Production method and device for controlling germane preparation by adjusting electromotive force

A production method and electromotive force technology, applied in the direction of sampling devices, chemical instruments and methods, metal hydrides, etc., can solve the problems of lack of control methods, difficulty in application, poor repeatability, etc., achieve simplified reaction condition measurement and control technology, and improve effective performance and accuracy, low by-product hydrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

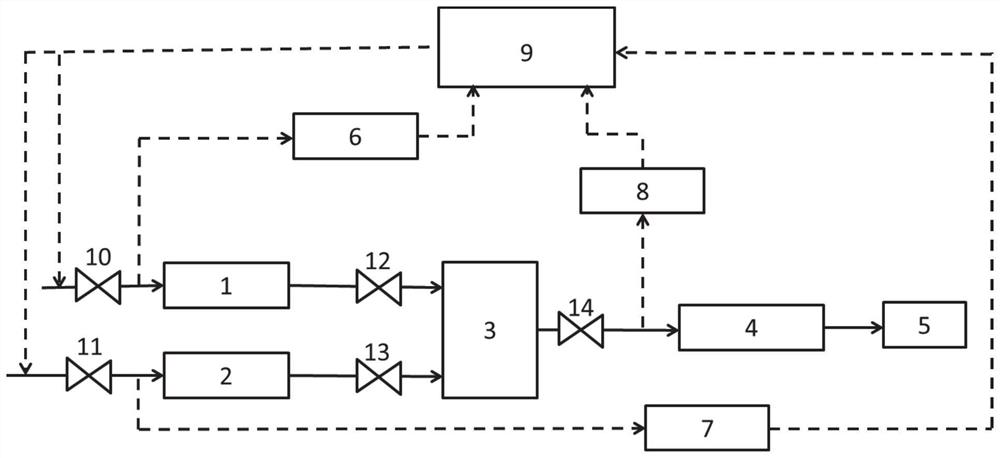

[0049] Example 1, refer to figure 1

[0050] The germane preparation equipment includes a reactor 3, and the germane preparation equipment is further provided with:

[0051] Feeder for acidic aqueous solution 1. MBH 4 and GeO 2 The alkaline aqueous solution feeder 2, the alkaline feed sampler 7, the acid feed sampler 6, the discharge sampler 8 and the electrical function test controller 9;

[0052] The feed line of the feeder 1 of the acidic aqueous solution has a first valve 10, MBH 4 and GeO 2 The feed pipeline of the alkaline aqueous solution feeder 2 has a second valve 11;

[0053] The feeder 1 of the acidic aqueous solution and the reactor 3 are connected by pipelines and are provided with a third valve 12; MBH 4 and GeO 2 The alkaline aqueous solution feeder 2 and the reactor 3 are connected by pipelines and are provided with a fourth valve 13;

[0054] The outlet pipe of the reactor has a fifth valve 14;

[0055] The acidic feed sampler 6 has sampling points be...

Embodiment 2

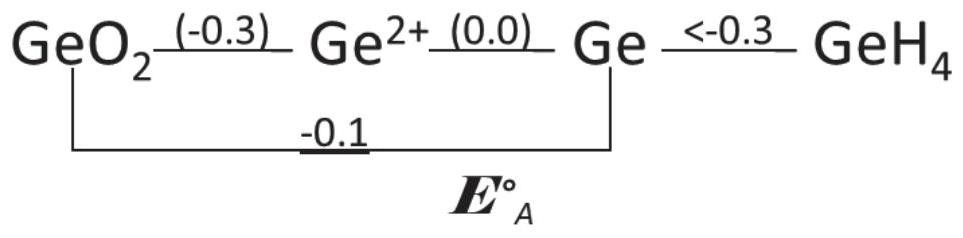

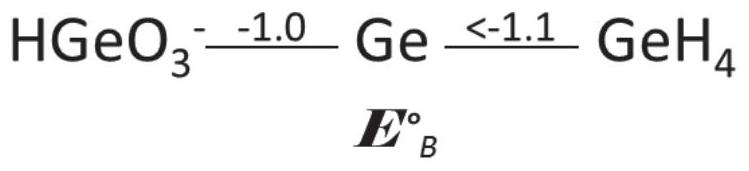

[0066] The present invention adopts the method and device for manipulating germane preparation by adjusting electromotive force, and is characterized in that the control reaction conditions are within the range of spontaneous electromotive force, which satisfies E A >0 conditions, the temperature, starting material and product concentration conditions are optimized in the spontaneous reaction range. GeO 2 (8.1 g) and NaBH 4 (17.69 g) was dissolved in 520 ml of KOH solution successively, and the pH value after 10-fold dilution of sampling was 13.45; the sulphuric acid solution was prepared respectively, and the pH value after 10-fold dilution of sampling was 0.82; the prepared acidic solution and alkaline solution were mixed To achieve the discharge requirement of pH 1.18, the reaction temperature is controlled at 25°C; the product collected in the gas phase is roughly separated and separated to remove moisture to obtain 5.80 grams of crude germane, and then the impurities suc...

Embodiment 3

[0068] The invention adopts the method and device for manipulating germane preparation by adjusting electromotive force, opening the second valve, raw material MBH 4 (17.52 g) and GeO 2 (8.08 g) of KOH alkaline aqueous solution (515 ml) was sampled by alkaline sampler 7 and analyzed and approved by electrical function test 9 (10-fold dilution pH value was 13.45) through alkaline feeder 2 and the fourth valve opened. to the reactor 3, then acidified by the sulfuric acid from the acid feeder 1, which was sampled by the first valve opened and the acid sampler 6 and the electrical function test controller 9 test and approved before entering the reactor (10 times diluted The pH value is 0.52) and then flows into the reactor 3 through the opened third valve 12; the reacted discharge is sent to the electrical function test controller 9 through the opened fifth valve and the sampler 8, and after the test is approved ( The pH value is 1.02) to keep the reaction continuing, otherwise t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com