Patents

Literature

35 results about "Aurin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aurin (C.I. 43800), sometimes named rosolic acid or corallin is an organic compound, forming yellowish or deep-red crystals with greenish metallic luster. It is practically insoluble in water, freely soluble in alcohol. It is soluble in strong acids to form yellow solution, or in aqueous alkalis to form carmine red solutions.

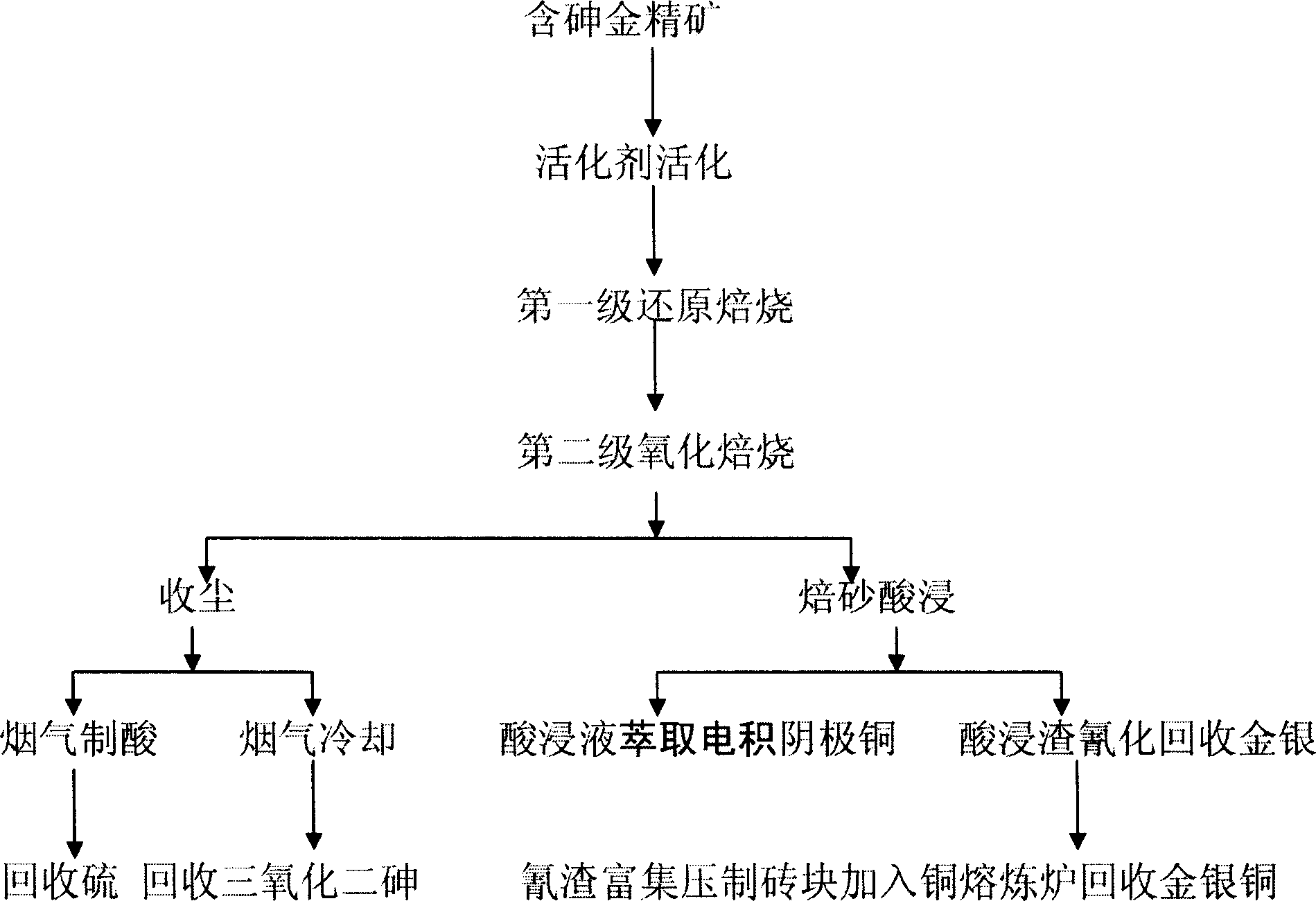

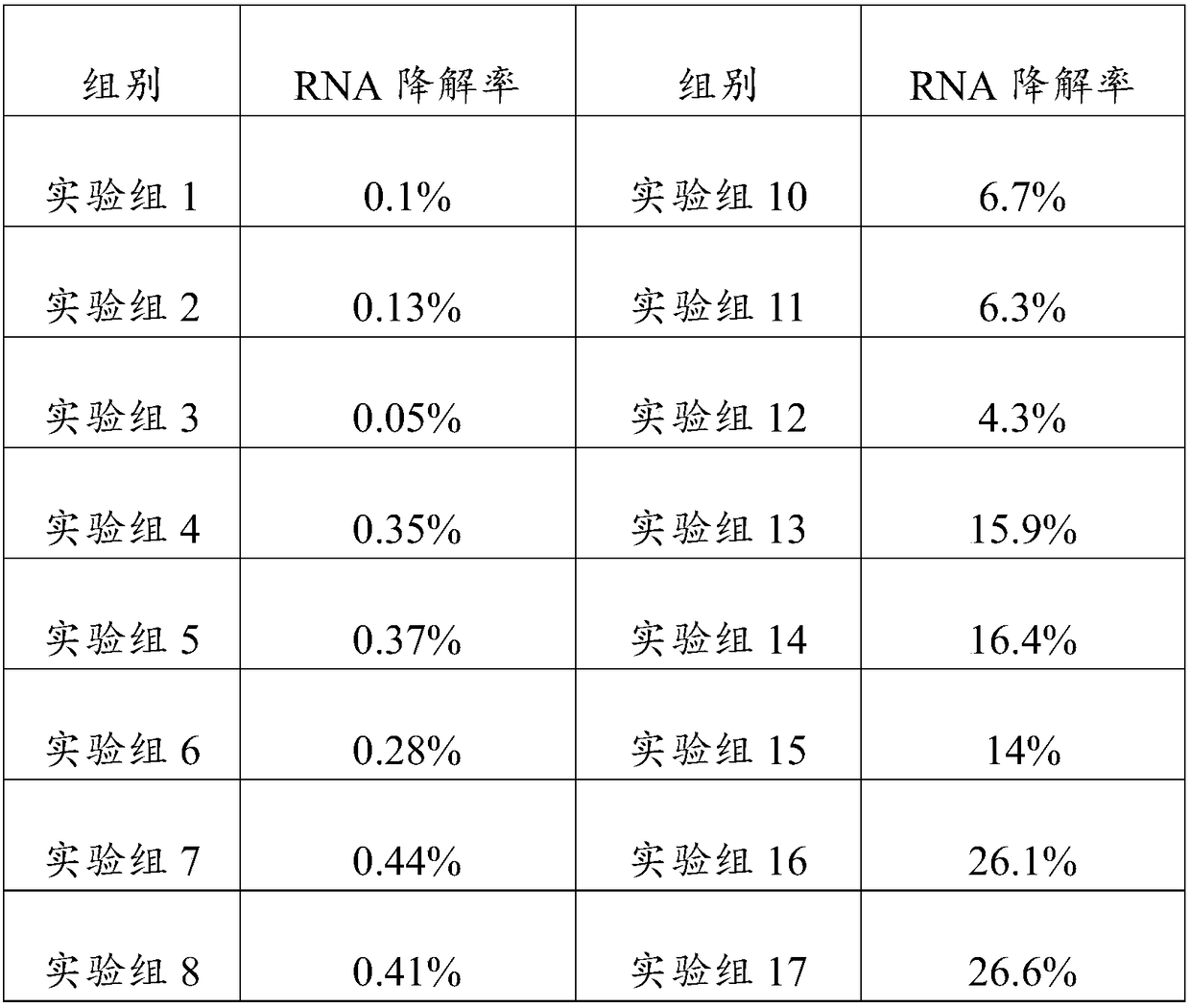

Method of extracting gold and silver from arsenic containing aurin ore

InactiveCN1904094ALow impurity contentAvoiding the problem of chemical synthesis of iron arsenatePhotography auxillary processesProcess efficiency improvementSulfurCopper

The present invention relates to a method for extracting gold and silver from arsenical gold headings. It is characterized by that said method includes the following steps: (1), using activating agent to make activation; (2), first-stage reduction and calcinations; (3), second-stage oxidation and calcinations; (4), acid-pickling, using acid-pickling liquor to make extraction and electrodepositing cathode copper; (5), cyaniding acid-pickling dregs and recovering gold and silver; and (6), calcining smoke gas, making trentment and recovering arsenic and recovering sulfur.

Owner:SHANDONG GUODA GOLD

Leaching method for complicated cupric sulfide aurin ore

ActiveCN1821428ALow impurity contentImprove leaching rateMetal/metal-oxides/metal-hydroxide catalystsSlurryHydrometallurgy

The present invention relates to wet metallurgical technology, and is especially leaching process of complicated cupric sulfide aurin ore. The process includes stirring leaching ore slurry under normal pressure oxidizing condition, extraction, cyanidation-zinc powder displacement to recover Au, Ag and Cu, and floating to enrich and hot filtering to recover sulfur. In the stirring leaching step, one or several of ferric nitrate, ferric sulfate, ferric chloride, vanadium oxide, manganese oxide and titanium oxide as catalyst to alter the surface activity of the cupric sulfide is added in the amount of 0.05-1.0 mol / L. The present invention has the features of normal pressure and normal pressure leaching, easy control, low production cost, environment friendship, etc.

Owner:厦门紫金矿冶技术有限公司

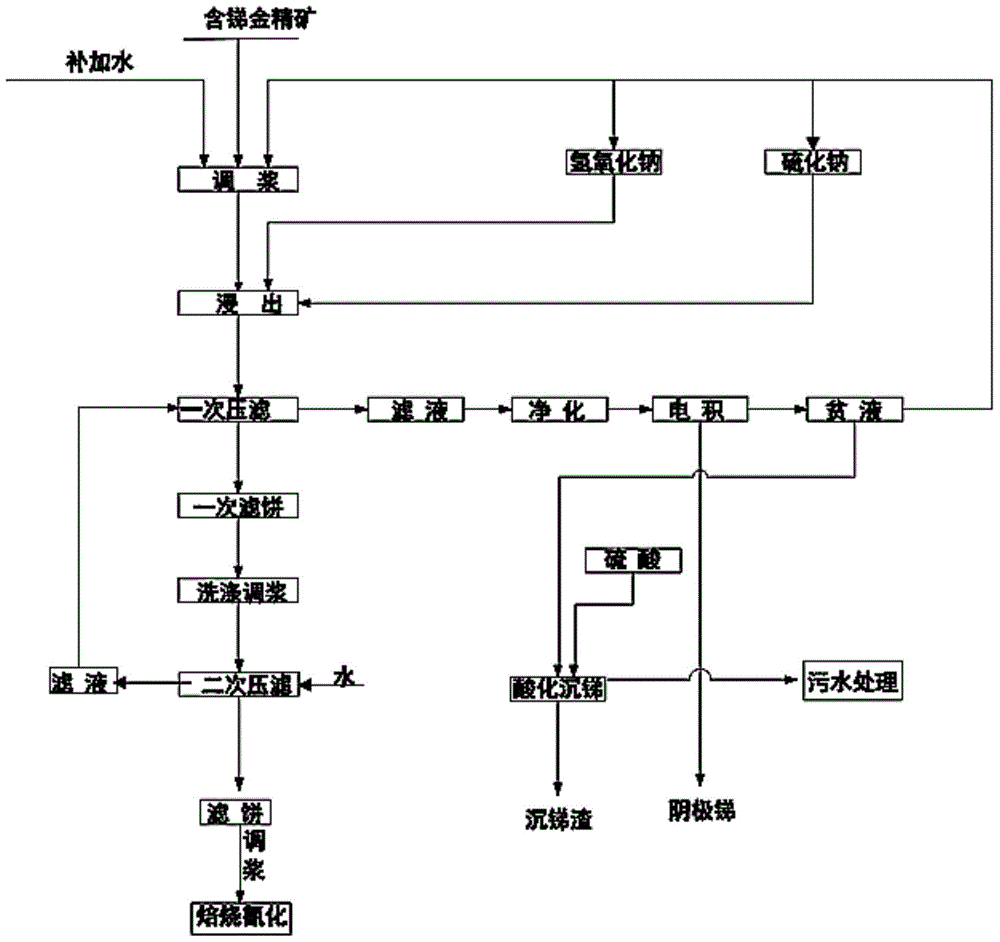

New technology for recovering antimony from antimony-containing gold concentrate

InactiveCN104831315AAvoid restrictionsGuaranteed stabilityPhotography auxillary processesProcess efficiency improvementHigh concentrationFiltration

The invention relates to a new technology for recovering antimony from antimony-containing gold concentrate. The technology comprises the steps of pulping, leaching, press filtration washing, electrodeposition and waste liquid treatment. The technology overcomes restriction of electrodeposition of traditional wet antimony making technologies on a high antimony raw material through high concentration leaching and antimony-containing liquid circulating enrichment, solves the restriction of traditional smeltery roasting-cyaniding technologies on the antimony-containing gold concentrate raw material, and guarantees the technology stability and continuity through adopting a high efficiency device and technologic link technologic index control.

