Patents

Literature

68 results about "Phosphorane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

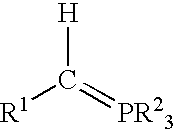

A phosphorane (IUPAC name: λ⁵-phosphane) is a functional group in organophosphorus chemistry with pentavalent phosphorus. It has the general formula PR₅. The parent hydride compound is the hypothetical molecule PH₅. The derivative pentaphenylphosphorane (Ph₅P) is stable.

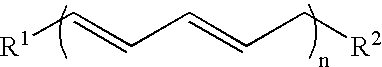

Process for preparing functional group-containing olefinic compounds

ActiveUS6838576B1High yieldStereoselectivity can be controlledPreparation by ester-hydroxy reactionOrganic compound preparationCompound aLeaving group

A process for preparing functional group-containing olefinic compounds comprises the steps of (a) reacting at least one alkylidene phosphorane with at least one carbonyl-containing compound that comprises at least one group that is a leaving group, or that is capable of subsequent conversion to a leaving group, to form an olefinic compound that comprises at least one leaving group, the carbonyl-containing compound being selected from the group consisting of ketones and aldehydes; and (b) reacting the olefinic compound with at least one functional group-containing nucleophile to form a functional group-containing olefinic compound.

Owner:3M INNOVATIVE PROPERTIES CO

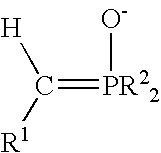

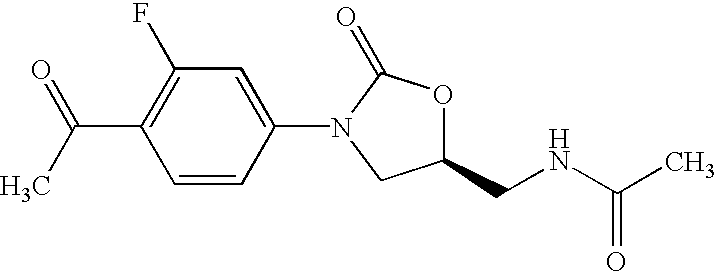

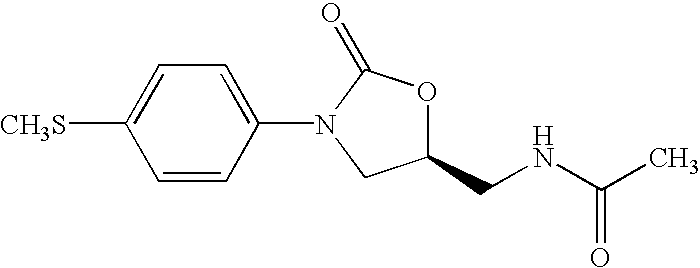

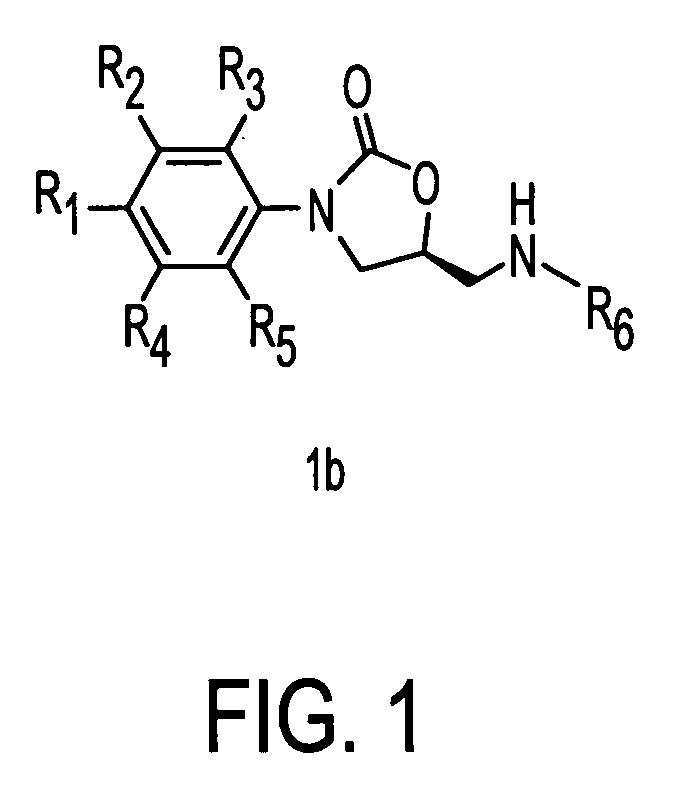

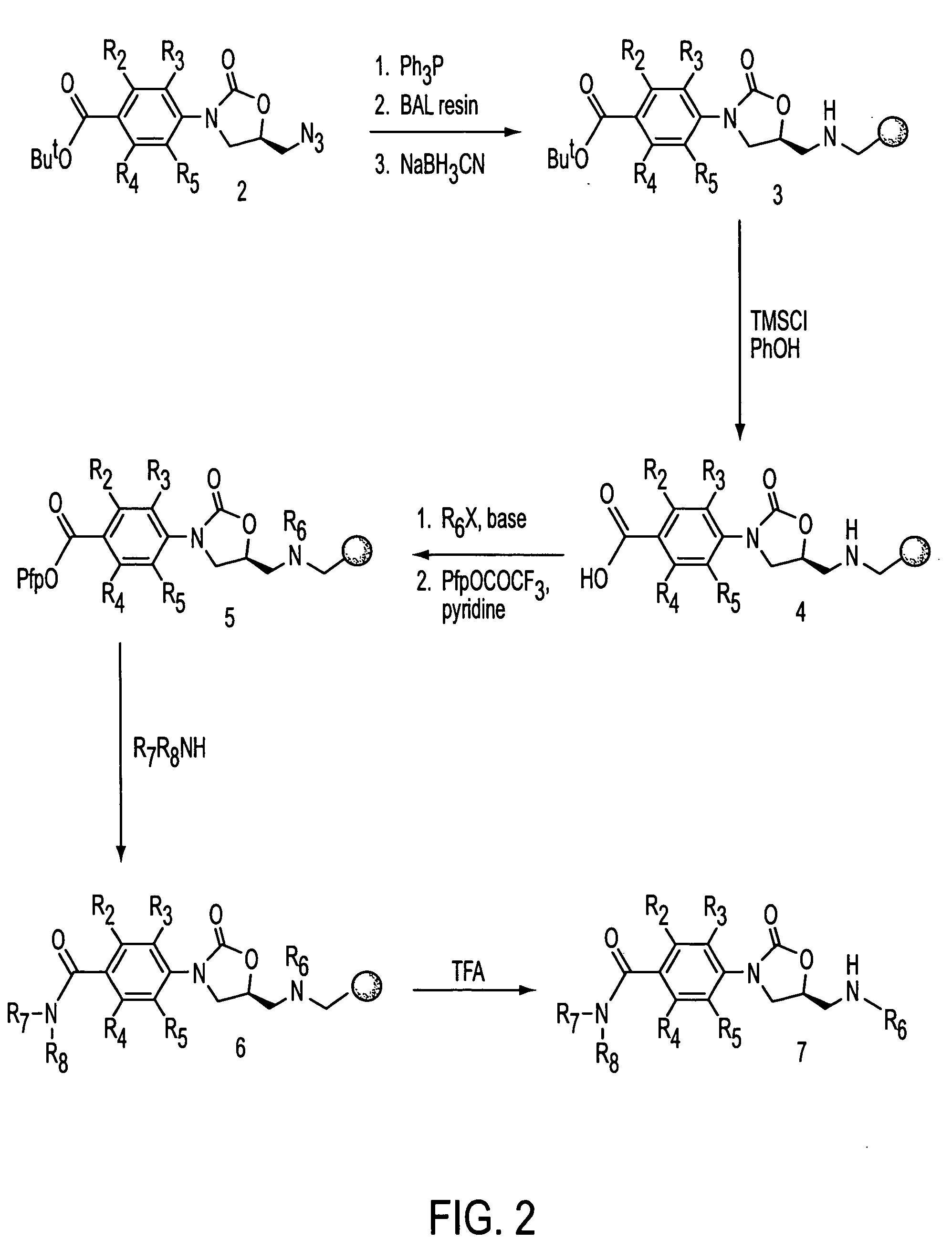

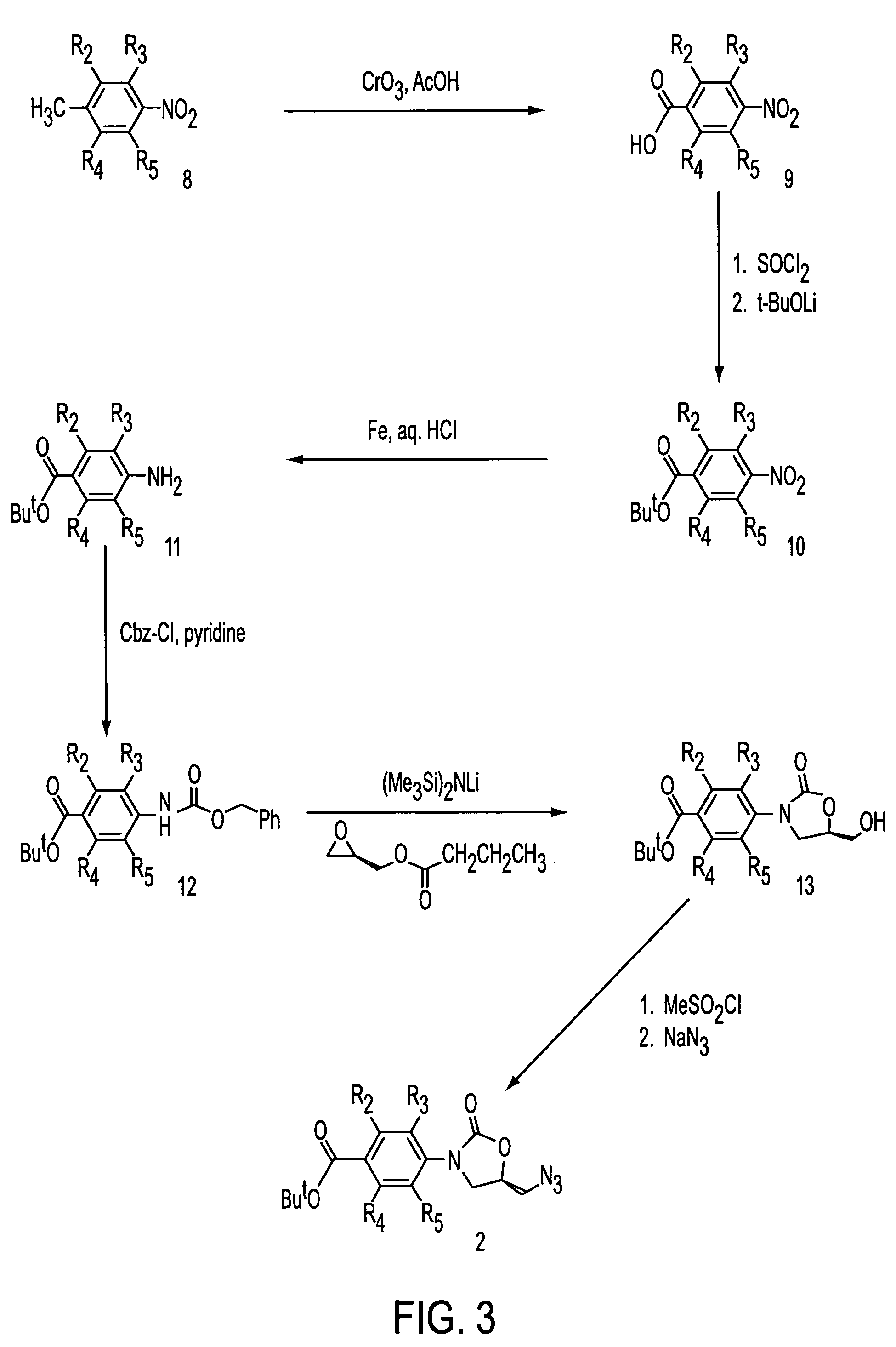

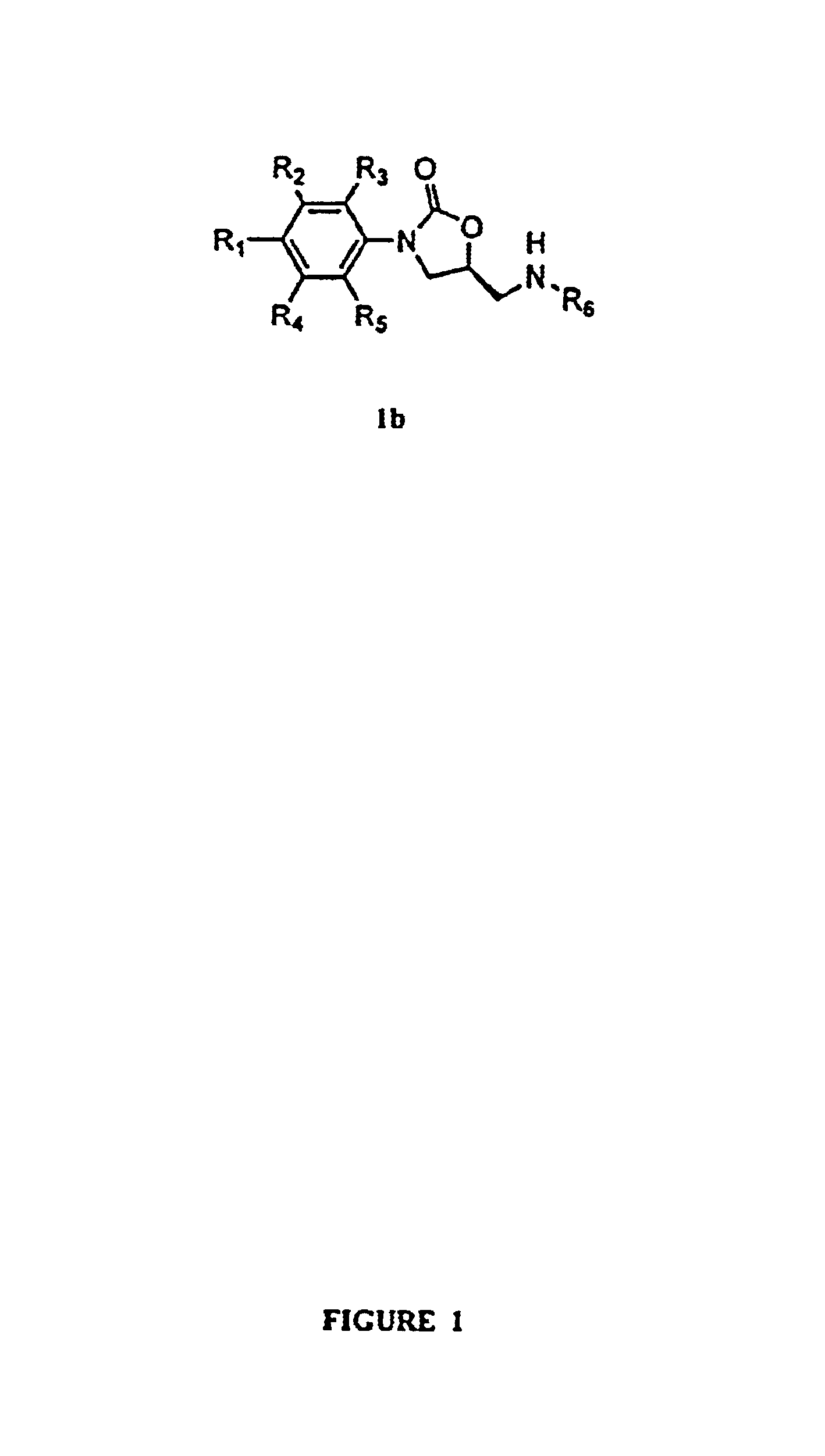

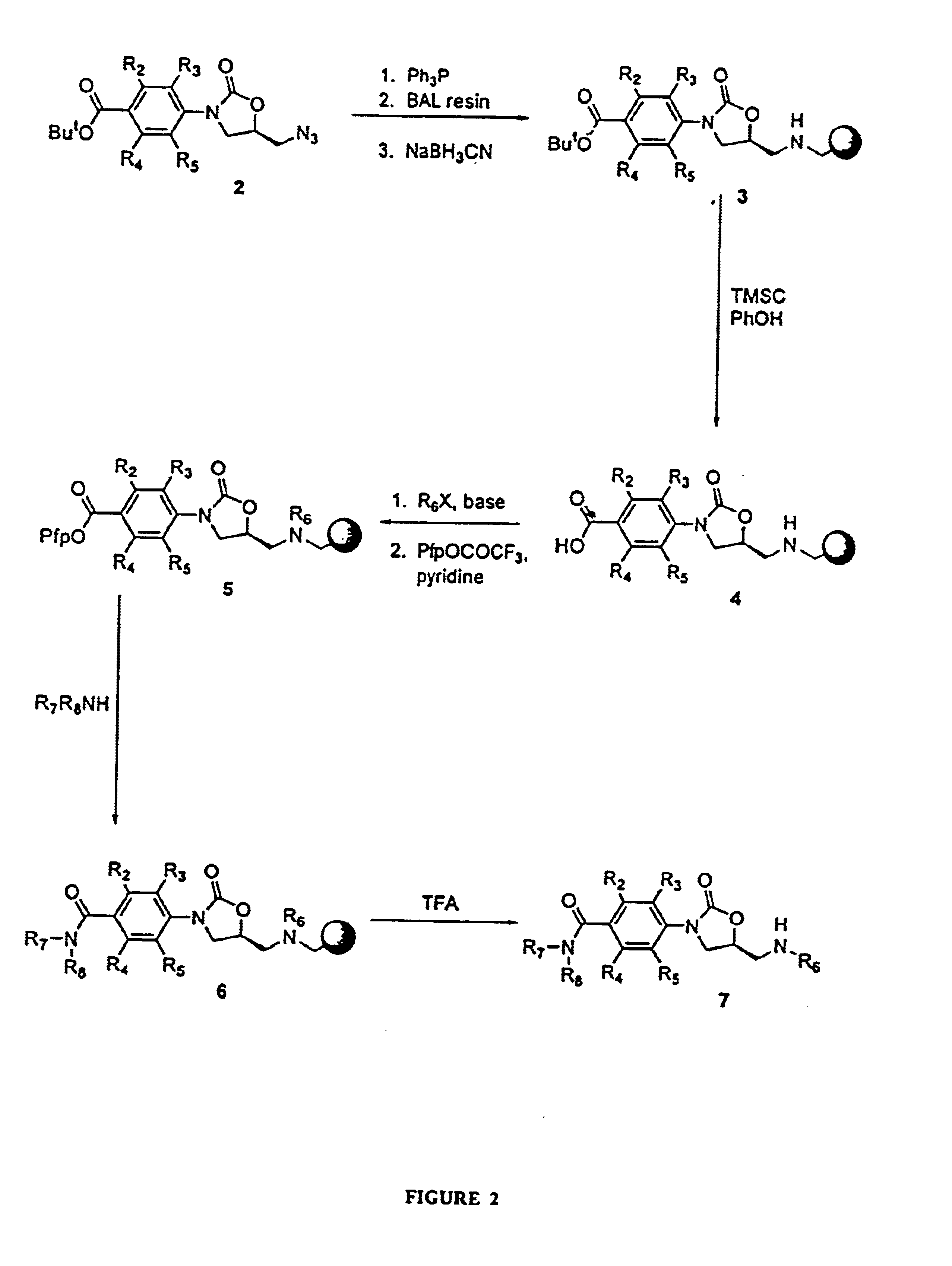

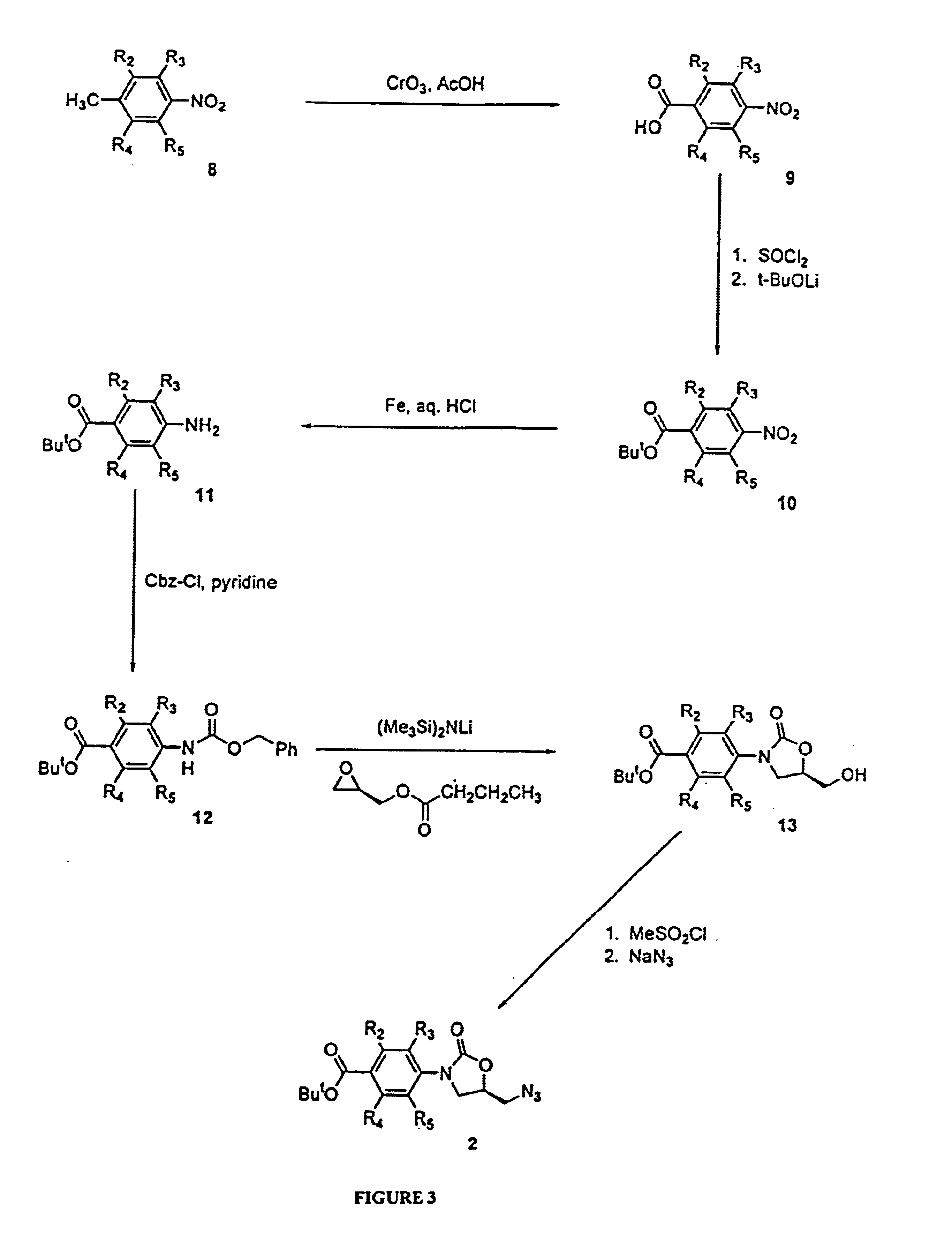

Oxazolidinone combinatorial libraries, compositions and methods of preparation

InactiveUS6562844B2Rapid productionEasy to synthesizeBiocideGroup 5/15 element organic compoundsLibrary preparationCombinatorial chemistry

Oxazolidinones and methods for their synthesis are provided. Also provided are combinatorial libraries comprising oxazolidinones, and methods to prepare the libraries. Further provided are methods of making biologically active oxazolidinones as well as pharmaceutically acceptable compositions comprising the oxazolidinones. The methods of library preparation include the attachment of oxazolidinones to a solid support. The methods of compound preparation in one embodiment involve the reaction of an iminophosphorane with a carbonyl containing polymeric support.

