Method for measuring copper content in high-lead-gold concentrates

A method of determination and technology of copper content, which is applied in the direction of chemical analysis by titration, measurement device, preparation of test samples, etc., can solve problems such as unstable measurement results and clogged instruments, and achieve improved stability and accuracy , good applicability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Include the following steps:

[0070] (1) Weigh 0.3g sample, the mass is m 0 , accurate to 0.0001g, put the sample in a 400mL beaker, moisten it with a small amount of water, add 0.5g of ammonium fluoride, add 20mL of saturated solution of nitric acid-potassium chlorate, cover the watch glass, after heating and dissolving completely, take it off and cool;

[0071] (2) Add 10mL of sulfuric acid, continue to heat until there is thick smoke for 2 minutes, remove and cool;

[0072] (3) Rinse the watch glass and cup wall with water, add water to 100mL, boil slightly for 10min, remove, cool to room temperature, add 5mL of absolute ethanol, and let stand for 1h;

[0073] (4) Filter with slow quantitative filter paper, take the filtrate in a 400mL beaker, wash the beaker once with lotion, precipitate 3 times, keep the filtrate, and discard the precipitate;

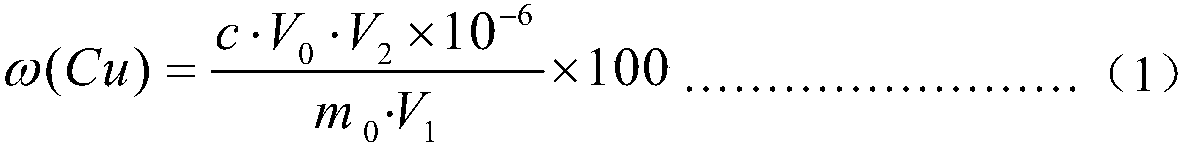

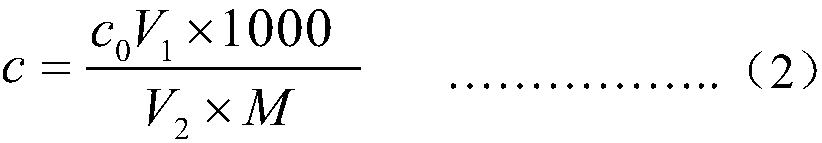

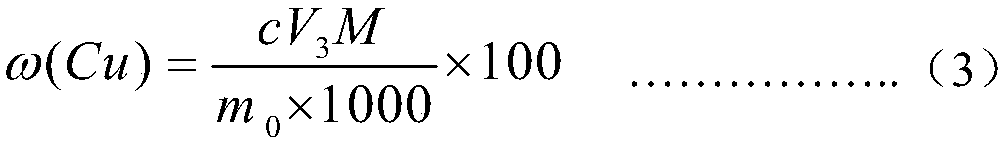

[0074] (5) Filtrate is placed on heating plate heating, exhausts to sulfuric acid smoke, takes off cooling, measures wi...

Embodiment 2

[0130] Include the following steps:

[0131] (1) Weigh 0.3g sample, the mass is m 0 , accurate to 0.0001g, put the sample in a 400mL beaker, moisten it with a small amount of water, add 0.5g of ammonium fluoride, add 20mL of saturated solution of nitric acid-potassium chlorate, cover the watch glass, after heating and dissolving completely, take it off and cool;

[0132] (2) Add 10mL of sulfuric acid, continue to heat until it emits thick smoke for 2.5min, remove and cool;

[0133] (3) Rinse the watch glass and cup wall with water, add water to 100mL, boil slightly for 10min, remove, cool to room temperature, add 5mL of absolute ethanol, and let stand for 1h;

[0134] (4) Filtrate with slow quantitative filter paper, take the filtrate into a 400mL beaker, wash the beaker 2 times with lotion, precipitate 3 times, retain the filtrate, and discard the precipitate;

[0135] (5) Filtrate is placed on heating plate heating, exhausts to sulfuric acid smoke, takes off cooling, measu...

Embodiment 3

[0145] Include the following steps:

[0146] (1) Weigh 0.3g sample, the mass is m 0 , accurate to 0.0001g, put the sample in a 400mL beaker, moisten it with a small amount of water, add 0.5g of ammonium fluoride, add 20mL of saturated solution of nitric acid-potassium chlorate, cover the watch glass, after heating and dissolving completely, take it off and cool;

[0147] (2) Add 10mL of sulfuric acid, continue to heat until it emits thick smoke for 3 minutes, then remove and cool;

[0148] (3) Rinse the watch glass and cup wall with water, add water to 100mL, boil slightly for 10min, remove, cool to room temperature, add 5mL of absolute ethanol, and let stand for 1h;

[0149] (4) Filtrate with slow quantitative filter paper, the filtrate is taken over by a 400mL beaker, wash the beaker 2 times with lotion, precipitate 4 times, retain the filtrate, and discard the precipitate;

[0150] (5) Filtrate is placed on heating plate heating, exhausts to sulfuric acid smoke, takes off...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com