Prepn process of iron red with salfated roasted dreg of sulfur containing aurin ore

A technology of sulfuration roasting and gold concentrate, applied in the direction of iron oxide, iron oxide/iron hydroxide, fibrous filler, etc., can solve the problems of rising raw material prices, air pollution, and shortage of raw materials, and increase the utilization of tailings resources efficiency, reduce environmental pollution, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

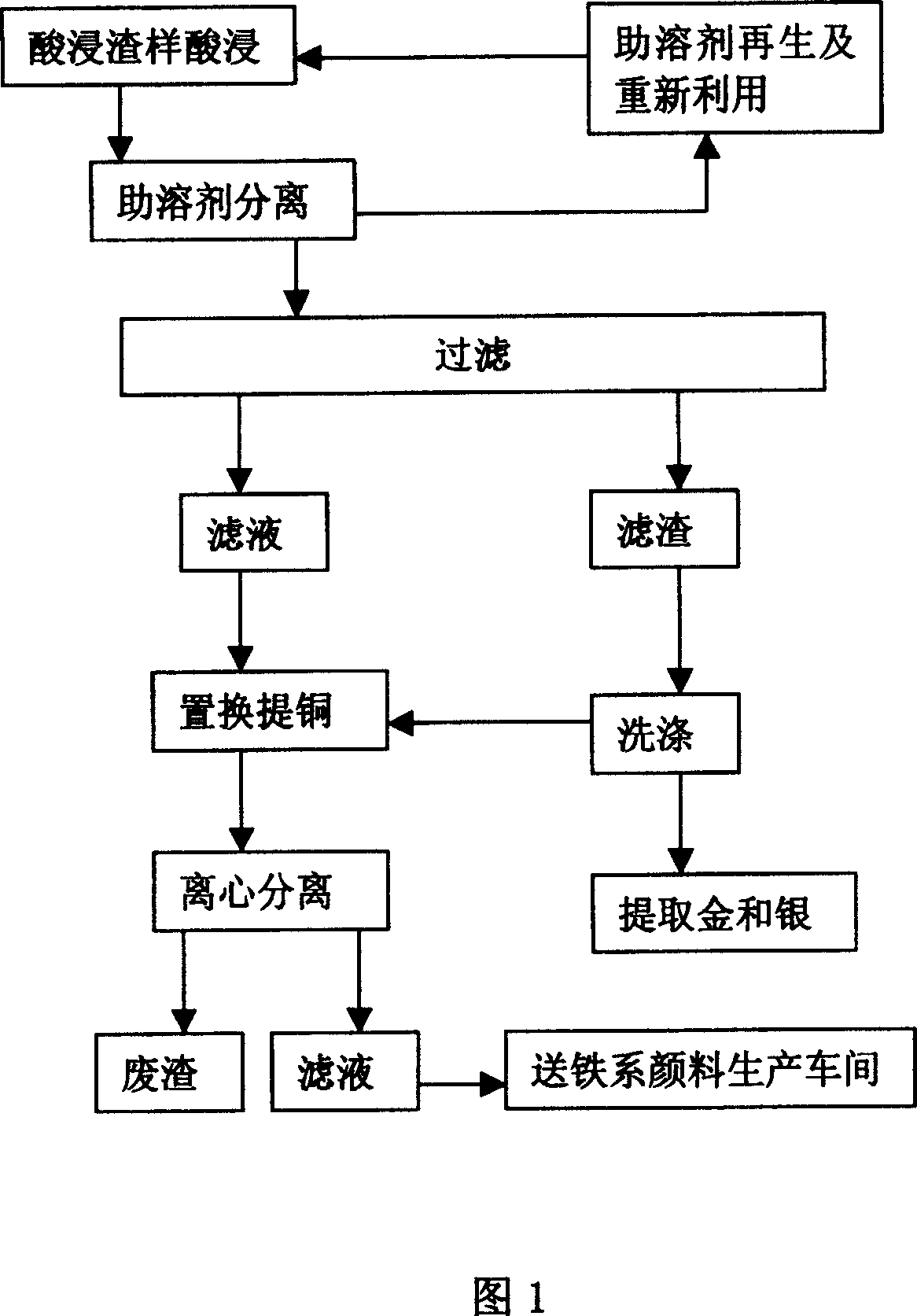

Method used

Image

Examples

Embodiment 1

[0011] Add 60% sulfuric acid in the reactor with stirrer, start the stirrer to stir, add roasting slag at one time, the weight ratio of roasting slag and sulfuric acid solution is 2:1, and the weight ratio of roasting slag and cosolvent is 1:1, The composition of the co-solvent is 1% sodium EDTA, 30% CuO, 20% Fe 2 O 3 , 40% SiO 2 and 9%Al 2 O 3 . The leaching rate of iron is 100%, and the leaching rate of gold and silver is more than 98% at 80 ℃ temperature for 6 hours. Filter, neutralize the filtrate with ammonia water to pH 1, add flocculant ferric chloride to remove the precipitation, separate the cosolvent, and then add ammonia water at 50°C until the iron ions are completely precipitated. After filtering again, the filtrate is used to recover ammonia water and alkali, and the filter residue is washed, dried and calcined at 300°C. The calcined iron red can be obtained after grinding to reach the particle size required by iron red pigment, and its quality index (see at...

Embodiment 2

[0013] Add 30% sulfuric acid in the reactor with stirrer, start the stirrer to stir, add roasting slag at one time, the weight ratio of roasting slag and sulfuric acid solution is 10:1, and the weight ratio of roasting slag and cosolvent is 50:1, The composition of the co-solvent is 25% sodium EDTA, 1% CuO, 30% Fe 2 O 3 , 60% SiO 2 The reaction temperature is 100 DEG C, the reaction time is 1h, the iron leaching rate is 100%, and the gold and silver leaching rate is over 98%. The extract was filtered, the temperature of the system was brought down to room temperature, and then filtered. The filtrate was neutralized with alkali to pH 1.3, flocculant alum was added, the precipitate was removed, the cosolvent was separated, and then ammonia water was added at 90° C. until the iron ions were completely precipitated. After filtration, the filtrate was used to recover ammonia water and alkali, and the filter residue was washed, dried and calcined at 680°C. The calcined iron red ...

Embodiment 3

[0015] Add 45% sulfuric acid in the reactor with stirrer, start the stirrer to stir, add roasting slag at one time, the weight ratio of roasting slag and sulfuric acid solution is 5:1, and the weight ratio of roasting slag and cosolvent is 100:1, The composition of the co-solvent is 10% sodium EDTA, 2% CuO, 15% Fe 2 O 3 , 50% SiO 2 and 5%Al 2 O 3 The reaction temperature is 60 DEG C, the reaction time is 5h, the leaching rate of iron is 100%, and the leaching rate of gold and silver is over 98%. The extract was filtered, the temperature of the system was brought down to room temperature, and then filtered. The filtrate was neutralized with alkali to pH 1.5, flocculant polyacrylamide was added to remove the precipitation, the cosolvent was separated, and then ammonia water was added at 90° C. to complete the precipitation of iron ions. After filtration, the filtrate was used to recover ammonia water and alkali, and the filter residue was washed, dried and calcined at 500°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com