Owner:PHARMACIA & UPJOHN CO

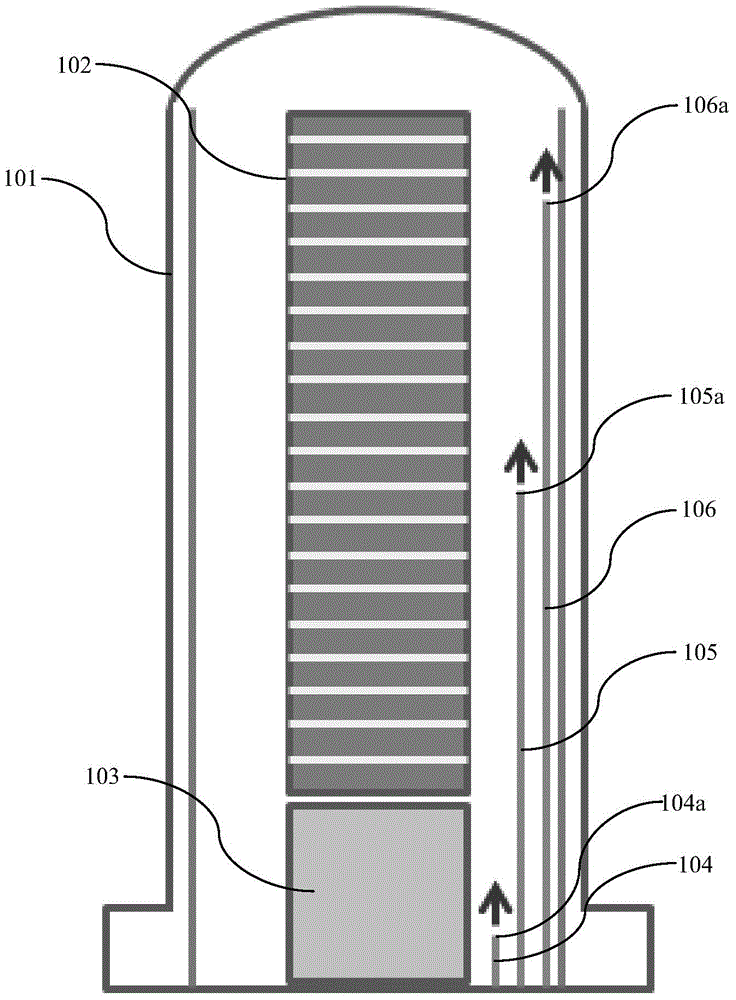

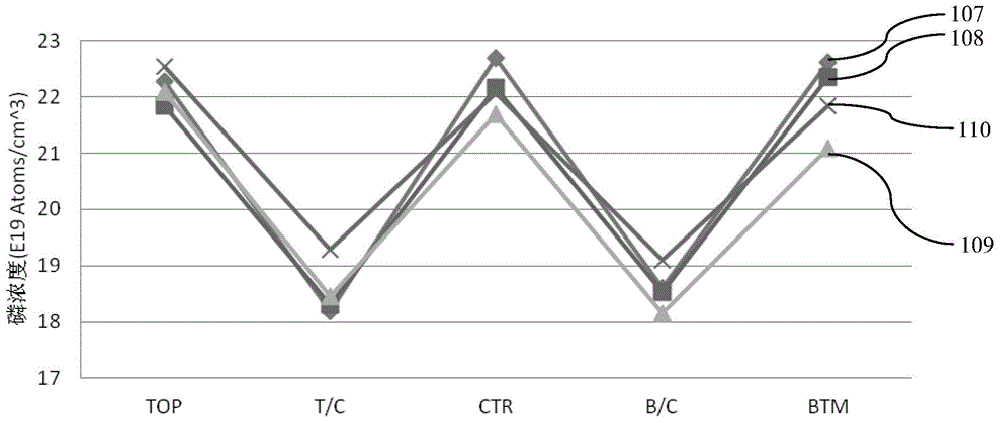

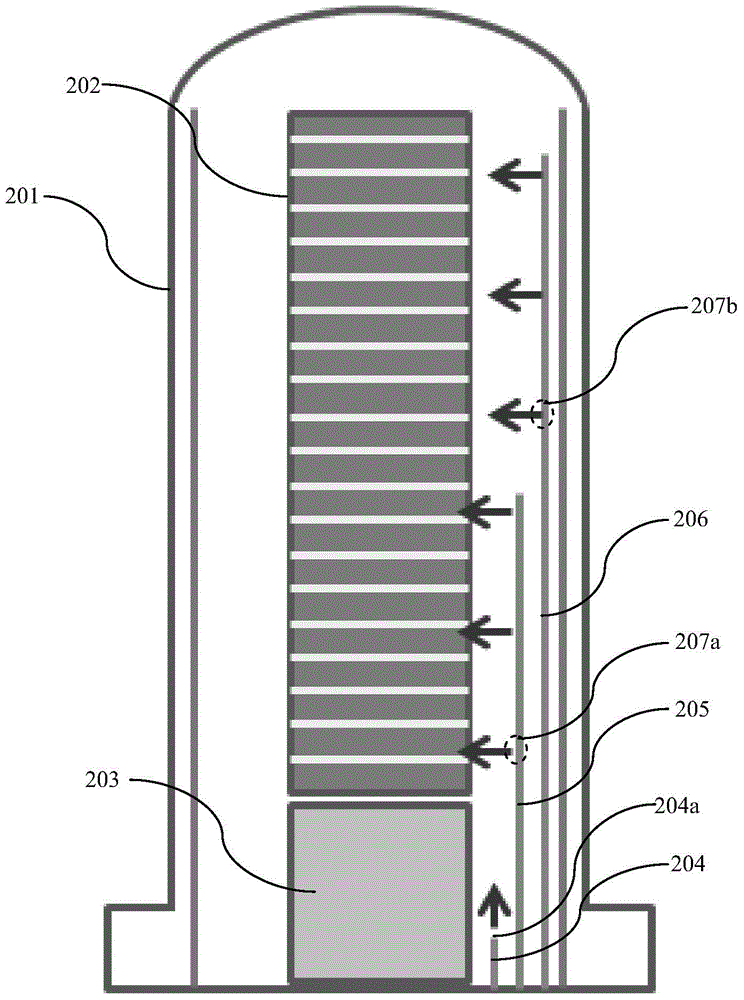

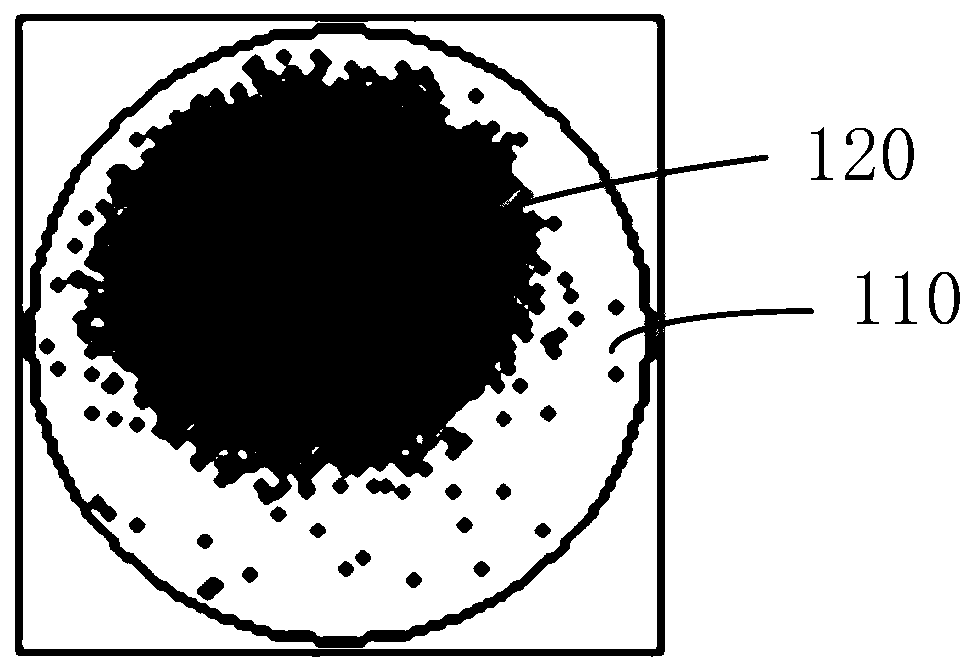

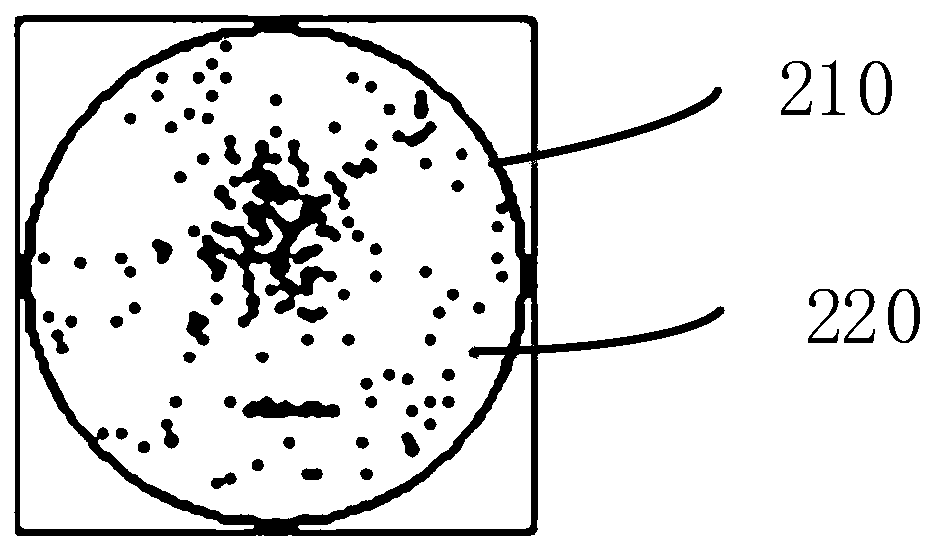

Method and structure for improving phosphorus concentration uniformity of doped polycrystalline or noncrystalline silicon chips

ActiveCN104576330AAvoid the W distribution caseImprove Phosphorus Concentration UniformityDiffusion/dopingSemiconductor/solid-state device manufacturingEngineeringSilicon chip

The invention discloses a method for improving the phosphorus concentration uniformity of doped polycrystalline or noncrystalline silicon chips. According to the method, a furnace tube is adopted for growth, phosphorane is introduced through three nozzle pipelines, and the top ends of the nozzle pipelines are arranged at the bottom, the middle and the top of a crystal boat respectively; gas is emitted from the top of the first nozzle pipeline; a plurality of lateral gas outlets are formed in each of the second and third nozzle pipelines at intervals; the diameters of the lateral gas outlets of each pipeline are gradually increased in a direction from the bottom end to the top end and adjusted by testing the phosphorus concentration of the monitored silicon chips at the fixed monitoring positions of the crystal boat; the positions of the lateral gas outlets are adjusted by testing a phosphorus concentration curve along the whole crystal boat. The invention further discloses a structure for improving the phosphorus concentration uniformity of the doped polycrystalline or noncrystalline silicon chips. According to the method and the structure, the phosphorus concentration uniformity of the silicon chips can be improved and the production cost can be reduced.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

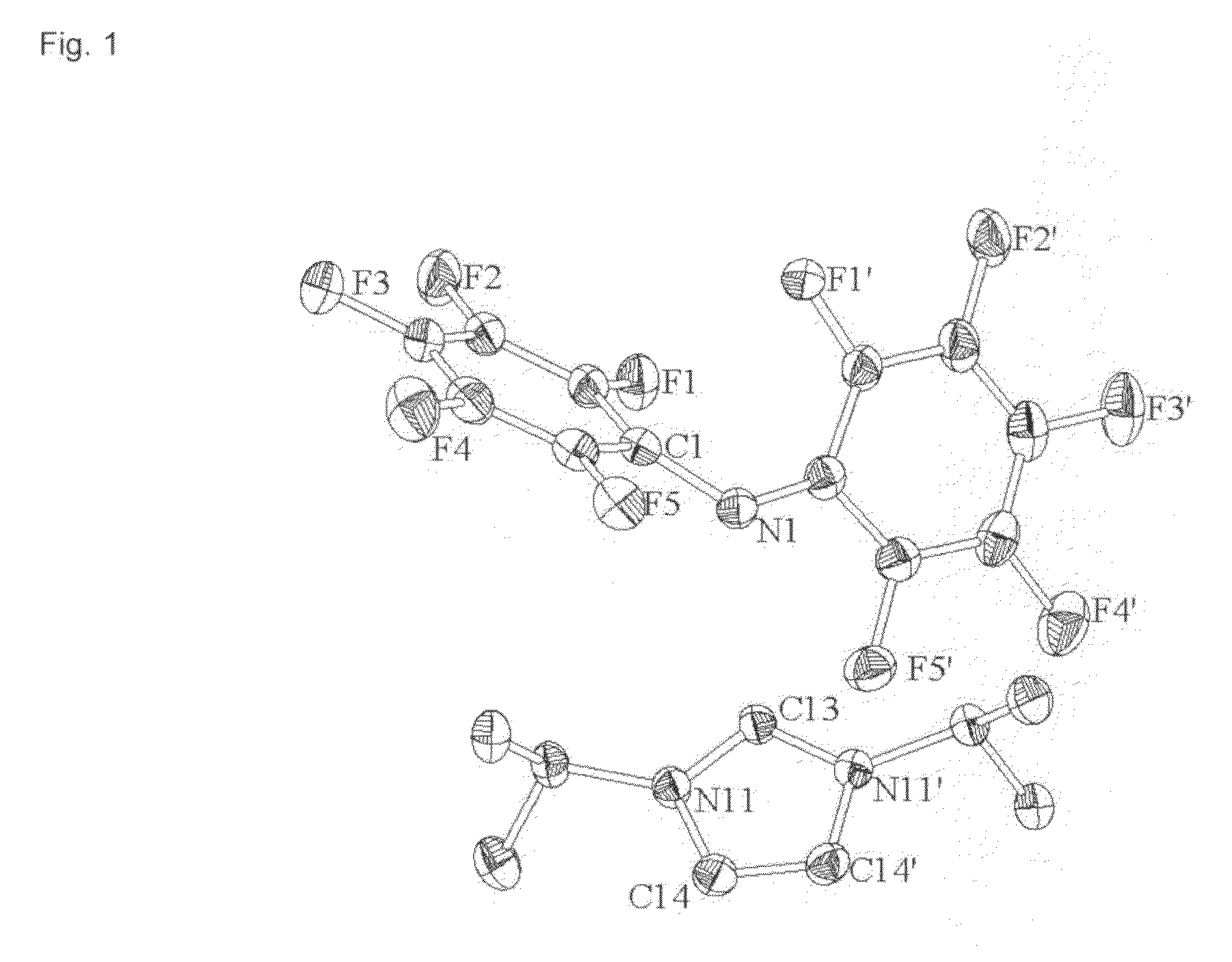

Hydrophobic Ionic Liquids

InactiveUS20090298189A1Organic compound preparationComponent separationPyridiniumRechargeable battery pack

The subject of the invention at hand are novel, a little basic, fluorinated pentafluorophenyl imide anions, which can be used as anions in ionic liquids. Methods for producing ionic liquids are described, which contain these novel pentafluorophenyl imide ions as anions, as well as quaternary organic ammonium ions, guanidinium ions, N-organo-pyridinium ions, imidazolium, imidazolidinium or benzimidazolidinium ions, alkyl-alkylidene phosphoranes or aryl-alkylidene phosphoranes as cations. Alternative methods according to the present invention provide ionic liquids through reaction of ketene N,N-diacetals or alkyl or aryl-alkylidene phosphoranes with acids.The ionic liquids according to the present invention are suitable, for example, as solvents for syntheses, as mobile and / or stationary phase in chromatography, as electrolyte systems for batteries, galvanic elements, fuel cells and rechargeable battery packs.

Owner:PHILIPPS UNIV MARBURG

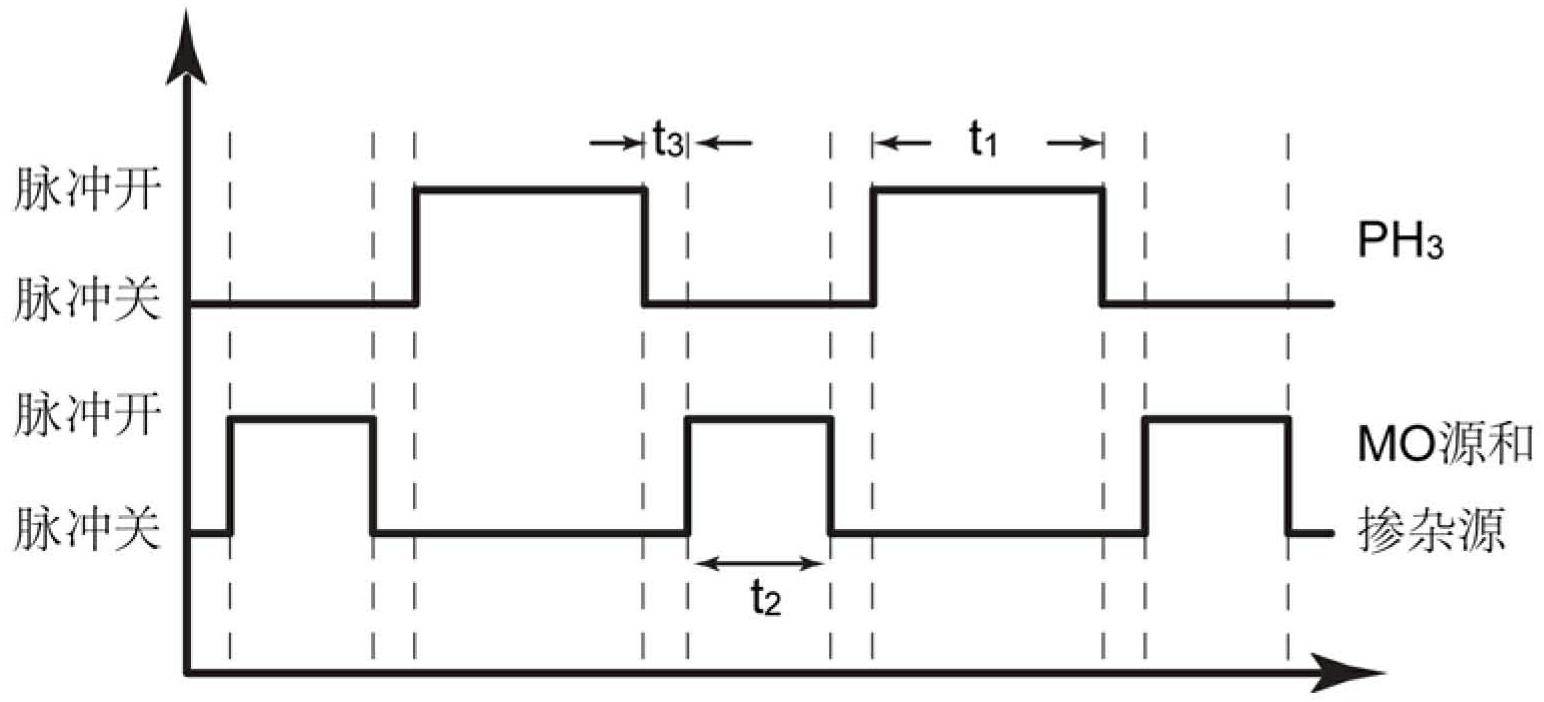

Method by adopting impulse airflow method to grow gallium phosphide (GaP) current extension layer

ActiveCN102593274AImprove efficiencyExtend your lifePolycrystalline material growthFrom chemically reactive gasesGas phaseChemical vapor deposition

The invention discloses a method by adopting an impulse airflow method to grow a gallium phosphide (GaP) current extension layer, which is characterized in that: a molybdenum (MO) source containing gallium atoms, phosphorane and a doping source are alternatively introduced into a reaction chamber of a metal organic chemical gas-phase precipitation system in a pulse way, or the flow-rate of the phosphorane is maintained constant, the MO source containing t he gallium atoms and the doping source are introduced in a pulse way. Due to adoption of the method, transition time of gallium atoms and phosphorus atoms on the surface of an extension layer can be increased, so that the gallium atoms and the phosphorus atoms can adequately cover the surface of the extension layer, and a GaP current extension layer with high quality can be obtained.

Owner:XIAMEN CHANGELIGHT CO LTD

Oxazolidinone combinatorial libraries, compositions and methods of preparation

InactiveUS20050004174A1Rapid productionBiocideGroup 5/15 element organic compoundsLibrary preparationCombinatorial chemistry

Oxazolidinones and methods for their synthesis are provided. Also provided are combinatorial libraries comprising oxazolidinones, and methods to prepare the libraries. Further provided are methods of making biologically active oxazolidinones as well as pharmaceutically acceptable compositions comprising the oxazolidinones. The methods of library preparation include the attachment of oxazolidinones to a solid support. The methods of compound preparation in one embodiment involve the reaction of an iminophosphorane with a carbonyl containing polymeric support.

Owner:GORDEEV MIKHAIL F +4

Graded zinc diffusing method based on MOCVD (Metal-Organic Chemical Vapor Deposition) system for producing chip of indium-gallium-arsenic photoelectric detector

ActiveCN101567407AIncrease the carrier concentrationImprove responsivenessFinal product manufactureChemical vapor deposition coatingPressure riseDiffusion methods

The invention relates to a graded zinc diffusing method based on an MOCVD system for producing the chip of an indium-gallium-arsenic photoelectric detector. The method comprises the following steps: a semiconductor wafer which does not form an InGaAs PIN structure of a PN junction is cleaned and blown to dry by high-purity nitrogen; an MOCVD reaction chamber is heated up, depressurized and cleaned; the semiconductor wafer is placed in the reaction chamber; the pressure of the reaction chamber is set; diffusion taking a zinc phosphide compound which is formed by zinc methide (DMZn) and phosphorane (PH3) at high temperature as a diffusion source is conducted with the presence of catalytic reaction and the shielding gas; after the completion of the diffusion, the gas is turned off, the reaction chamber is cooled down and filled with nitrogen and has a pressure rise; and the wafer which undergoes the diffusion is taken out of the reaction chamber. As the diffusion rules of zinc in InP material and InGaAs material have great difference, the graded diffusion method is adopted. With the method, both the InP layer and the InGaAs layer can have rather high current carrier concentration, good interface, rather good homogeneity, technique repeatability, high response and precise control and can be manufactured on a large scale.

