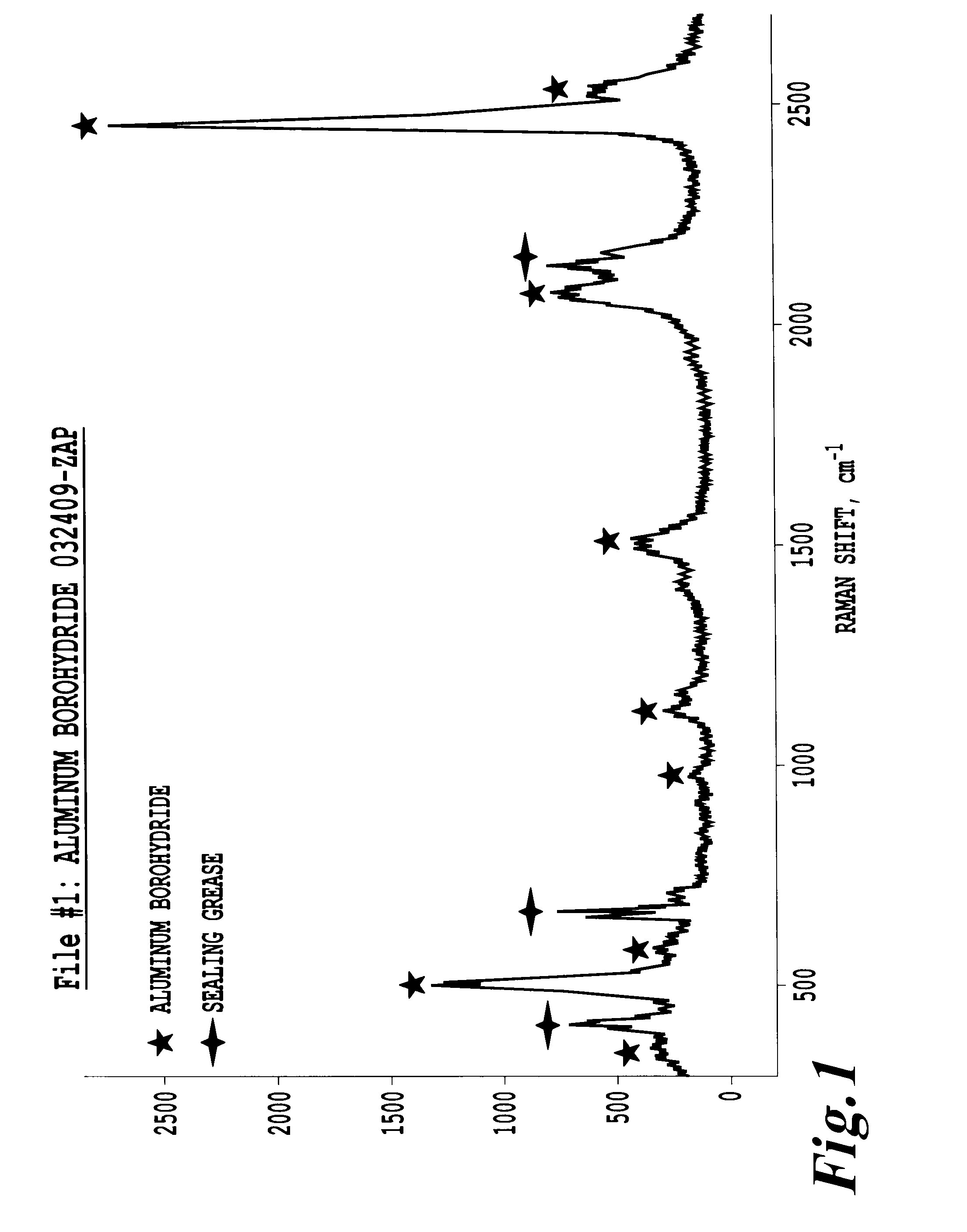

Method and apparatus for purification of hydride gas streams

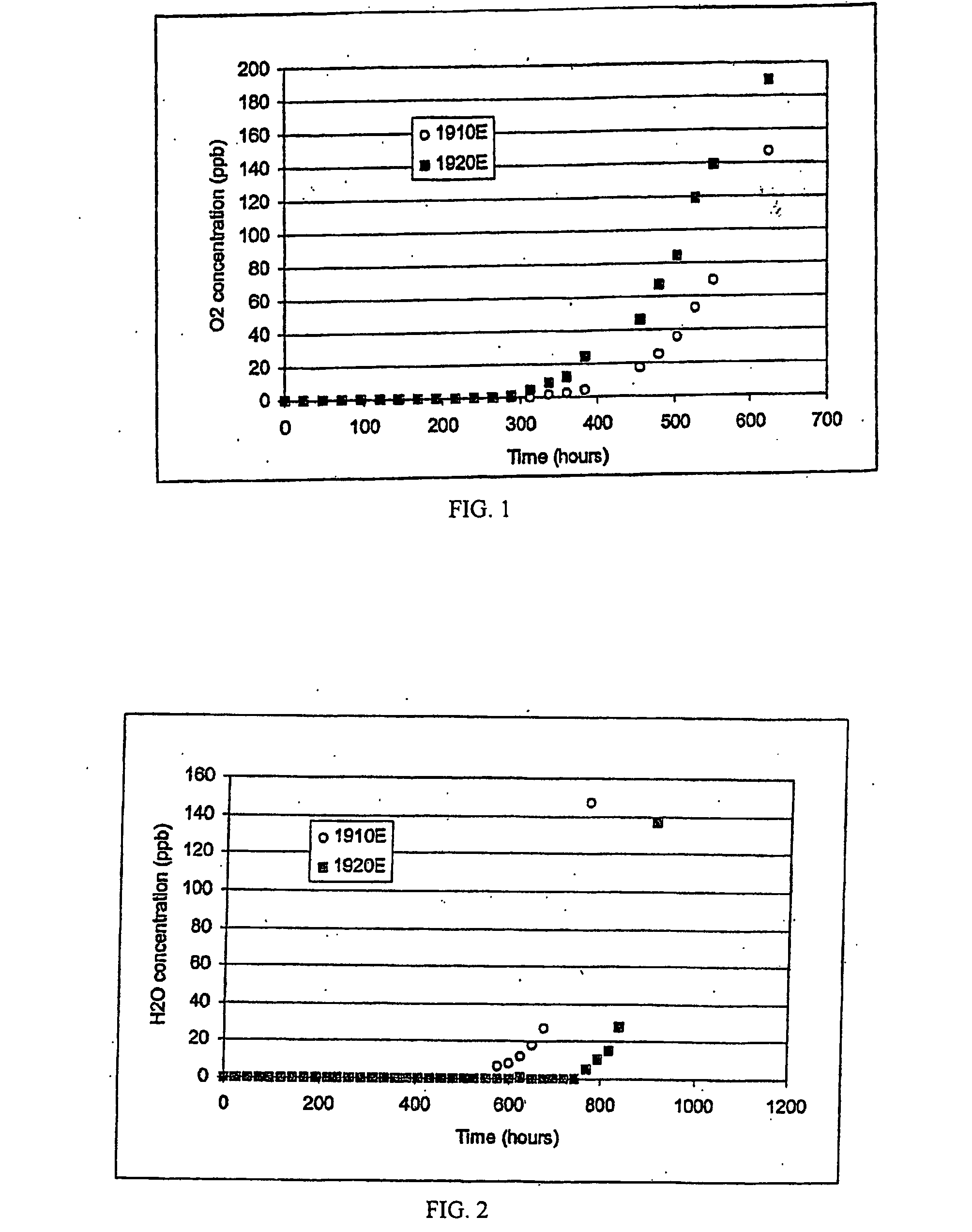

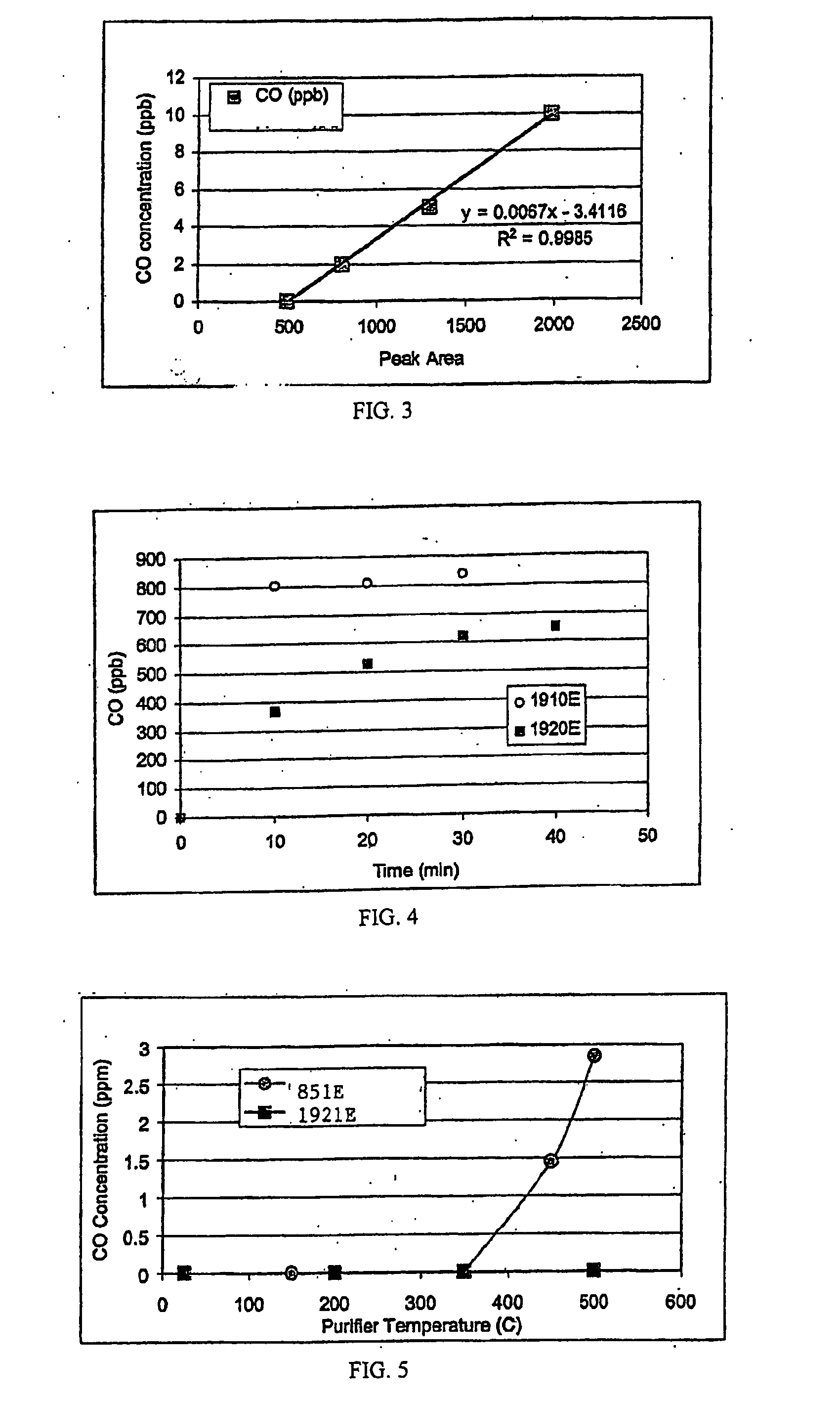

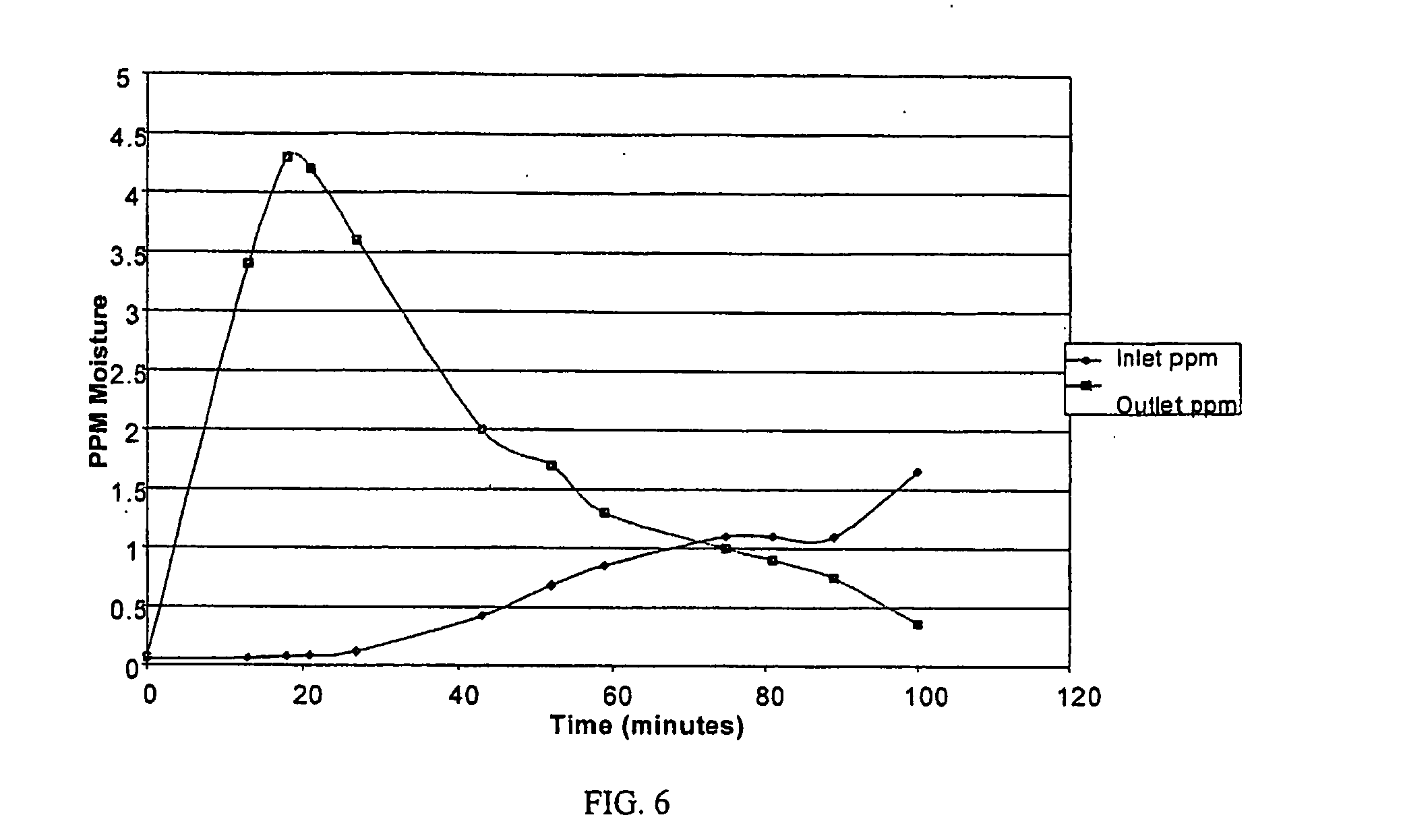

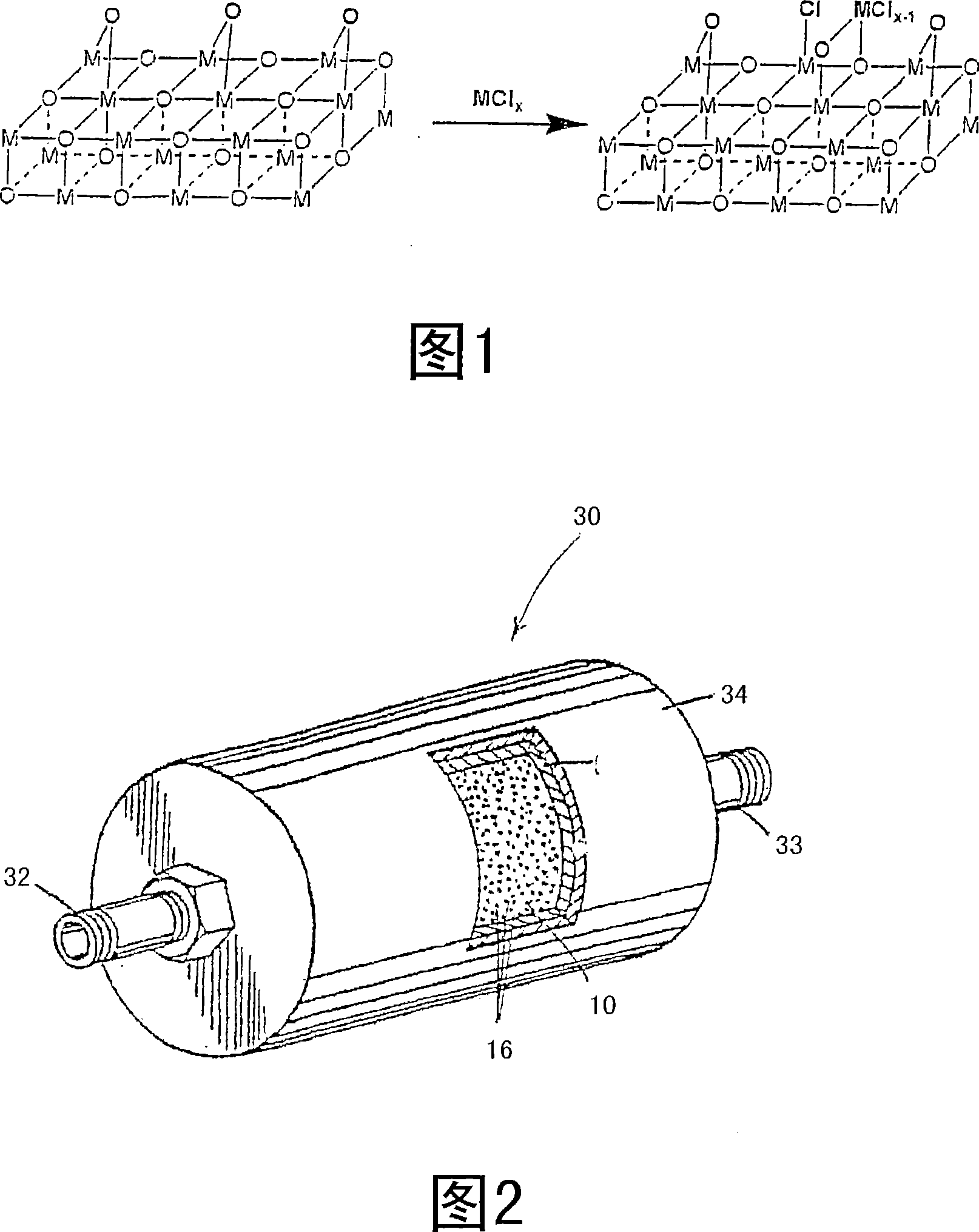

A process and apparatus for the decontamination of gaseous contaminants (especially oxygen, carbon dioxide and water vapor) from hydride gases (including their lower alkyl analogs) down to <=100 ppb contaminant concentration are described. The critical component is a high surface area metal oxide substrate with reduced metal active sites, which in various physical forms is capable of decontaminating such gases to <=100 ppb, <=50 ppb or <=10 ppb level without being detrimentally affected by the hydride gases. The surface area of the substrate will be >=100 m2 / g, and preferably 200-800 m2 / g. Oxides of various metals, especially manganese or molybdenum, can be used, and mixtures of integrated oxides, or one type of oxide coated on another, may be used. The substrate is preferably retained in a hydride-gas-resistant container which is installed in a gas supply line, such as to a gas- or vapor-deposition manufacturing unit. The invention provides final decontamination for hydride gas streams intended for gas- or vapor-deposition formation of high purity LED, laser (especially blue laser), electronic, optical or similar products, and can be used in combination with upstream preliminary decontamination process and / or upstream or downstream solid particulate removal units.