Owner:ZHAOJIN MINING +1

Method for smelting arsenic-containing gold concentrate

InactiveCN101078057AGood processing effectHigh recovery rateSulfur compoundsProcess efficiency improvementCooling towerArsenic oxide

A kind of smelting method of aurin mine containing arsenic, it contains the following technology steps: primary burning, second-class burning, The burning residue after burning will be added into the pickling ark with the soot separated to be pickled. The filtrate will be used to extract copper, the filter cake will be separated and cyanide residue and golden mud can be gained, and the golden mud will be smelted to extract gold bullion. The character of it is that the smoke gas, which has been catch dust by primary burning and second-class burning, will be drew arsenic in according to hop-pocket drying method. The process is as following, the smoke gas containing arsenic will enter the spray cooling tower and be quench by spraying water, the arsenic oxide will become solid and be separated out from gaseous crystal, the smoke gas will take arsenic oxide solid into bag arsenic catcher, and the arsenic oxide solid will be collected into ash bucket after being filtrated by hop-pocket, and then will be packed and finished product can be gained. The smoke gas after arsenic catching will enter the acid making system, and produce vitriol by cleanse workshop section, translation workshop section and dried absorbing workshop section, the finished vitriol product will be gained, and the off-gas will be exhaled into air. The technology of it is simple and feasible, and it is easy to operate, the coefficient of recovery and arsenic catching rate are both high, the investment of it is low, and the running cost of it is low.

Owner:SHANDONG HUMON SMELTING

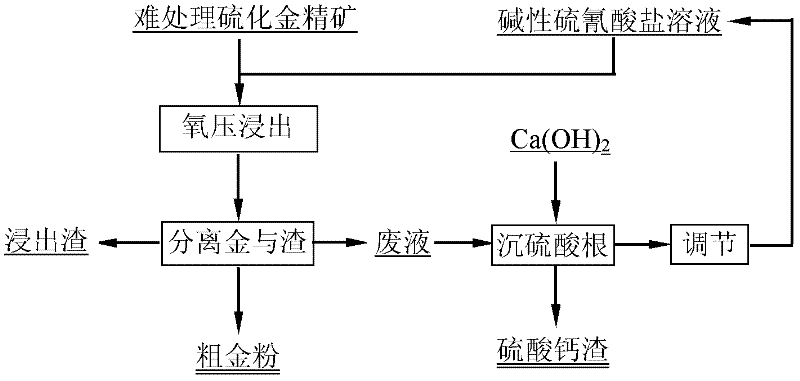

Method for leaching gold from refractory gold sulfide concentrate by using alkaline thiocyanate solution under oxygen pressure

InactiveCN102242260AAvoid secondary packagingImprove leaching rateProcess efficiency improvementDecompositionSulfide minerals

The invention discloses a method for leaching gold from a refractory gold sulfide concentrate by using alkaline thiocyanate solution under oxygen pressure, which comprises the following steps of: leaching at the temperature of between 110 and 200 DEG C under the oxygen pressure of 0.3 to 1.5MPa for 1.0 to 8.0 hours by using alkaline solution containing 0.1 to 3.0M thiocyanate in a solid-to-liquid ratio of 100 to 300g / L; and separating and recovering the gold from the solution to obtain waste liquid, regenerating to obtain alkali, and returning to the next leaching. The refractory gold concentrate is directly leached by the alkaline thiocyanate solution under the oxygen pressure without being pretreated, the process flow is short, efficiency is high, and cost is low; roasting is eliminated, and the pollution of low-concentration SO2 flue gas, As2O3 smoke and the like is avoided; and during oxygen pressure leaching, the gold is subjected to oxidative cooperated leaching while sulfide minerals in the gold concentrate are subjected to oxidative decomposition, so that the secondary packaging of the gold is avoided, and the leaching rate of the gold is improved.

Owner:CENT SOUTH UNIV

Method for recovering gold from all-sliming cyanidation gold extraction slag

InactiveCN101392326AHigh recovery rateBuoyancy recoveryProcess efficiency improvementSlagSurface cleaning

The invention provides a method for recovering gold from all-slime cyanidation leaching gold residue. The method includes the flotation technology which is characterized in that: in the slurry of the all-slime cyanidation leaching gold residue, sulphuric acid and organic ketone are added till the pH value of the slurry is 7 to 8, wherein, the sulphuric acid and the organic ketone are added according to the mass ratio of 2 to 5:1 to 2; simultaneously, according to 0.02 permile to 0.05 permile of the solid mass of the slurry, oleic acid or oleate is added, and after the flotation technology, gold concentrate is obtained. The addition of the sulphuric acid and the organic ketone takes the function of neutralization of the alkalescence of the slurry and the surface cleaning of minerals, and furthermore, activates gold-bearing minerals, the floatability of which is recovered and increased. The oleic acid or the oleate can cause partial unactivated gold-bearing minerals with fine grains to produce flocculation, and then become concentrate products which float off with other gold-bearing minerals, thereby improving the gold recovery rate which can reach over 90 percent. The method has simple technology, convenient operation, low manufacturing cost and high gold recovery rate.

Owner:KUNMING UNIV OF SCI & TECH

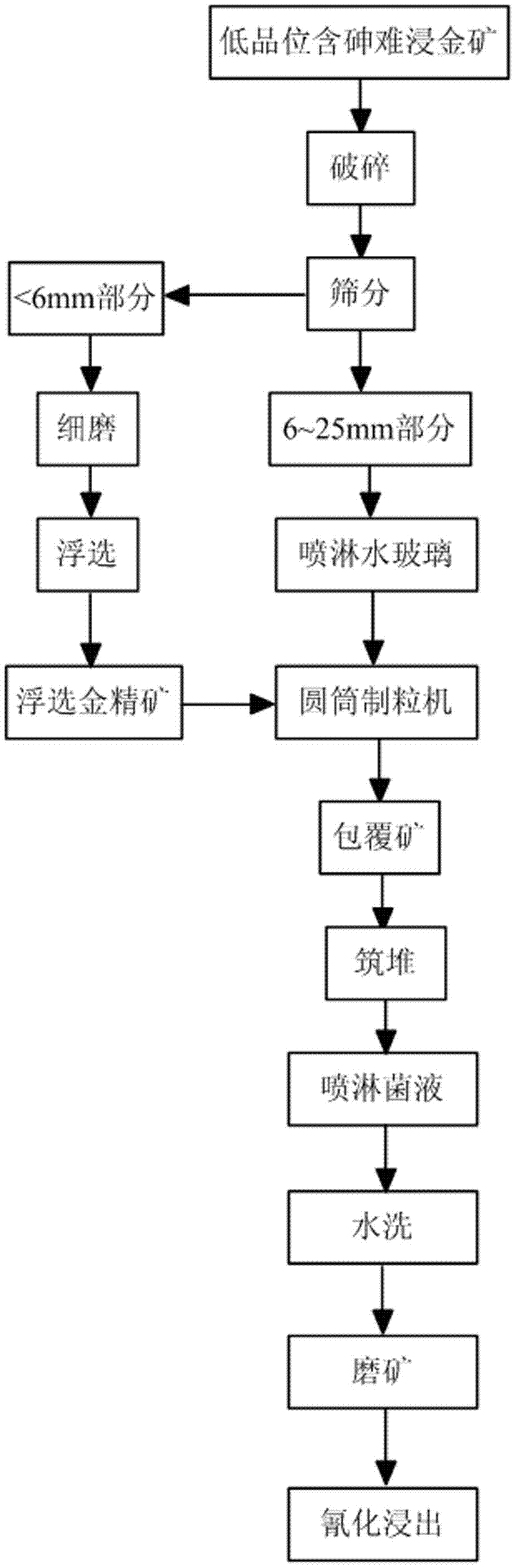

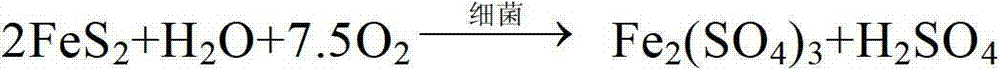

Coated biological oxidation pretreatment method of low-level arsenic refractory gold ores

ActiveCN102230084AHigh recovery rateIncrease oxidation rateProcess efficiency improvementPretreatment methodEnergy expenditure

The invention provides a coated biological oxidation pretreatment method of low-level arsenic refractory gold ores. The method comprises the following steps of: (1) crushing and screening low-level arsenic refractory gold ores to obtain fine ores and ores; making the fine ores into flotation gold concentrate; uniformly spraying sodium silicate adhesive on the surfaces of the fine ores so as to obtain adhesive ores; (2) uniformly coating the flotation gold concentrate on the surfaces of the adhesive ores; (3) after piling the ores, spraying sulfuric acid; (4) spraying bacteria liquid on ore piles; (5) when the arsenic removal rate of the ores in the ore piles is more than 60 % and the desulfurization degree is more than 40 %, stopping the spraying of the bacteria liquid so as to finish biological oxidation pretreatment. By using the method provided by the invention, the recycling rate of the gold can be increased; and the method provided by the invention has the advantages of low production cost, les energy consumption, less drug usage, low labor intensity, simple process flow, low equipment requirement, easiness in implementation and no generation of waste gas.

Owner:NORTHEASTERN UNIV

Multiple roasting gold extracting method for unmanageable arsenic-containing gold concentrate

A kind of method to extract gold by time and time burning with aurin mine containing arsenic difficult to deal with, and it belongs to the mineral pretreatment technology field of gold meltallurgy industry. The character of it is as following, (1) blending: Coal powder will be added into ore tailing, which has be extracted gold by secondary burning to cyanate, according to the weight rate 7-10%, and will be uniformly mixed. (2) burning: the material prepared will be delivered into the roasting kiln to burn, the temperature will be controlled at 550-680deg.C, the smoke gas will be drained after be cleaned by dust catching, the burning residue produced will be cyanided.(3) cyaniding : the bullion will be reclaimed from the burning residue according to the routine method to extract gold by cyanating. Coal powder will be added into the ore tailing, which has be extracted gold by secondary burning to cyanide, and they will be burned over again, the ore tailing will be extract bullion by cyanating method after it has been burned, so it can be realized to reclaim bullion production furthest form aurin mine containing arsenic difficult to deal with, and the problem that the reclaim of bullion from aurin mine containing arsenic difficult to deal with is low. It takes advantage of the gold mine fully, and improves the availability of resource, the method of it is easy and feasible, is also economic.

Owner:SHANDONG GUODA GOLD

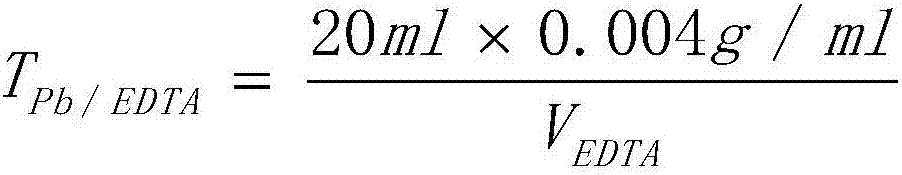

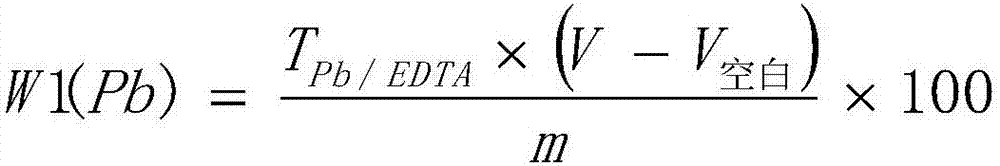

Method for simply and efficiently determining content of lead in gold concentrate

InactiveCN107515273AExpand the scope of testingMake up for the problem of blind spots in measurement methodsChemical analysis using titrationColor/spectral properties measurementsAurinPotassium chlorate