Owner:WUHAN HUAGONG GENUINE OPTICS TECH

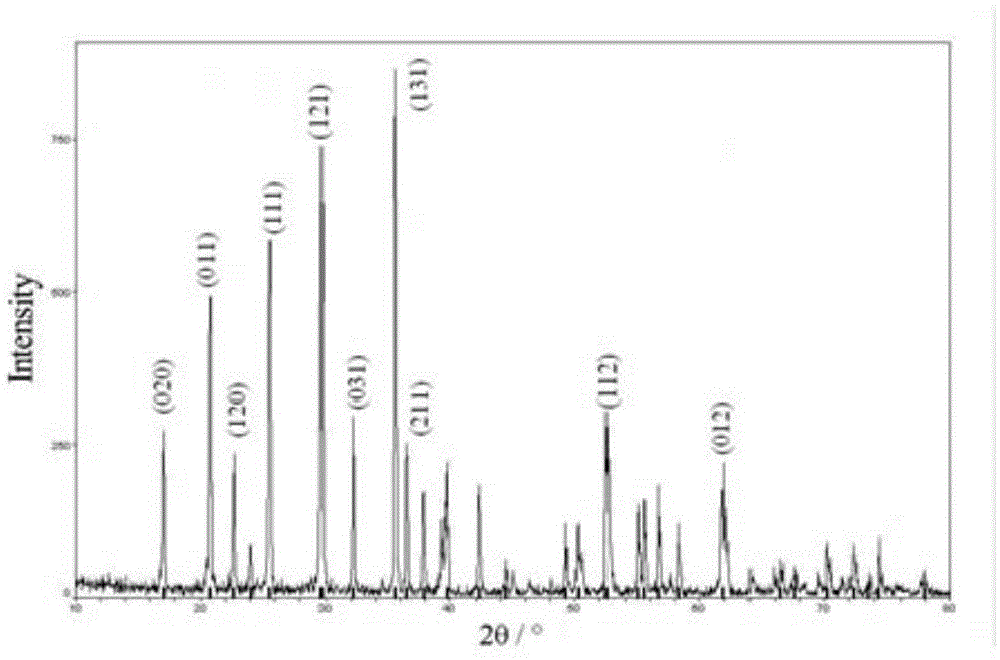

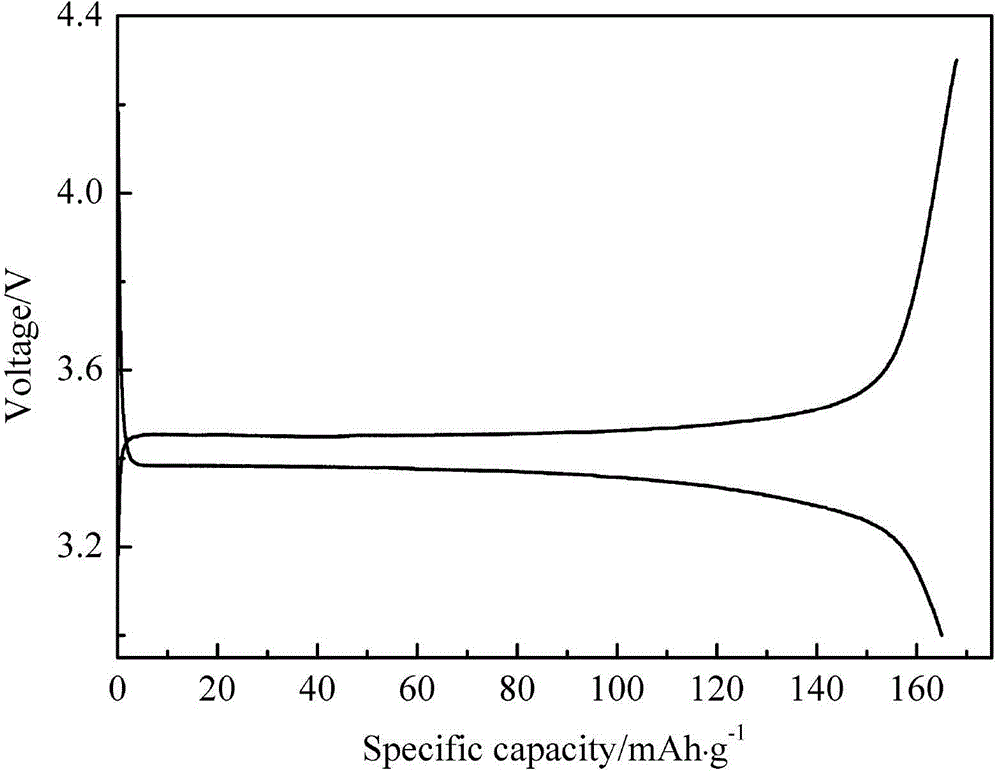

Method for covering lithium iron phosphate conducting layer by use of radio frequency plasma enhanced chemical vapor deposition

The invention discloses a method for covering a lithium iron phosphate conducting layer by use of radio frequency plasma enhanced chemical vapor deposition. The method comprises the following steps: putting lithium iron phosphate in a reaction chamber and performing a reaction on the lithium iron phosphate for 10-20 minutes in the presence of radio frequency plasmas in a diluted reactant gas, wherein the total pressure of the reaction chamber is kept in a range of 10-1000Pa, the electrical output power of the radio frequency plasmas is in the range of 60-400W, the diluted reactant gas is formed by mixing a diluent gas and a reactant gas in a volume ratio of (5-20):1, the reactant gas is one or mixed gases of any two of silane, SiH3Cl, SiH2Cl2, borane, germane and phosphorane, and the diluent gas is any one of hydrogen, nitrogen, helium, neon, argon, krypton and xenon; therefore, the conducting layer covered lithium iron phosphate is obtained. Compared with conventional chemical vapor deposition, the method has the advantages of high reactivity, low reaction temperature and short reaction time.

Owner:SIHUI DABOWEN IND CO LTD

Method for synthesizing chiral cyproconazole

The invention provides a method for synthesizing chiral cyproconazole, which comprises the following steps: carrying out ylide reaction on 1-(4-chlorphenyl)-2-cyclopropyl-1-acetone used as the raw material and methylidene triphenyl phosphorane to generate 1-(4-chlorphenyl)-2-cyclopropyl-1-propylene; carrying out epoxidation reaction on the 1-(4-chlorphenyl)-2-cyclopropyl-1-propylene and an epoxidation reagent under the action of a transition metal catalyst to produce an epoxidation intermediate; and carrying out ring opening on the epoxidation intermediate and 1,2,4-triazole to obtain the target product chiral cyproconazole. The chiral cyproconazole synthesized by the method of the invention has the advantages of high optical purity (e.e% is greater than 80%) and high total reaction yield (greater than 75%), and is suitable for industrial production.

Owner:合肥华纳生物医药科技有限公司

Preparation method of sacubitril intermediate having low triphenylphosphine oxide content

InactiveCN106946742AReduce contentCarbamic acid derivatives preparationOrganic compound preparationSodium bicarbonateCarbamate

The invention relates to a preparation method of a sacubitril intermediate having low triphenylphosphine oxide content. The preparation method comprises that water, isopropyl acetate, sodium bromide, sodium bicarbonate and tetramethylpiperidine oxide into (R)-tert-butyl(1-([1, 1'-biphenyl]-4-yl)-3-hydroxypropane-2-yl)carbamate, adding a sodium hypochlorite solution into the mixture drop by drop for a reaction, after the reaction, carrying out layering, taking an organic layer, adding ethoxyformylethylidenetriphenyl phosphorane into the organic layer, after a reaction, concentrating the reaction product, removing isopropyl acetate, adding ethanol, water and lithium hydroxide into the mixture, carrying out heating until reflux, carrying out concentration until drying, adding water and activated carclazyte into the product, carrying out stirring at the room temperature, filtering the mixture, adding ethanol and acetic acid into the filtrate, carrying out heating until reflux, and carrying out cooling and stirring to precipitate solids which are the sacubitril intermediate finished products. The preparation method can reduce triphenylphosphine oxide content of the (R)-tert-butyl(1-([1, 1'-biphenyl]-4-yl)-3-hydroxypropane-2-yl)carbamate.

Owner:常州沃腾化工科技有限公司

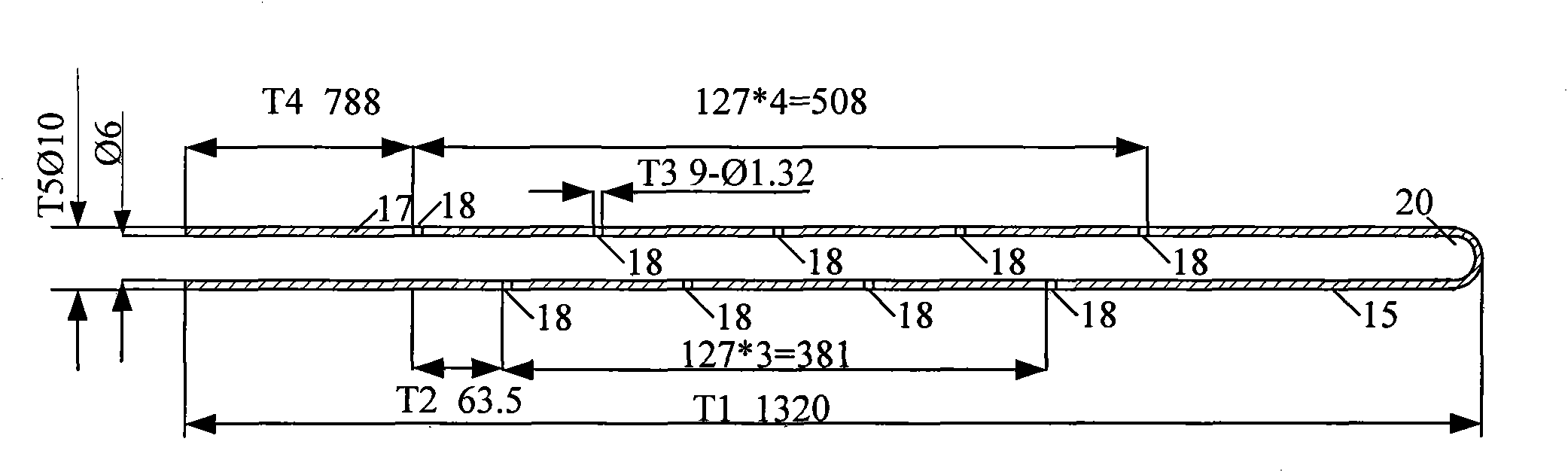

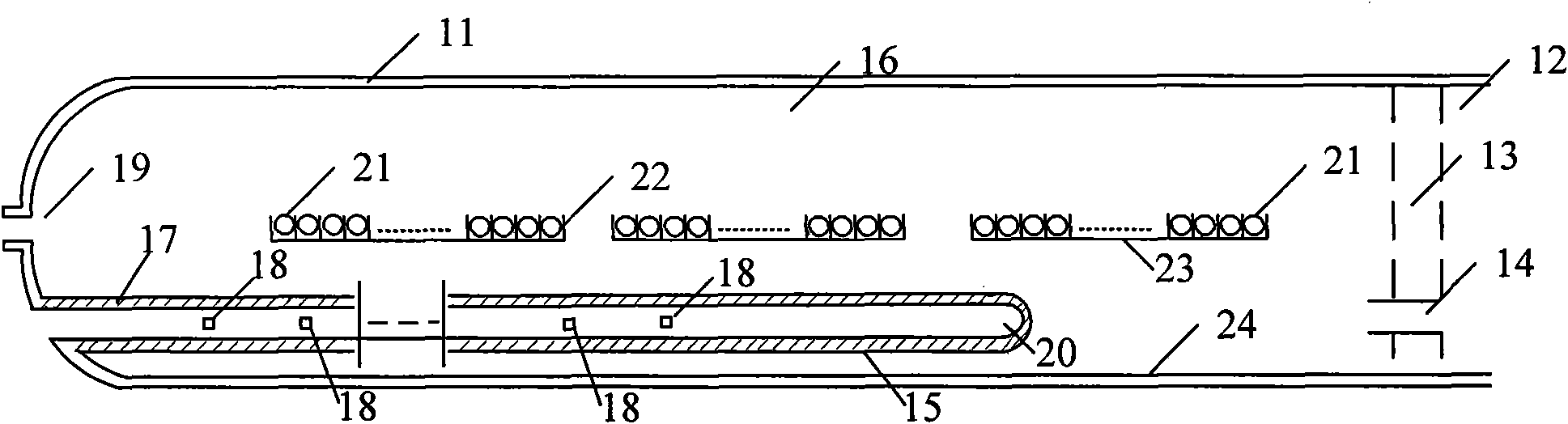

Horizontal furnace tube and method for producing in-situ doped polysilicon

InactiveCN101993079AEvenly distributedImprove thickness uniformityPolycrystalline material growthSilicon compoundsSilanesPhosphorane

The invention discloses a horizontal furnace tube and a method for producing in-situ doped polysilicon. In order to solve the problem that the uniformity of the polysilicon is poor when the in-situ doped polysilicon is synthesized in the prior art, the invention discloses the horizontal furnace tube for producing the in-situ doped polysilicon, which comprises a tube body 11 and a reaction cavity 16 surrounded by the tube body 11, a tubular gas injector 15 extends into the reaction cavity 16 in the axial direction of the tube body 11, a plurality of small holes 18 are arranged on a tube wall 17 of the injector 15, and one end 20 of the gas injector far away from the gas injection is sealed. Because phosphorane and silane are uniformly distributed in a cavity of the furnace tube through injecting reaction gas in the injector 15, the thickness uniformity of the in-situ doped polysilicon is improved.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

Hydrophobic ionic liquids

The subject of the invention at hand are novel, a little basic, fluorinated pentafluorophenyl imide anions, which can be used as anions in ionic liquids. Methods for producing ionic liquids are described, which contain these novel pentafluorophenyl imide ions as anions, as well as quaternary organic ammonium ions, guanidinium ions, N-organo-pyridinium ions, imidazolium, imidazolidinium or benzimidazolidinium ions, alkyl-alkylidene phosphoranes or aryl-alkylidene phosphoranes as cations. Alternative methods according to the present invention provide ionic liquids through reaction of ketene N,N-diacetals or alkyl or aryl-alkylidene phosphoranes with acids.The ionic liquids according to the present invention are suitable, for example, as solvents for syntheses, as mobile and / or stationary phase in chromatography, as electrolyte systems for batteries, galvanic elements, fuel cells and rechargeable battery packs.