Owner:SAES PURE GAS

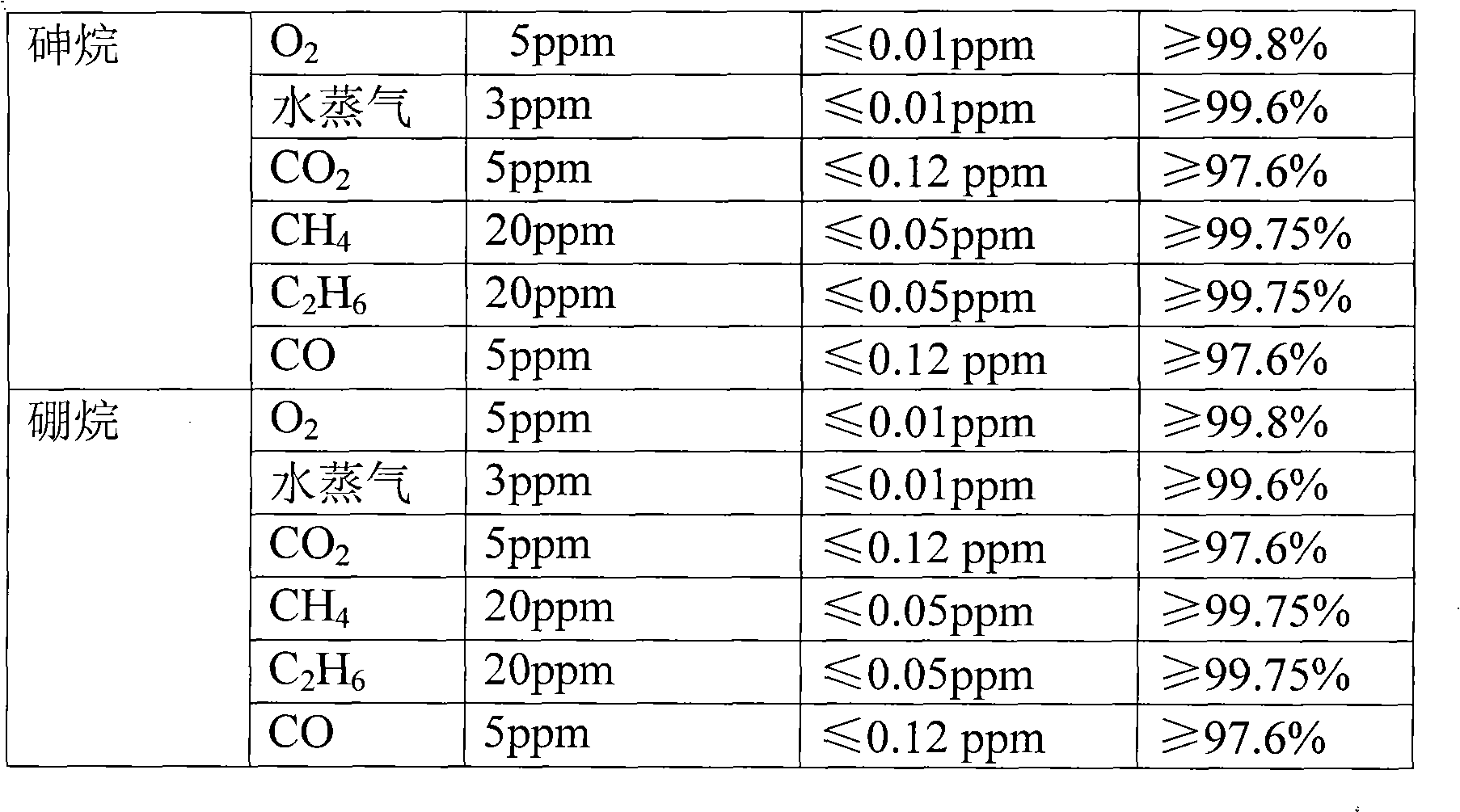

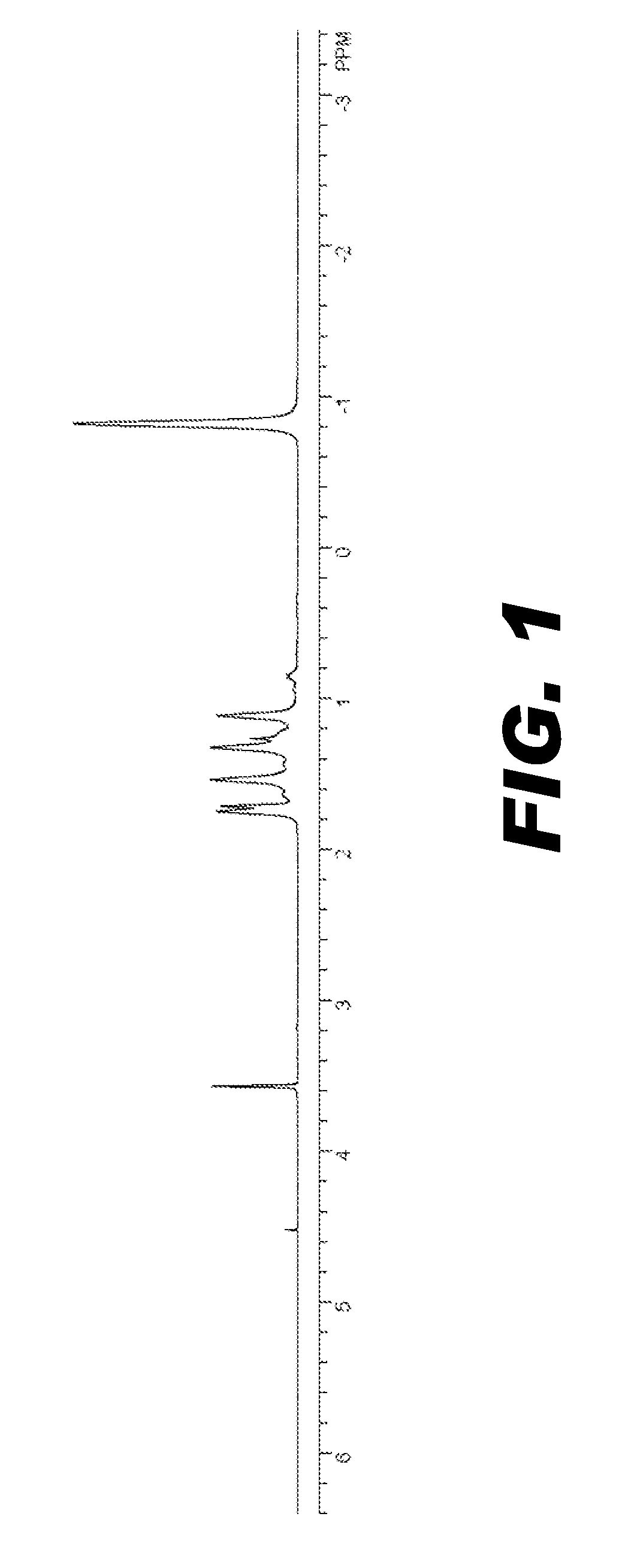

Method of making silane compositions

ActiveUS7498015B1Good ink stabilityDeposition process is enhancedHydride purification/stabilisationSilicon compoundsSilanesCharge carrier mobility

A method of making hydrogenated Group IVA compounds having reduced metal-based impurities, compositions and inks including such Group IVA compounds, and methods for forming a semiconductor thin film. Thin semiconducting films prepared according to the present invention generally exhibit improved conductivity, film morphology and / or carrier mobility relative to an otherwise identical structure made by an identical process, but without the washing step. In addition, the properties of the present thin film are generally more predictable than those of films produced from similarly prepared (cyclo)silanes that have not been washed according to the present invention. The present invention advantageously provides semiconducting thin film structures having qualities suitable for use in electronics applications, such as display devices or RF ID tags, while enabling high-throughput manufacturing processes that form such thin films in seconds or minutes, rather than hours or days as with conventional photolithographic processes.

Owner:ENSURGE MICROPOWER ASA

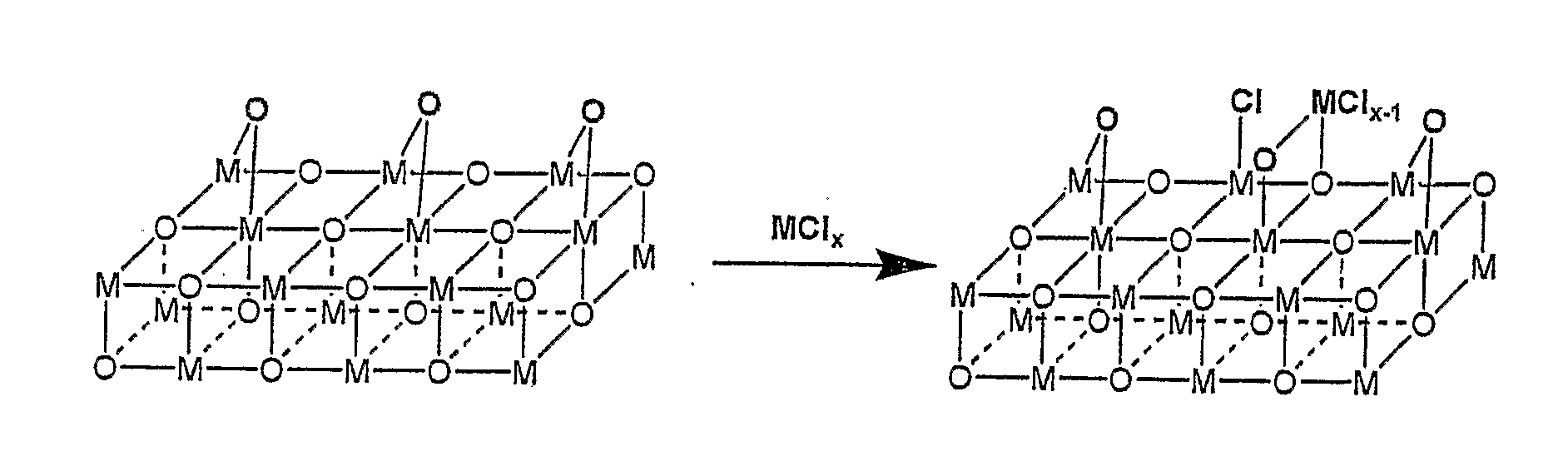

Purification of hydride gases

Purification material for removing a contaminant from an impure hydride gas comprising an adsorbent comprising a reduced metal oxide on a porous support and a desiccant. The porous support may be selected from the group consisting of activated carbon, alumina, silica, zeolite, silica alumina, titania, zirconia, and combinations thereof. The reduced metal oxide may comprise one or more metals selected from the group consisting of Group I alkali metals (lithium, sodium, potassium, rubidium, and cesium), Group II alkaline earth metals (magnesium, calcium, strontium, and barium), and transition metals (manganese, nickel, zinc, iron, molybdenum, tungsten, titanium, vanadium, cobalt, and rhodium). The desiccant may be selected from the group consisting of hygroscopic metal salts, zeolites, single metal oxides, mixed metal oxides, and combinations thereof.

Owner:VERSUM MATERIALS US LLC

Purification of hydride gases

Purification material for removing a contaminant from an impure hydride gas comprising an adsorbent comprising a reduced metal oxide on a porous support and a desiccant. The porous support may be selected from the group consisting of activated carbon, alumina, silica, zeolite, silica alumina, titania, zirconia, and combinations thereof. The reduced metal oxide may comprise one or more metals selected from the group consisting of Group I alkali metals (lithium, sodium, potassium, rubidium, and cesium), Group II alkaline earth metals (magnesium, calcium, strontium, and barium), and transition metals (manganese, nickel, zinc, iron, molybdenum, tungsten, titanium, vanadium, cobalt, and rhodium). The desiccant may be selected from the group consisting of hygroscopic metal salts, zeolites, single metal oxides, mixed metal oxides, and combinations thereof.

Owner:VERSUM MATERIALS US LLC

Soluble metal hydride/transition metal dichalcogenide alloys

InactiveUS6143359ALiquid surface applicatorsAlkali/alkaline-earth/beryllium/magnesium hydridesOrganic solventAlloy

A new class of metal hydride alloy and processes for forming these alloys is disclosed. The alloys are comprised essentially of organically soluble metal hydrides and single molecular layer type transition metal dichalcogenides. They are produced via a non-metallurgical route in organic solvents under mild conditions. These alloys have exhibited improved qualities in battery applications.

Owner:LIGHTYEAR TECH

Metal hydride stability treatment method

Belonging to the technical field of materials, the invention relates to a metal hydride stability treatment method. The treatment method specifically comprises the steps of: (1) dissolving an adhesive in an anhydrous solvent to prepare a liquid glue; (2) adding the liquid glue into a metal hydride, and conducting stirring to form a liquid glue coated metal hydride; and (3) filtering and drying the liquid glue coated metal hydride to obtain the metal hydride undergoing stability treatment. According to the invention, by forming a compact and uniform organic membrane on the metal hydride surface, air and water can be effectively isolated, and the storage time of the metal hydride under normal temperature can be obviously improved, thus solving the storage and use stability problems of the metal hydride under natural conditions.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Silane compositions, methods of making the same, method for forming a semiconducting and/or silicon-containing film, and thin film structures formed therefrom

ActiveUS7799302B1Reduce the amount requiredReduce the presence of impuritiesAluminium silicatesHydride purification/stabilisationDisplay deviceCharge carrier mobility

A method of making hydrogenated Group IVA compounds having reduced metal-based impurities, compositions and inks including such Group IVA compounds, and methods for forming a semiconductor thin film. Thin semiconducting films prepared according to the present invention generally exhibit improved conductivity, film morphology and / or carrier mobility relative to an otherwise identical structure made by an identical process, but without the washing step. In addition, the properties of the present thin film are generally more predictable than those of films produced from similarly prepared (cyclo)silanes that have not been washed according to the present invention. The present invention advantageously provides semiconducting thin film structures having qualities suitable for use in electronics applications, such as display devices or RF ID tags, while enabling high-throughput manufacturing processes that form such thin films in seconds or minutes, rather than hours or days as with conventional photolithographic processes.

Owner:ENSURGE MICROPOWER ASA

Methods of making silane compositions

InactiveUS8124040B1Reduce the amount requiredReduce impuritySilicon hydridesHydride purification/stabilisationLithography processSilanes

A method of making hydrogenated Group IVA compounds having reduced metal-based impurities, compositions and inks including such Group IVA compounds, and methods for forming a semiconductor thin film. Thin semiconducting films prepared according to the present invention generally exhibit improved conductivity, film morphology and / or carrier mobility relative to an otherwise identical structure made by an identical process, but without the washing step. In addition, the properties of the present thin film are generally more predictable than those of films produced from similarly prepared (cyclo)silanes that have not been washed according to the present invention. The present invention advantageously provides semiconducting thin film structures having qualities suitable for use in electronics applications, such as display devices or RF ID tags, while enabling high-throughput manufacturing processes that form such thin films in seconds or minutes, rather than hours or days as with conventional photolithographic processes.

