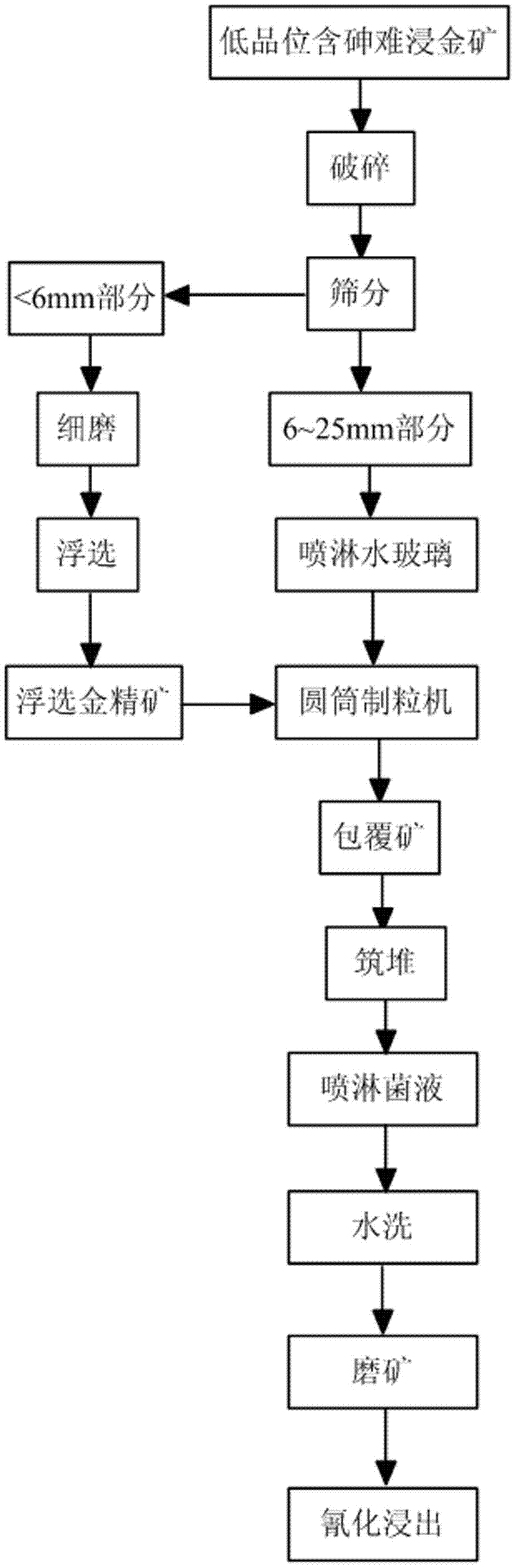

Coated biological oxidation pretreatment method of low-level arsenic refractory gold ores

A bio-oxidation, low-grade technology, applied in the direction of improving process efficiency, to achieve the effect of low production cost, easy implementation and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Using a low-grade arsenic-containing refractory gold ore in Anhui Province, the main element content is Au 1.91g / t, Fe 3.28%, S 3.65%, As 0.388%; the low-grade arsenic-containing refractory gold ore is used as raw material after crushing and screening Separate the finely crushed ore with a particle size of less than 6mm and the crushed ore with a particle size of 6~25mm; the finely crushed ore is finely ground and floated to make flotation gold concentrate, and its main element content is Au 12.3g / t, Fe 34.27%, S 37.4%, As 1.91%;

[0030] Spray evenly on the crushed ore surface with binder water glass to obtain bonded crushed ore, the dosage of water glass is 100L / t crushed ore;

[0031] Use a cylinder granulator to evenly wrap the flotation gold concentrate on the surface of the bonded crushed ore to make a coated ore. The mass ratio of the flotation gold concentrate to the bonded crushed ore is 1:10;

[0032] Build a heap of coated ore, and then spray sulfuric acid o...

Embodiment 2

[0039] Using a low-grade arsenic-containing refractory gold ore in Hunan Province, the main element content is Au 1.74g / t, Fe 2.83%, S 3.17%, As 0.129%; the low-grade arsenic-containing refractory gold ore is used as raw material after crushing and screening Separate the finely crushed ore with a particle size of less than 6mm and the crushed ore with a particle size of 6~25mm; the finely crushed ore is finely ground and flotation to make flotation gold concentrate, and its main element content is Au 22.1g / t, Fe 37.9%, S 39.1%, As 1.395%;

[0040] Spray evenly on the crushed ore surface with binder water glass to obtain bonded crushed ore, the dosage of water glass is 75L / t crushed ore;

[0041] Use a cylinder granulator to evenly wrap the flotation gold concentrate on the surface of the bonded crushed ore to make a coated ore. The mass ratio of the flotation gold concentrate to the bonded crushed ore is 1: 20;

[0042] Build a heap of coated ore, then spray sulfuric acid on ...

Embodiment 3

[0048] Using a low-grade arsenic-containing refractory gold ore in Liaoning Province, the main element content is Au 1.37g / t, Fe 3.24%, S 3.66%, As 0.197%; the low-grade arsenic-containing refractory gold ore is used as raw material after crushing and screening Separate the finely crushed ore with a particle size of less than 6mm and the crushed ore with a particle size of 6~25mm; the finely crushed ore is finely ground and flotation to make flotation gold concentrate, and its main element content is Au 14.1g / t, Fe 36.2%, S 38.2%, As 2.16%;

[0049] Spray evenly on the crushed ore surface with binder water glass to obtain bonded crushed ore, the dosage of water glass is 150L / t crushed ore;

[0050] Use a cylinder granulator to evenly wrap the flotation gold concentrate on the surface of the bonded crushed ore to make a coated ore. The mass ratio of the flotation gold concentrate to the bonded crushed ore is 1:5;

[0051] Build a heap of coated ore, then spray sulfuric acid on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com