Owner:PHILIPPS UNIV MARBURG

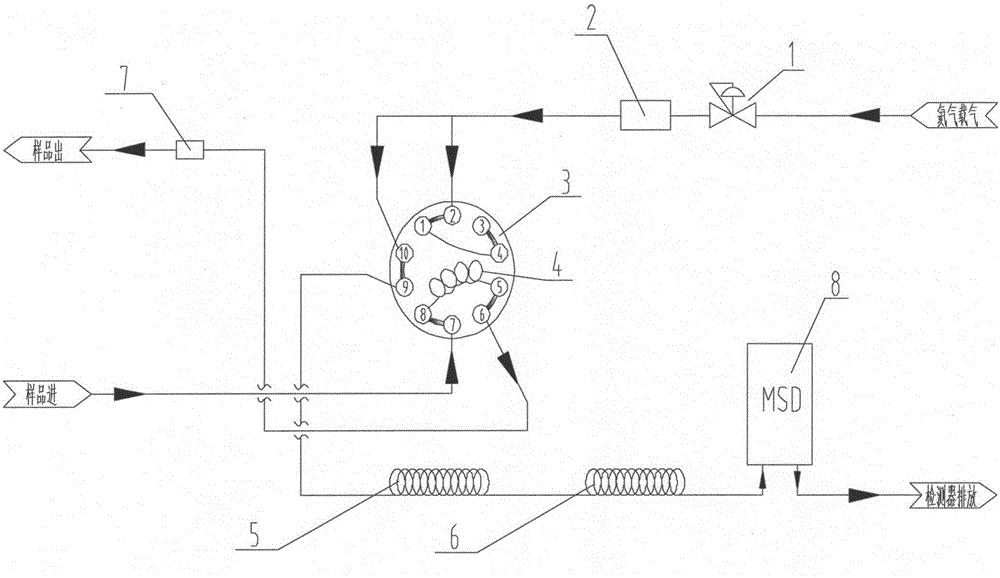

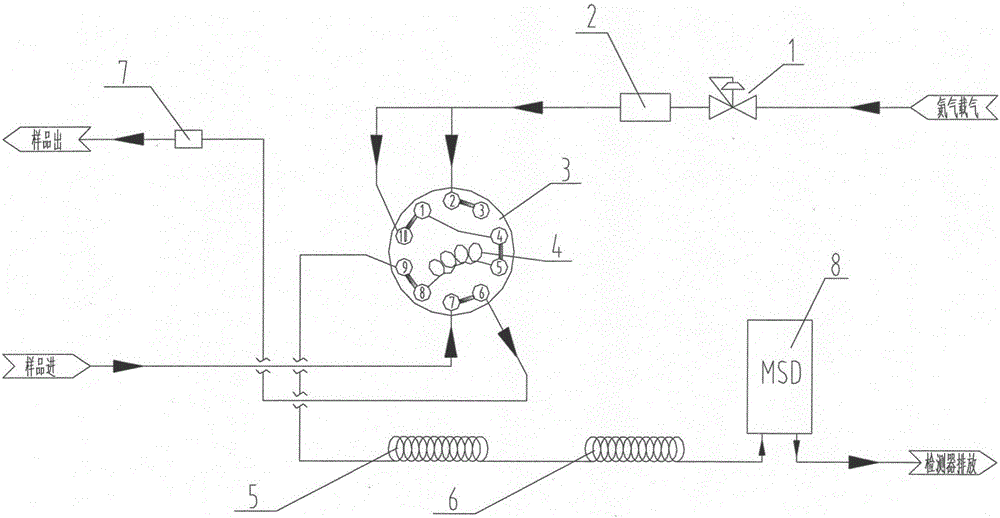

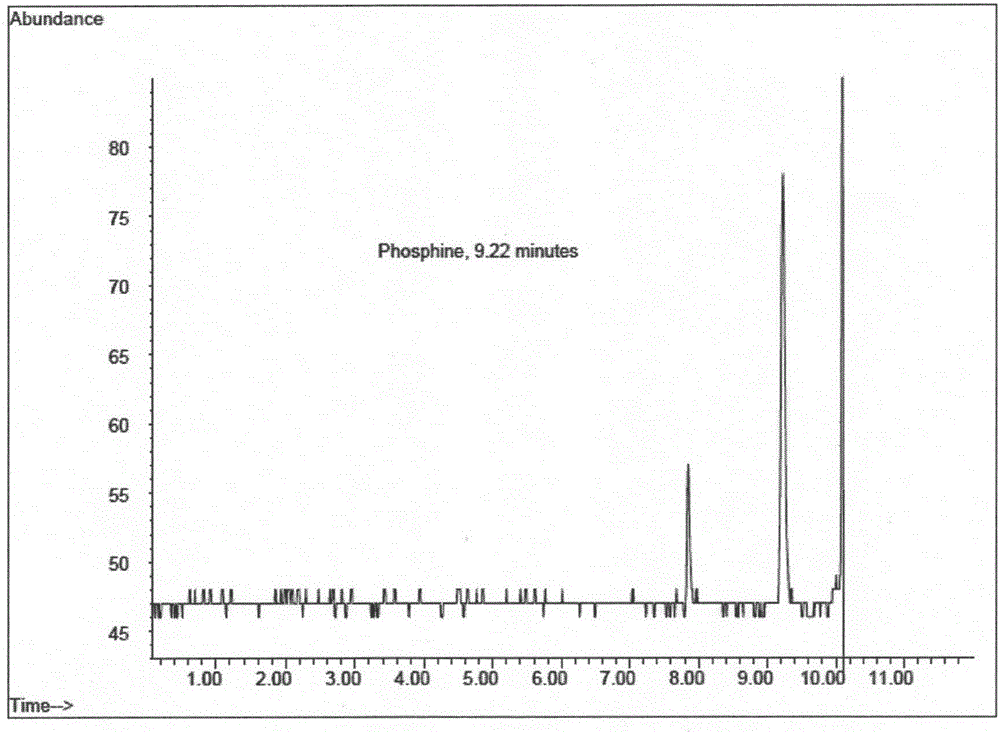

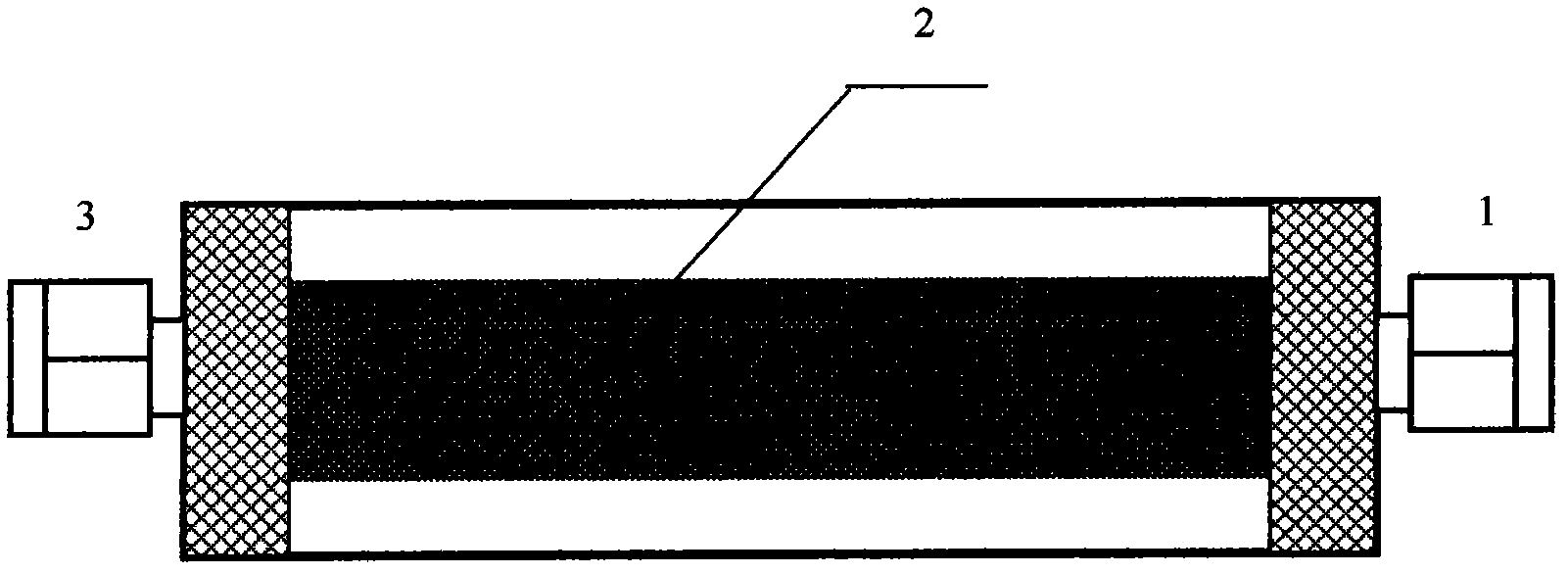

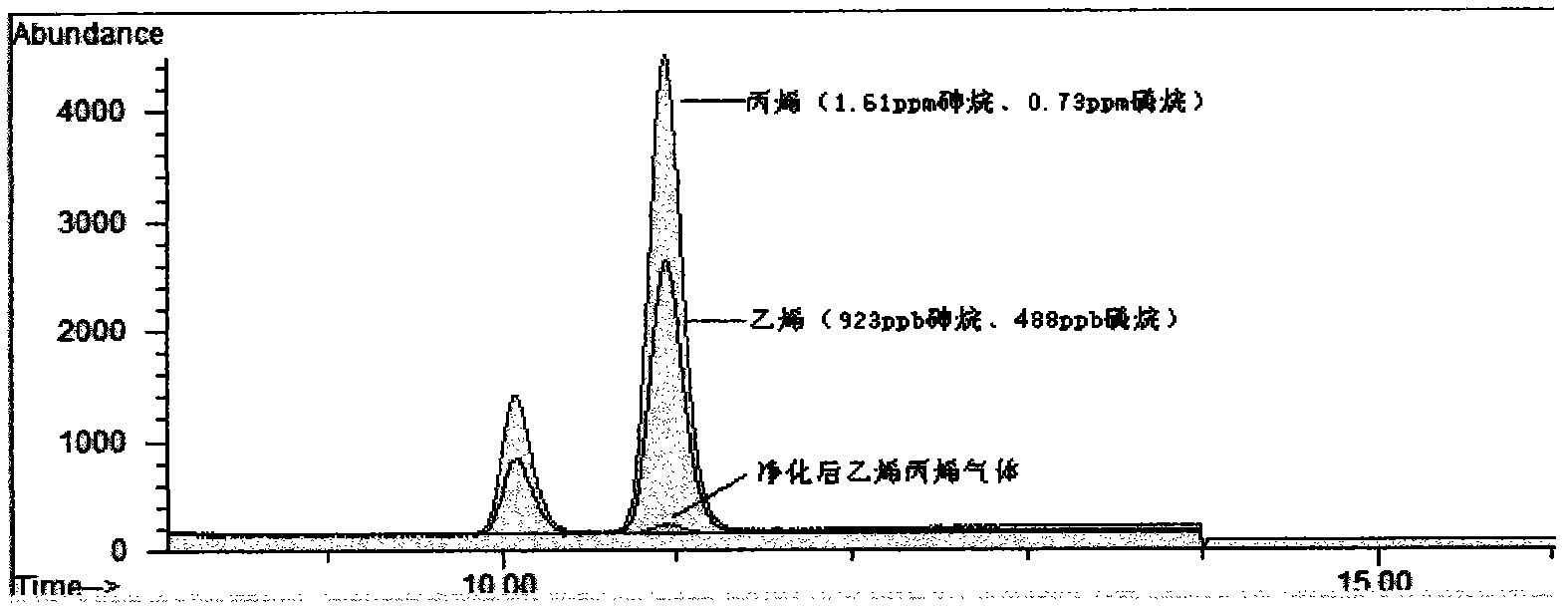

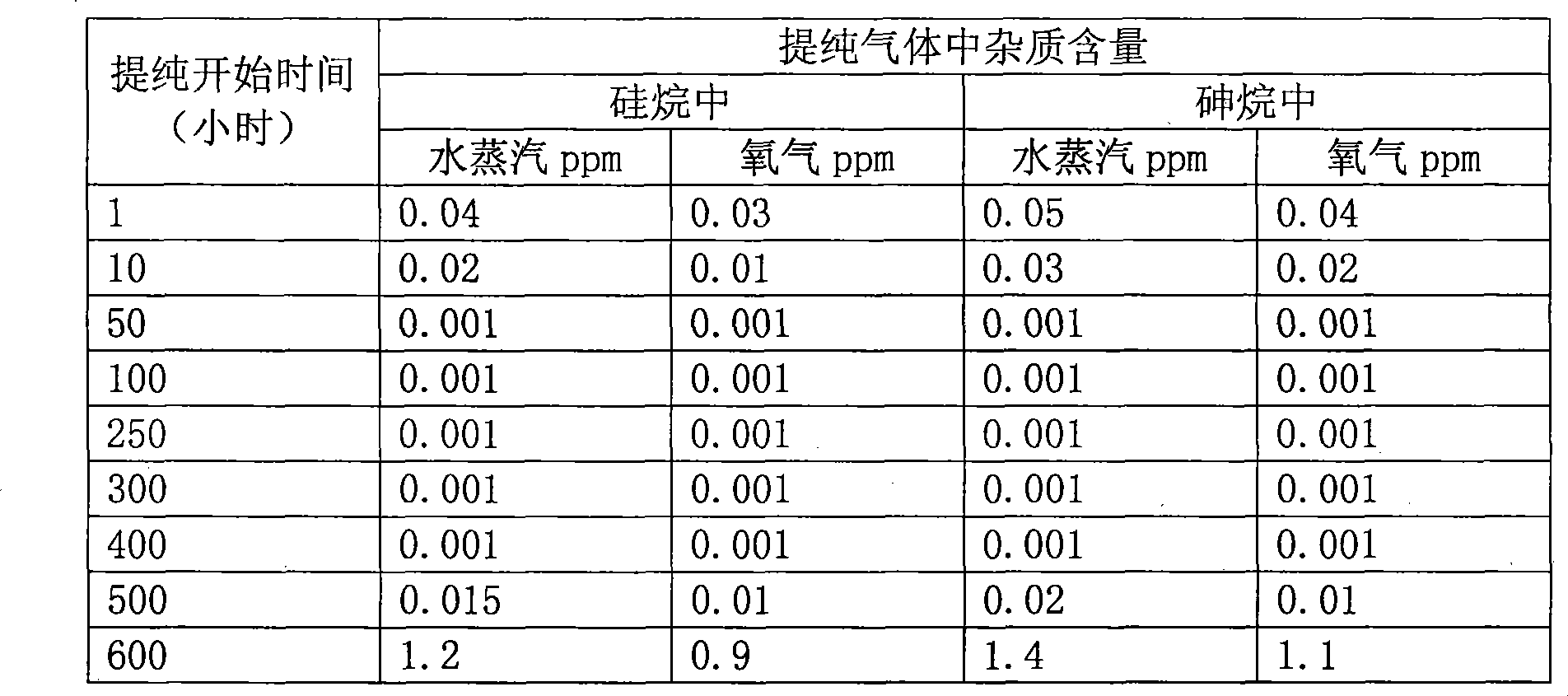

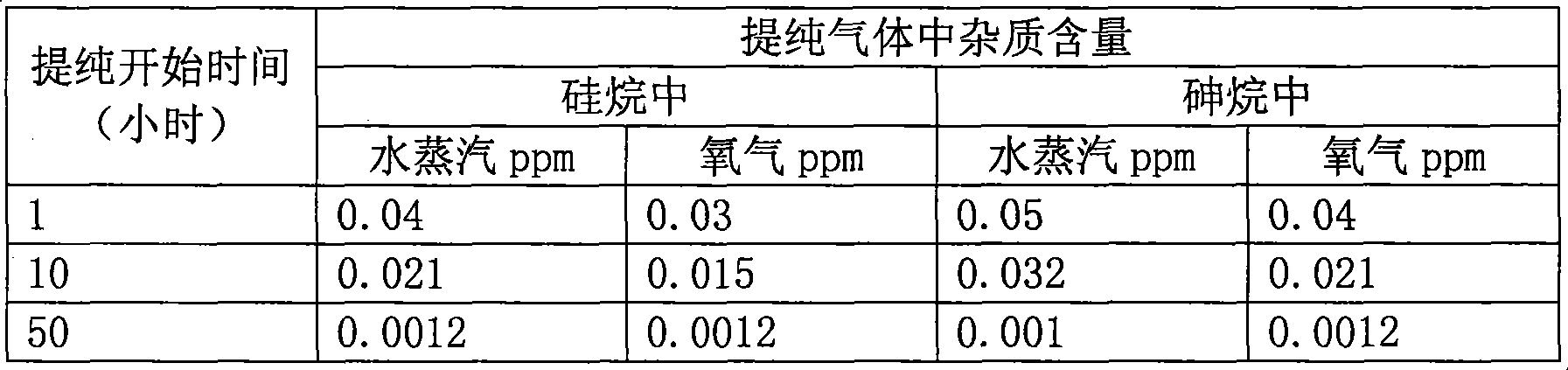

Device and method for analyzing content of phosphorane impurities in electronic grade arsenic hydride

The invention provides a device and method for analyzing content of phosphorane impurities in electronic grade arsenic hydride. The device for analyzing the content of phosphorane impurities in electronic grade arsenic hydride is characterized by comprising a ten-way valve, a quantitative loop, a first separating analytical column, a second separating analytical column and a detector, wherein the No.10 port of the ten-way valve is communicated with a carrier gas inlet; the No.9 port of the ten-way valve is connected with the first separating analytical column; the first separating analytical column is connected with the second separating analytical column; the second separating analytical column is connected with the detector; the No.6 port of the ten-way valve is connected with a sample outlet; the No.7 port of the ten-way valve is connected with a sample inlet; and in a detection state, the No.10 port of the ten-way valve is communicated with the No.1 port, the No.1 port is communicated with the No.4 port, the No.4 port is communicated with the No.5 port, the No.5 port is communicated with the No.8 port through the quantitative loop, the No.8 port is communicated with the No.9 port, and the No.6 port is communicated with the No.7 port. The device provided by the invention has the advantages of high accuracy in analyzing the trace phosphorane impurities in electronic grade arsenic hydride, short analysis time, less sample consumption and high sensitivity.

