Coupling gold-extracting process for high-sulfur and high-iron arsenic-containing refractory gold concentrates

A technology for refractory gold and high-sulfur iron, applied in the direction of improving process efficiency, can solve the problems of low comprehensive gold recovery rate, high production cost, environmental pollution, etc., and achieve high comprehensive gold recovery rate, low production cost and environmental protection. friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

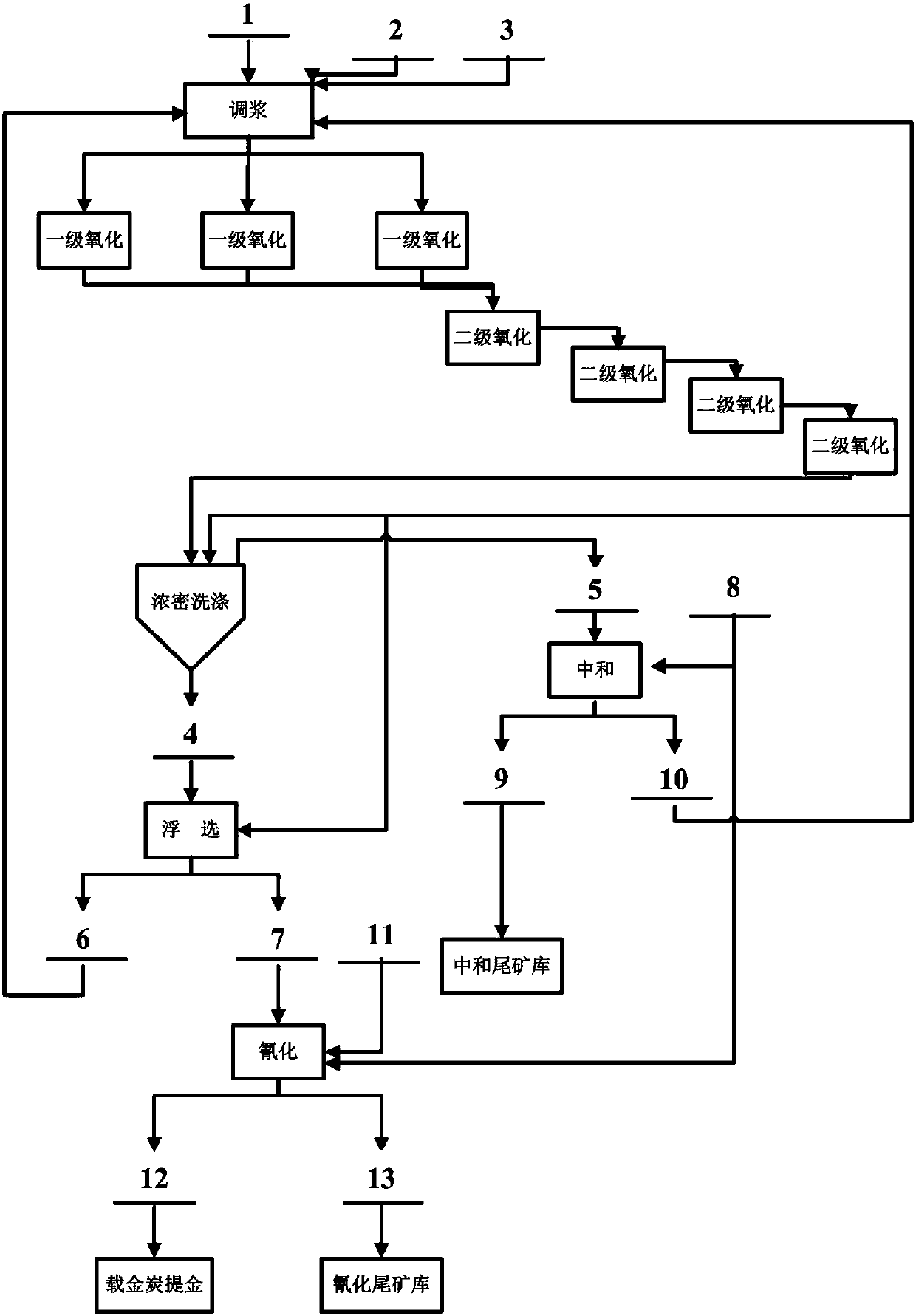

Method used

Image

Examples

Embodiment 1

[0035] Adopt technology of the present invention:

[0036](1) Biological oxidation, grind 1 kg of refractory gold concentrate (Au 48.85g / t, sulfur 40.45%, iron 40.20%, arsenic 2%) until the ore fineness is -0.074mm, accounting for 86.38%, add water to adjust to slurry Concentration of 15%, then add culture medium and leaching microorganisms to carry out two-stage biological oxidation, biological oxidation temperature 40 ℃, residence time 8 days;

[0037] (2) Dense washing, dense washing of oxidized ore pulp, overflow of the output oxidized liquid to neutralize and remove impurities, and bottom flow of oxidized ore pulp to flotation;

[0038] (3) Flotation, oxidize pulp to control flotation pulp concentration 25%, sodium lignosulfonate 25g / t, add xanthate 40g / t after stirring for 10 minutes, flotation concentrate yield 5.98%, gold concentrate gold Grade 58.42g / t;

[0039] (4) Cyanide, flotation tailings lime milk to adjust pH to 10, control sodium cyanide concentration 0.05%,...

Embodiment 2

[0041] Adopt technology of the present invention:

[0042] (1) Biological oxidation, grind 1 kg of refractory gold concentrate (Au 68.25g / t, sulfur 45.25%, iron 45.20%, arsenic 2.3%) until the ore fineness is -0.074mm, accounting for 86.38%, add water to adjust to slurry Concentration of 10%, then add culture medium and leaching microorganisms to carry out two-stage biological oxidation, biological oxidation temperature 40 ℃, residence time 8 days;

[0043] (2) Dense washing, dense washing of oxidized ore pulp, overflow of the output oxidized liquid to neutralize and remove impurities, and bottom flow of oxidized ore pulp to flotation;

[0044] (3) Flotation, the flotation concentration of 22% is controlled by oxidative pulping, sodium lignin sulfonate 40g / t dry residue, after stirring for 15 minutes, xanthate 60g / t dry residue is added, the flotation concentrate yield is 7.54%, gold Concentrate gold grade is 64.85g / t,

Embodiment 3

[0047] Adopt technology of the present invention:

[0048] (1) Biological oxidation, grind 1 kg of refractory gold concentrate (Au 38.15g / t, sulfur 38.82%, iron 37.30%, arsenic 1.8%) to ore fineness -0.045mm90.24%, add water to adjust to pulp concentration 15%, then add culture medium and leaching microorganisms to carry out two-stage biological oxidation, the oxidation temperature is 40°C, the oxidation time is 7 days, and the pulp concentration is 12%;

[0049] (2) Dense washing, dense washing of oxidized ore pulp, overflow of the output oxidized liquid to neutralize and remove impurities, and bottom flow of oxidized ore pulp to flotation;

[0050] (3) Flotation, the flotation concentration is 30% controlled by oxidation pulping, sodium lignin sulfonate 60g / t dry residue, after stirring for 15 minutes, xanthate 40g / t dry residue is added, the flotation concentrate yield is 6.54%, gold Concentrate gold grade is 38.95g / t;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com