Owner:ENSURGE MICROPOWER ASA

Hydride gas purification for the semiconductor industry

ActiveUS20060188420A1Increase capacityOrganic chemistryNitrogen compoundsRare-earth elementLanthanide

Owner:MYKROLIS CORP +1

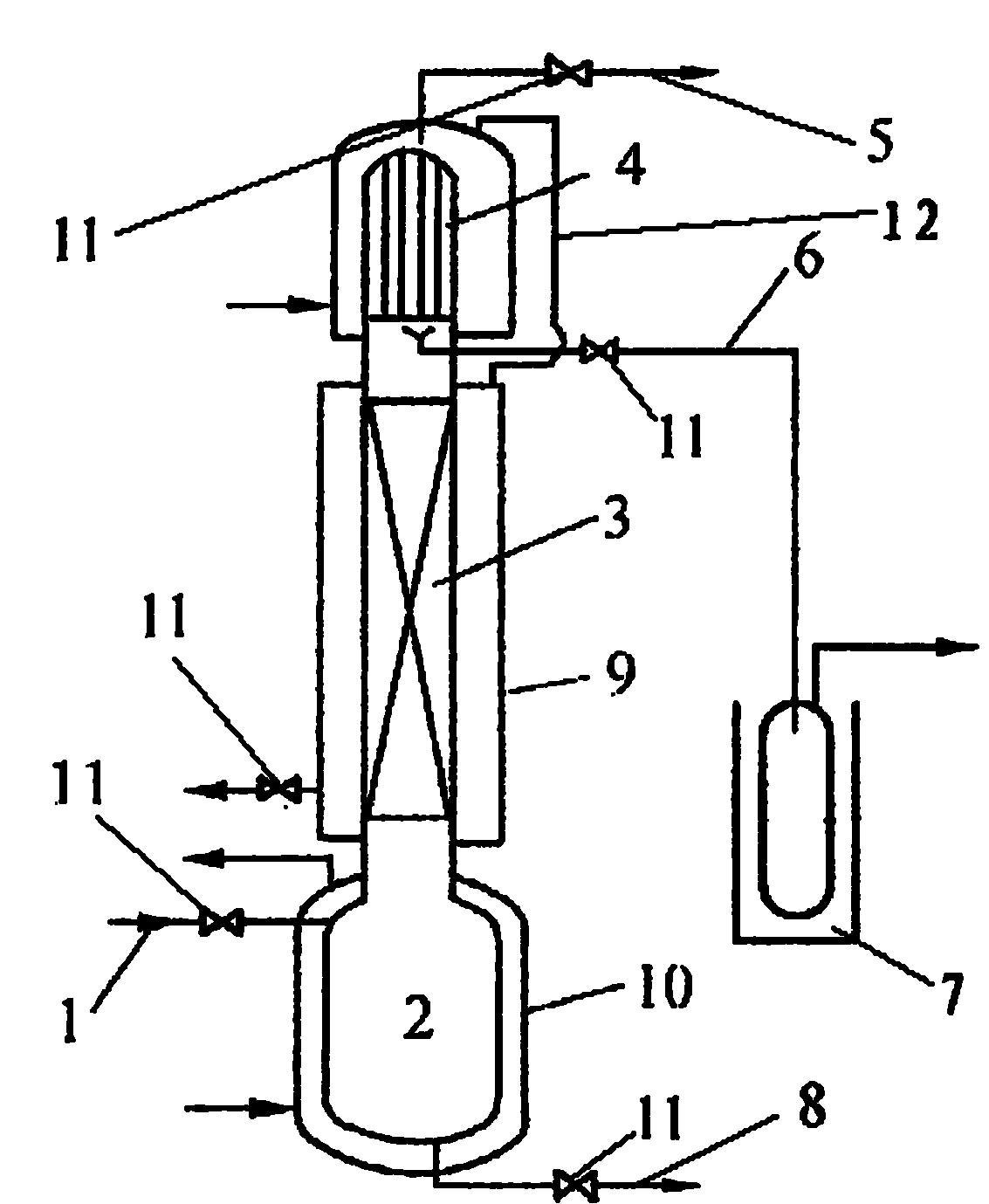

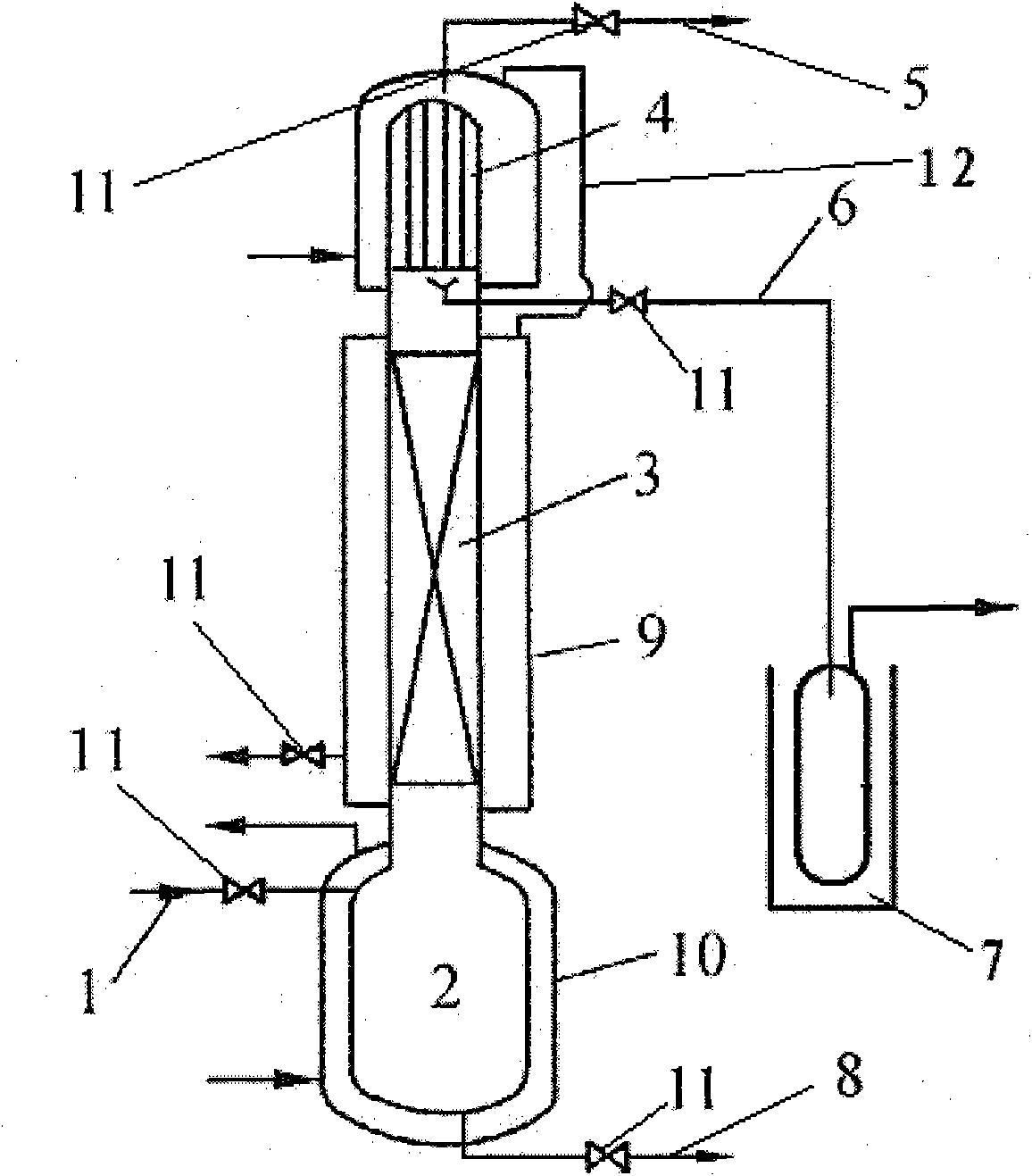

Technology for preparing high-purity diborane in rectification and adsorption combined purifying mode

InactiveCN101811668AIdeal preparation technologyReasonable designHydride purification/stabilisationReboilerBoiling point

The invention discloses technology for preparing high-purity diborane in a rectification and adsorption combined purifying mode, which is mainly characterized in that a feed gas inlet pipe, a reboiler outside which a reboiler heating jacket is arranged, a filled tower outside which a filled tower cooling jacket is arranged, a condenser, a low-boiling impurity discharge pipe, a liquid product (high-purity B2H6) take-out pipe, a product receiving groove, a high-boiling impurity discharge pipe and a valve are assembled together through a connecting pipeline according to the system function. The technology has reasonable design and convenient use, and is ideal high-purity diborane preparation technology.

Owner:TIANJIN TAIHENG GASES

Flotation method and application of alpha-AlH3

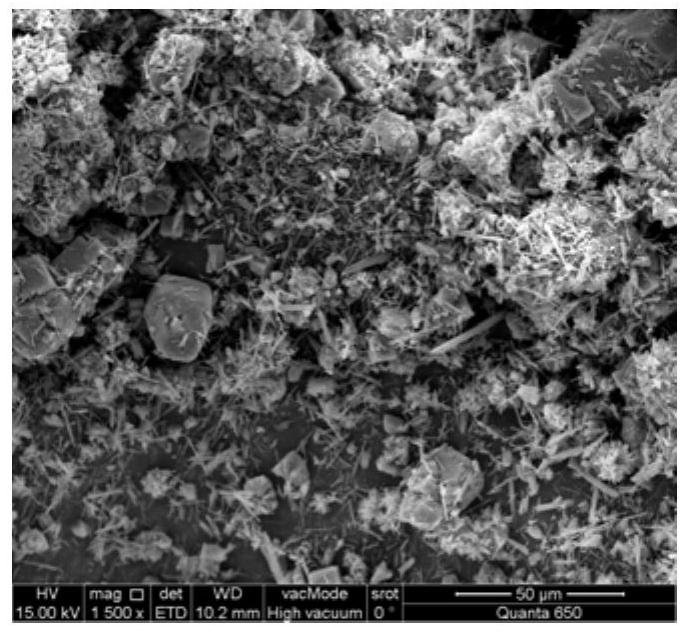

ActiveCN110550607ADoes not affect the preparation processSimple separation techniqueHydride purification/stabilisationFlotationFriction sensitivityHigh energy

The invention relates to a flotation method and application of alpha-AlH3, and belongs to the technical field of energetic materials. Alpha crystal type AlH3 and non-alpha crystal type AlH3 have different inherent properties such as physical and chemical properties, surface adsorption characteristics, crystal appearance characteristics and the like, so that high-efficiency separation of alpha crystal type AlH3 and non-alpha crystal type AlH3 is realized by adopting a specific flotation solution by virtue of a separation and purification function of ultrasonic waves, and then high-quality alphacrystal type AlH3 and non-alpha crystal type AlH3 are obtained. Safety of an application of the high quality alpha crystal type AlH3 in composite high-energy solid propellants is verified through impact sensitivity and friction sensitivity experiments. The high-quality alpha crystal type AlH3 has high hydrogen content, and slurry sensitivity of the high-energy propellants based on the high-quality alpha crystal type AlH3 is low.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Antioxidation method of light rare earth metal hydride

InactiveCN103979496AFix security issuesEasy to useHydride purification/stabilisationTransition element hydridesAdhesiveRare earth

The invention relates to an antioxidation handling method of a light rare earth metal hydride and belongs to the field of materials technology. The method comprises the following specific steps: (1) carrying out dehydration and deoxygenization treatments on a solvent so as to prepare an anhydrous anaerobic solvent; (2) dissolving an adhesive in the anhydrous solvent to prepare a glue solution; (3) dropping the above glue solution into a light rare earth metal hydride, stirring and suspending to form a glue solution coated light rare earth metal hydride; (4) filtering the solution-coated metal hydride and drying to obtain the light rare earth metal hydride which has undergone stability processing. The glue solution also can be directly added into the light rare earth metal hydride; the glue solution and the light rare earth metal hydride are kneaded to form a flexible ball; the flexible ball undergoes pelleting and drying is carried out so as to obtain the light rare earth metal hydride. According to the invention, the air and water can be isolated effectively. Thus, the safety problem of the light rare earth metal hydride stored and used under natural conditions is solved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

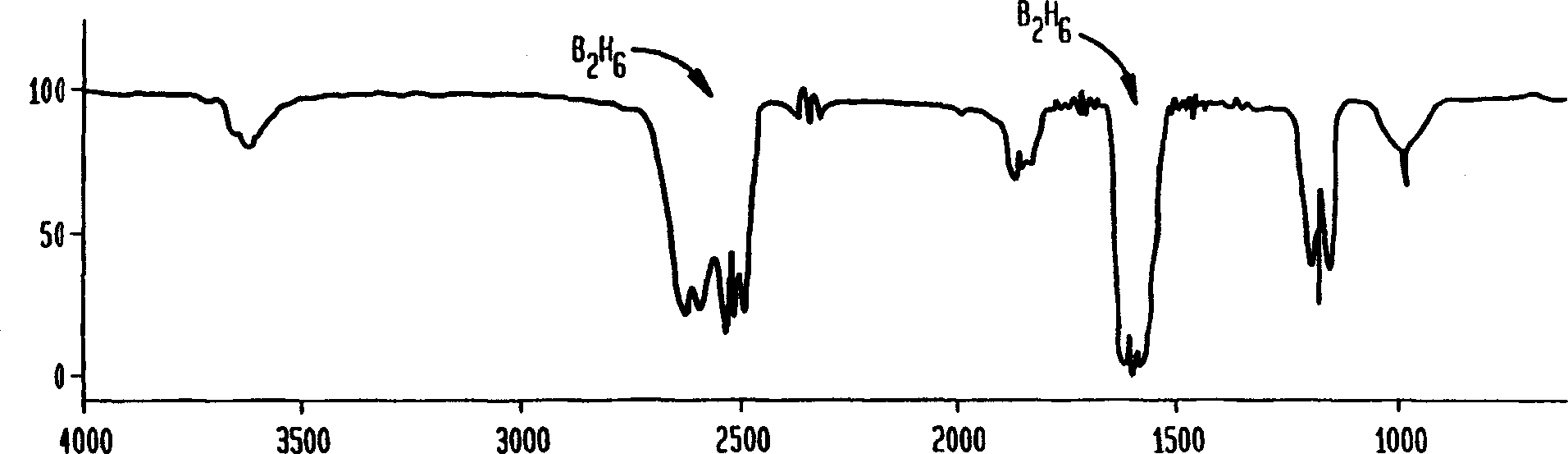

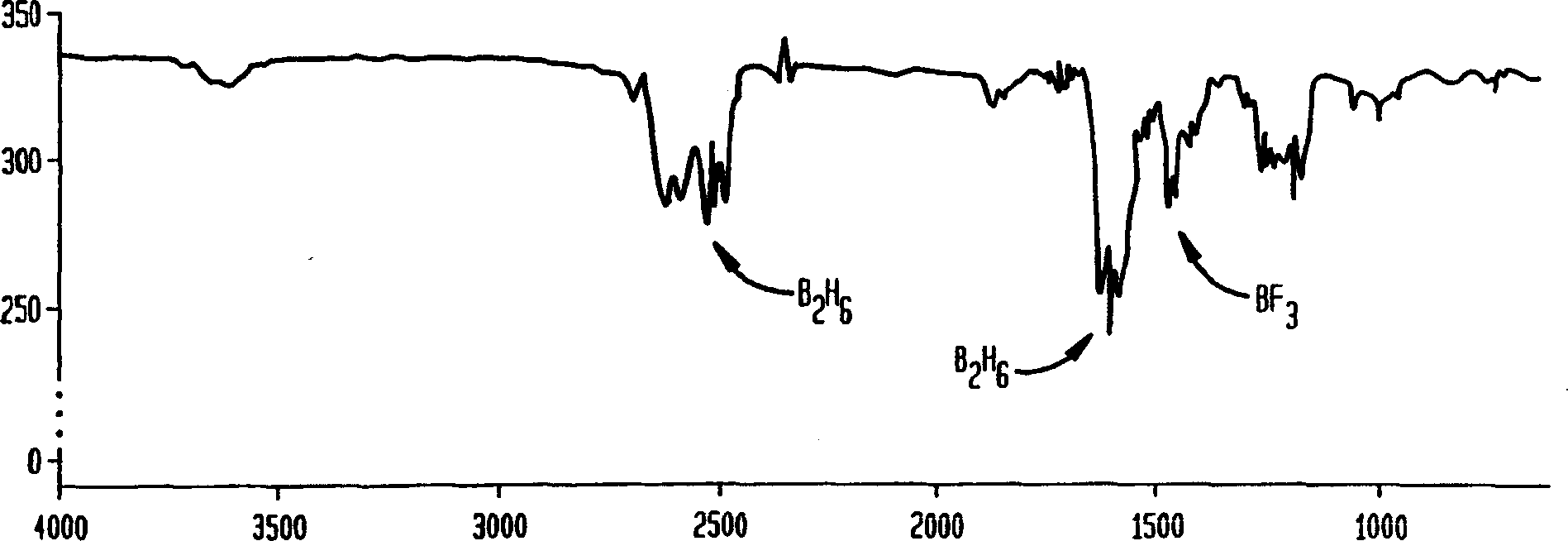

Preparation and purification of diborane

BF3, CO2 or both are removed from a mixture containing these gases with B2H6 by contacting the mixture with an inorganic hydroxide such as LiOH. B2H6 is synthesized by contacting BF3 with KBH4.