Owner:CHANGCHUN GOLD RES INST

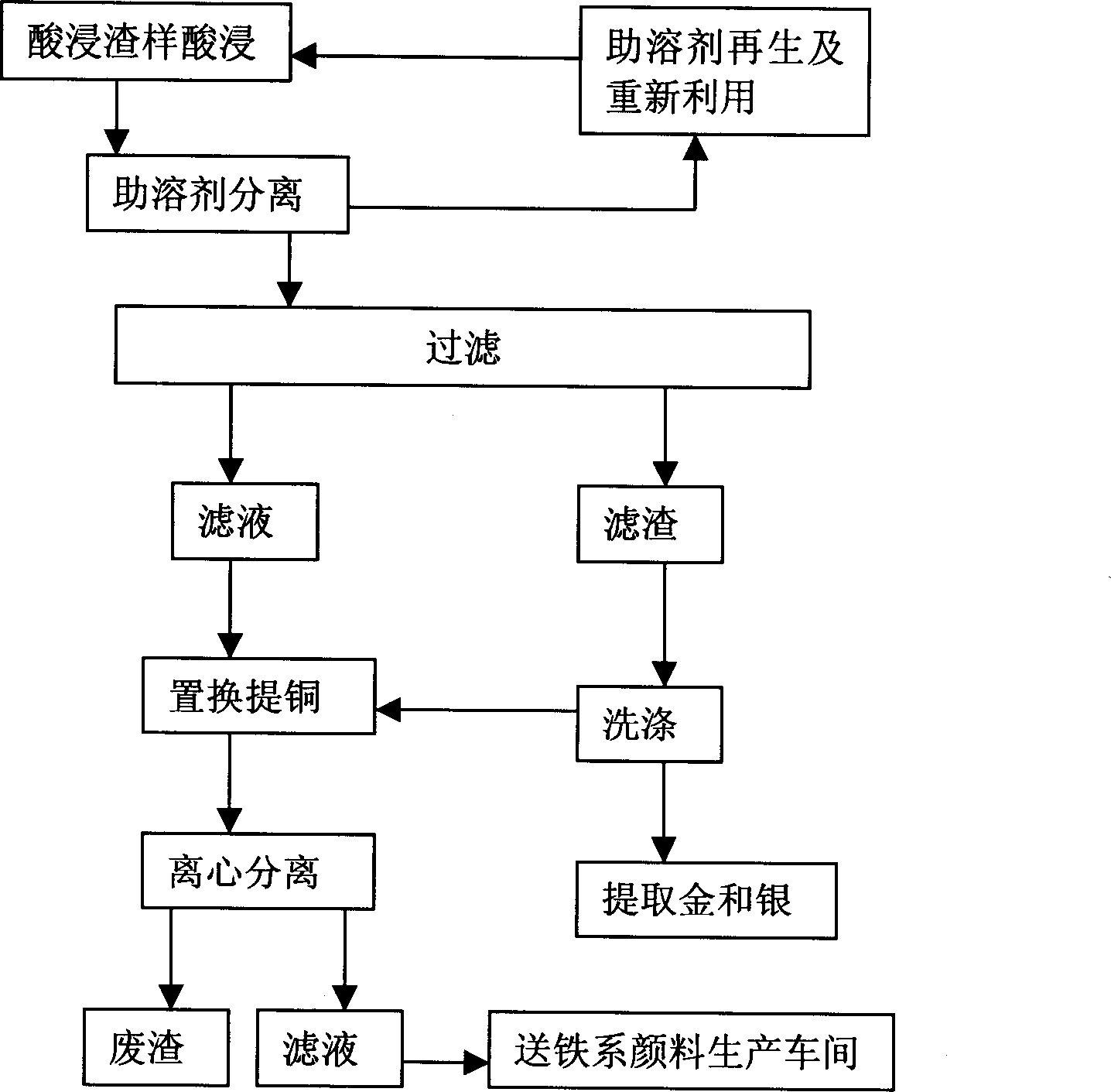

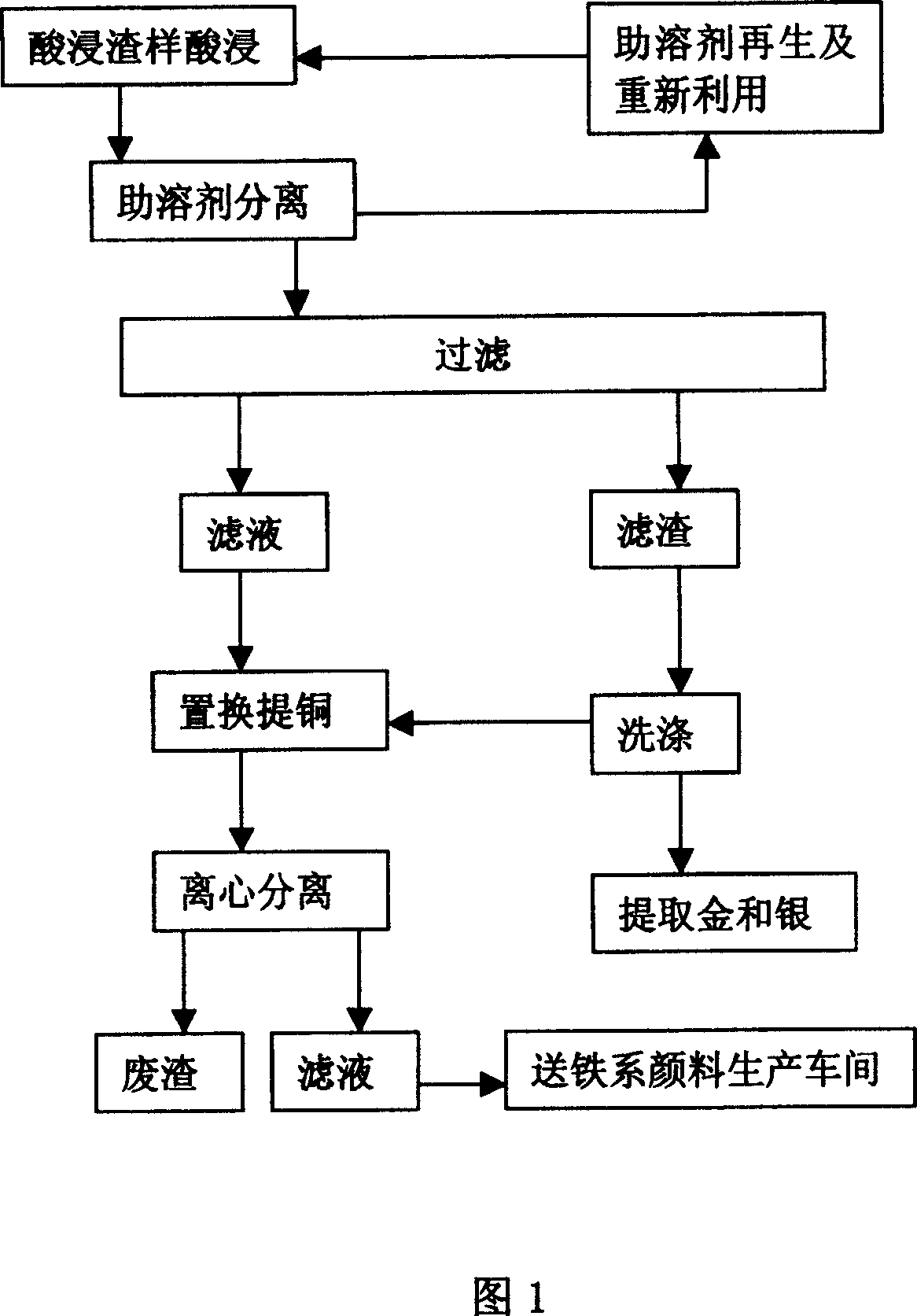

Prepn process of iron red with salfated roasted dreg of sulfur containing aurin ore

InactiveCN1772628AImprove raw materialsImprove resource utilizationPigmenting treatmentFerric oxidesResource utilizationSulfur containing

The preparation process of iron red with sulfated roasted dregs of sulfur containing aurin ore includes the following steps: 1. adding 30-60 % concentration sulfuric acid and roasted dregs in the weight ratio of 1 to 2-10 via stirring, adding co-solvent in 0.01-1 time the weight of roasted dregs, reacting at 60-100 deg.c for 1-6 hr, and filtering to obtain filtrate and filter residue; 2. neutralizing the filtrate with ammonia water, controlling pH 1-2, adding ammonia water at 50-90 deg.c to precipitate partial iron ion and adding flocculant; and 3. washing the obtained precipitate, drying, calcining at 300-700 deg.c and grinding to required fineness to obtain iron red. The present invention has the advantages expanded iron red preparing material range, raised tail ore resource utilization, raised post gold extracting efficiency, lowered power consumption, and lowered environmental pollution.

Owner:DONGHUA UNIV +1

Serum-free culture medium without animal origin components for culturing Vero cell micro-carrier

InactiveCN101864393BPromote growthSame densityArtificial cell constructsVertebrate cellsSerotoninVitamin C

Owner:INST OF BIOENG ACAD OF MILITARY MEDICAL SCI OF THE CHINESE

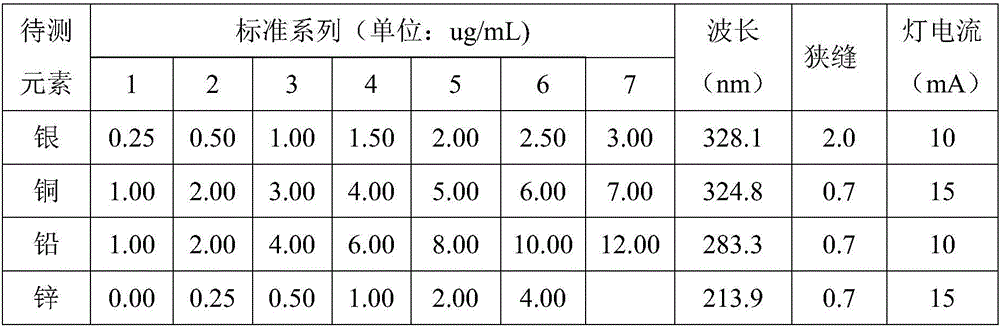

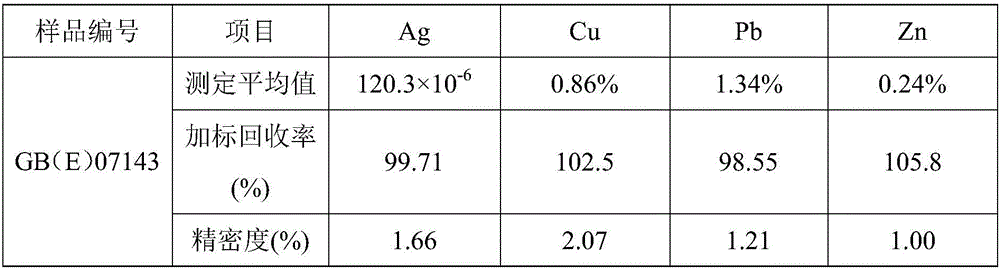

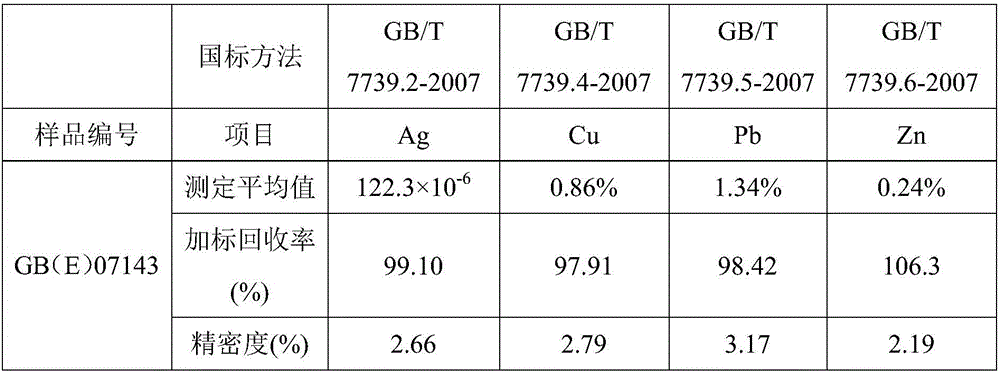

Method for determining content of silver, copper, lead and zinc elements in gold concentrate

InactiveCN105973822AAvoid joiningEliminate the effects ofPreparing sample for investigationColor/spectral properties measurementsEnvironmental resistanceDissolution

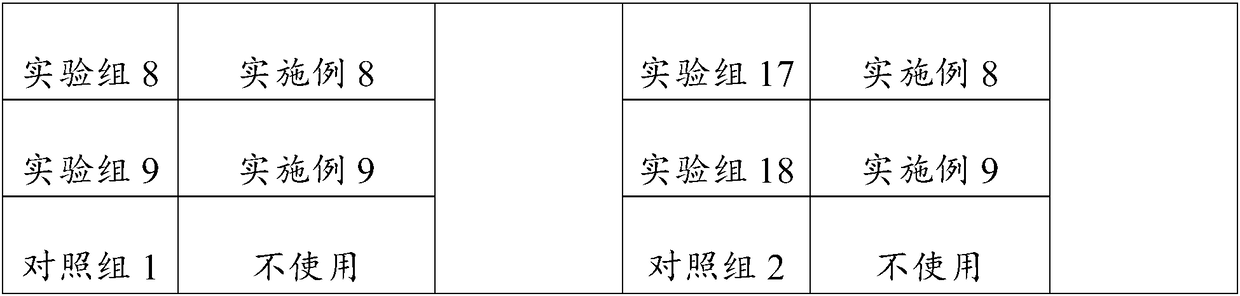

The invention relates to a method for determining the content of silver, copper, lead and zinc elements in gold concentrate, and belongs to the field of analytical chemistry. The method comprises the steps that degradation is conducted on gold concentrate samples, the gold concentrate samples are subjected to smashing and drying, 0.2 g-0.5 g of samples are weighed, water is added for wetting, hydrochloric acid is added, a watch glass is used for covering, low-temperature heating is conducted for 5 min to 10 min, nitric acid is added, dissolution is conducted, perchloric acid is added, heating is conducted continuously till thick white smoke appears, steaming is conducted till the samples are shaped like wet salt, the samples are taken down for cooling, hydrochloric acid is added, the beaker wall and the watch glass are washed with water, heating is conducted to dissolve salts, a solution is added to the scale volume of a 100 mL volumetric flask, dilution is conducted with pure water to the scale, mixing is conducted to be uniform, and standing and clarifying are conducted; continuous determining is conducted on the silver, copper, lead and zinc elements in the gold concentrate. The method for determining the content of the silver, copper, lead and zinc elements in the gold concentrate has the advantages that the silver, copper, lead and zinc elements in the gold concentrate are continuously determined, the experimental processes are simplified, the method is simple, the detection speed is high, the experiment cost is reduced, conservation and environmental protection are achieved, the measurement range is widened, and the accuracy of determination of the silver, copper, lead and zinc elements in the gold concentrate is improved.