Owner:SHANGHAI ZHENGFAN TECH +1

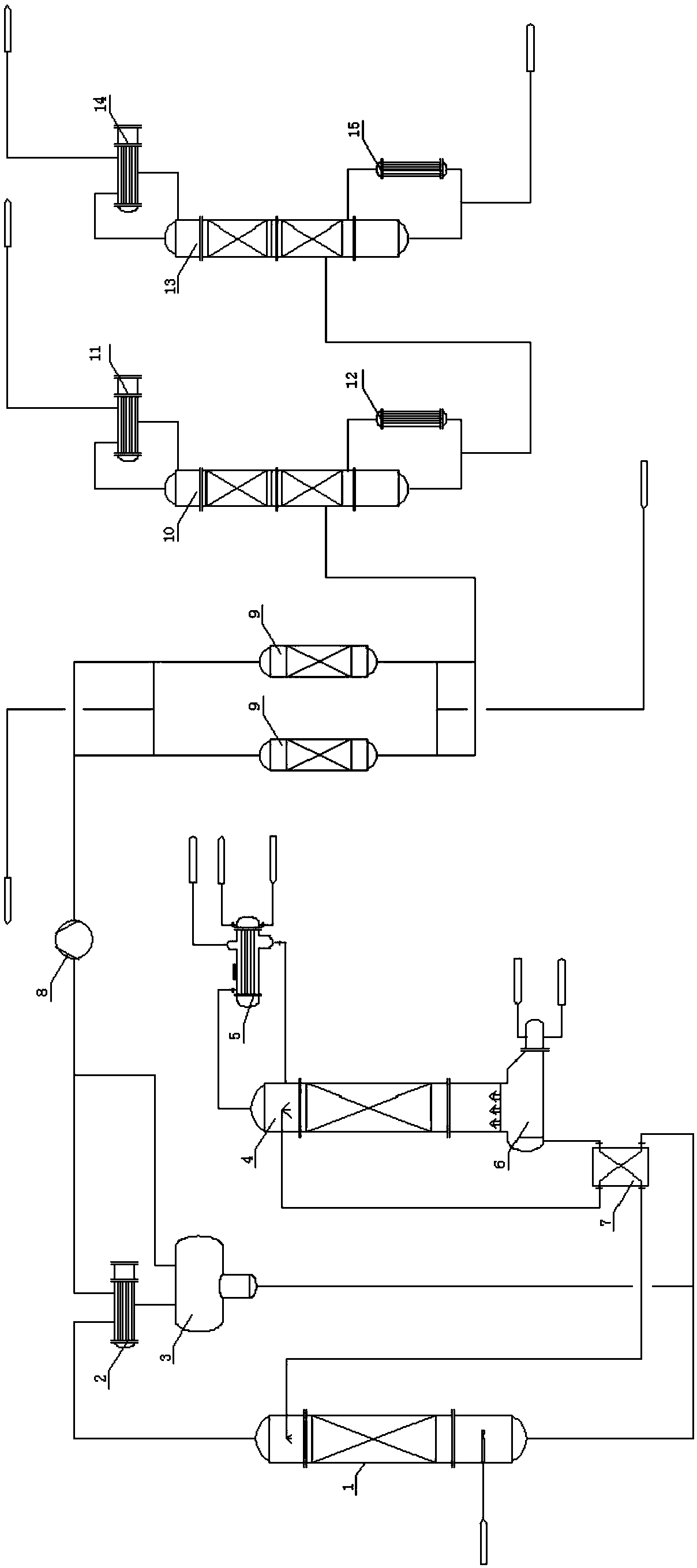

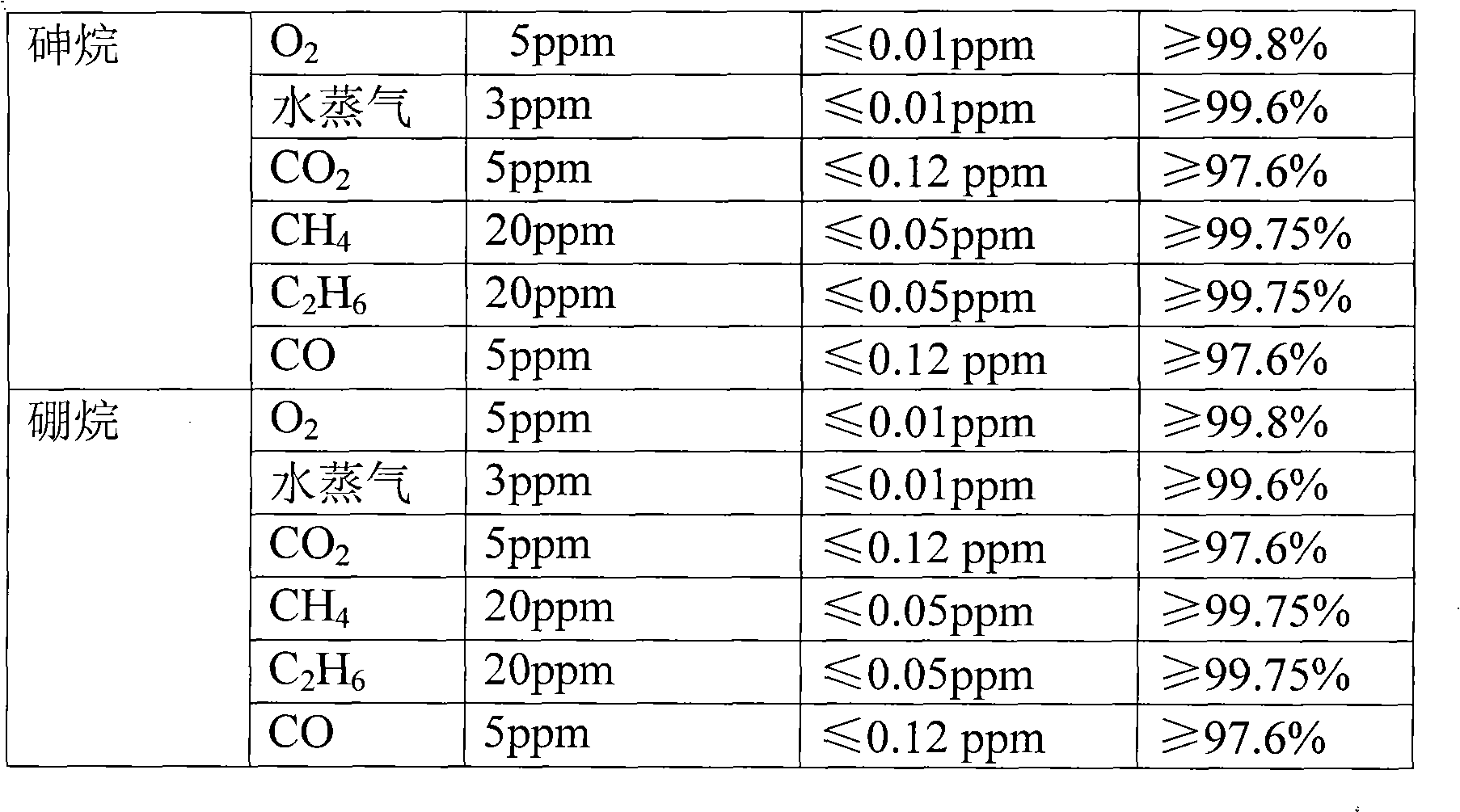

Electronic grade phosphorane purification system and processing method

The invention discloses an electronic grade phosphorane purification system. The electronic grade phosphorane purification system comprises an absorbing tower, a compressor, an adsorption system, a light removal rectifying tower, and a heavy removal rectifying tower. The invention also discloses an electronic grade phosphorane processing method. The method comprises the following steps: a phosphorane raw material is introduced in the tower from bottom of the absorbing tower, realizes counter-current contacting with absorption liquid from down to up, and the whole hydrogen sulfide and carbon dioxide accounting for 10-40% of that of total amount are absorbed; gas at the top of the absorbing tower is compressed through a compressor and is introduced to the adsorption system, and passes through an adsorbent layer for absorbed dehydration from up to down; the gas through the absorbed dehydration is introduced to the light removal rectifying tower for rectification, a light component is discharged from the top of the light removal rectifying tower to a condenser at the top of the light removal rectifying tower, a heavy component is introduced to the heavy removal rectifying tower for rectification, the light component is discharged from the top of the tower and is discharged to the condenser at top of the heavy removal rectifying tower, and noncondensable gas at the top of the condenser is a phosphorane finished product. The phosphorane purification system takes amine liquid as absorption liquid, and the purity of the obtained phosphorane is greatly increased, which can achieve 7N.

