Cyanide residue three-level reverse thickening purifying method of gold concentrate smelting industry

A technology for gold concentrate and cyanide slag, which is applied in chemical instruments and methods, separation methods, filtration circuits, etc., can solve the problems of high processing difficulty and high processing and disposal costs, and achieves good processing indicators, low processing costs, environmental and economical Significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

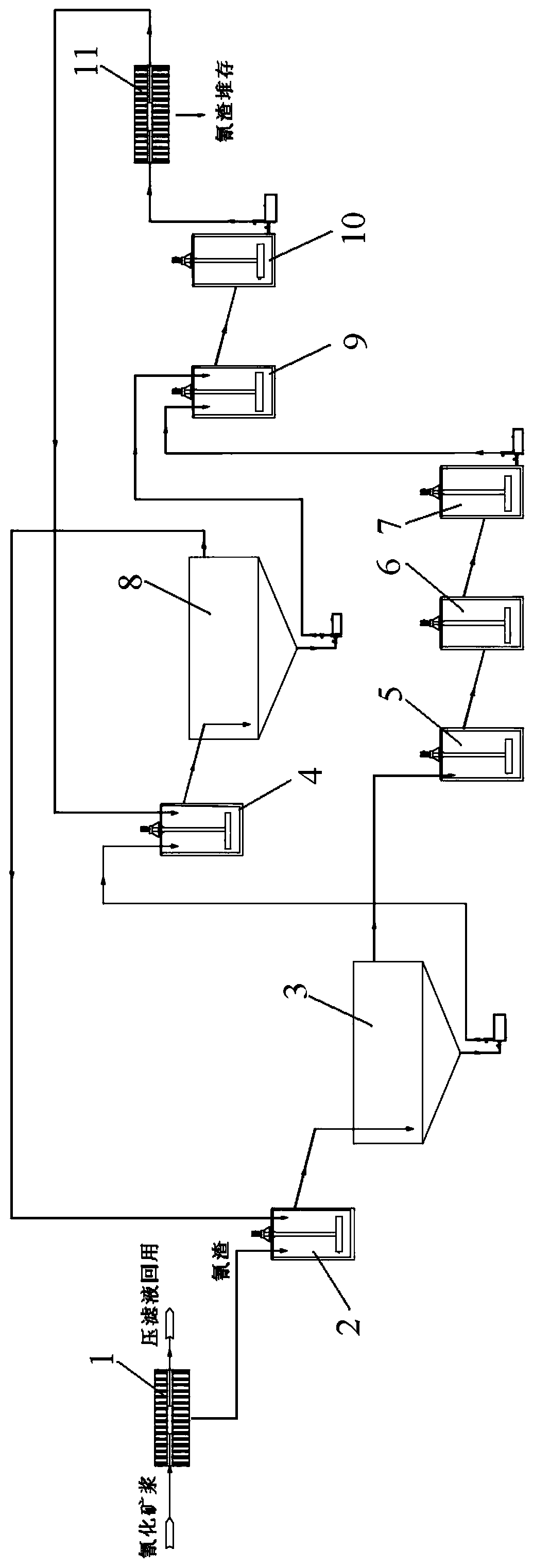

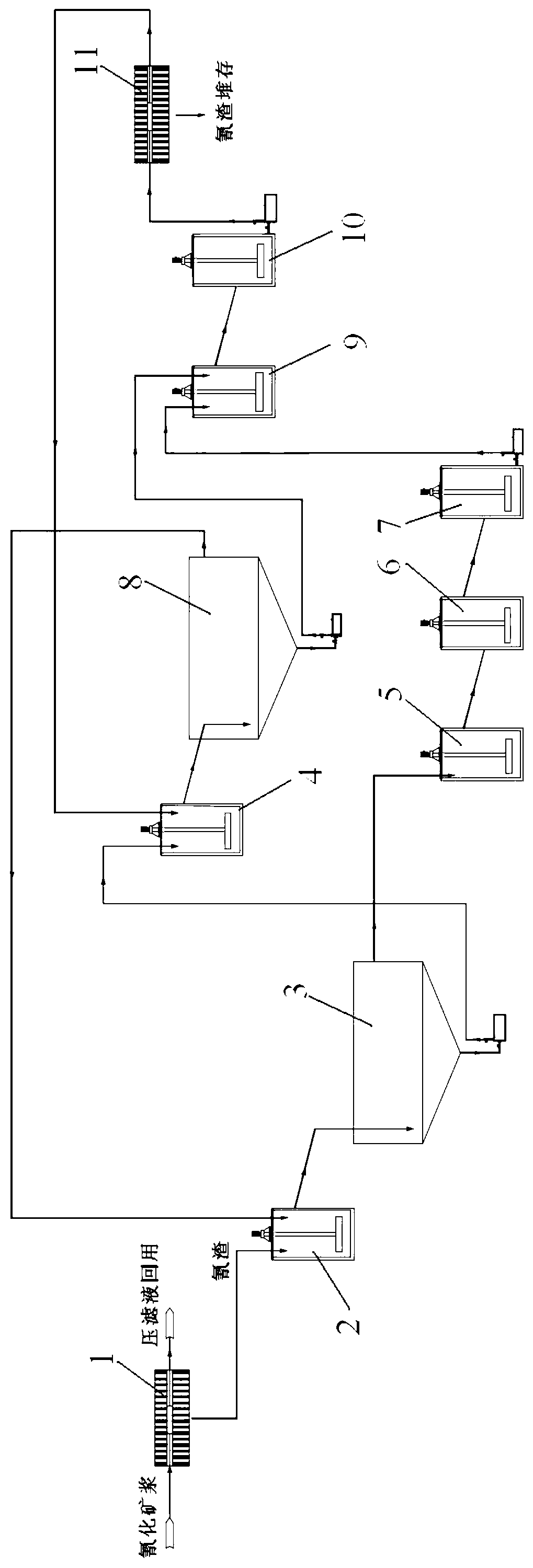

[0019] Include the following steps:

[0020] (1) The cyanide slurry produced by the cyanidation process of the gold concentrate smelting enterprise is passed into the filter press-1 for pressure filtration, the filter press-1 is used to reuse the filtrate, and the cyanide slag that is filtered out by the filter press-1 is added to the adjustment Slurry adjustment is carried out in the stock tank one 2, and the total cyanide concentration in the cyanide slurry liquid phase that described gold concentrate smelting enterprise cyanide process produces is 1500mg / L, and the press filter residue moisture content of filter press one is 25%, adjusts The residence time of slurry tank 1 is 1h;

[0021] (2) The cyanide pulp adjusted in pulping tank 1 2 enters thickener 1 3 for thickening, the bottom flow of thickener 1 3 enters pulping tank 2 4 for pulping, and the supernatant overflows in thickener 1 3 in turn Enter the stirring reaction device one 5 and the stirring reaction device two...

Embodiment 2

[0026] Include the following steps:

[0027] (1) The cyanide slurry produced by the cyanidation process of the gold concentrate smelting enterprise is passed into the filter press-1 for pressure filtration, the filter press-1 is used to reuse the filtrate, and the cyanide slag that is filtered out by the filter press-1 is added to the adjustment Slurry mixing is carried out in the stock tank one 2, and the total cyanide concentration in the cyanide slurry liquid phase that described gold concentrate smelting enterprise cyanide process produces is 2000mg / L, and the pressure filter residue moisture content of filter press one is 28%, adjusts The residence time of slurry tank 1 is 1h;

[0028] (2) The cyanide pulp adjusted in pulping tank 1 2 enters thickener 1 3 for thickening, the bottom flow of thickener 1 3 enters pulping tank 2 4 for pulping, and the supernatant overflows in thickener 1 3 in turn Enter the stirring reaction device one 5 and the stirring reaction device two ...

Embodiment 3

[0033] Include the following steps:

[0034] (1) The cyanide slurry produced by the cyanidation process of the gold concentrate smelting enterprise is passed into the filter press-1 for pressure filtration, the filter press-1 is used to reuse the filtrate, and the cyanide slag that is filtered out by the filter press-1 is added to the adjustment Slurry mixing is carried out in the stock tank one 2, and the total cyanide concentration in the cyanide slurry liquid phase that described gold concentrate smelting enterprise cyanide process produces is 3000mg / L, and the press filter residue moisture content of filter press one is 30%, adjusts The residence time of slurry tank 1 is 1h;

[0035] (2) The cyanide pulp adjusted in pulping tank 1 2 enters thickener 1 3 for thickening, the bottom flow of thickener 1 3 enters pulping tank 2 4 for pulping, and the supernatant overflows in thickener 1 3 in turn Enter the stirring reaction device one 5 and the stirring reaction device two 6 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com