Owner:CHANGCHUN GOLD RES INST

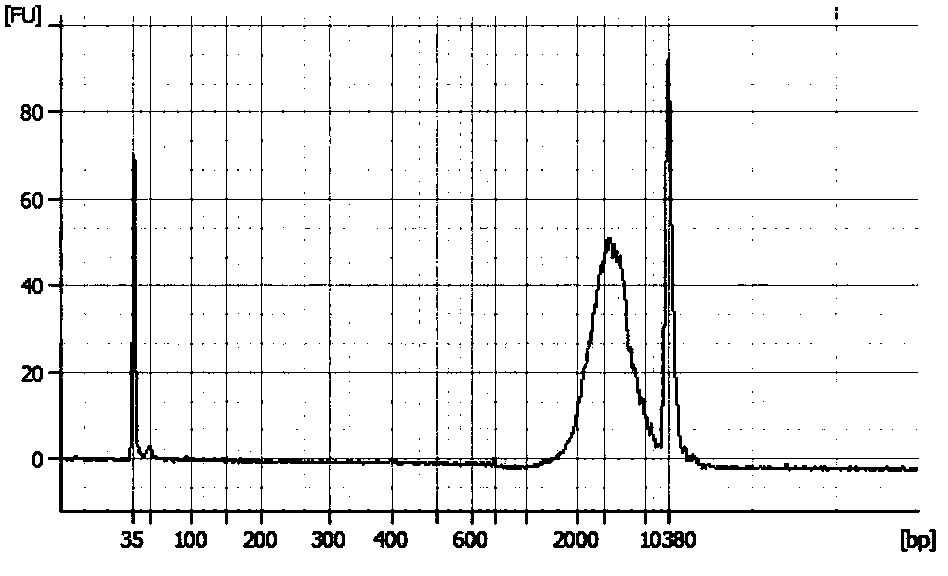

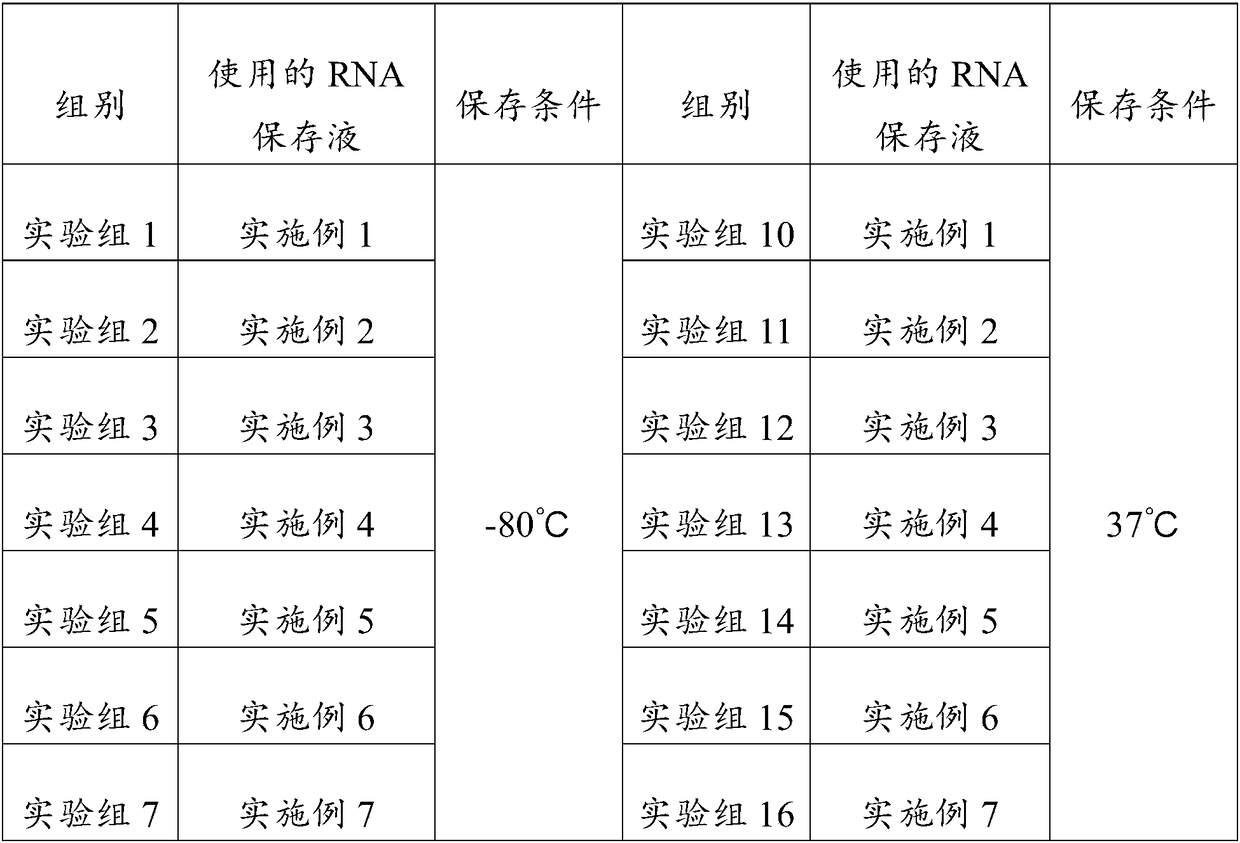

Stably preserved RNA (ribonucleic acid) quality control serum of lung cancer fusion gene detection kit

ActiveCN108085391AEffectively Monitor AccuracyEffectively Monitor StabilityMicrobiological testing/measurementRNA quality controlLung cancer

The invention discloses a stably preserved RNA (ribonucleic acid) quality control serum of a lung cancer fusion gene detection kit. The quality control serum contains the following ingredients: a positive reference, a negative reference and a detection limit reference. The positive reference, the negative reference and the detection limit reference respectively contain a corresponding fusion geneRNA, aurin ammonium triformate salt, a preservative and bestatin hydrochloride; the preservative is selected from glycine, epsilon-polylysine or cysteine. According to the RNA quality control serum provided by the invention, free RNAs can be effectively prevented from being degraded, a stable environment is provided for the RNAs, and the preservation time of the RNAs is prolonged; meanwhile, the RNA quality control serum has the advantages of being low in preparation cost, stable in performance, easy in preservation and the like; the factors such as personnel operation, instrument states, theeffectiveness of the kit and the like can be effectively monitored, so that the accuracy and reliability of the detection kit can be greatly improved.