Owner:HONEYWELL INTPROP

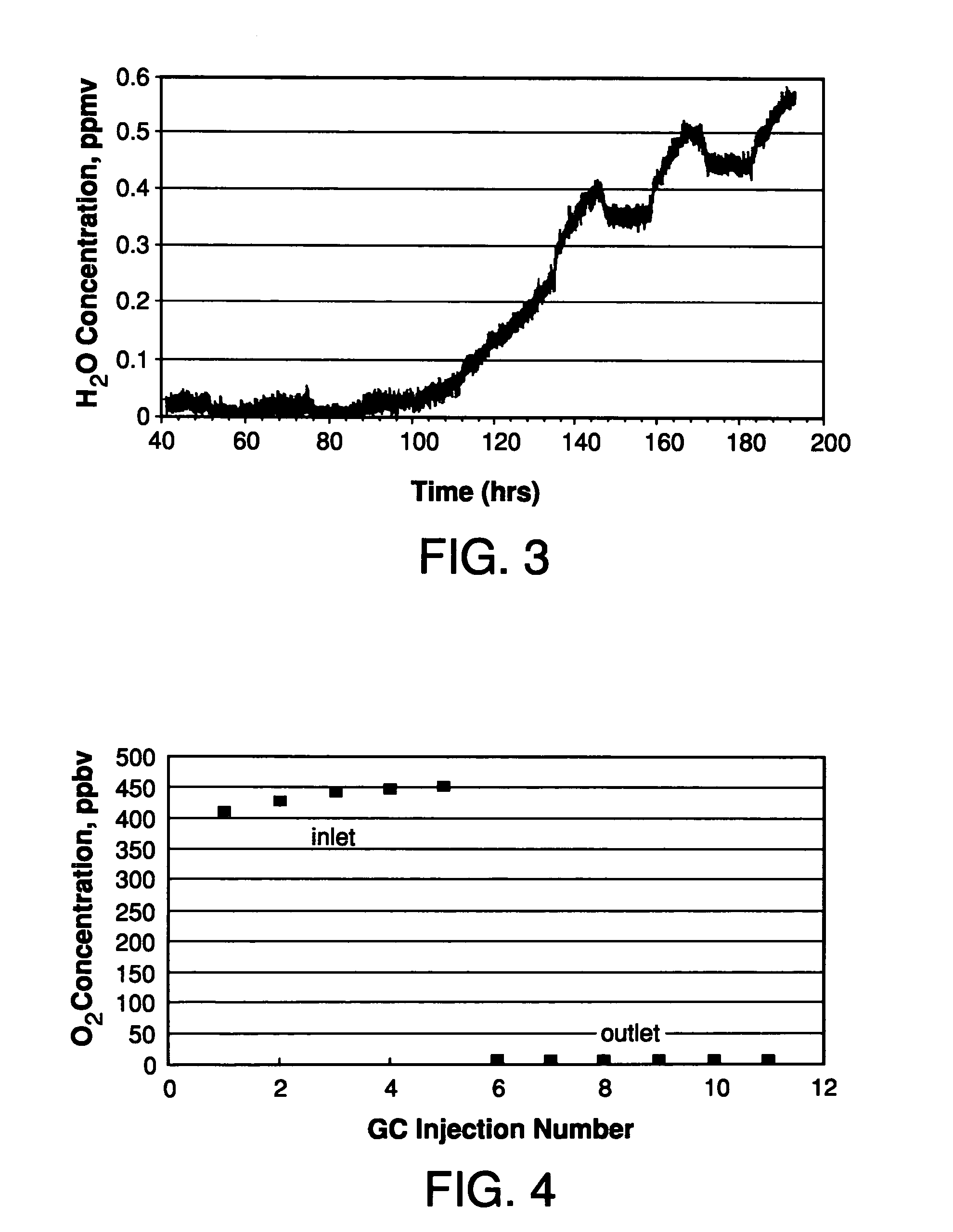

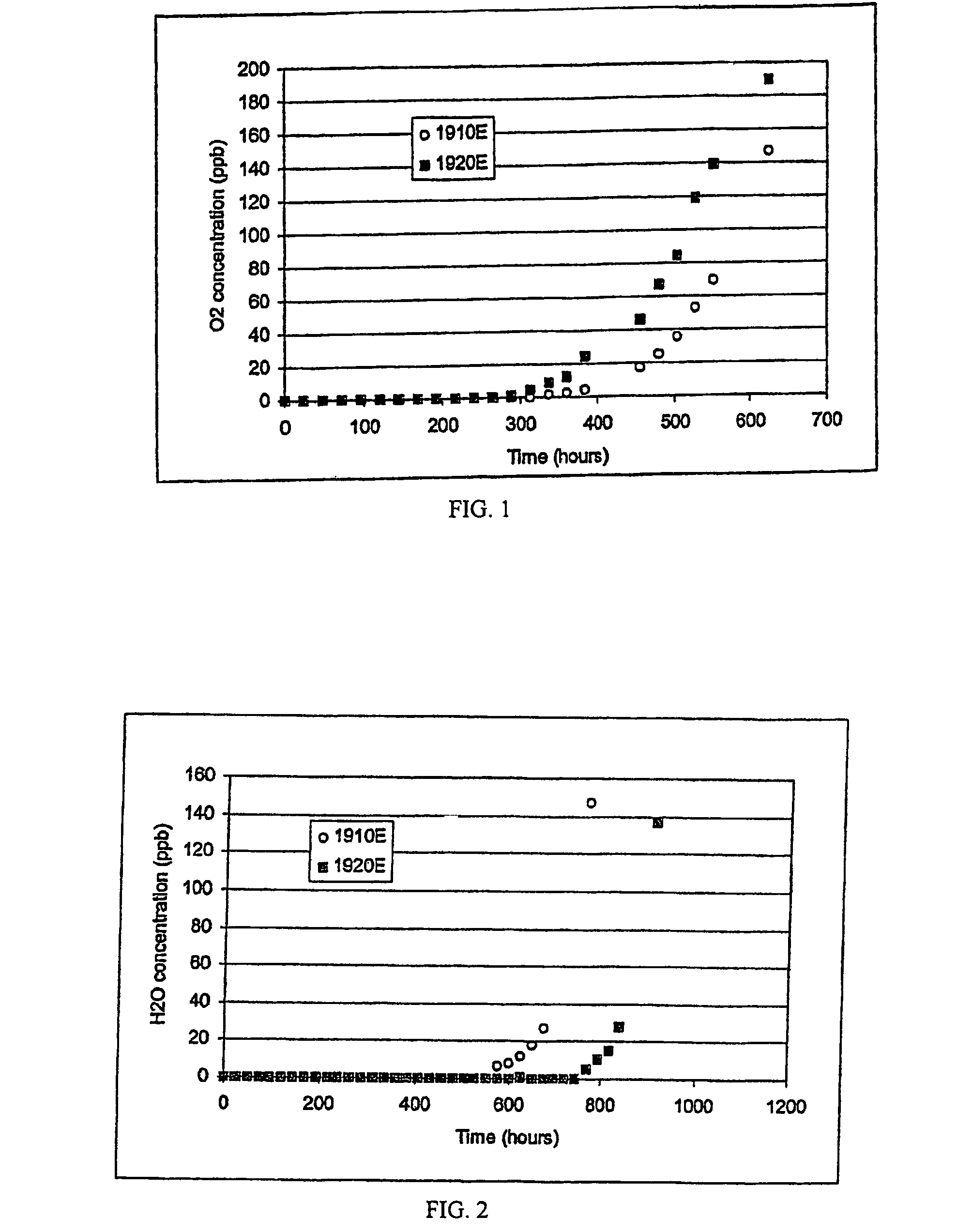

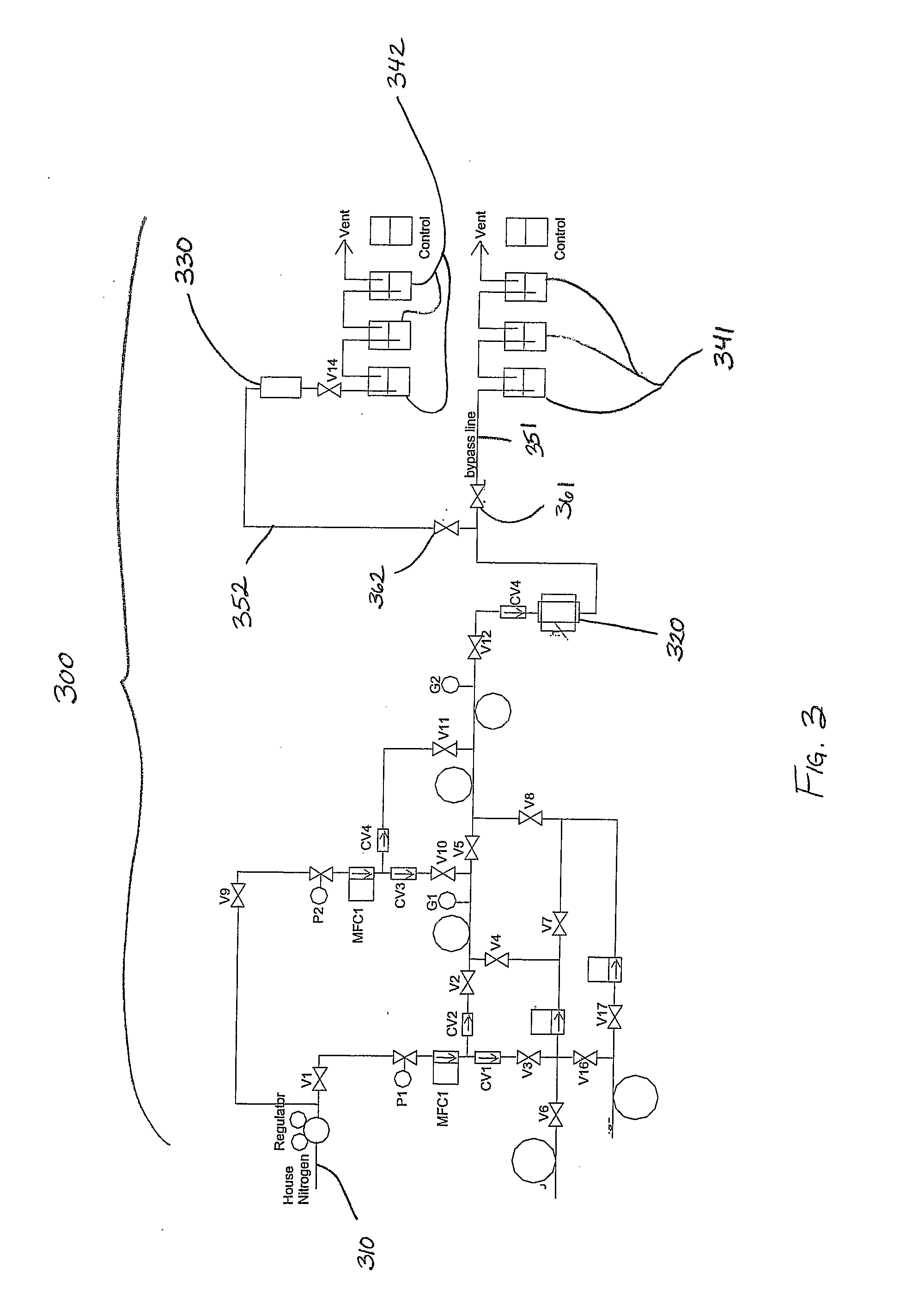

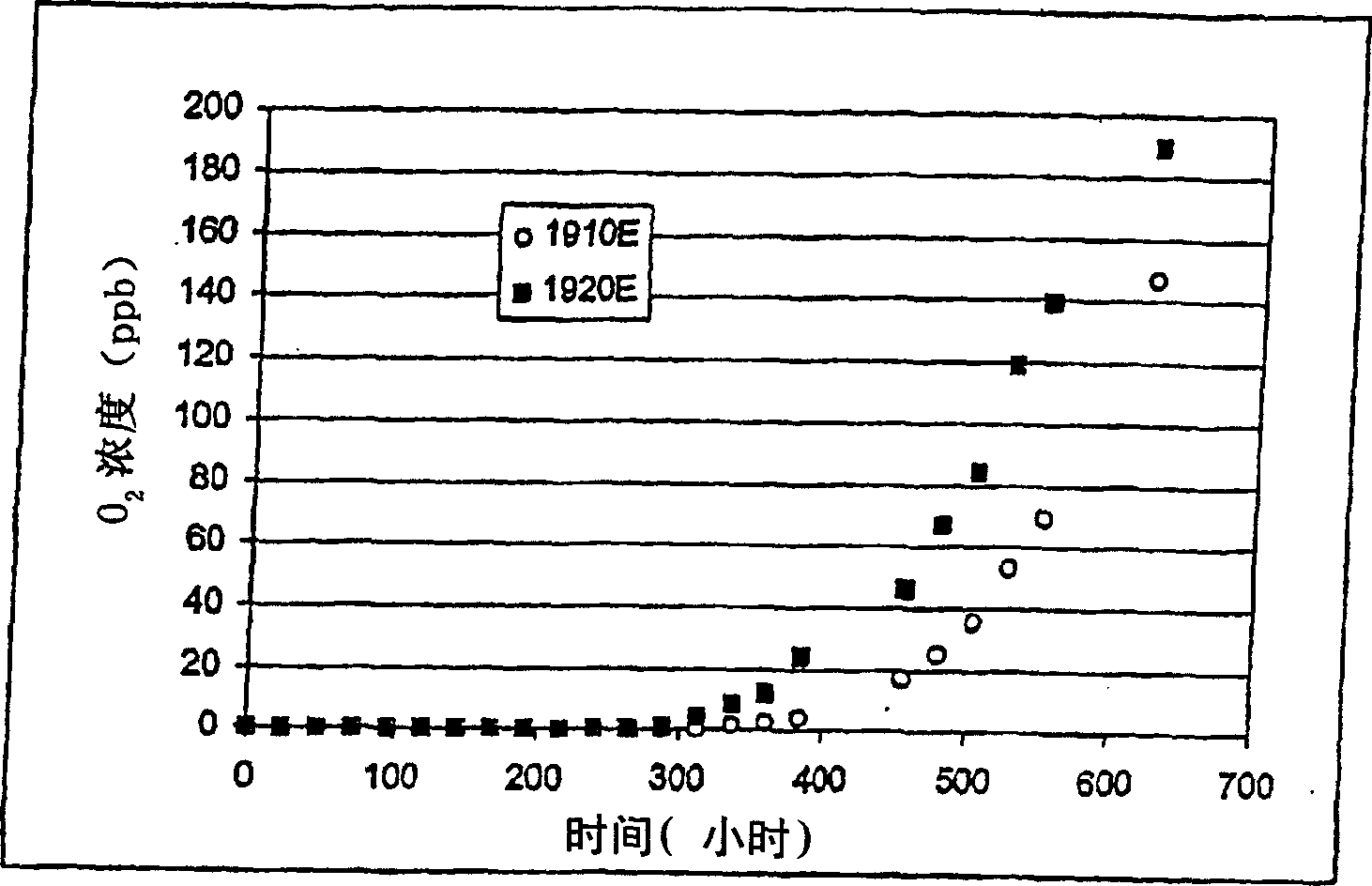

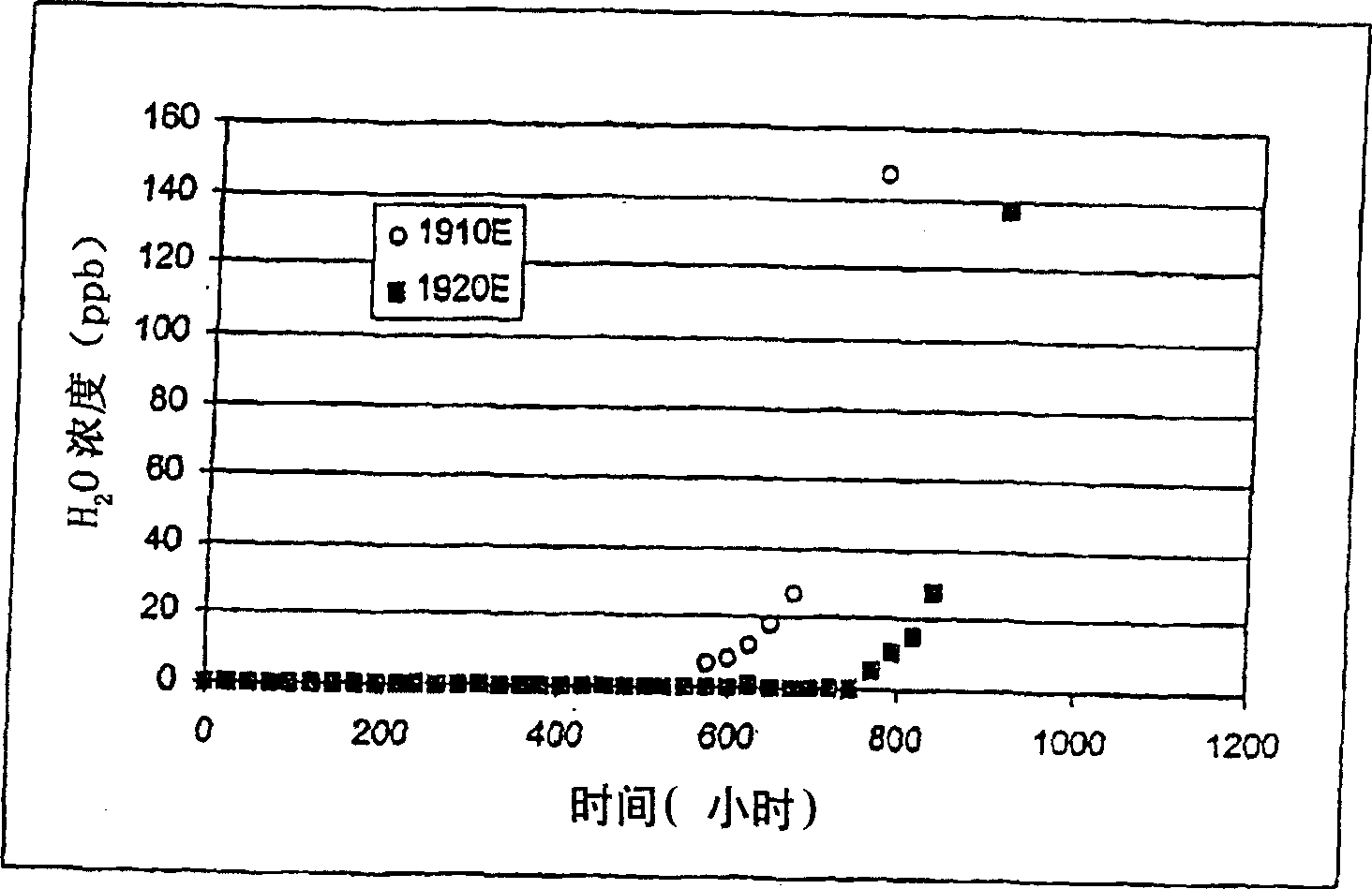

Hydride gas purification for the semiconductor industry

ActiveUS7510692B2Highly efficient gas purification substrateEfficient removalOrganic chemistryNitrogen compoundsRare-earth elementLanthanide

