Method for leaching gold from refractory gold sulfide concentrate by using alkaline thiocyanate solution under oxygen pressure

A thiocyanate, alkaline solution technology, applied in the direction of improving process efficiency, can solve the problems of low production efficiency, high gold recovery rate, long process flow, etc., and achieves low cost, improved leaching rate, and short process flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

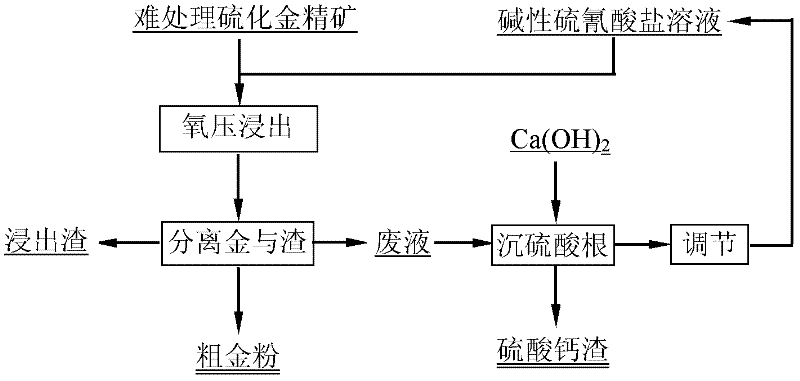

Image

Examples

Embodiment 1

[0041] The chemical composition (mass fraction, %) of high-arsenic and low-grade gold sulfide concentrate from a mine in Hunan is as follows: As10.02, S 36.40, Fe 42.43, Zn 1.05, Si 3.69, Al 0.98, Mg 0.85, Ca 1.21, Au 24.62 g / t.

[0042] The leaching conditions of alkaline thiocyanate solution for direct oxygen pressure leaching of gold from refractory gold sulfide concentrate: ammonium thiocyanate 1.5M, solid-to-liquid ratio 250g / L, ammonia addition is the theoretical consumption (theoretical consumption of ammonia The amount is 22.76M / kg gold concentrate). 1.2 times (ie 6.83M), oxygen pressure 0.6MPa, temperature 120 ℃ under the conditions of leaching for 8.0h. After filtering, the gold content in the filtrate was analyzed to obtain a gold leaching rate of 90.86%; the filtrate was replaced with iron powder three times the theoretical consumption for 1.0 h at room temperature, and the gold replacement recovery rate was 99.5%. The sulfate radical in the filtrate is 2.52M. Af...

Embodiment 2

[0044] The chemical composition (mass fraction, %) of gold sulfide concentrate produced by a mine is as follows: As 6.2, S 14.48, Fe13.64, Cu 0.05, Si 34.2, Al 3.2, Mg 1.15, Ca 2.11, Au 65.89g / t.

[0045] The leaching conditions of alkaline thiocyanate solution for direct oxygen pressure leaching of gold from refractory gold sulfide concentrate: ammonium thiocyanate 0.2M, solid-to-liquid ratio 200g / L, ammonia addition is the theoretical consumption (theoretical consumption of ammonia The amount is 1.5 times (2.71M) of 9.05M / kg gold concentrate), the oxygen pressure is 1.5MPa, and the temperature is 180°C for 2.0h. The pulp solution after leaching is used to adsorb gold with 3-stage countercurrent activated carbon at 70°C, and the recovery rate of gold is 94.65%. Ammonium concentration, returned for next leaching.

Embodiment 3

[0047] The chemical composition (mass fraction, %) of gold sulfide concentrate produced by a mine is as follows: As 0.56, S 8.48, Fe 11.34, Cu 0.04, Al 1.25, Mg 10.02, Ca 4.87, Au 83.78g / t, Ag 1252g / t.

[0048] The leaching conditions of alkaline thiocyanate solution for direct oxygen pressure leaching of gold from refractory gold sulfide concentrate: calcium thiocyanate 3.0M, solid-to-liquid ratio 120g / L, calcium hydroxide addition is the theoretical consumption (hydroxide The theoretical consumption of calcium is 2.5 times (ie 0.79M) of 2.65M / kg gold concentrate), oxygen pressure is 0.4MPa, and temperature is 160℃ for 4.0h. The pulp solution after leaching is used to adsorb gold with 5-stage countercurrent activated carbon at 30°C, and the recovery rate of gold is 95.78%. After filtering, the sulfate radical in the solution is 0.01M, adjust the concentration of calcium thiocyanate, and return to the next leaching. The leaching rate of silver is 92.19%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com