Owner:GUANGZHOU JINQIRUI BIOTECHNOLOGY CO LTD

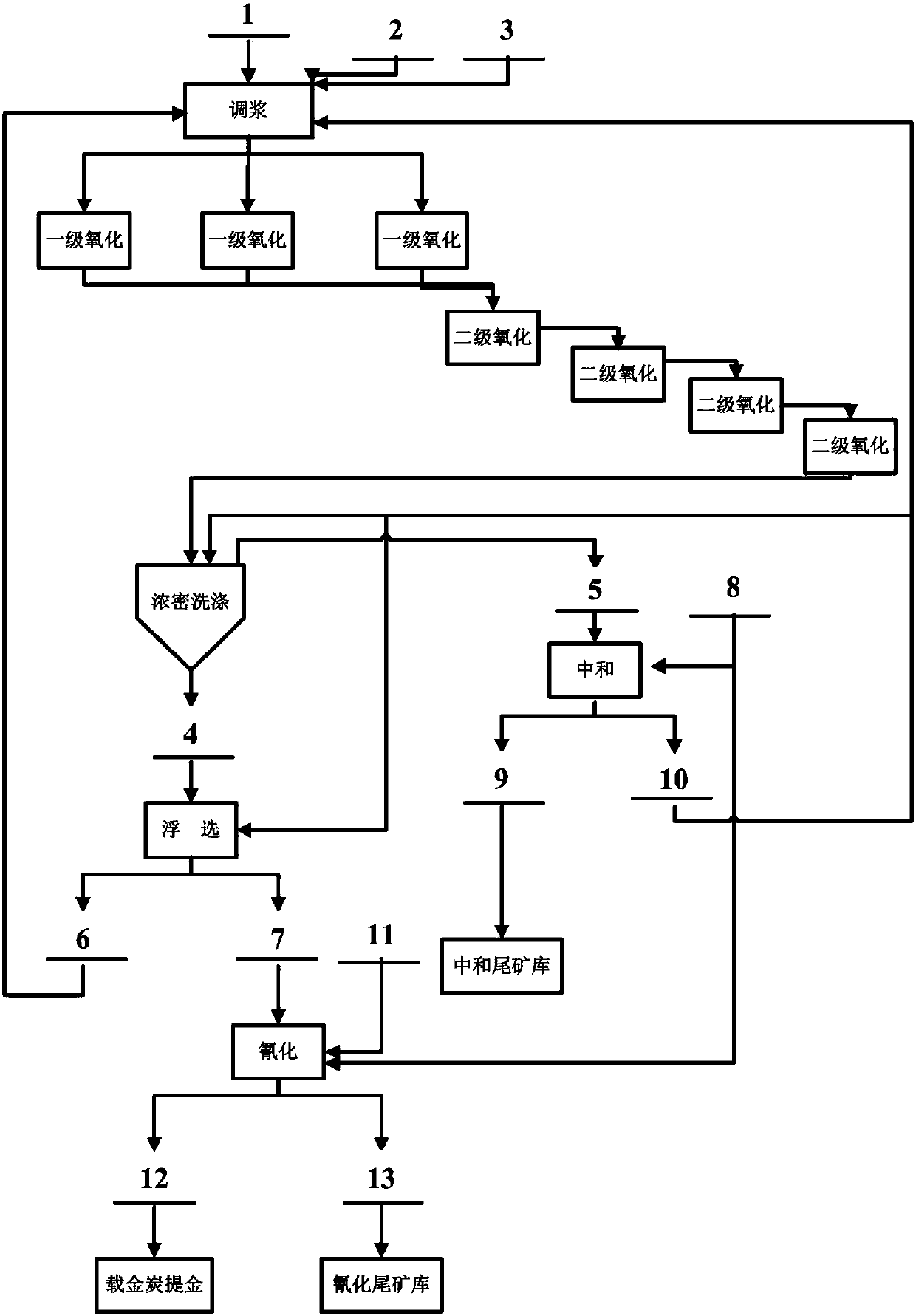

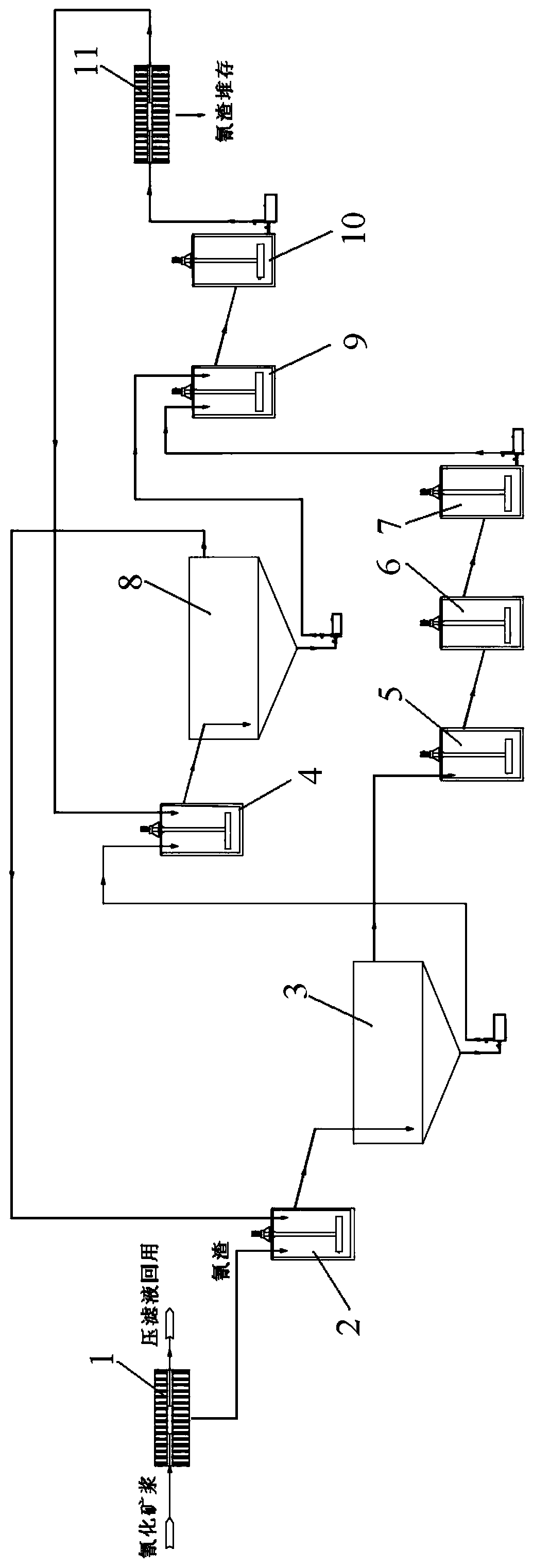

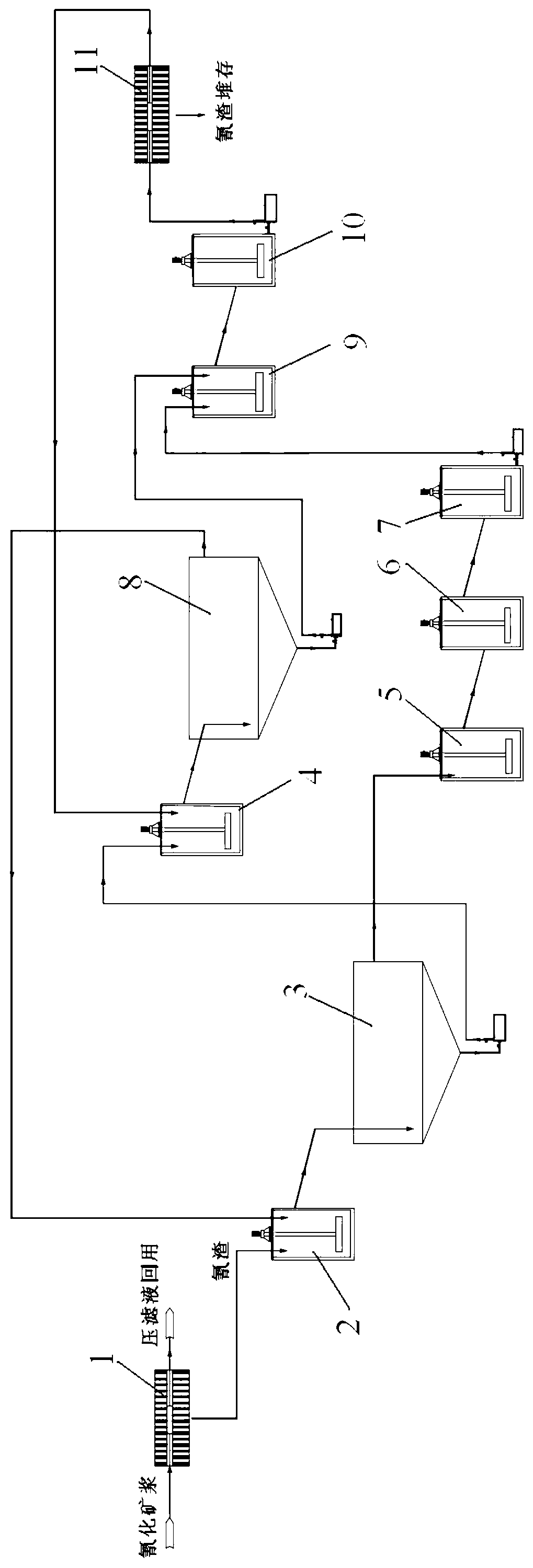

Coupling gold-extracting process for high-sulfur and high-iron arsenic-containing refractory gold concentrates

InactiveCN107805711AGuaranteed uptimeAvoid enteringProcess efficiency improvementActivated carbonAurin

The invention relates to a coupling gold-extracting process for high-sulfur and high-iron arsenic-containing refractory gold concentrates. The coupling gold-extracting process is carried out accordingto the following steps and conditions that biological oxidation is conducted, specifically, pulp-mixing is conducted, a 9k iron-free culture medium and mineral leaching microorganisms of a high-acid-resistant and arsenic-resistant strain are added, then, two-stage biological oxidation is conducted, and the temperature and the oxidation time are controlled; dense washing is conducted, specifically, second-stage biological oxidation mineral pulp is subjected to dense washing, countercurrent washing with the grade being 3-4 is conducted, and lime milk overflows into an oxidation solution to conduct a neutral reaction; flotation is conducted, specifically, sodium lignin sulfonate and xanthate are added for flotation; and cyaniding is conducted, specifically, lime milk, sodium cyanide and activated carbon are added in the gold flotation concentrates, the cyaniding pH value, the carbon density and the cyaniding time are controlled, gold-loading carbon and cyanide slag are obtained, and thegold-loading carbon is put into a gold-loading carbon refining system for extracting gold. According to the coupling gold-extracting process, the situation that part of unoxidized sulfide enters a cyaniding system can be avoided, and the situation that cyanide and thiocyanide enter a biological oxidation working section to recycle the part of gold-containing unoxidized sulfide is eliminated; and the coupling gold-extracting process has the advantages that the production cost is low, the investment is less, the equipment is simple, the process is coupled simply, biological oxidation operation is stable, the gold comprehensive recovery is high, and environmental friendliness is achieved, and is suitable for application of extracting gold from the high-sulfur and high-iron arsenic-containingrefractory gold concentrates.