Owner:MYKROLIS CORP +1

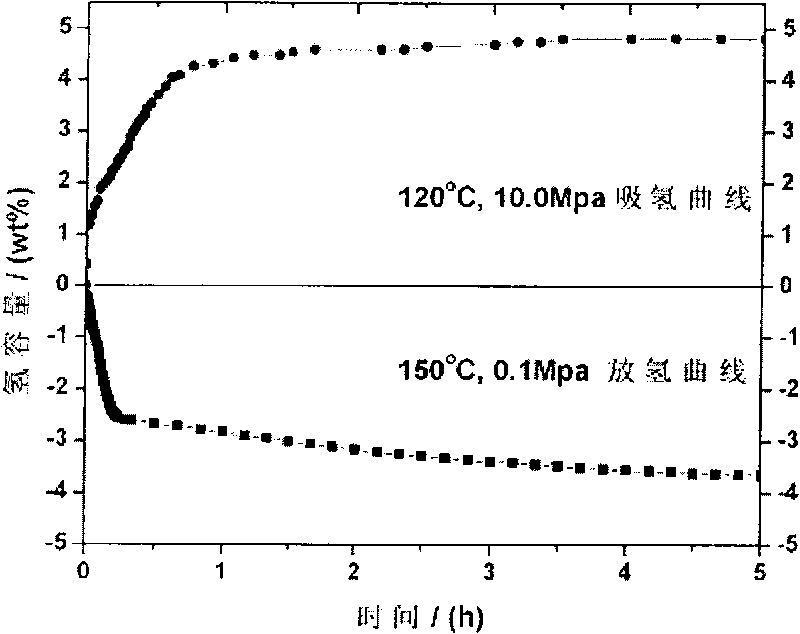

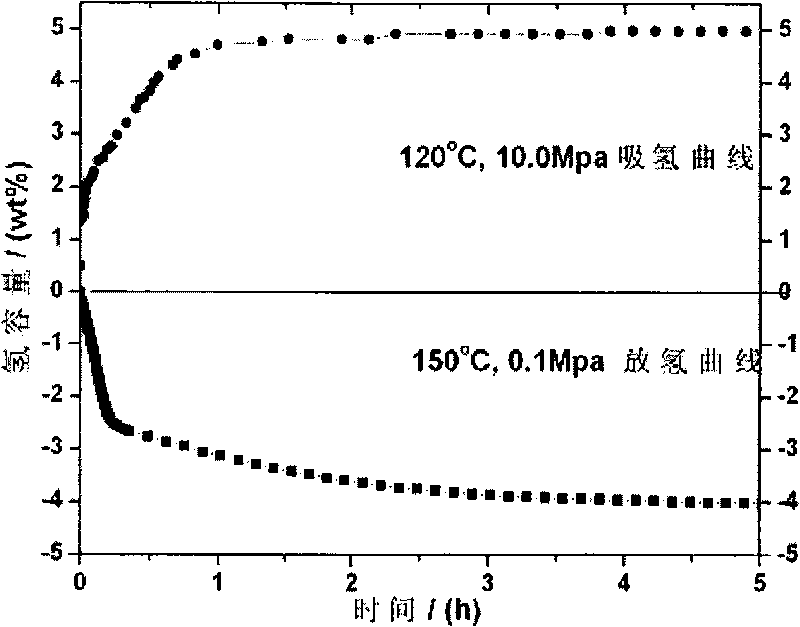

CeH2.5-NaH-Al composite hydrogen storage material and preparation method thereof

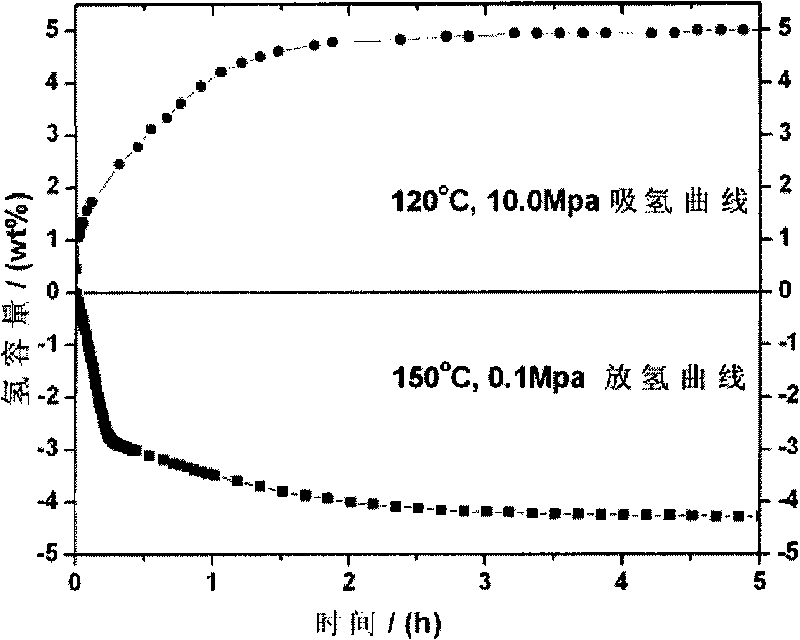

InactiveCN101733147AHas reversible hydrogen storage and discharge performanceImprove cycle stabilityHydrogenOrganic-compounds/hydrides/coordination-complexes catalystsPolymer scienceHydrogen absorption

The invention relates to CeH2.5-NaH-Al composite hydrogen storage material and preparation method thereof. The composite hydrogen storage material is prepared by mixing 1-4 percent mol of CeH2.5 with grain size of less than 0.5mum and 48-49.5 percent mol of NaH as well as 48-49.5 percent mol of Al through hydrogenation and ball-milling, wherein the ratio of NaH to Al is 1:1. The composite material has effective hydrogen discharge capacity reaching 4.3wt% under the conditions that the temperature is 150 DEG C and the atmosphere pressure is 1, reversibly absorbs the hydrogen of above 4.9 wt% under the conditions that the temperature is 120 DEG C and the hydrogen absorption pressure is 10.0MPa, and has better cyclical stability.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Removal Of Metal Contaminants From Ultra-High Purity Gases

InactiveUS20080107580A1Improve production stabilityDefective products are minimizedHydrogen bromideNitrogen compoundsUltra high purityDevice failure

The invention is a method and apparatus for removing metal compounds from ultra-high purity gases using a purifier material comprising a high surface area inorganic oxide, so that the metals do not deposit on a sensitive device and cause device failure.

Owner:ENTEGRIS INC

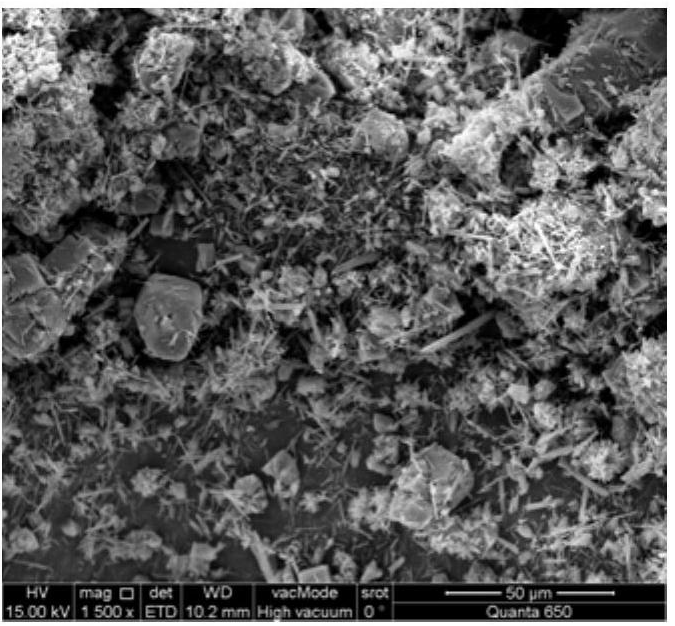

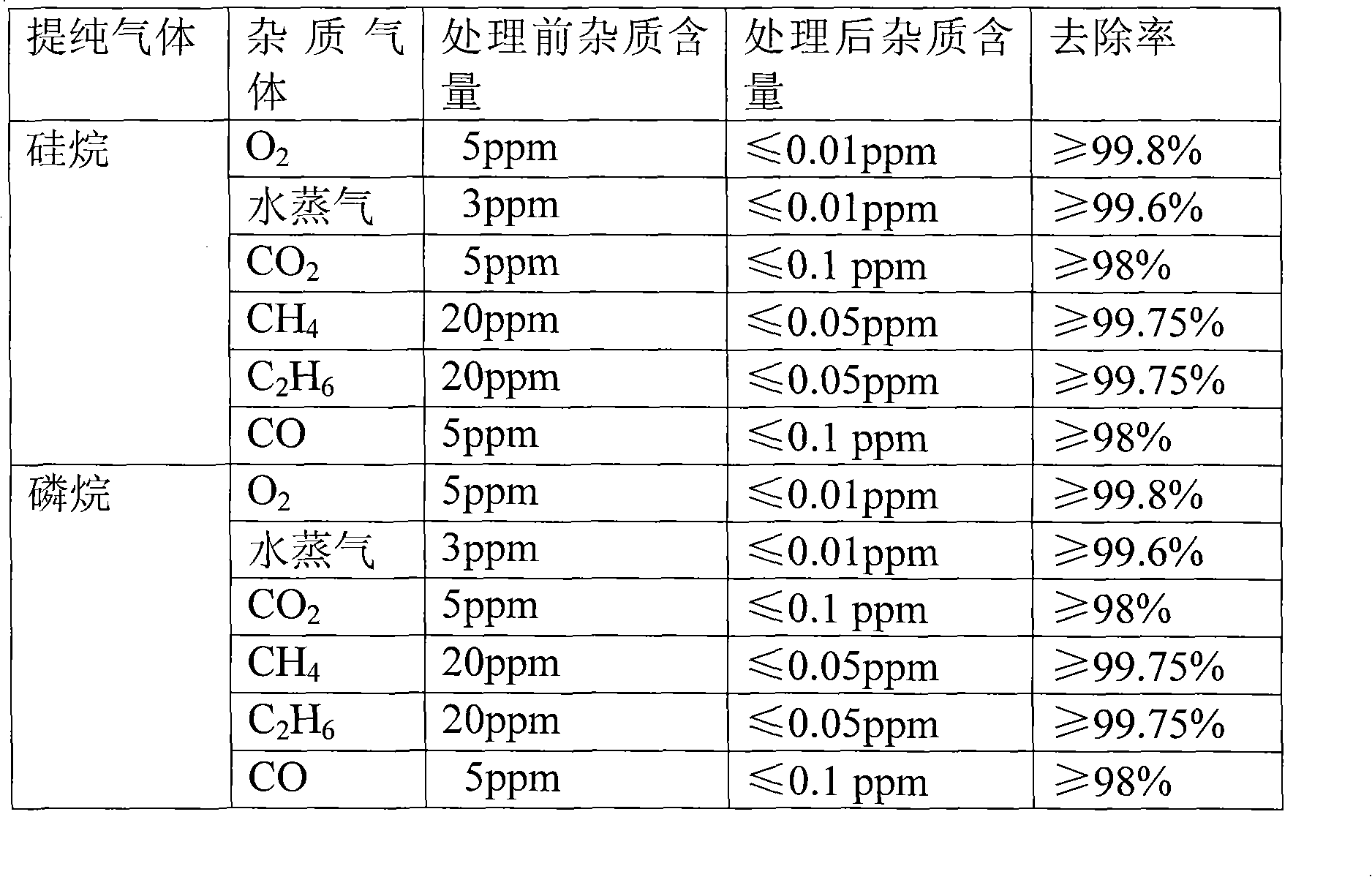

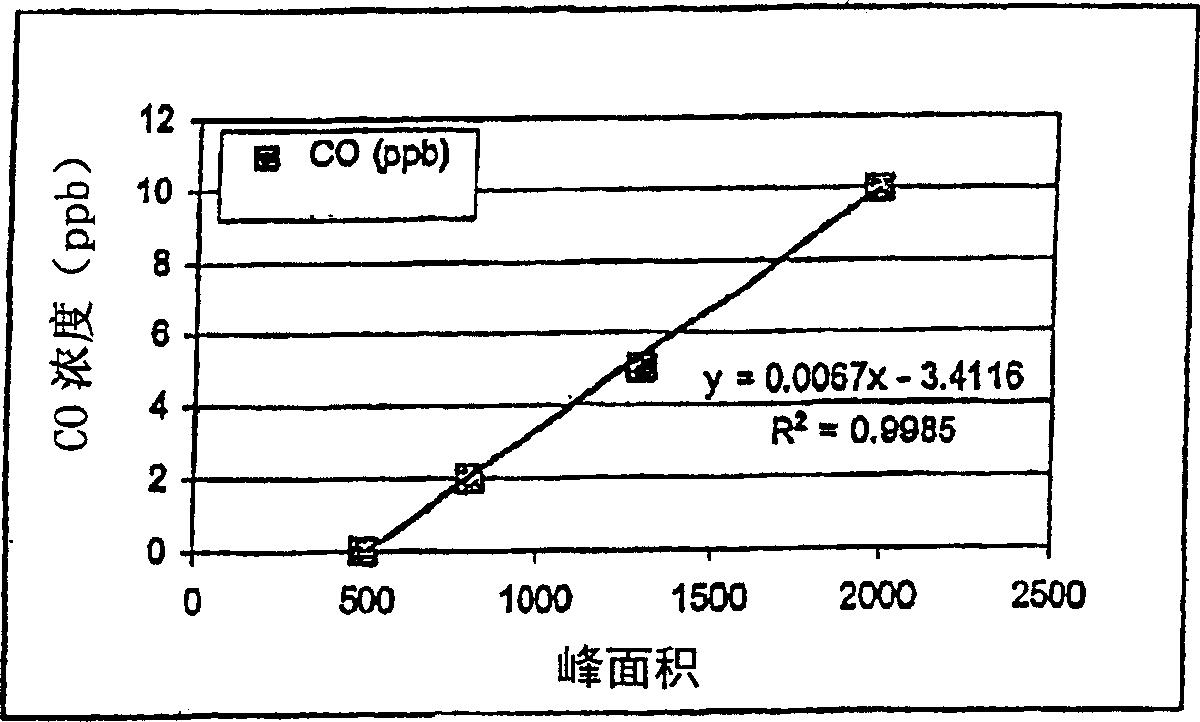

Purification adsorption agent for silicone hydride, phosphorane, arsine or borane gases and preparation method thereof

InactiveCN101342478AHigh removal rateHigh purityOther chemical processesSilicon hydridesMetallic aluminumSorbent

The invention discloses to a refining adsorbent for silane gas, phosphorane gas, arsine gas or borane gas and a preparation method thereof, relating to a gas refining adsorbent and a preparation method. The invention solves the problems that the removal rate of foreign gas in the silane gas, the phosphorane gas, the arsine gas or the borane gas by adopting the prior palladium powder adsorbent is low, thereby needing further assistant decomposition. The refining adsorbent consists of a carrier and a metallic aluminum layer on the surface of the carrier. The preparation method is as follows: in the presence of hydrogen gas, mixed gas of the hydrogen gas and aluminum methide is sprayed on the surface of the carrier in the temperature of 600 to 650 DEG C so as to obtain the refining adsorbent for the silane gas, the phosphorane gas, the arsine gas or the borane gas. Under the condition that the assistant decomposition is not added, the refining adsorbent of the invention is tested to show a result that the removal rate of CO2 is higher than 95 percent; the removal rate of CH4 is higher than 98 percent; the removal rate of C2H6 is higher than 98 percent; the removal rate of O2 is higher than 99.8 percent; the removal rate of CO is higher than 95 percent; and the removal rate of water vapor is higher than 99.6 percent.

Owner:王少志

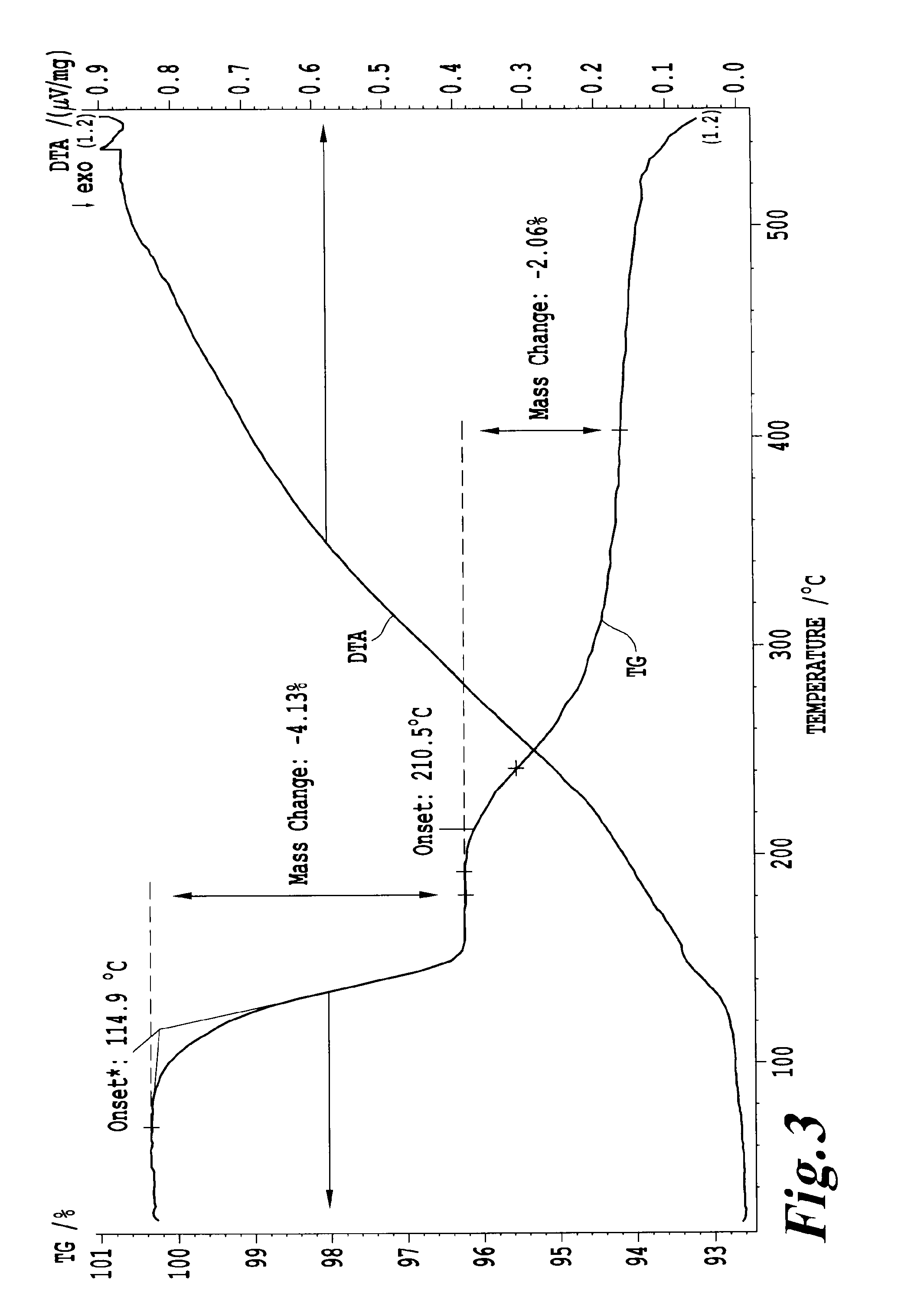

Metal amidoborane compositions and processes for their preparation

The present invention provides compositions comprising a metal amidoborane and an amine, and processes for preparing the metal amidoborane compositions. In particular, the process comprises contacting ammonia borane with a metal amide in the presence of an amine solvent to form the metal amidoborane composition. The invention also provides methods for generating hydrogen, wherein the method comprises heating the metal amidoborane composition such that hydrogen is released.

Owner:SIGMA ALDRICH CO LLC

Hydride gas purification for the semiconductor industry

ActiveCN1826167AHydrogen separation using solid contactDispersed particle separationRare-earth elementLanthanide

A method for hydride gas purification uses materials having at least one lanthanide metal or lanthanide metal oxide. The method reduces contaminants to less than 100 parts per billion (ppb), preferably 10 ppb, more preferably 1 ppb. The material can also include transition metals and transition metal oxides, rare earth elements and other metal oxides. The invention also includes materials for use in the method of the invention.