Owner:南京佳华科技股份有限公司

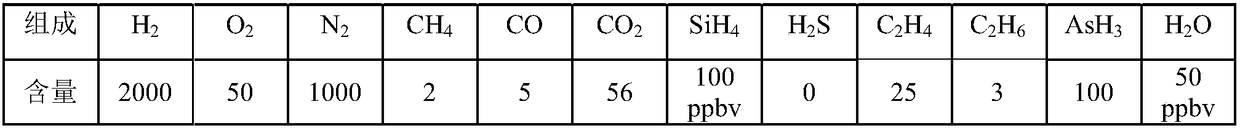

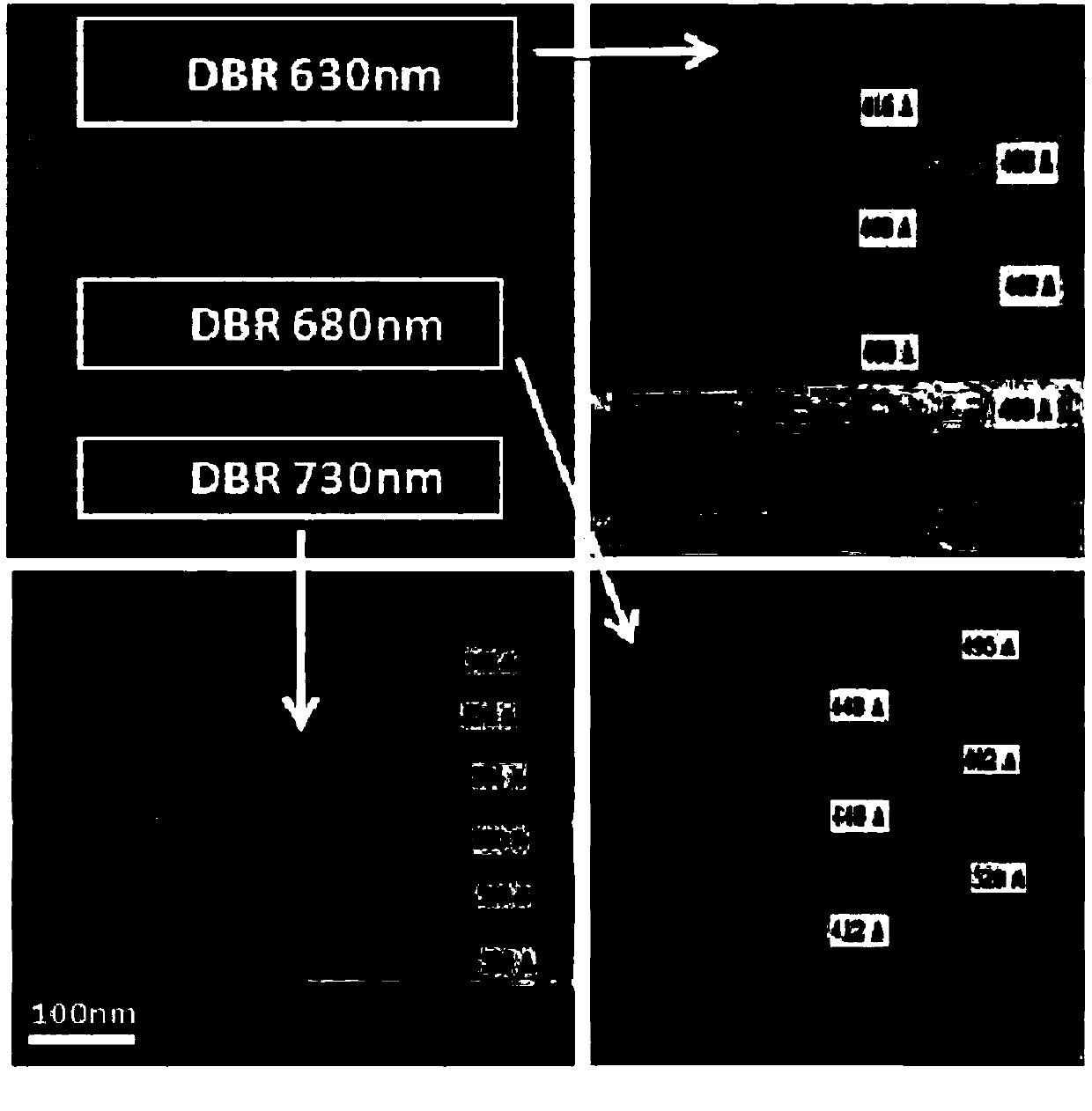

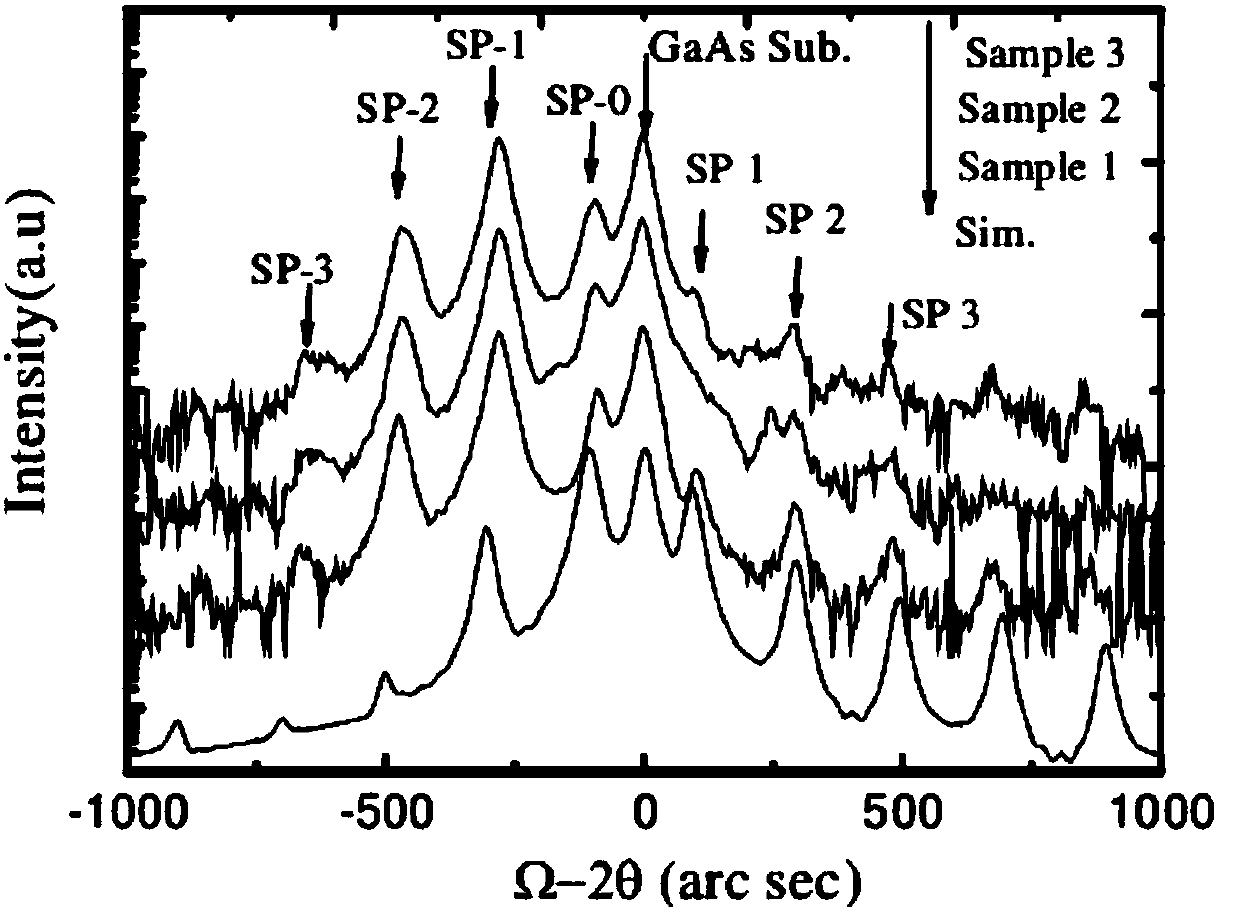

Composite-DBR-structure-based AlGaInP light-emitting diode

InactiveCN108091739AImprove photoelectric performanceImprove optical output powerSemiconductor devicesDisilaneChemical vapor deposition

The invention provides a composite-DBR-structure-based AlGaInP light-emitting diode. The preparation method comprises: a metal organic chemical vapor deposition system uses high-purity hydrogen as carrier gas, trimethyl gallium, trimethylaluminum, trimethylindium, arsine and phosphorane as Ga, Al, In, As, and P sources, and disilane and magnesocene as N and P type dopants. According to the invention, with the three-reflected central wavelength composite DBR, the reflection efficiency is high and the luminous efficiency of the AlGaInP LED is improved substantially. The influences on the luminous efficiency of the LED by the composite DBR with many reflected central wavebands is studied.

Owner:FOSHAN DONGSHEN METAL PROD CO LTD

Purificant for adsorbing arsine and phosphorane in olefin tail gas and preparation method for purificant

ActiveCN102806066AReduce contentSimple ingredientsOther chemical processesDispersed particle separationAdditive ingredientLead salt

The invention relates to normal-temperature purificant for adsorbing arsine and phosphorane in olefin tail gas, and is used for the field of purification for atmospheric pollution. The purificant comprises, in mass percent, from 1% to 5% of potassium permanganate, from 2% to 9% of soluble ferric salt, from 1% to 8% of soluble lead salt and from 78% to 96% of activated carbon, wherein the activated carbon is a carrier; and the potassium permanganate, the soluble ferric salt and the soluble lead salt are active components. A preparation method for the purificant comprises the following process steps of (1) preparing the potassium permanganate, the soluble ferric salt and the soluble lead salt into aqueous solution; (2) loading the potassium permanganate, the soluble ferric salt and the soluble lead salt onto the activated carbon carrier by using an impregnating method so as to obtain a loaded active metal carrier; and (3) drying the loaded active metal carrier in a dry medium so as to obtain the finished purificant. The purificant has the advantages of simple ingredients, low price and low using cost. After the olefin tail gas is purified by the purificant, the content of the arsine and the content of the phosphorane are lower than 10ppb (volume fraction).

Owner:CHINA PETROLEUM & CHEM CORP +1

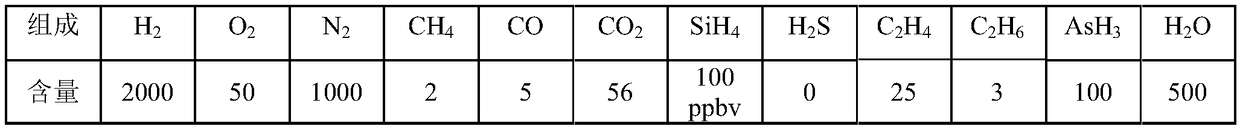

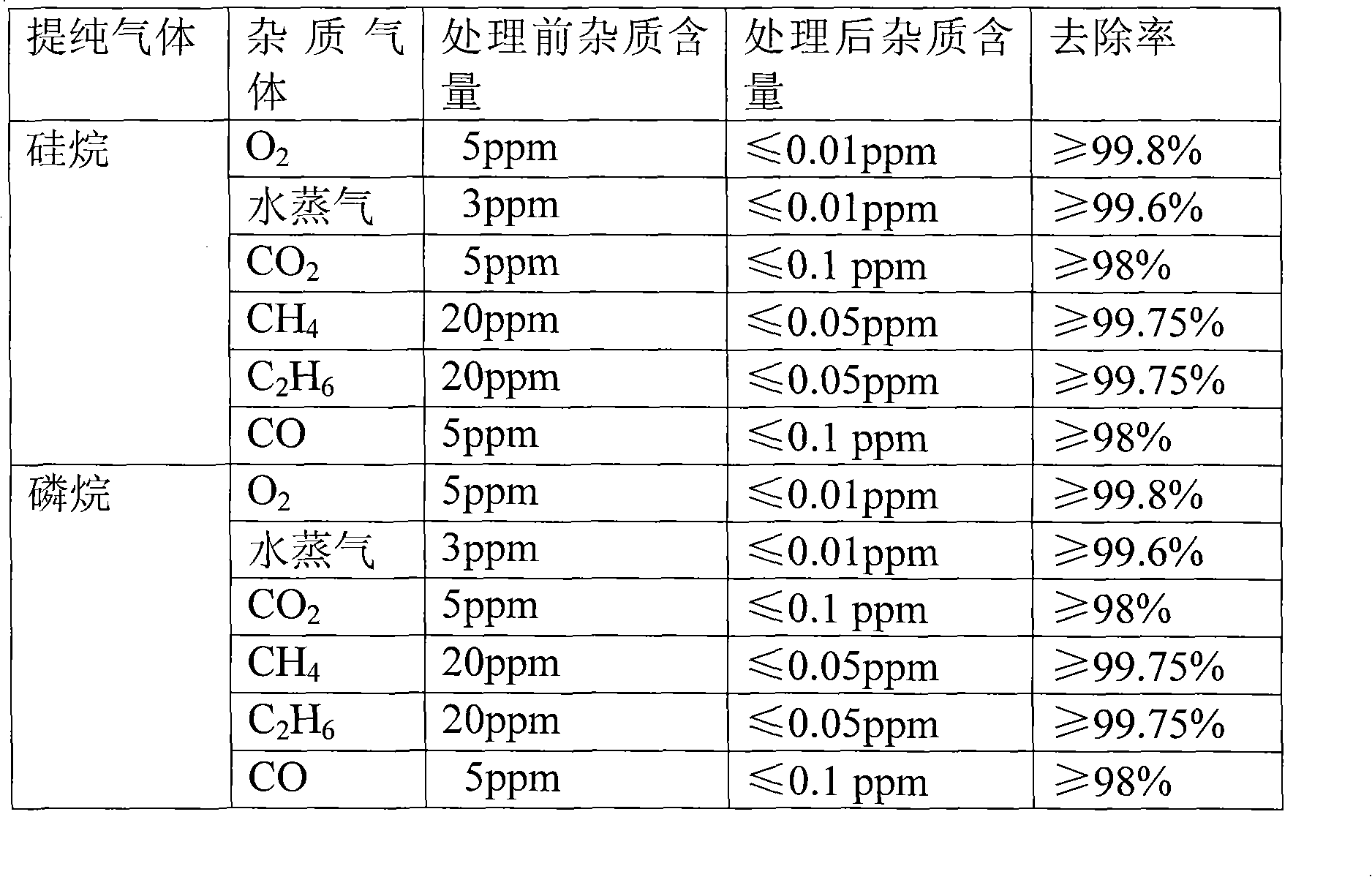

Purification adsorption agent for silicone hydride, phosphorane, arsine or borane gases and preparation method thereof

InactiveCN101342478AHigh removal rateHigh purityOther chemical processesSilicon hydridesMetallic aluminumSorbent

The invention discloses to a refining adsorbent for silane gas, phosphorane gas, arsine gas or borane gas and a preparation method thereof, relating to a gas refining adsorbent and a preparation method. The invention solves the problems that the removal rate of foreign gas in the silane gas, the phosphorane gas, the arsine gas or the borane gas by adopting the prior palladium powder adsorbent is low, thereby needing further assistant decomposition. The refining adsorbent consists of a carrier and a metallic aluminum layer on the surface of the carrier. The preparation method is as follows: in the presence of hydrogen gas, mixed gas of the hydrogen gas and aluminum methide is sprayed on the surface of the carrier in the temperature of 600 to 650 DEG C so as to obtain the refining adsorbent for the silane gas, the phosphorane gas, the arsine gas or the borane gas. Under the condition that the assistant decomposition is not added, the refining adsorbent of the invention is tested to show a result that the removal rate of CO2 is higher than 95 percent; the removal rate of CH4 is higher than 98 percent; the removal rate of C2H6 is higher than 98 percent; the removal rate of O2 is higher than 99.8 percent; the removal rate of CO is higher than 95 percent; and the removal rate of water vapor is higher than 99.6 percent.

Owner:王少志

Method and apparatus for production of electronic grade hydrogen gas

InactiveCN105439087AImprove purification efficiencyHydrogen separation using solid contactHydrogen separation using liquid contactBoron trichlorideImpurity

The present invention discloses a method and an apparatus for the production of electronic grade hydrogen gas, and the method comprises the following steps: (1) tail gas of the production of polysilicon is treated to obtain hydrogen gas with a purity of 99.808-99.945%, and the hydrogen gas with the purity of 99.808-99.945% is adsorbed by an activated carbon adsorption agent; and (2) an aqueous solution containing sodium hydroxide and potassium permanganate is used for rinsing to obtain the electronic grade hydrogen gas. The electronic grade hydrogen gas with a purity of 99.9999% can be obtained, hydrogen chloride, boron trichloride, phosphoric chloride, phosphorane, CH3BCl2, (CH3) 2PH other impurities in the hydrogen gas with the purity of 99.808-99.945% obtained by treatment of the tail gas of the production of polysilicon can be completely removed, hydrogen purification efficiency is high, and waste hydrogen gas, in the production of polysilicon, which cannot produce high-purity polysilicon is purified for turning the waste into the high-value electronic grade hydrogen gas.

Owner:XINTE ENERGY

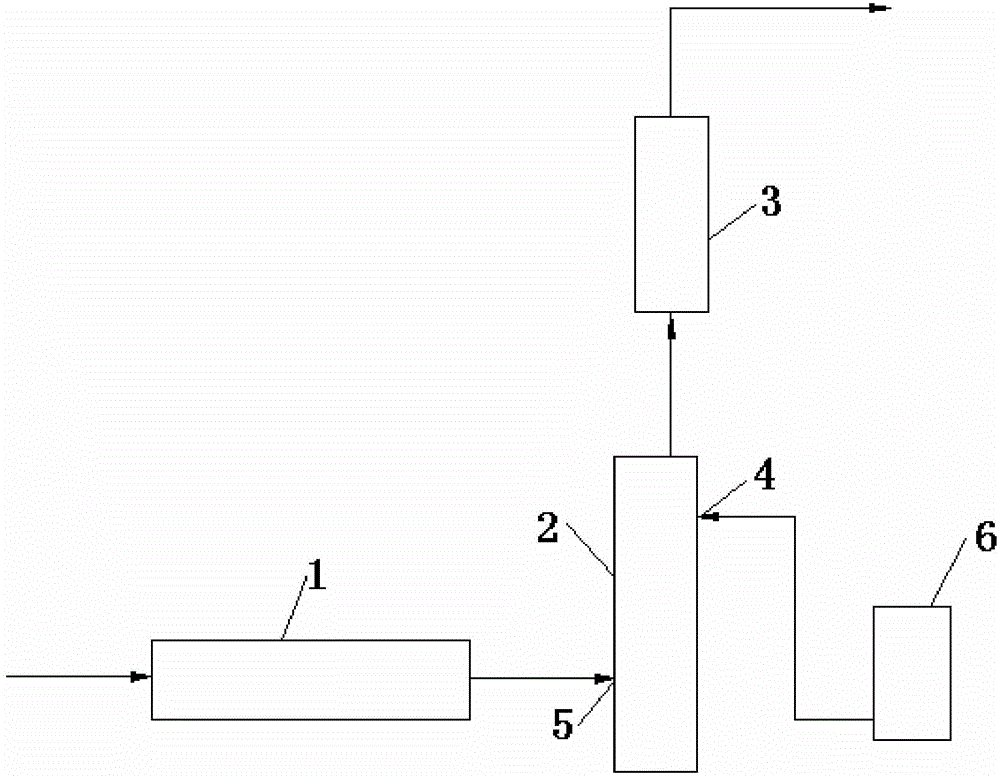

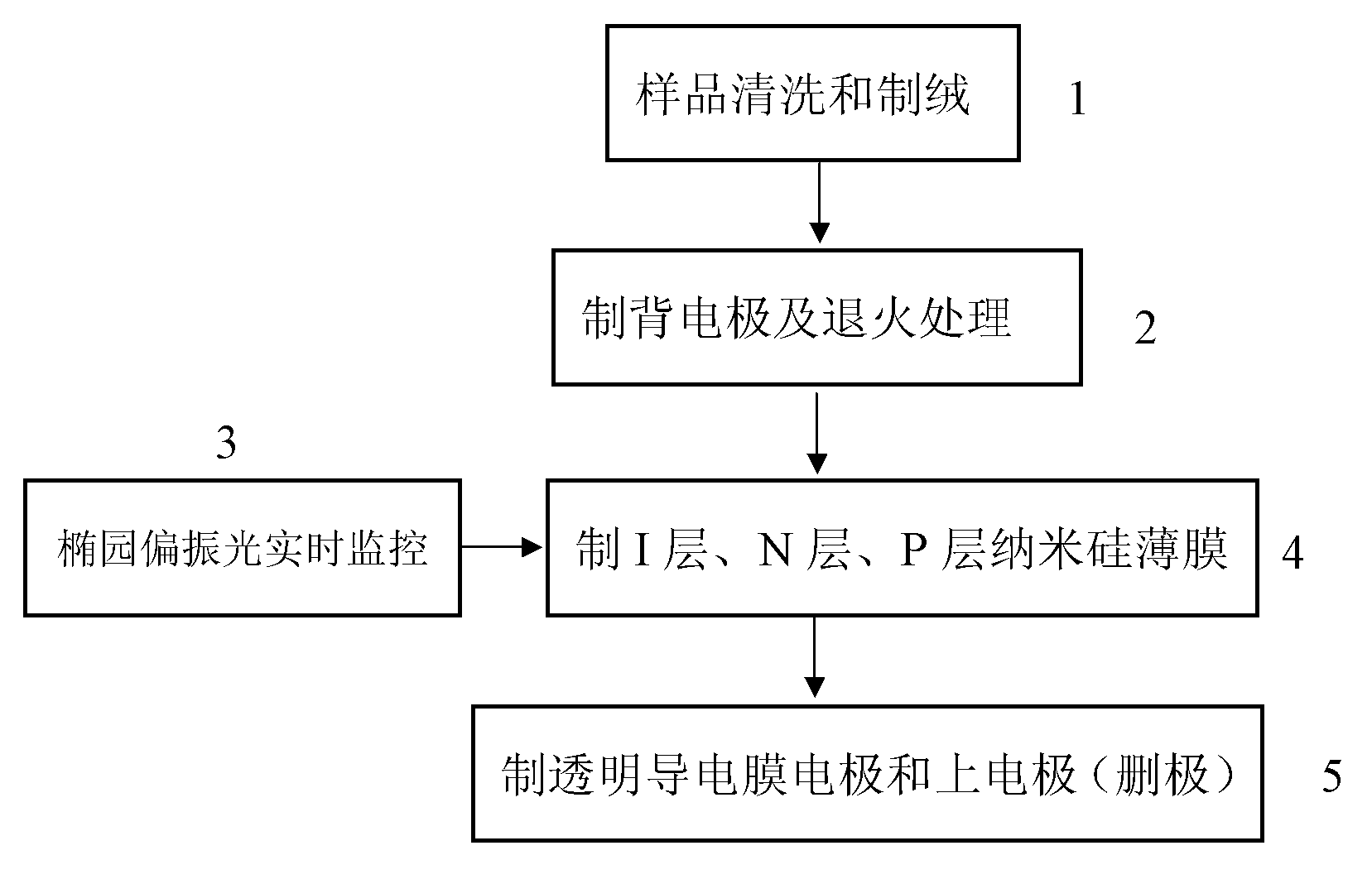

Nano silicon film solar battery elliptic polarized light real-time monitoring preparation method