Owner:ZIJIN MINING GROUP +1

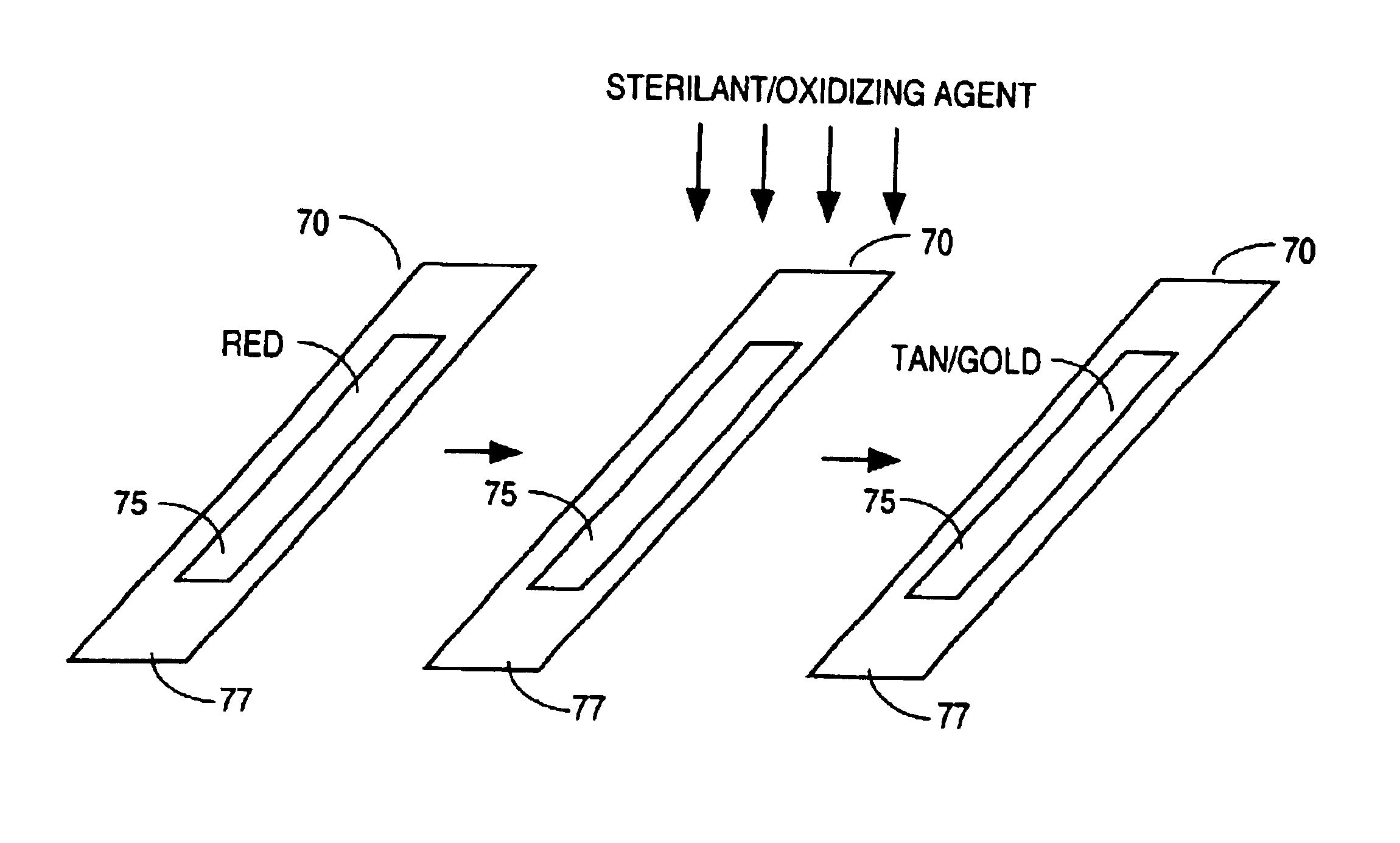

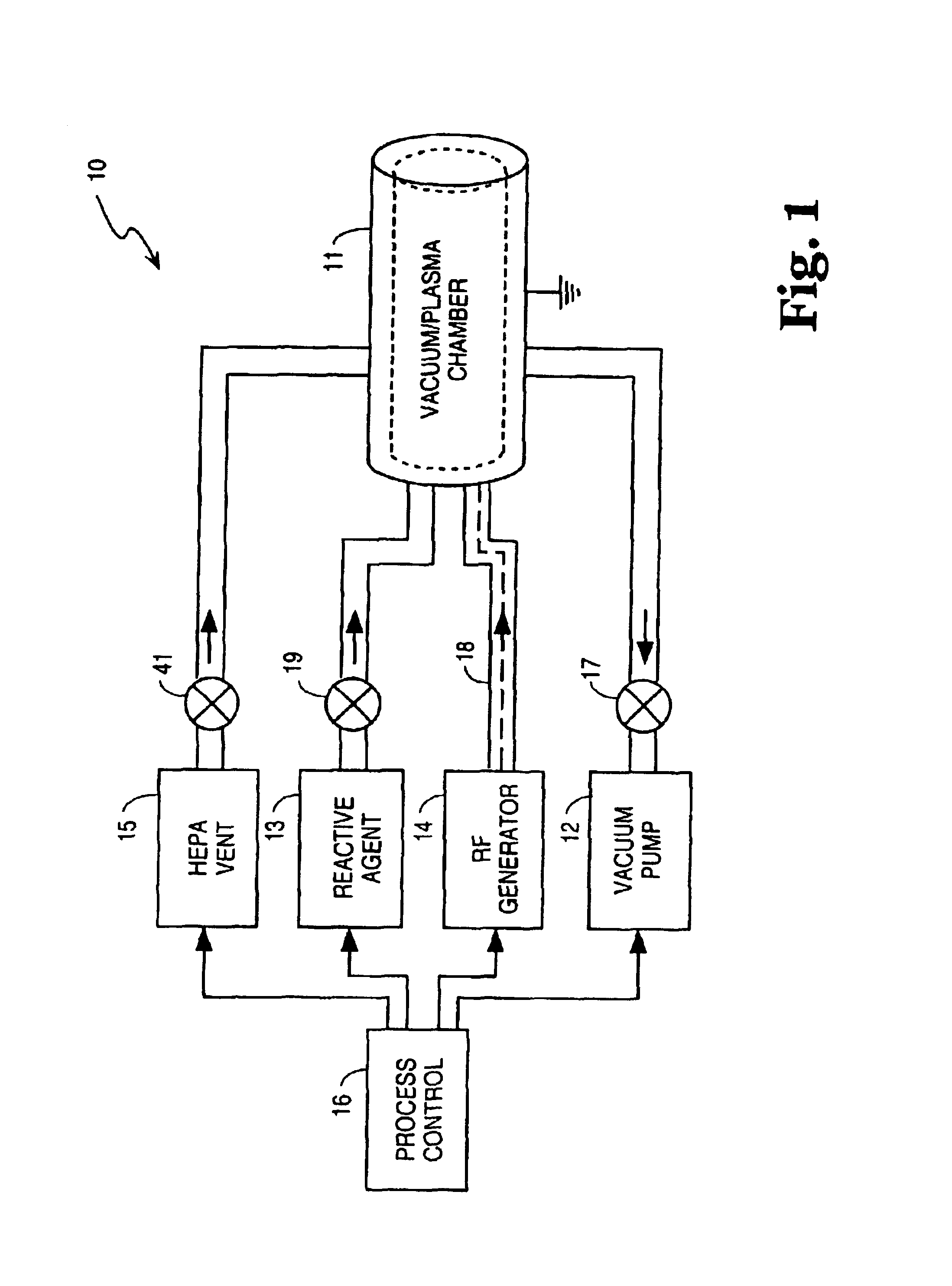

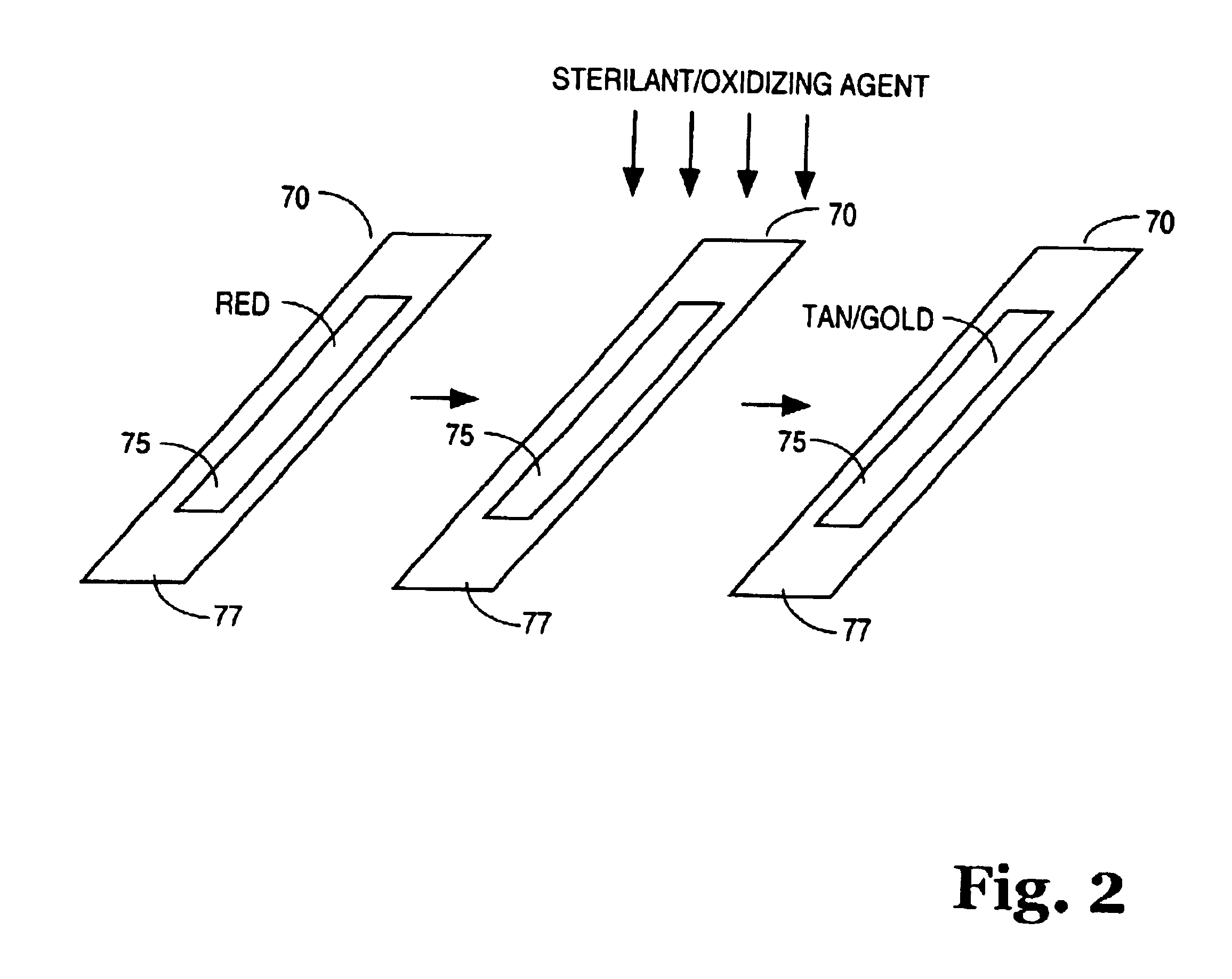

Chemical indicator

InactiveUS6936223B2Other chemical processesMaterial analysis by observing effect on chemical indicatorOxidizing agentAurin

A chemical indicator of an aurin moiety in a substrate to detect the presence of an oxidizing agent.

Owner:ETHICON INC

Method of extracting gold tail slag from arsenic containing aurin ore then extracting gold and silver

The present invention relates to a method for extracting gold tailings from arsenical glod headings and further extracting gold and silver. Said extraction method includes the following steps: 1), enriching cyanogens dregs which are obtained after the arsenical gold headings are smelted by cyanidation process and whose gold and silver are recovered, pressing the cyanogens dregs into brick block; and 2), adding the cyanogens dregs enriched brick block into a copper smelting furnace and further recovering noble metals of gold and silver and copper.

Owner:SHANDONG GUODA GOLD

Dearsenification method of gold concentrates

InactiveCN105087900ANothing producedReduce construction costsProcess efficiency improvementMassicotEnergy consumption

The invention discloses a dearsenification method of gold concentrates. The method comprises the following steps: preparing the gold concentrates into ore pulp, then spraying onto the surface of a block-shaped supporting object, and piling in; dropping and leaching with bacterial liquid; washing to remove acid through clean water; performing ore washing through an ore washing machine, so as to separate the support from the gold concentrates to obtain a product. The method has the advantages of being small in device assembling cost, small in energy consumption, good in the dearsenification effect, free of arsenic flue dust, adjustable in scale, and easy for industrialization; the leaked bacterial liquid contains iron, and arsenic can be removed completely after adjusting alkali and depositing; in addition, arsenic-containing substances are stable.

Owner:厦门紫金矿冶技术有限公司

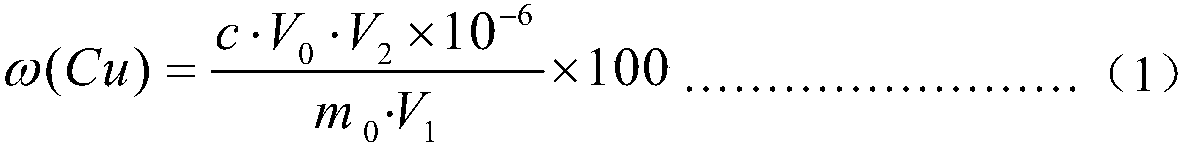

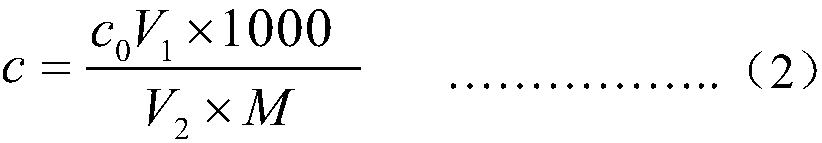

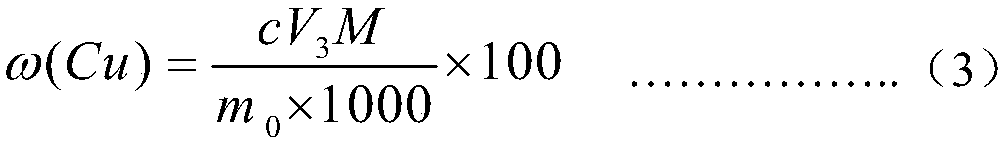

Method for measuring copper content in high-lead-gold concentrates

InactiveCN108303389AImprove accuracyImprove stabilityChemical analysis using titrationPreparing sample for investigationIonHydrochloric acid

The invention relates to a method for measuring the copper content in high-lead-gold concentrates, and belongs to a method for measuring the copper content in ores. According to the method, a nitric acid-potassium chlorate saturated solution is used for dissolving a test specimen; sulfuric acid is used for precipitating lead ions; after the filtering, filter liquid is distilled until sulfuric acidsmoke thoroughly disappears; materials with the copper content being less than 2 percent are leached by hydrochloric acid; AAS determination is performed; the materials with the copper content beinggreater than 2 percent are leached by distilled water; the iodometry titration determination is performed. The copper content determination range in the lead concretes is 0.050 to 25.00 percent; the determination accuracy is improved; the copper measurement stability of the high-lead gold concentrates is improved; the measurement range is expanded; good application performance is realized.