Owner:ENTEGRIS INC

Removal of metal contaminants from ultra-high purity gases

InactiveCN1988948ASkill improvedImprove stabilityHydrogen bromideNitrogen compoundsUltra high purityDevice failure

The invention is a method and apparatus for removing metal compounds from ultra-high purity gases using a purifier material comprising a high surface area inorganic oxide, so that the metals do not deposit on a sensitive device and cause device failure.

Owner:ENTEGRIS INC

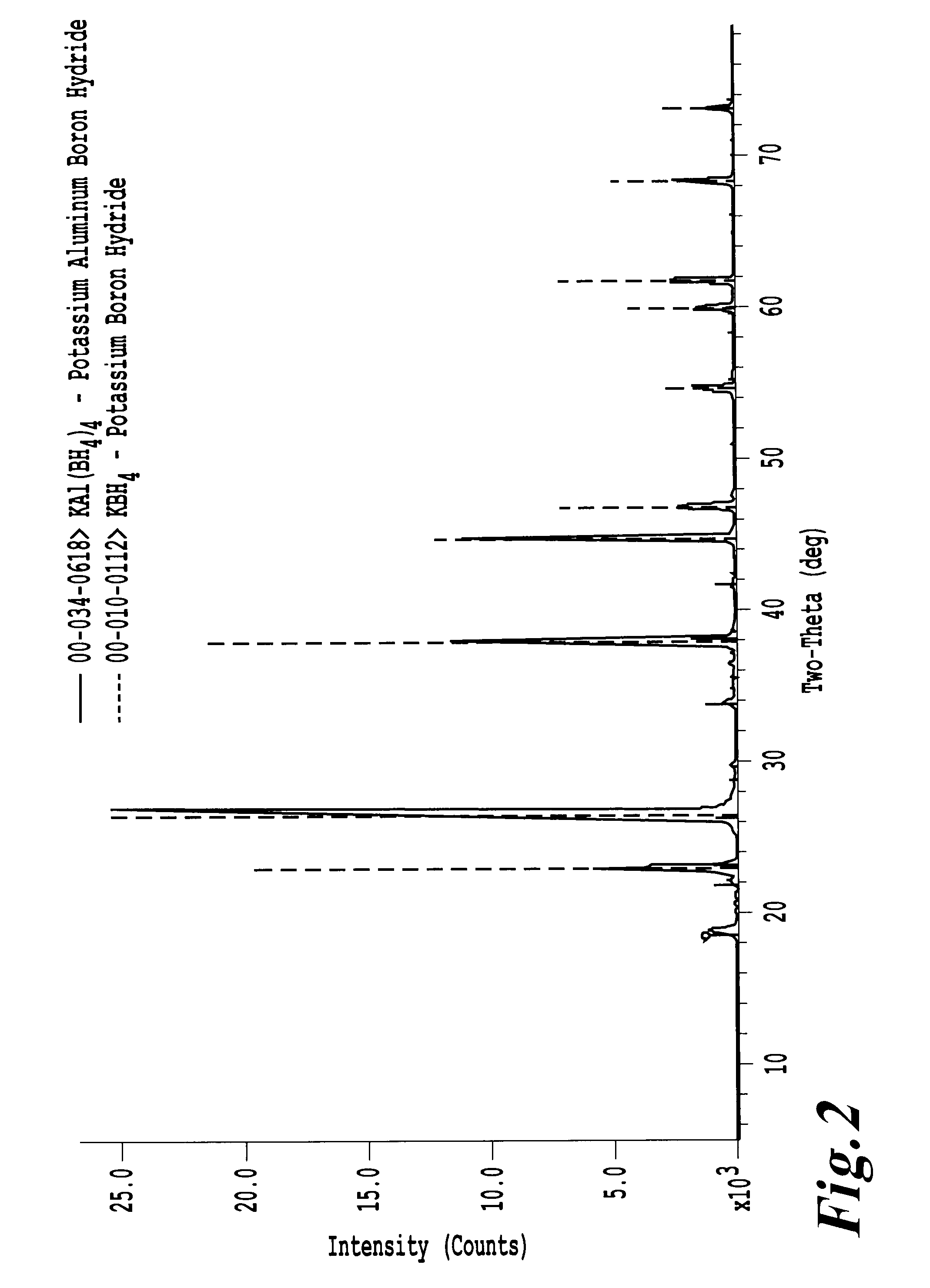

High capacity stabilized complex hydrides for hydrogen storage

InactiveUS20120156118A1Good chemical stabilityImproved thermodynamic characteristicMonoborane/diborane hydridesHydride purification/stabilisationAdductLarge capacity

Complex hydrides based on Al(BH4)3 are stabilized by the presence of one or more additional metal elements or organic adducts to provide high capacity hydrogen storage material.

Owner:TOYOTA JIDOSHA KK +1

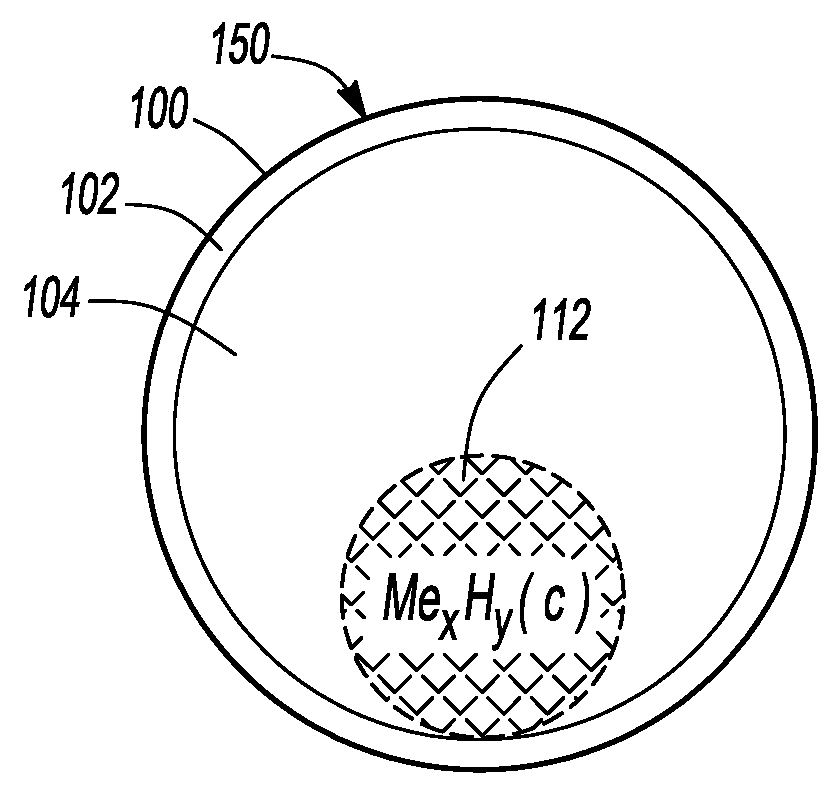

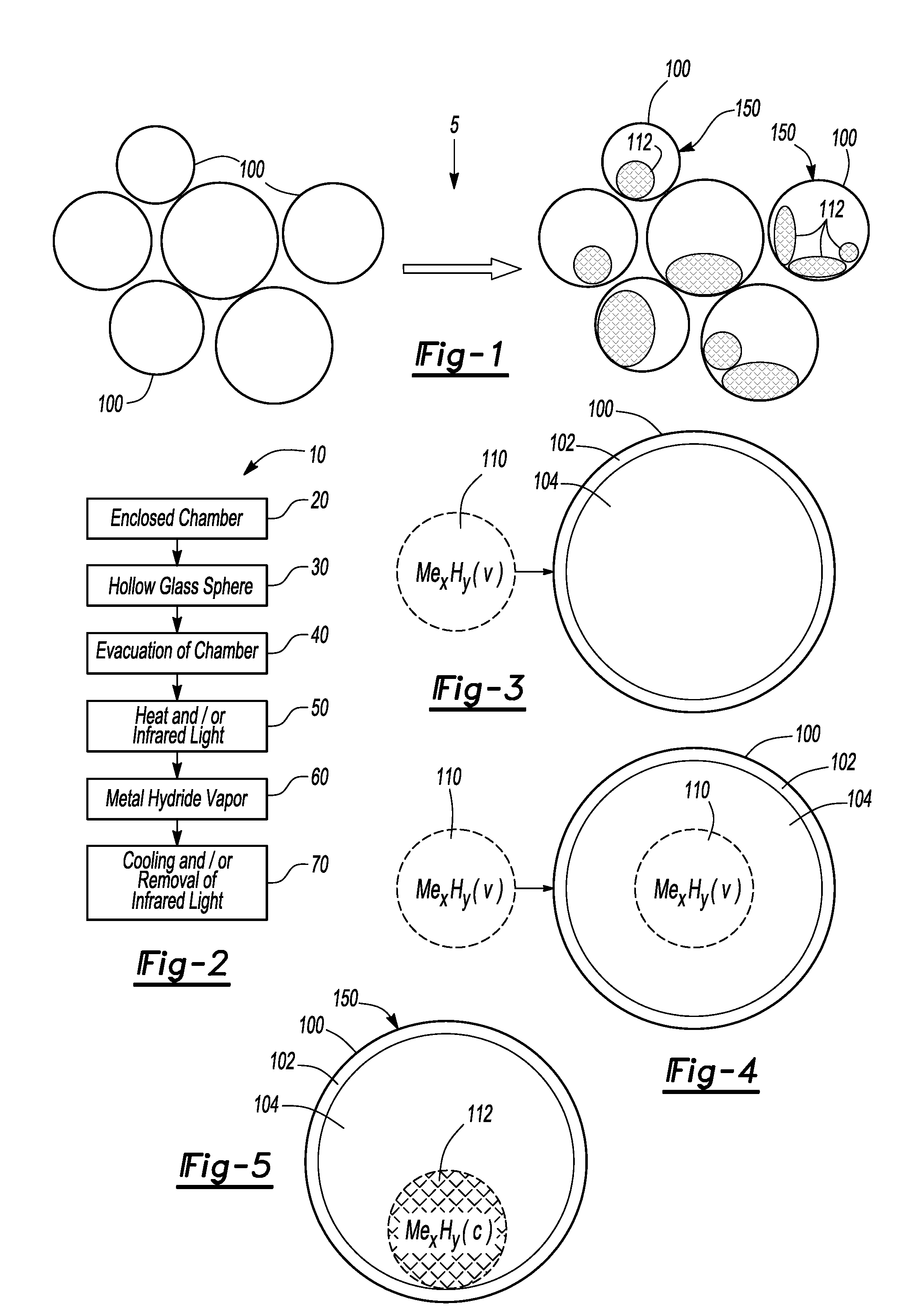

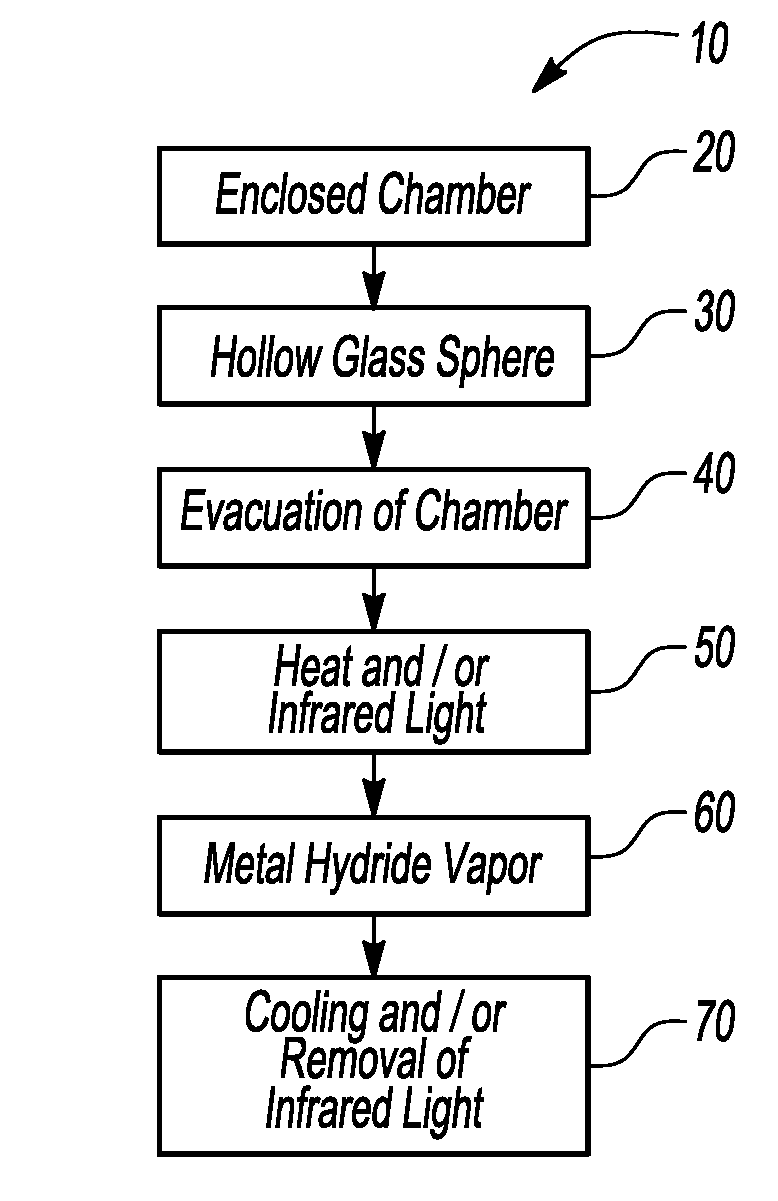

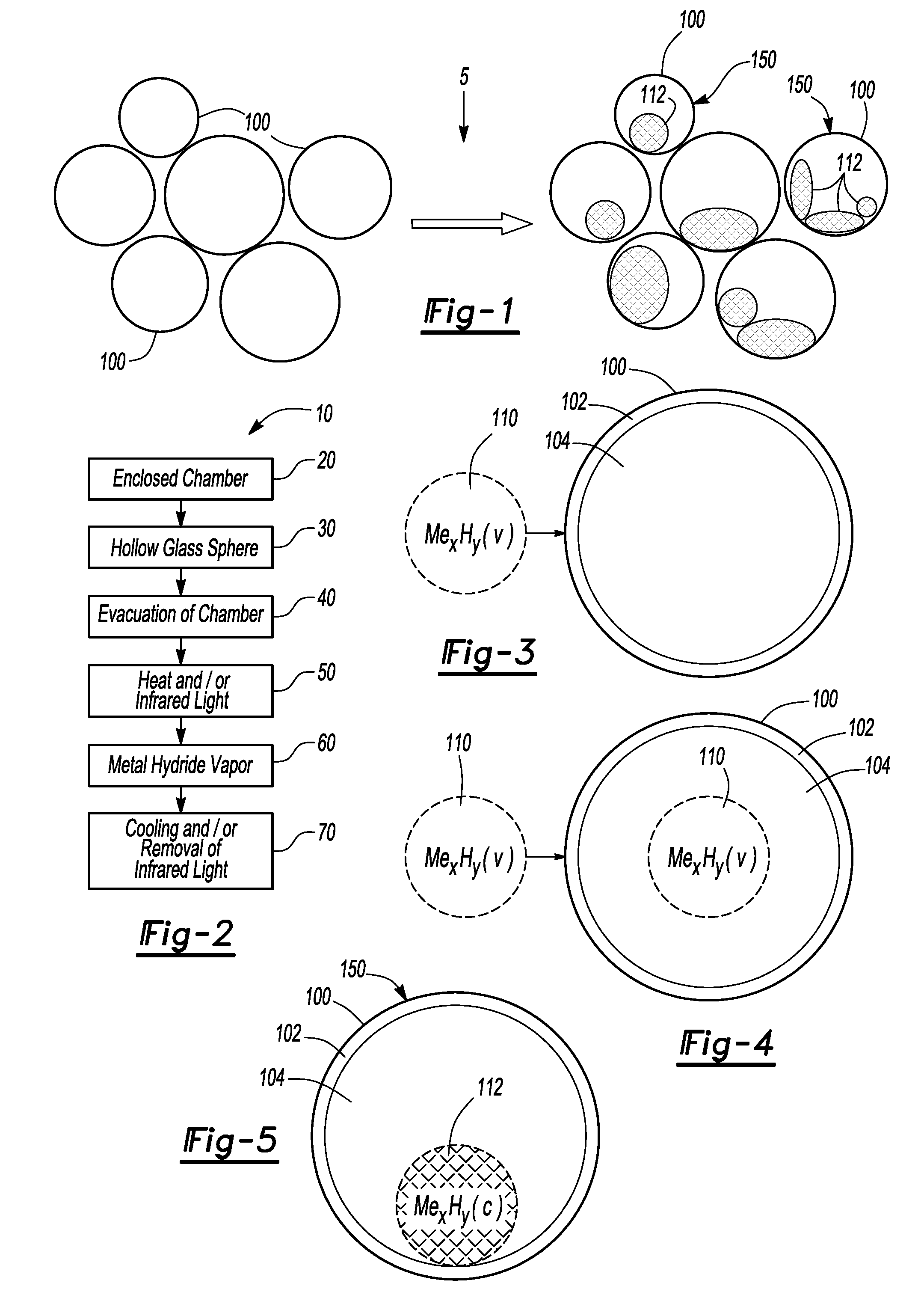

Method for encapsulating reactive metal hydrides

A process for encapsulating a metal hydride within a hollow glass sphere is provided. The process includes providing a hollow glass sphere, the hollow glass sphere having a shell enclosing an inner volume. The hollow glass sphere is placed within an enclosed chamber and the chamber is evacuated such that a negative pressure is present therewithin. The hollow glass sphere within the evacuated enclosed chamber is subjected to an external element such that the shell affords for molecules to diffuse therethrough. In some instances, the external element is heat, infrared light and combinations thereof. Thereafter, a metal hydride is provided in the form of a vapor and the evacuated enclosed chamber with the hollow glass sphere is exposed to metal hydride vapor and molecules of the metal hydride diffuse through the shell into the inner volume. Thereafter, the external element is removed from the hollow glass sphere such that diffusion of molecules through the shell is generally prohibited and the metal hydride within the hollow glass sphere is in a dense state.