Owner:CHANGCHUN GOLD RES INST

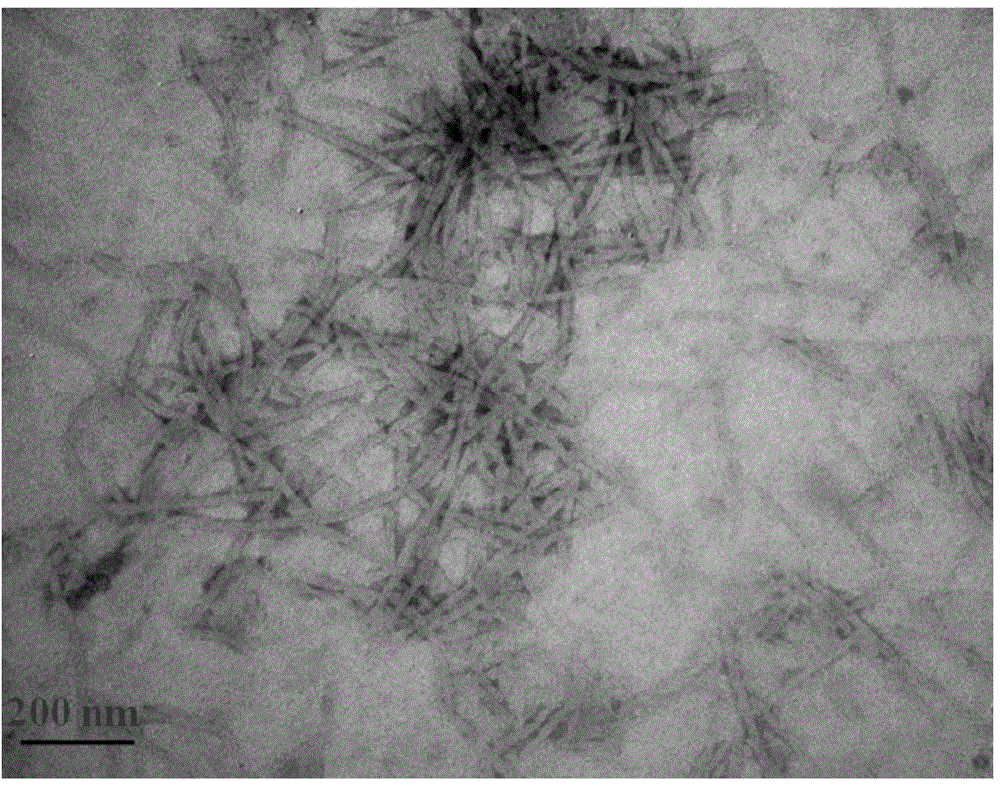

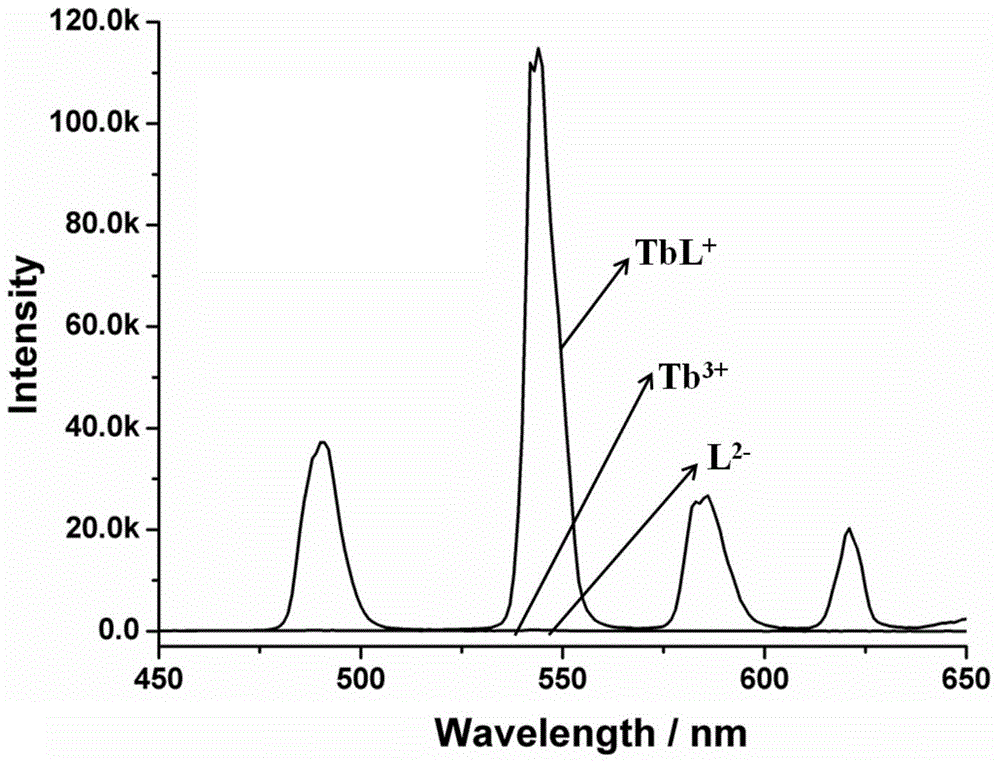

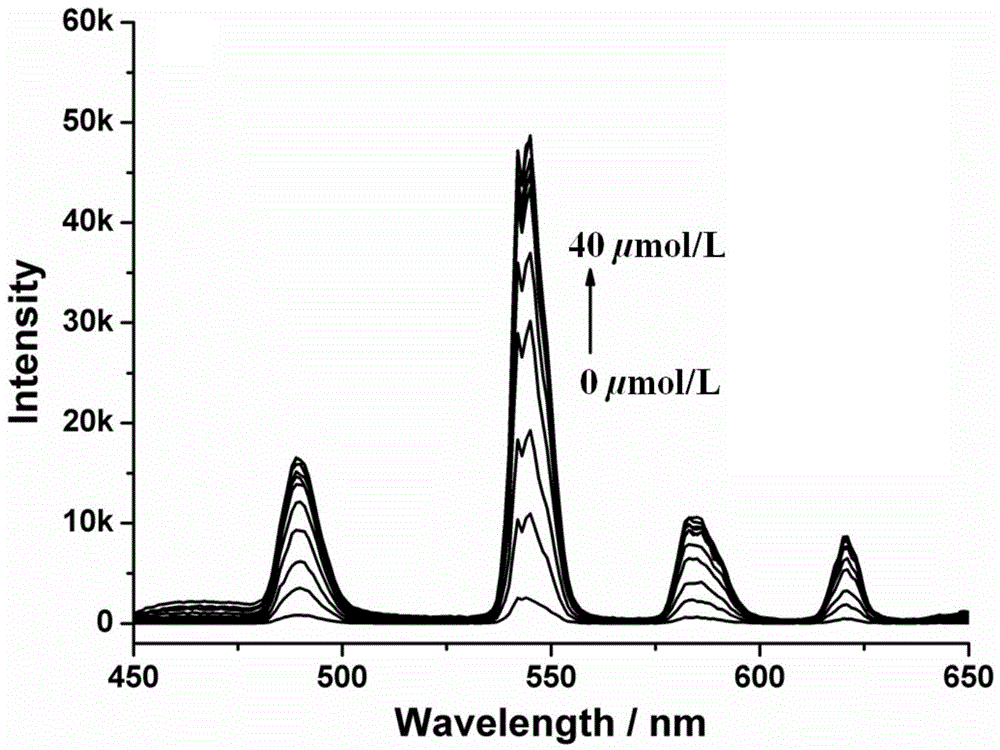

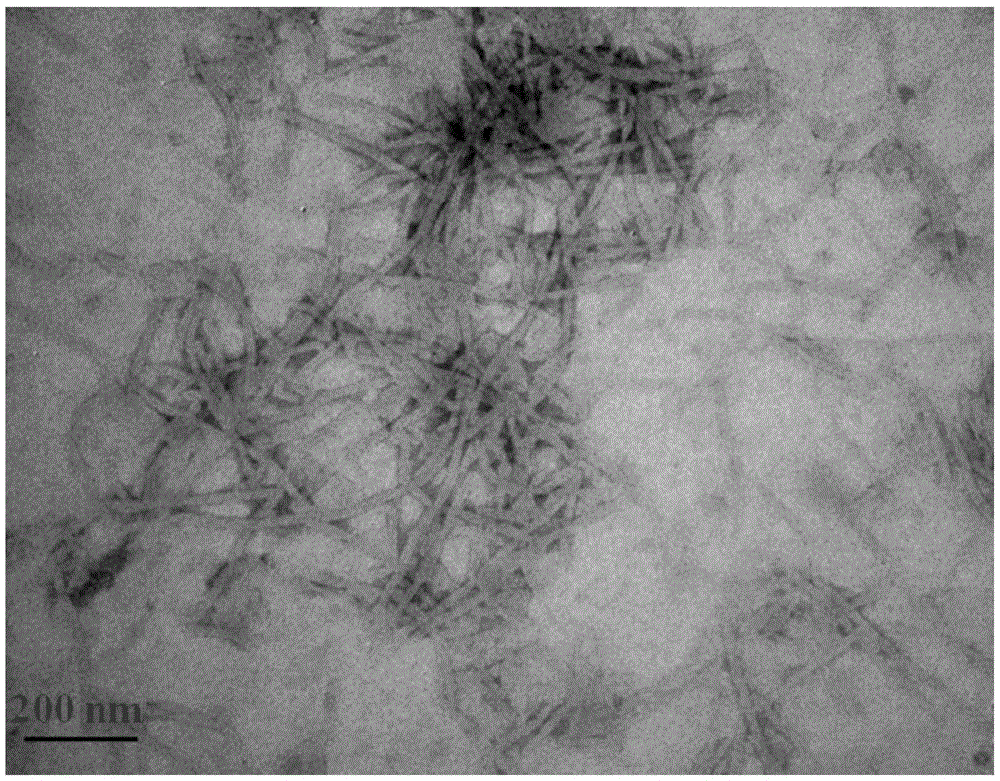

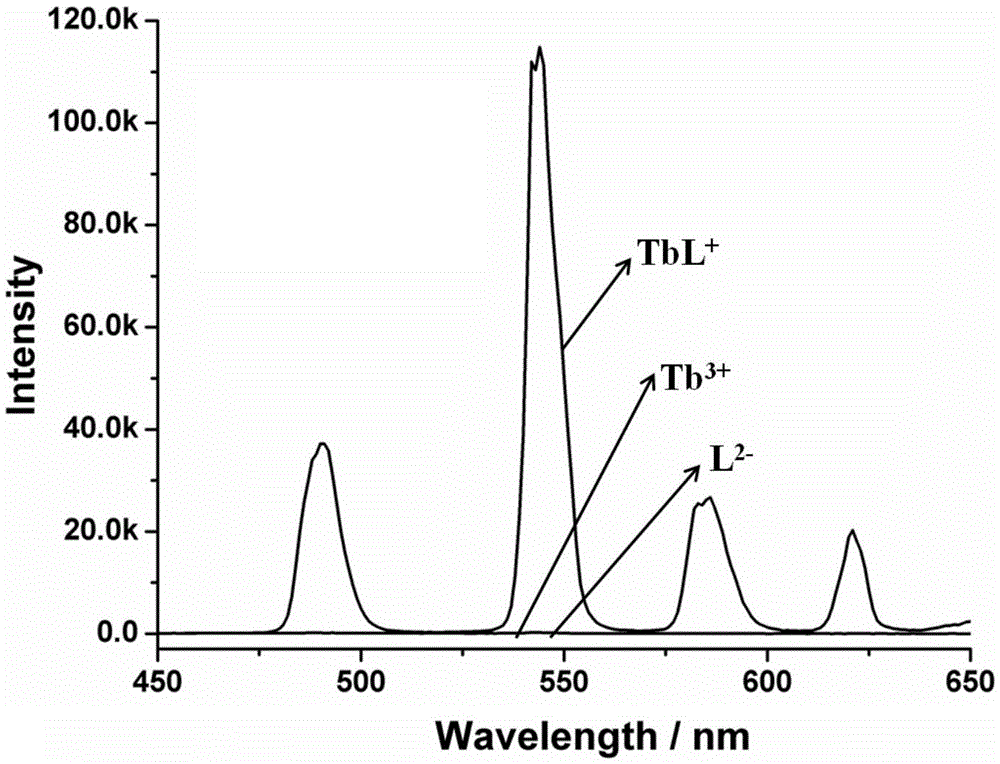

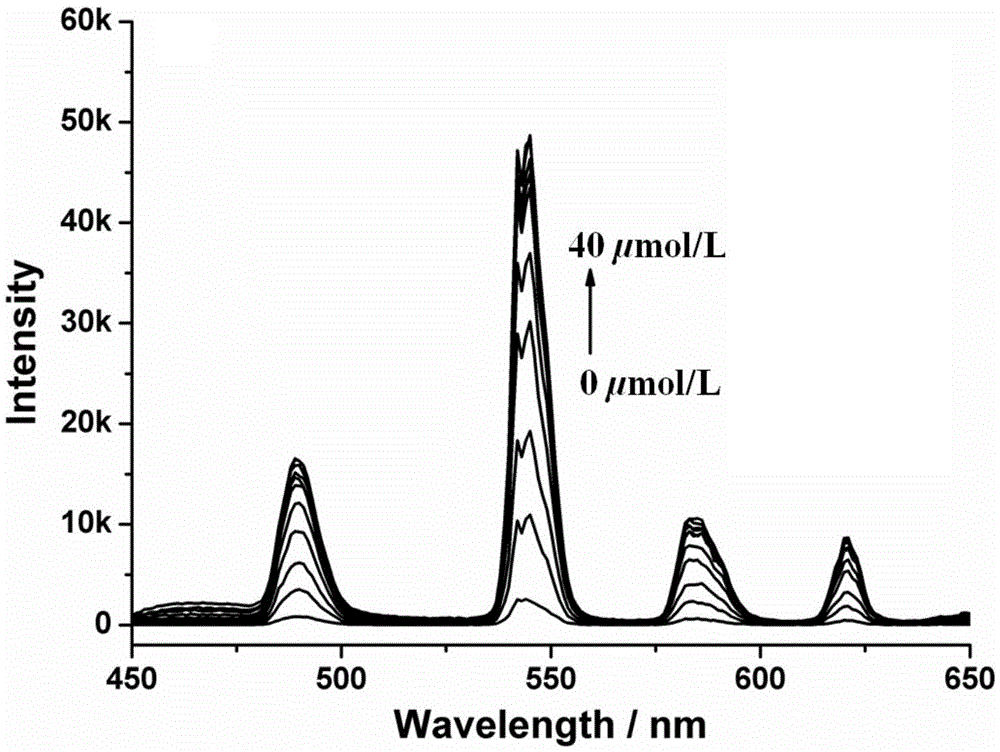

Amphiphilic Tb (III) complex, preparation method thereof and preparation method and application of fluorescent nano-fibers

InactiveCN104447935AEasy to prepareSimple and fast operationSteroidsFluorescence/phosphorescenceFiberChemical reaction

The invention relates to an amphiphilic Tb (III) complex, a preparation method thereof and a preparation method and application of fluorescent nano-fibers. By virtue of characteristics of a rigid framework, biocompatibility and self-assembling of cholesterol molecules, the amphiphilic Tb (III) complex containing a cholesterol structural unit and bi-picolinic acid is designed and prepared, the supermolecule fluorescent nano-fibers based on the amphiphilic Tb (III) complex are assembled, and action mechanisms of the fluorescent nano-fibers and aurintricarboxylic acid are researched; by virtue of synergetic complexing between aurintricarboxylic acid and ions of Tb (III) and an energy transfer process, aurintricarboxylic acid is efficiently sensed. Related reaction conditions are mild and easy to achieve, the preparation method of the fluorescent nano-fibers is simple, convenient and easy to operate, the prepared fluorescent nano-fibers are uniform in size, the sensitivity for detecting aurintricarboxylic acid is high, the selectivity is good, and the fluorescent nano-fibers are hopeful for being used for researching the pharmaceutical process of aurintricarboxylic acid.

Owner:SHAANXI NORMAL UNIV

RNA (Ribonucleic Acid) preservation solution and application thereof

ActiveCN108103054AAvoid degradationDoes not affect propertiesMicrobiological testing/measurementDNA preparationEpsilon-PolylysineGlycine

The invention discloses an RNA (Ribonucleic Acid) preservation solution. The RNA preservation solution is prepared from aurin ammonium triformate, a preservative and bestatin hydrochloride, wherein the preservative is selected from glycine, epsilon-polylysine and cysteine. The RNA preservation solution provided by the invention can be used for effectively preventing free RNA from being degraded, providing a stable environment for RNA and prolonging the preservation time of the RNA; meanwhile, the subsequent detection efficiency of the RNA and the accuracy of a detection result are not influenced.

Owner:GUANGZHOU JINQIRUI BIOTECHNOLOGY CO LTD

Chinese medicinal preparation for treating diabetes

InactiveCN103990039AGood treatment effectLittle side effectsMetabolism disorderPlant ingredientsSide effectTherapeutic effect

The invention aims to provide a Chinese medicinal preparation for treating diabetes and with good treatment effect and small side effect. The aim of the invention is realized in this way: the Chinese medicinal preparation is prepared by: mixing 10-20 parts by weight of dogwood, 15-35 parts by weight of polygonatum, 20-40 parts by weight of radix rehmanniae, 25-35 parts by weight of semen litchi, 20-40 parts by weight of Cistanche, 5-15 parts by weight of Scrophularia ningpoensis, 25-35 parts by weight of Fructus alpiniae oxyphyllae, 35-45 parts by weight of Astragalus complanatus, 25-45 parts by weight of Hainan agilawood, 35-50 parts by weight of aurin powder, 35-50 parts by weight of polygonum multiflorum powder and bighead atractylodes rhizome powder, 25-45 parts by weight of Poria, 30-50 parts by weight of Chinese yam, 25-45 parts by weight of mulberries, and 35-55 parts by weight of balsam pear, and grinding the raw materials into powder. The Chinese medicinal preparation provided by the invention is a prescription based on years of clinical experience of the hospital, and is very popular with patients due to significant treatment effect.

Owner:黑龙江康元神经专科医院有限责任公司

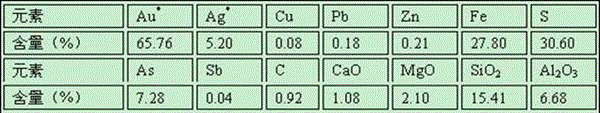

Method of extracting gold and silver from arsenic containing aurin ore

InactiveCN100404707CLow impurity contentAvoiding the problem of chemical synthesis of iron arsenatePhotography auxillary processesProcess efficiency improvementSulfurCopper

The present invention relates to a method for extracting gold and silver from arsenical gold headings. It is characterized by that said method includes the following steps: (1), using activating agent to make activation; (2), first-stage reduction and calcinations; (3), second-stage oxidation and calcinations; (4), acid-pickling, using acid-pickling liquor to make extraction and electrodepositing cathode copper; (5), cyaniding acid-pickling dregs and recovering gold and silver; and (6), calcining smoke gas, making trentment and recovering arsenic and recovering sulfur.