Owner:TOYOTA MOTOR CO LTD

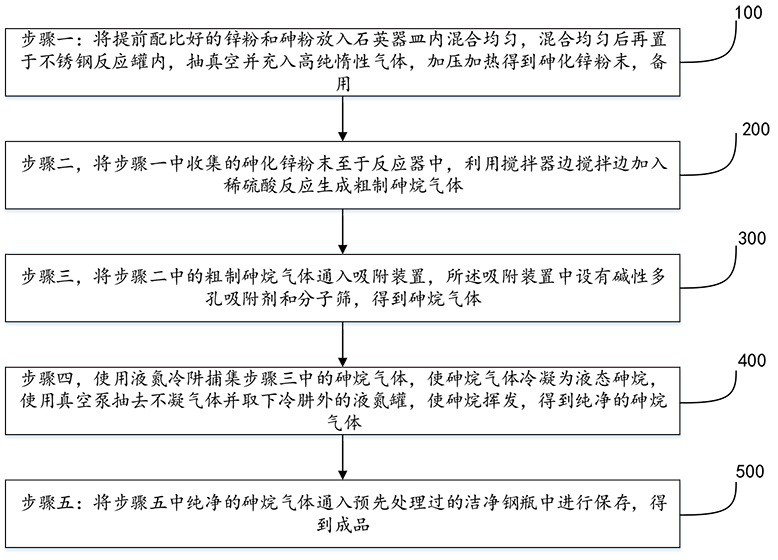

Synthesis and purification method of arsine

InactiveCN112520699ALess impuritiesHigh purityArsenic/antimony hydridesHydride purification/stabilisationMolecular sieveArsine

The invention relates to a synthesis and purification method of arsine. The method comprises the following steps: 1. putting zinc powder and arsenic powder into a quartz vessel, uniformly mixing, putting into a stainless steel reaction tank, vacuumizing, introducing high-purity inert gas, and pressurizing and heating to obtain zinc arsenide powder; 2, putting the zinc arsenide powder into a reactor, and adding dilute sulfuric acid to react to generate crude arsine gas; 3, introducing the crude arsine gas into an adsorption device to obtain arsine gas; 4, arsine gas is captured through a liquidnitrogen cold trap, the arsine gas is condensed into liquid arsine, non-condensable gas is pumped out through a vacuum pump, a liquid nitrogen tank outside the cold hydrazine is taken down, arsine isvolatilized, and pure arsine gas is obtained; and 5, introducing the pure arsine gas into a pre-treated clean steel cylinder for storage to obtain a finished product. Impurities in arsine gas can beeffectively reduced, the purity of arsine is improved, and meanwhile, the addition of an adsorbent and the selection of a molecular sieve are carried out in one device, so that the reaction efficiencycan be improved.

Owner:深圳市博纯半导体材料有限公司 +1

Method for encapsulating reactive metal hydrides

InactiveUS7914846B2Liquid surface applicatorsReversible hydrogen uptakeGlass spheresMaterials science

A process for encapsulating a metal hydride within a hollow glass sphere is provided. The process includes providing a hollow glass sphere, the hollow glass sphere having a shell enclosing an inner volume. The hollow glass sphere is placed within an enclosed chamber and the chamber is evacuated such that a negative pressure is present therewithin. The hollow glass sphere within the evacuated enclosed chamber is subjected to an external element such that the shell affords for molecules to diffuse therethrough. In some instances, the external element is heat, infrared light and combinations thereof. Thereafter, a metal hydride is provided in the form of a vapor and the evacuated enclosed chamber with the hollow glass sphere is exposed to metal hydride vapor and molecules of the metal hydride diffuse through the shell into the inner volume. Thereafter, the external element is removed from the hollow glass sphere such that diffusion of molecules through the shell is generally prohibited and the metal hydride within the hollow glass sphere is in a dense state.

Owner:TOYOTA MOTOR CO LTD

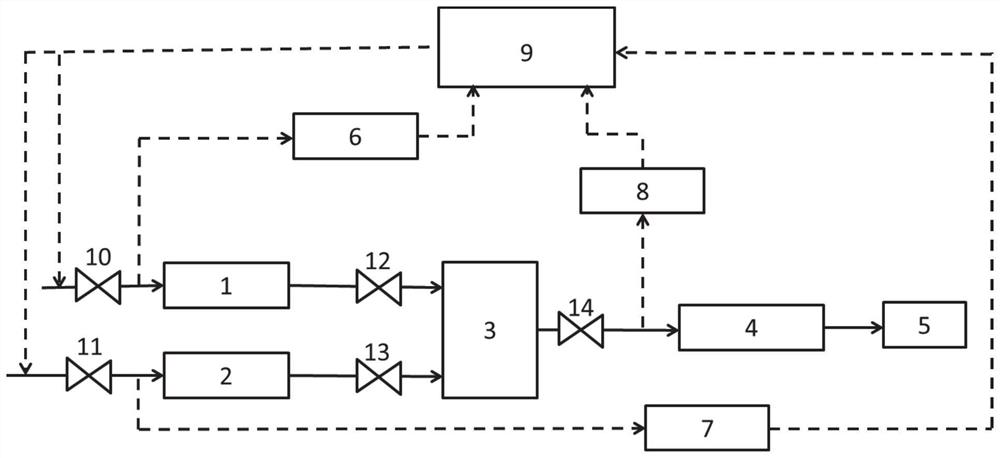

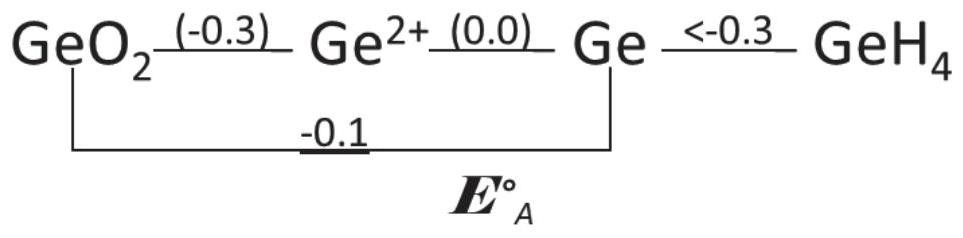

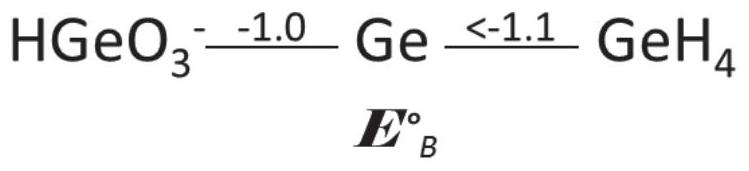

Production method and device for controlling germane preparation by adjusting electromotive force

PendingCN114655927ASimplified reaction condition measurement and control technologyImprove effectivenessWithdrawing sample devicesHydride purification/stabilisationAlkaline waterThermodynamics