Owner:SHANDONG GUODA GOLD

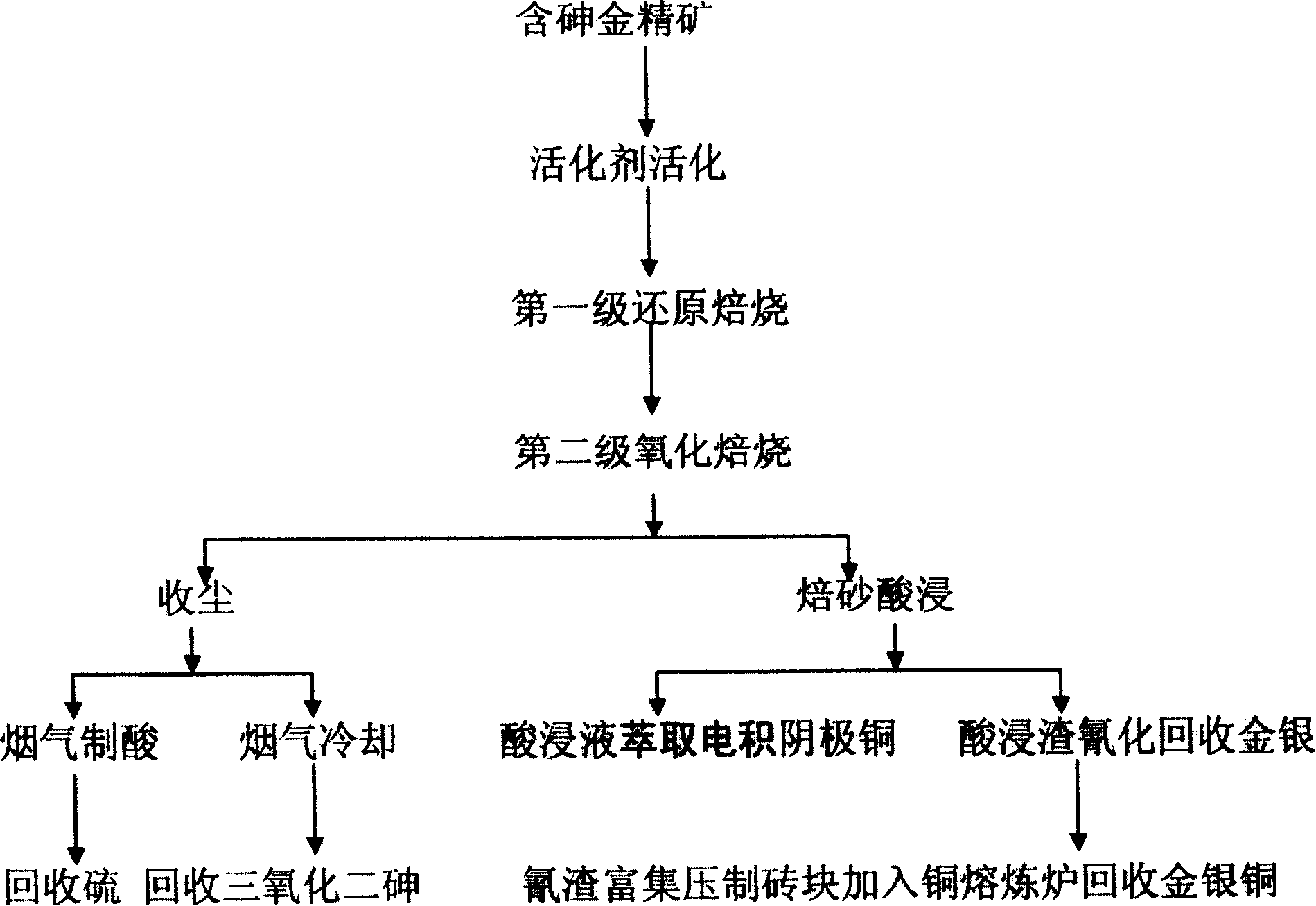

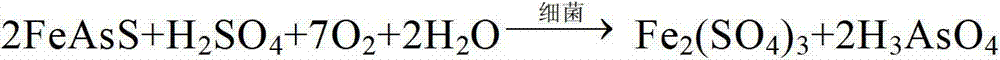

Two kinds of exclusive leaching bacteria used in the two-stage biological pre-oxidation gold extraction process of Carlin-type gold deposits

ActiveCN103911509BImprove leaching rateBig economic interestsProcess efficiency improvementSlagCarlin–type gold deposit

Owner:有研资源环境技术研究院(北京)有限公司

Cyanide residue three-level reverse thickening purifying method of gold concentrate smelting industry

InactiveCN109967495ASolve the problem of nowhere to storeAchieve removalSolid waste disposalFiltration circuitsThree levelCyanide

The invention relates to a cyanide residue three-level reverse thickening purifying method of a gold concentrate smelting industry, and belongs to gold industry solid waste treatment methods. Cyanidedore pulp is introduced into a first filter press to be filter-pressed, cyanide residues are added into a first pulp mixing groove to be subjected to pulp mixing and enter a first thickener to be thickened, underflow of the first thickener enters a second pulp mixing groove to be subjected to pulp mixing, supernatant of the first thickener overflows to sequentially enter a first stirring reactiondevice and a second stirring reaction device, hydrogen peroxide is added for treatment, and treating fluid automatically flows into a first buffer groove. The cyanided ore pulp mixed in a third pulp mixing groove enters a second buffer groove and enters a second filter press to be filter-pressed, and the cyanide residues filter-pressed in the second filter press are piled in a tailing pond. The cyanide residues are purified, the treated cyanide residues are legally piled, a contribution is made to valuable cyanide residue treatment of gold industry gold concentrate smelting enterprises, and the technology has high promotion applicability and lays a technical foundation for sustainable development of the gold industry.

Owner:CHANGCHUN GOLD RES INST

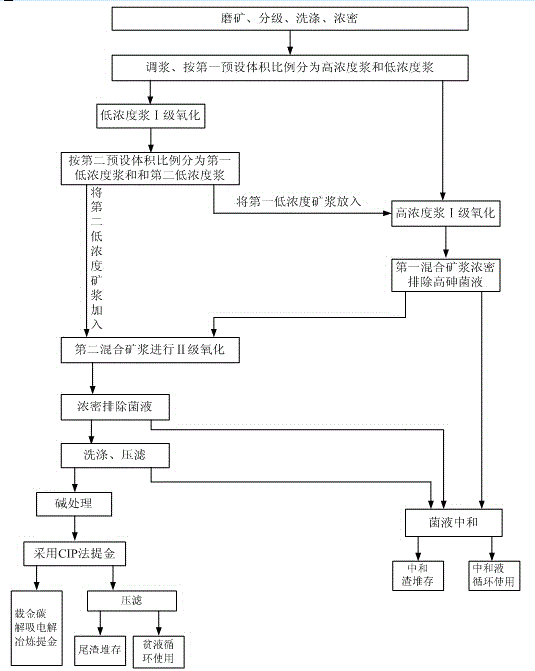

Branch biological oxidation technology for high-arsenic and high-sulfur gold concentrate

ActiveCN105714126AReproduce fastPromotes rapid oxidationProcess efficiency improvementHigh concentrationSulfur

The invention discloses a branch biological oxidation technology for a high-arsenic and high-sulfur gold concentrate. The branch biological oxidation technology comprises the steps that pretreatment is conducted, pulp is divided into low-concentration pulp and high-concentration pulp according to the first preset volume proportion, and the low-concentration pulp and the high-concentration pulp are placed in respective first-level oxidization tanks to be subjected to first-level oxidization; and after being subjected to first-level oxidization, the low-concentration pulp is divided into first low-concentration pulp and second low-concentration pulp, the first low-concentration pulp is placed in the first-level oxidation tank of the high-concentration pulp, first mixed pulp is formed to be subjected to first-level oxidization, high-arsenic bacterium liquid is thickened and eliminated, thickener base flow of the first mixed pulp is placed in a second-level oxidization tank of the second low-concentration pulp, second mixed pulp is formed, second-level oxidization is conducted, bacterium liquid is thickened and eliminated, and conventional cyaniding treatment is conducted. According to the branch biological oxidation technology for the high-arsenic and high-sulfur gold concentrate, the gold leaching rate is increased to 94.49% from 82.18% in the prior art and increased by 12.31%, and the biological oxidation time is effectively shortened by four days.

Owner:QINGDAO ZHIRUI BIOLOGICAL CO LTD

Prepn process of iron red with salfated roasted dreg of sulfur containing aurin ore

InactiveCN1313379CImprove raw materialsImprove resource utilizationPigmenting treatmentFerric oxidesResource utilizationSulfur containing

The preparation process of iron red with sulfated roasted dregs of sulfur containing aurin ore includes the following steps: 1. adding 30-60 % concentration sulfuric acid and roasted dregs in the weight ratio of 1 to 2-10 via stirring, adding co-solvent in 0.01-1 time the weight of roasted dregs, reacting at 60-100 deg.c for 1-6 hr, and filtering to obtain filtrate and filter residue; 2. neutralizing the filtrate with ammonia water, controlling pH 1-2, adding ammonia water at 50-90 deg.c to precipitate partial iron ion and adding flocculant; and 3. washing the obtained precipitate, drying, calcining at 300-700 deg.c and grinding to required fineness to obtain iron red. The present invention has the advantages expanded iron red preparing material range, raised tail ore resource utilization, raised post gold extracting efficiency, lowered power consumption, and lowered environmental pollution.

Owner:DONGHUA UNIV +1

Amphiphilic tb(Ⅲ) complexes, preparation methods thereof, and preparation methods and applications of fluorescent nanofibers

InactiveCN104447935BEasy to prepareSimple and fast operationSteroidsFluorescence/phosphorescenceFiberChemical reaction

The invention relates to an amphiphilic Tb (III) complex, a preparation method thereof and a preparation method and application of fluorescent nano-fibers. By virtue of characteristics of a rigid framework, biocompatibility and self-assembling of cholesterol molecules, the amphiphilic Tb (III) complex containing a cholesterol structural unit and bi-picolinic acid is designed and prepared, the supermolecule fluorescent nano-fibers based on the amphiphilic Tb (III) complex are assembled, and action mechanisms of the fluorescent nano-fibers and aurintricarboxylic acid are researched; by virtue of synergetic complexing between aurintricarboxylic acid and ions of Tb (III) and an energy transfer process, aurintricarboxylic acid is efficiently sensed. Related reaction conditions are mild and easy to achieve, the preparation method of the fluorescent nano-fibers is simple, convenient and easy to operate, the prepared fluorescent nano-fibers are uniform in size, the sensitivity for detecting aurintricarboxylic acid is high, the selectivity is good, and the fluorescent nano-fibers are hopeful for being used for researching the pharmaceutical process of aurintricarboxylic acid.

Owner:SHAANXI NORMAL UNIV

A method for enriching and separating lead-zinc mixed concentrate from gold concentrate cyanidation tailings

ActiveCN107899756BImprove utilizationReduce wasteFlotationFiltration separationMaterials scienceLead zinc

The invention relates to a method for enriching and separating lead and zinc mixed concentrates from gold concentrate cyaniding tailings. The method comprises the following steps: 1) enrichment of thelead and zinc mixed concentrates: cyaniding tailings are pulped by using water after extraction of gold, silver and copper; then, an activating agent is added in the pulp for stirring and activatingby 20-40 min; isopropyl ethyl thiamate is added for flotation; the flotated concentrates are the lead and zinc mixed concentrates; and the remains are sulfur concentrates; and 2) separation of the lead and zinc mixed concentrates: the lead and zinc mixed concentrates are pressed, filtered and dehydrated to prepare filter cakes; the filter cakes are mixed with the water for pulping; activated carbons, zinc sulfate and sodium thiosulfate are added in the pulp for stirring by 90-120 min to inhibit zinc; finally, ethyl nitrogen is added for flotation; the flotated matters are lead concentrates; and the remains are zinc concentrates. The method can further effectively recover gold, silver and copper from the gold concentrate cyaniding tailings, improves comprehensive utilization of resources, and reduces resource wastes.

Owner:SHANDONG GUODA GOLD

Reinforced leaching method for complex refractory gold ore

InactiveCN109881003AHigh recovery rateLess investmentProcess efficiency improvementHigh pressureCyanide leaching

The invention relates to a reinforced leaching method for complex refractory gold ore. According to the method, novel additives of CFZ-S and CFZ-C are added to cooperate with sodium hydroxide (NaOH) so as to perform reinforced pretreatment on complex refractory gold concentrate, and then a gold leaching agent is added for conventional gold leaching; the novel additives of CFZ-S and CFZ-C have theeffects of catalyzing, oxidizing and activating so that the oxidation reaction only occurred when the pozzuolite mineral are under high temperature and high pressure can be induced under normal temperature and normal pressure, then the gold wrapped in the pozzuolite mineral and other minerals can be dissociated and exposed, so that the carbon with preg-robbing capacity loses activity and then canno longer pay a role in pre-robbing; the a gold extraction agent is adopted for conventional leaching gold extraction, so that for the gold mineral containing 20%-35% of sulfur, 5%-25% of arsenic, 1%-3% of antimony and 1%-8% of carbon, the cyanide leaching rate is increased to 85%-98% from the ratio less than 10%-30%, the leaching speed is shortened by 50%, then the refractory gold ore becomes less refractory, and better economic benefits can be obtained.

Owner:柯柏友

Method for reducing sodium cyanide consumption in gold concentration cyanide leaching process

ActiveCN109280767AHigh recovery rateReduce consumptionProcess efficiency improvementSodium bicarbonateAcetic acid

The invention belongs to the technical field of smelting, and particularly relates to a method for reducing sodium cyanide consumption in a gold concentration cyanide leaching process. The method forreducing the sodium cyanide consumption in the gold concentration cyanide leaching process comprises the following steps that step A, water, ethylene diamine tetraacetic acid and sodium bicarbonate are stirred and mixed uniformly, andmixed liquid is obtained; step B, water is added into gold concentration mineral powder to perform size mixing, a sizing agent of 37-42% by mass is obtained, and themixed liquid obtained in the step A and sodium cyanide are added to obtain mixed mineral pulp; and step C, the mixed mineral pulp obtained in the step B is subjected to solid-liquid separation treatment. Operation of the method for reducing the sodium cyanide consumption in the gold concentration cyanide leaching process is simple, ethylene diamine tetraacetic acid and sodium bicarbonate are addedinto the gold concentration sizing agent to be combined withresiduary copper ions, iron ions and magnesium ions of the sizing agent, and the consumption of cyanide by heavy metal ions t is reduced, so that the using amount of sodium cyanide is reduced, and the recovery rate of gold is improved.

Owner:ZHAOJIN MINING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com