Owner:贺孝鸣

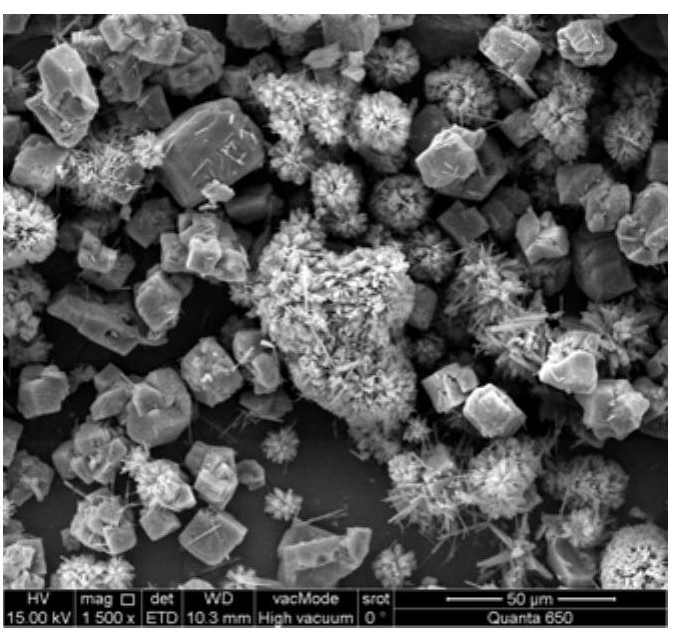

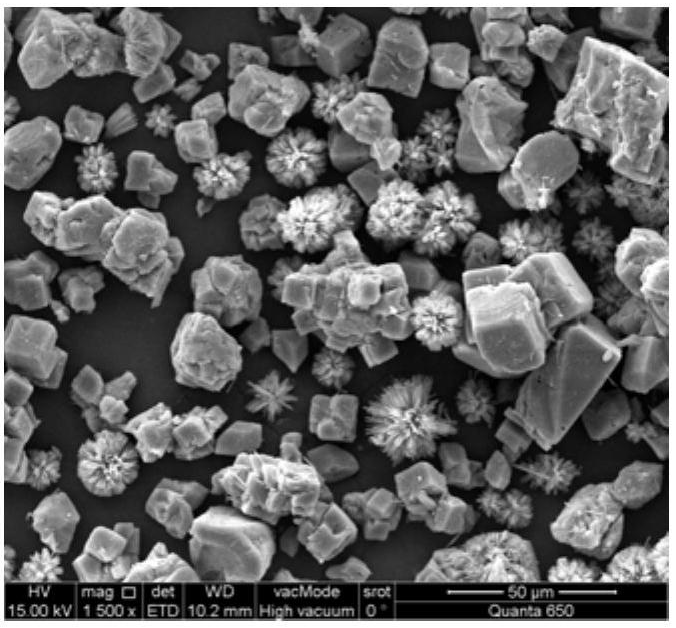

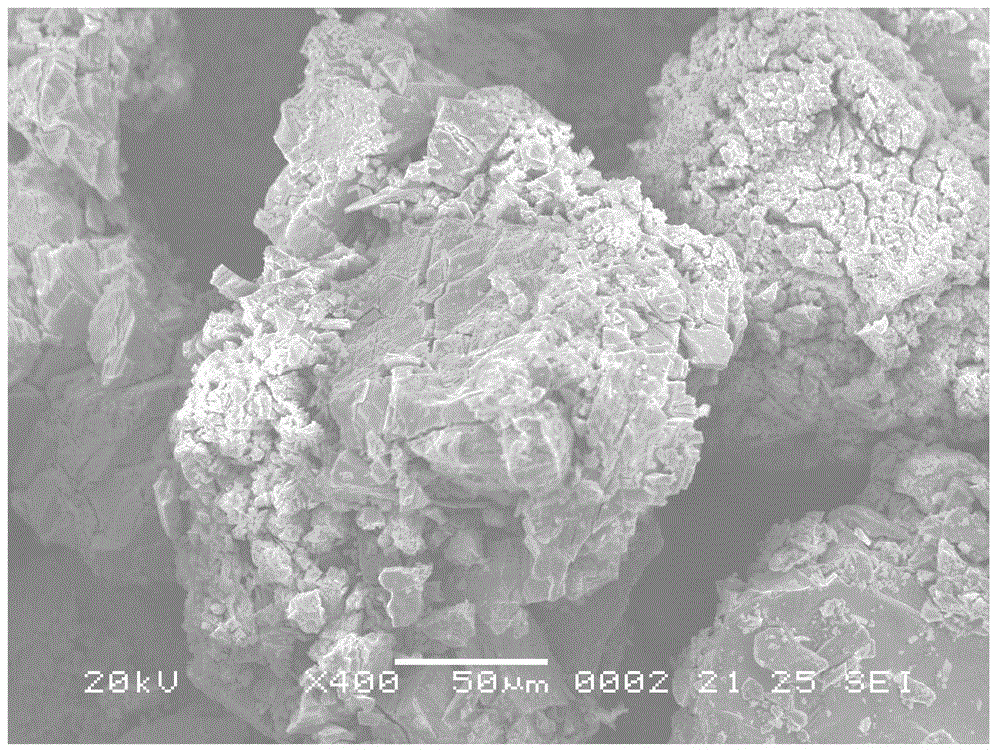

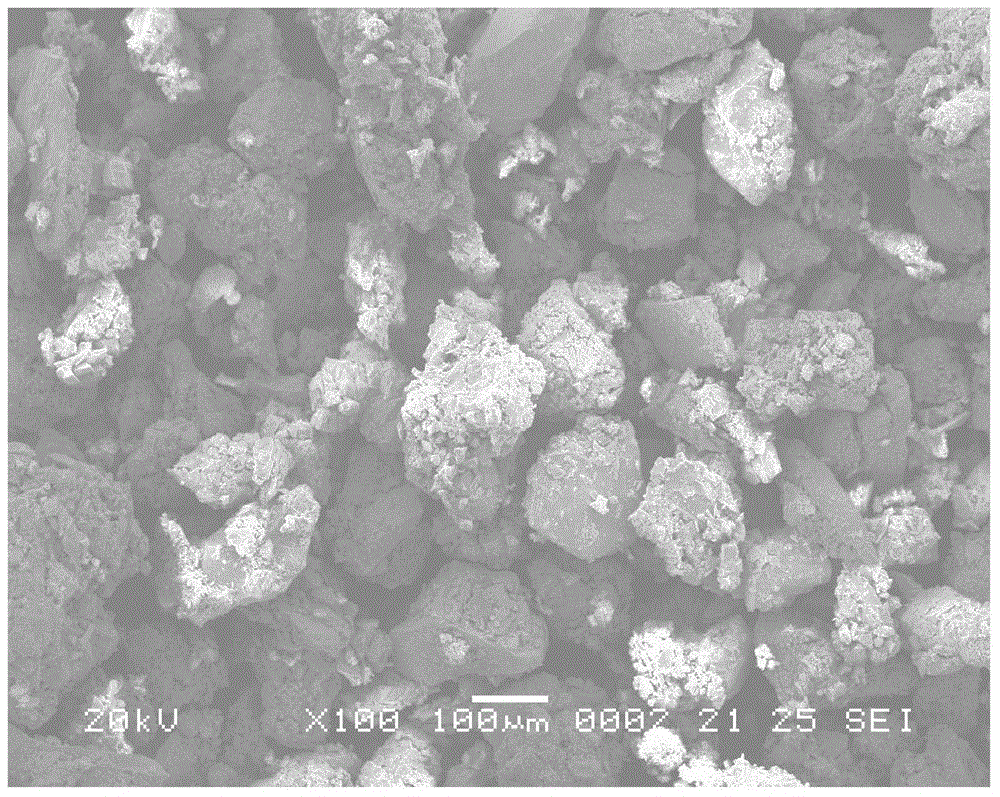

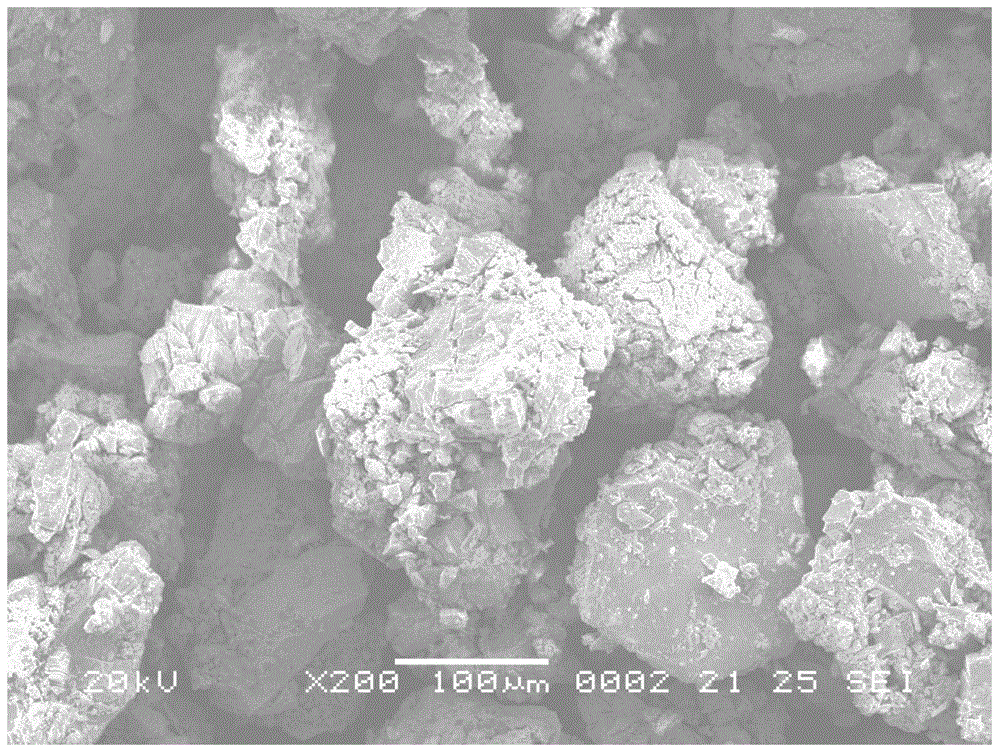

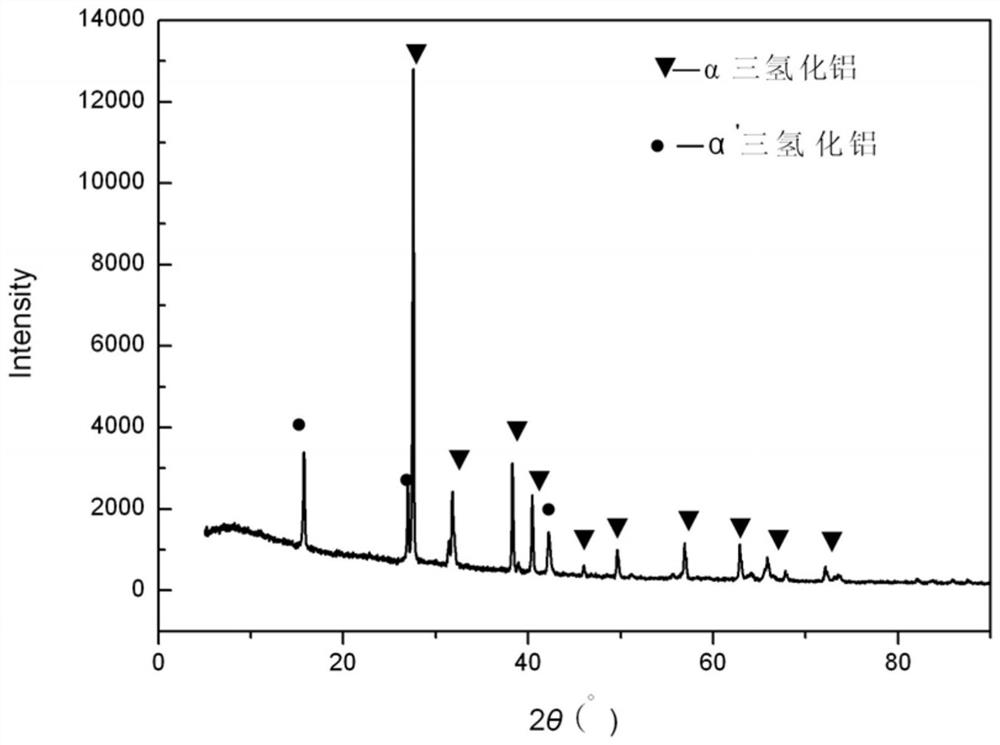

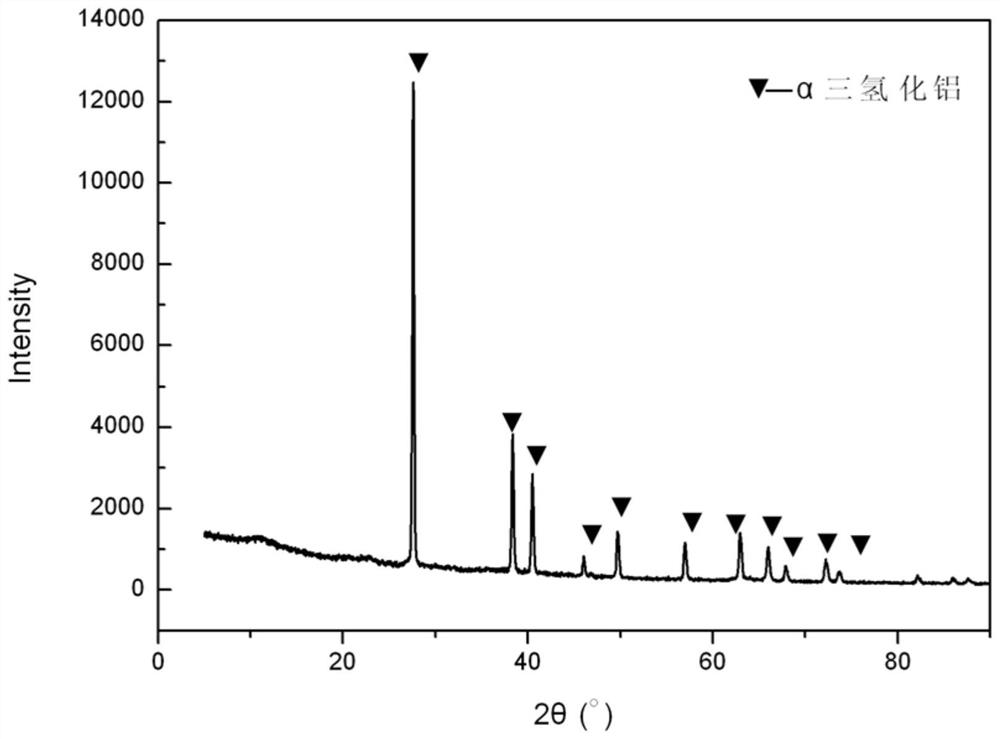

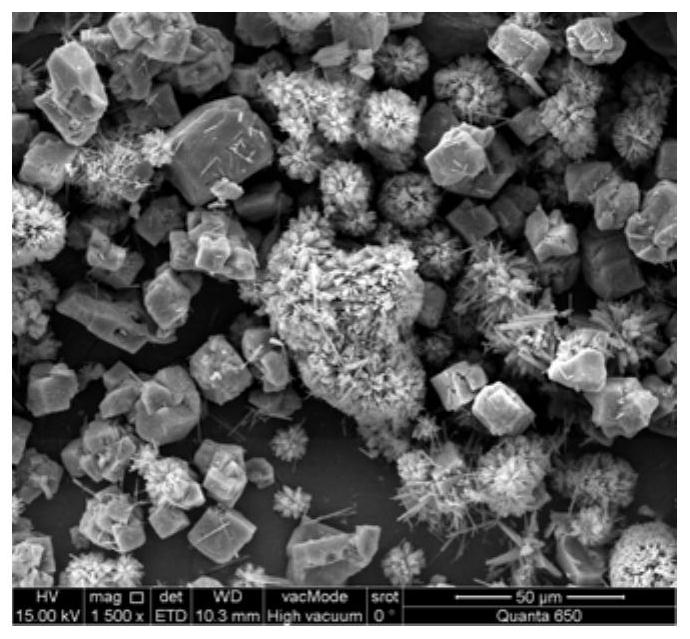

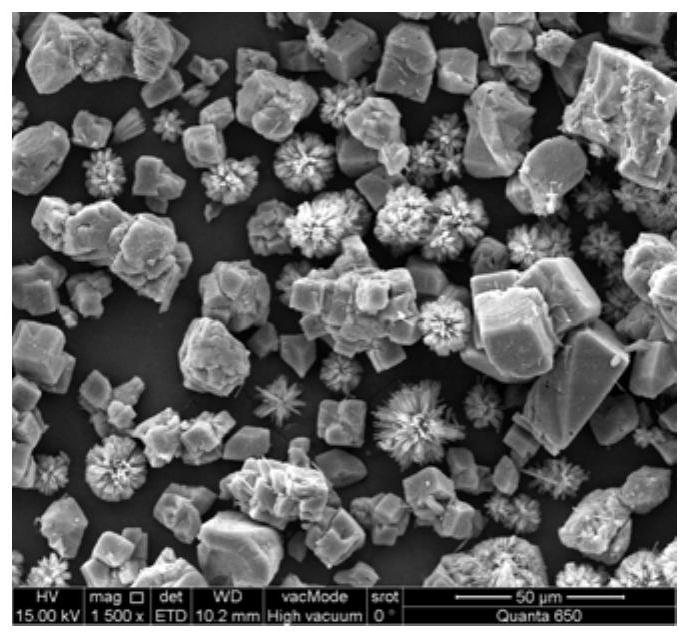

Method for removing alpha '-crystal form aluminum hydride

ActiveCN112209344AHigh purityLess solventHydride purification/stabilisationPhysical chemistryALUMINUM HYDRIDE

The invention provides a method for removing alpha '-crystal form aluminum hydride. The method comprises the following steps: 1. In an inert dry atmosphere, taking aluminum hydride to be purified, adding a solvent, and uniformly mixing; 2, transferring the uniformly mixed solution obtained in the step 1 to a reaction kettle, sealing the reaction kettle, heating the reaction kettle to 100-160 DEG C, and carrying out a constant temperature reaction; and 3, after the reaction is finished, naturally cooling and filtering to obtain a product, namely pure-phase alpha-crystal form aluminum hydride. According to the method disclosed by the invention, the alpha'-crystal form aluminum hydride can be completely and thoroughly removed, the purity of the finally obtained product is high and is alpha crystal form, and the alpha'-crystal form cannot be detected in the finally obtained product. According to the method, the amount of the used solvent is small, the reaction device is simple and easy tooperate, and the obtained product is free of alpha'-crystal form aluminum hydride. The method is mainly used for removing alpha'-crystal form aluminum hydride.

Owner:XIAN MODERN CHEM RES INST

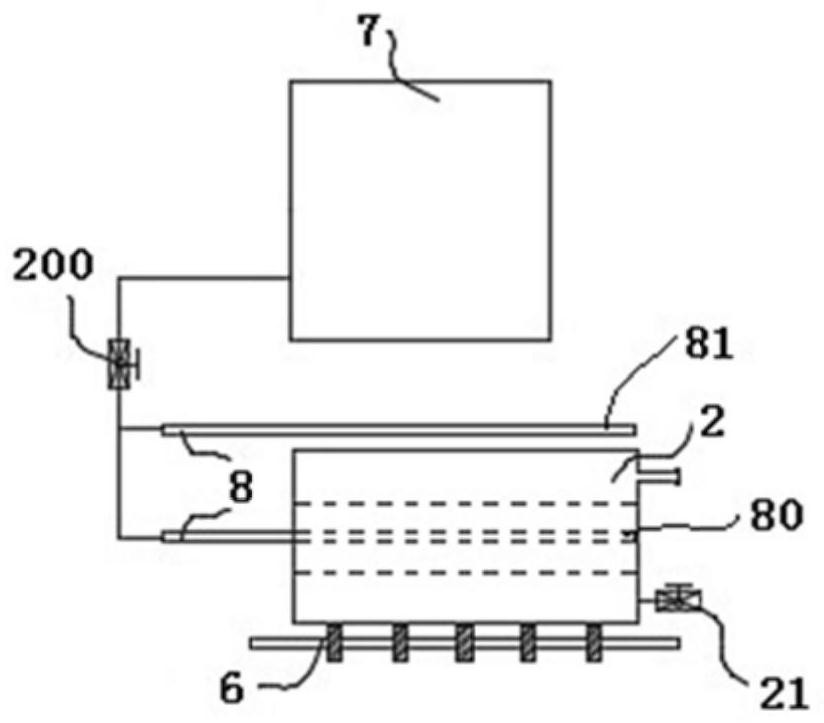

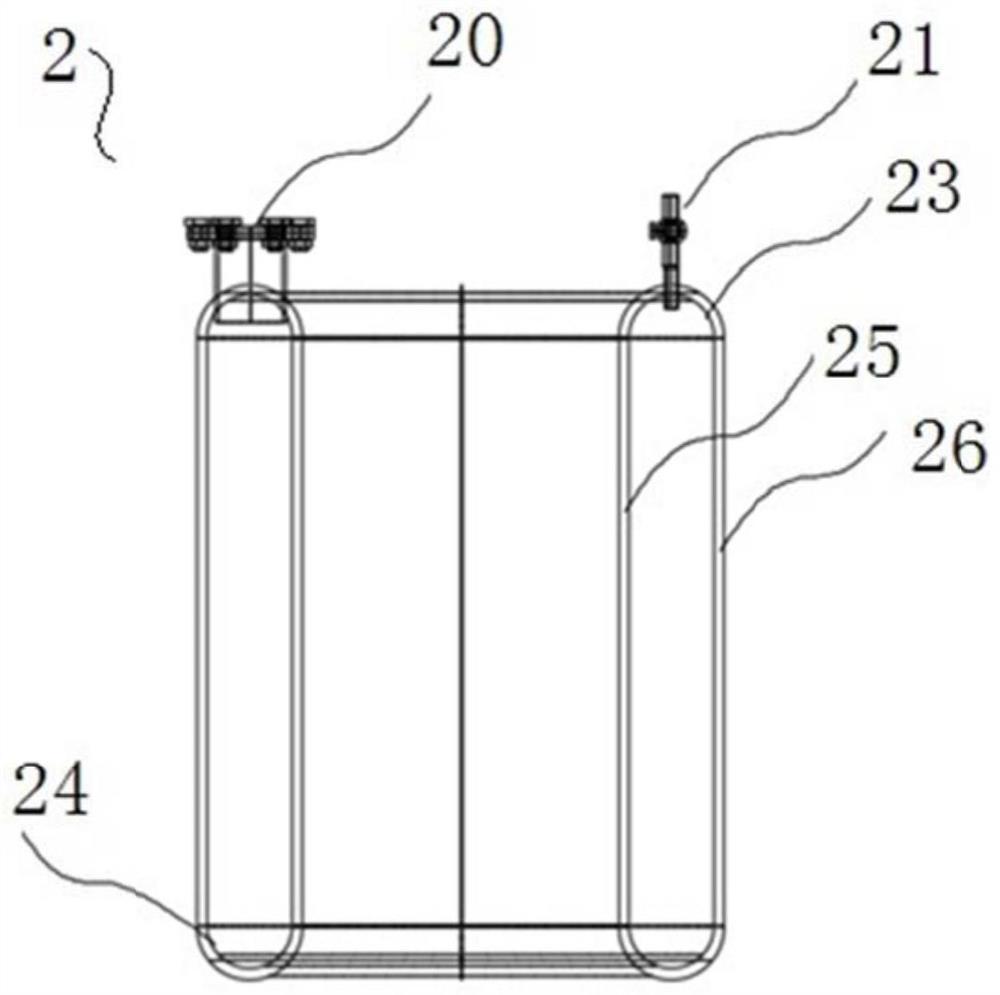

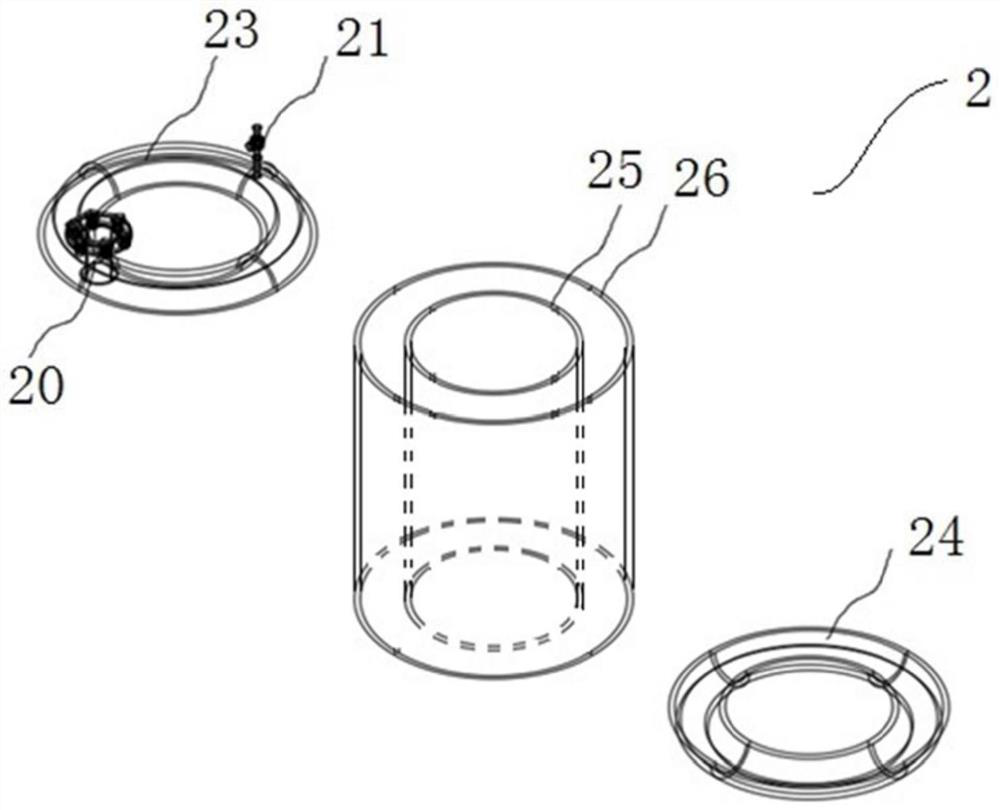

Temperature control synthesis device

PendingCN111892021AEffective control of reaction temperatureGood for laying flatHydride purification/stabilisationTemperature controlSprayer

The invention relates to a temperature control synthesis device. The temperature control synthesis device comprises: a cylindrical tank body, which is provided with a middle cavity and a sealed annular inner cavity surrounding the middle cavity, wherein the sealed annular inner cavity is used for accommodating a reaction material; a driving device, which is in transmission connection with the cylindrical tank body and can drive the cylindrical tank body to rotate around the axis of the cylindrical tank body, wherein the axis of the cylindrical tank body is arranged in a horizontal or inclinedstate; a temperature control system, which comprises a heat exchange medium source and a sprayer connected with the heat exchange medium source, wherein the sprayer comprises an inner sprayer corresponding to the middle cavity and spraying towards the cavity wall of the middle cavity and an outer sprayer located on the outer side of the cylindrical tank body and spraying towards the outer side face of the cylindrical tank body. Reaction raw materials are in full contact through rotation of the tank body, in the rotating process, the materials are mainly scattered on the cavity wall face of theannular inner cavity, the reaction temperature can be effectively controlled by spraying temperature control over the interior and the exterior of the cylindrical tank body, and the device can be used for synthesizing diborane and other substances sensitive to the reaction temperature.

Owner:HENAN UNIV OF SCI & TECH

Method for reducing activity of high-activity lithium hydride powder

ActiveCN112607706AReduced activityReduce security risksAlkali/alkaline-earth/beryllium/magnesium hydridesHydride purification/stabilisationPhysical chemistryHigh activity

The invention particularly relates to a method for reducing the activity of high-activity lithium hydride powder, which comprises the following steps: mixing the high-activity lithium hydride powder with a substance for reducing the activity of the high-activity lithium hydride powder to obtain a mixture; and standing the mixture in the air, so as to reduce the activity of the high-activity lithium hydride powder to a state that combustion and explosion cannot happen during digestion. According to the method for reducing the activity of the high-activity lithium hydride powder provided by the invention, the activity of the high-activity lithium hydride powder can be quickly reduced, so that the high-activity lithium hydride powder cannot be combusted, exploded and the like in a digestion process, and the safety risk of digestion of the lithium hydride powder is reduced.

Owner:CNNC JIANZHONG NUCLEAR FUEL

A kind of α-alh3 flotation method and its application

ActiveCN110550607BDoes not affect the preparation processSimple separation techniqueHydride purification/stabilisationFlotationCrystal morphologyHigh energy

The present invention relates to a kind of α-AlH 3 The flotation method and its application belong to the technical field of energetic materials. The present invention utilizes α crystal form and non-α crystal form AlH 3 Different physical and chemical properties, surface adsorption characteristics, crystal morphology characteristics and other inherent properties, with the help of ultrasonic separation and purification function, using a specific flotation liquid, the AlH 3 Medium α crystal form and non-α crystal form AlH 3 High-efficiency separation to obtain high-quality α-form AlH 3 and non-alpha crystal form. Through impact sensitivity and friction sensitivity experiments, the isolated high-quality α-crystal AlH was verified 3 Safety for applications in composite high-energy solid propellants. High-quality α-crystal form AlH of the present invention 3 High hydrogen content, based on high-quality alpha-form AlH 3 The slurry sensitivity of the high-energy propellant is low.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Use of Triammonium Salt of Aurin Tricarboxylic Acid as Risk Mitigant for Aluminum Hydride

A process and a resulting product by process of an aluminum hydride which is modified with by physically combining in a ball milling process an aluminum hydride with a triammonium salt of aurin tricarboxylic acid. The resulting product is an aluminum hydride which is resistant to air, ambient moisture, and liquid water while maintaining useful hydrogen storage and release kinetics.

Owner:BATTELLE SAVANNAH RIVER ALLIANCE LLC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com