InactiveCN102569517AGood repeatabilityLow costFinal product manufactureVacuum evaporation coatingGas phaseElectrical battery

The invention relates to a nano silicon film solar battery elliptic polarized light real-time monitoring preparation method, which comprises five steps: step 1: anisotropic corrosion on a monocrystalline silicon chip is undertaken by adopting a wet chemistry method to obtain a pyramid-shaped napped silicon chip substrate; step 2: a back electrode of the nano silicon film solar battery is prepared through a heat evaporation method or a magnetron sputtering method; step 3: an I layer nano silicon film is prepared by adopting a plasma enhanced chemical gas-phase deposition method through silane SiH4, an N layer nano silicon film is prepared by introducing the silane SiH4 and phosphorane PH3 mixed gas, and a P layer nano silicon film is prepared by introducing silane SiH4 and borane B2H5 mixed gas; step 4: the growth of the film is instantly monitored by adopting elliptic polarized light during the deposition process of the nano silicon film in step 3; and step 5: a transparent conductive film electrode and a top electrode of the nano silicon film solar battery can be prepared by adopting the heat evaporation method, magnetron sputtering method or the silk screen printing technology. The method has good application prospect in the photoelectric application and novel energy technical field.

Owner:BEIHANG UNIV

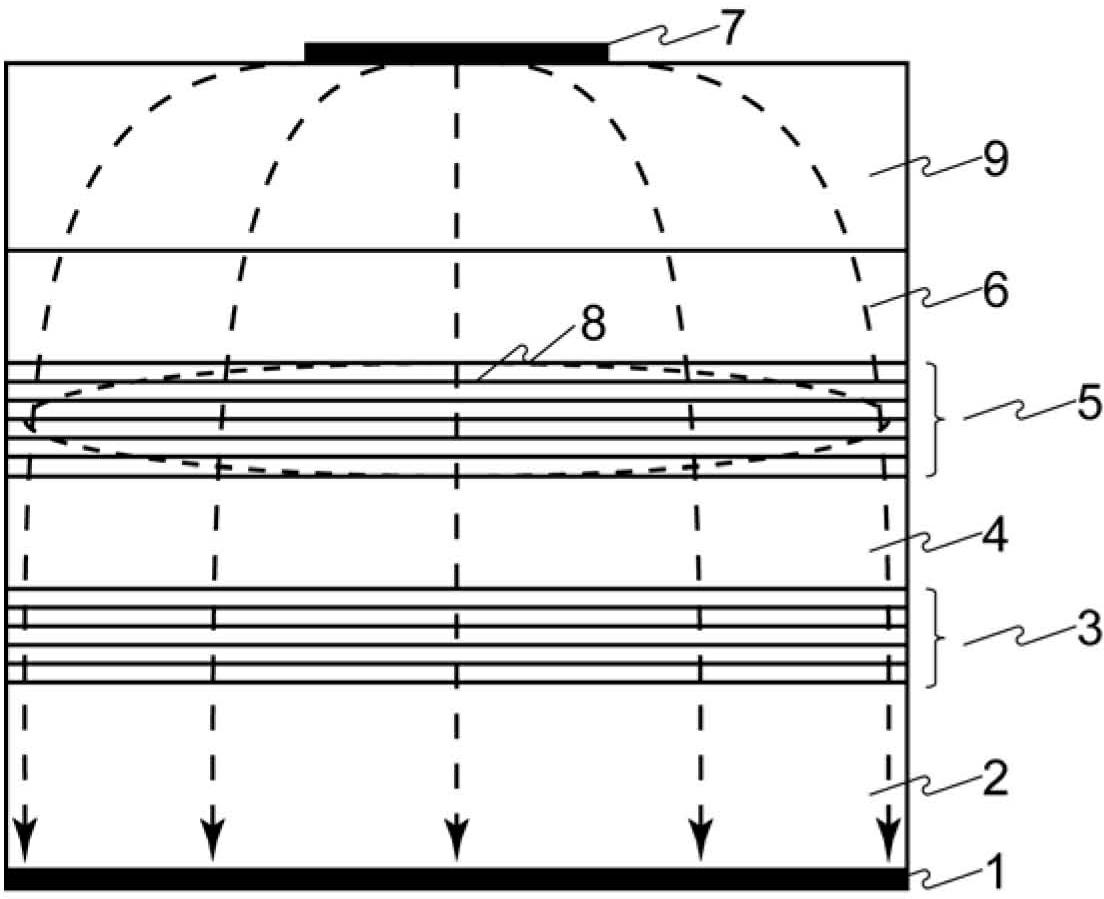

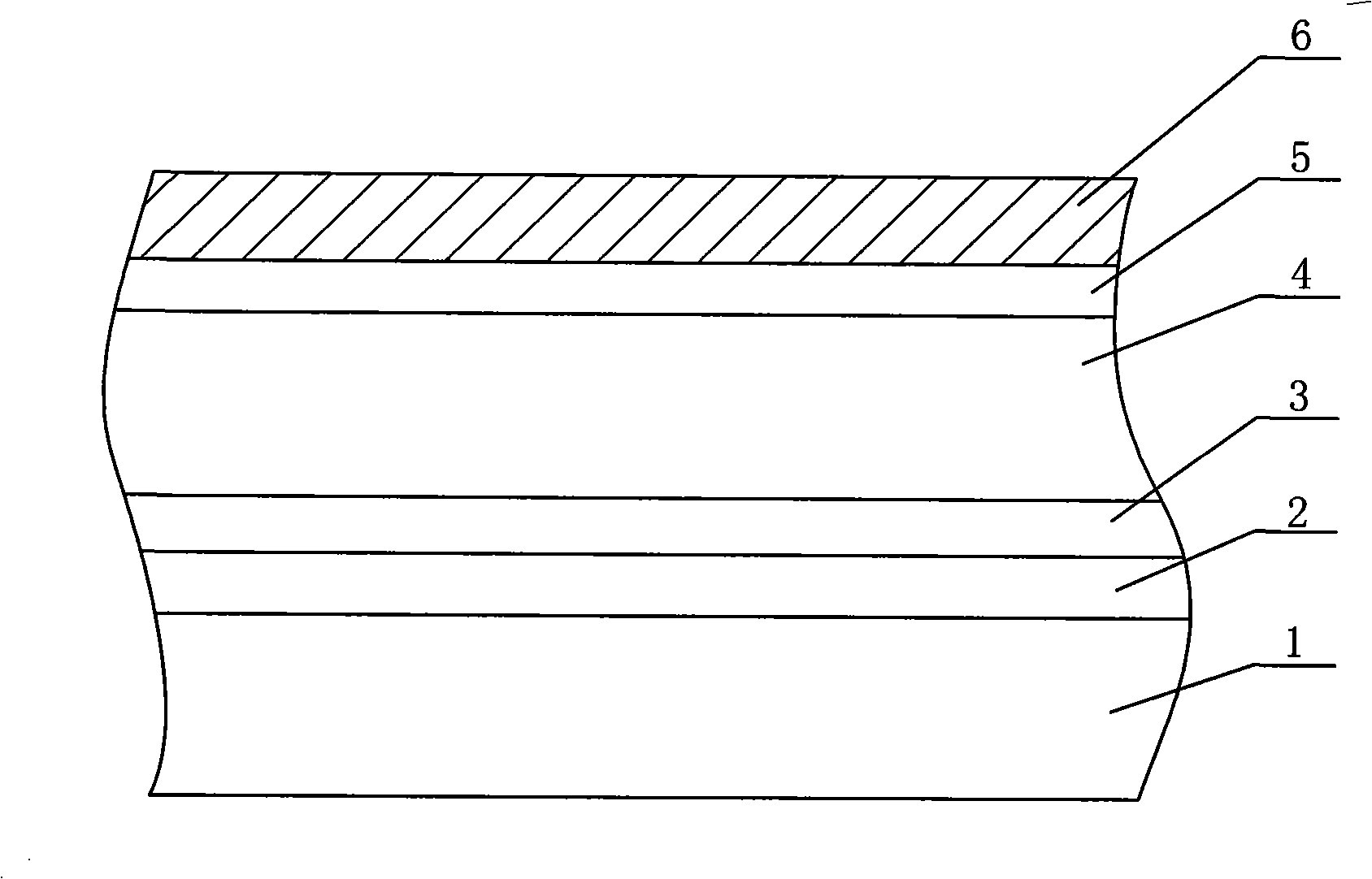

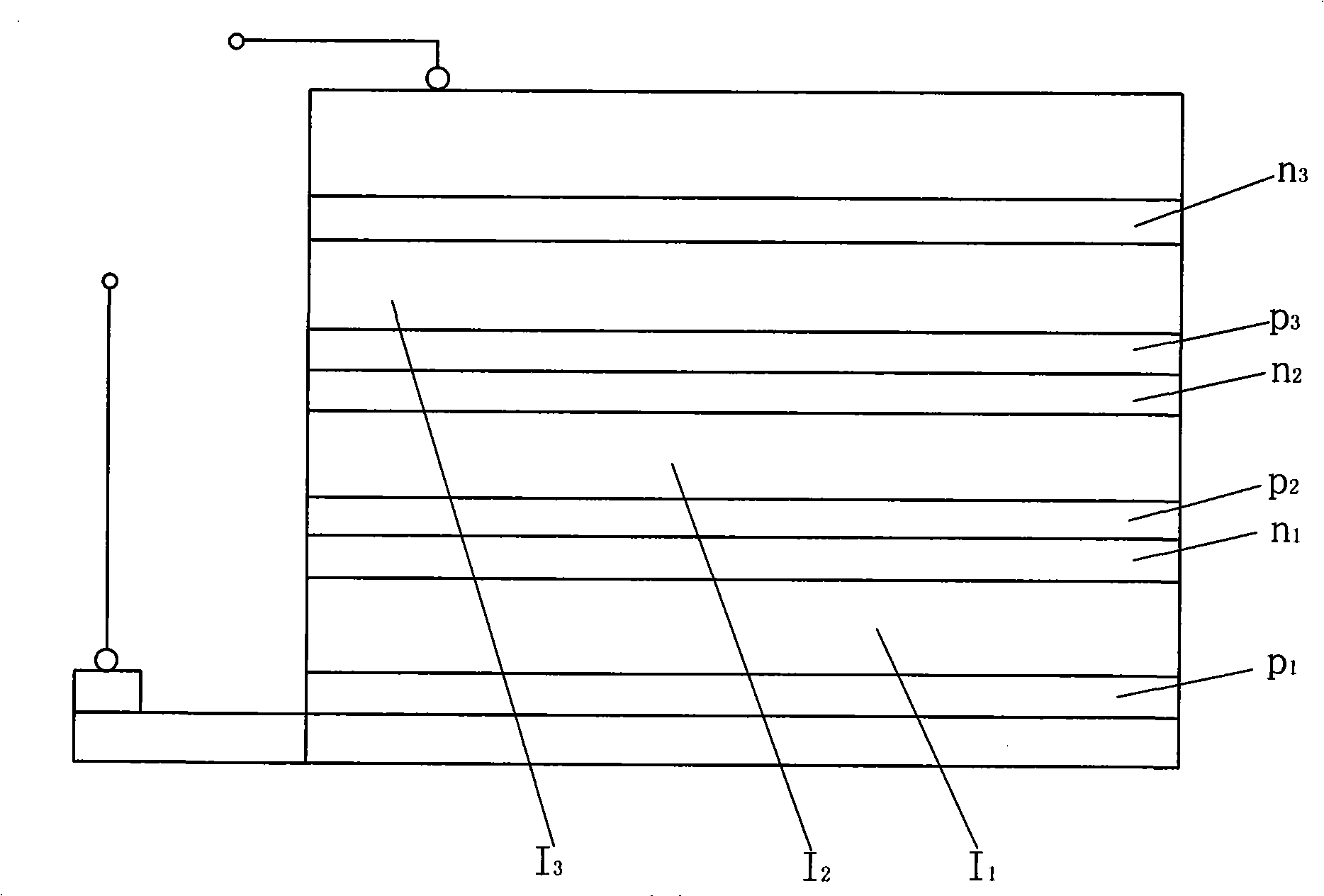

Highly efficient stacked thin-film solar cell of nano silicon

InactiveCN101290952AImprove conversion efficiencyEasy to collectPhotovoltaic energy generationSemiconductor devicesOrganic filmNano silicon

The invention relates to a stacked high-efficient nano silicon film solar cell. The stacked high-efficient nano silicon film solar cell has good photo-thermal stability, high conversion efficiency, good stability and reliability and low production cost, and comprises a cell substrate (1) the materials of which are glass or organic films, wherein, a PIN structures are arranged on the substrate (1); each PIN structure comprises a conductive film (2); a layer of boron P type amorphous silicon film (3) is grown on the conductive film (2); the crystalline state ratio Xc of the film is changed to form a variable bandgap nano silicon buffer layer (4); a layer of N type nano silicon film (5) is grown on the variable bandgap nano silicon buffer layer (4) by filling of phosphorane (PN3); and an electrode Ag / Al is coated on the silicon film (5). The stacked high-efficient nano silicon film solar cell is characterized in that: the crystalline state ratio xc of the variable bandgap nano silicon buffer layer (4) is between 40 and 53; the PIN structures are stacked; the conductive film (2) of a PIN structure which is positioned on the bottom layer covers the substrate (1); and the electrode Ag / Al covers the silicon film (5) of a PIN structure which is positioned on the top layer.

Owner:无锡市纳微电子有限公司

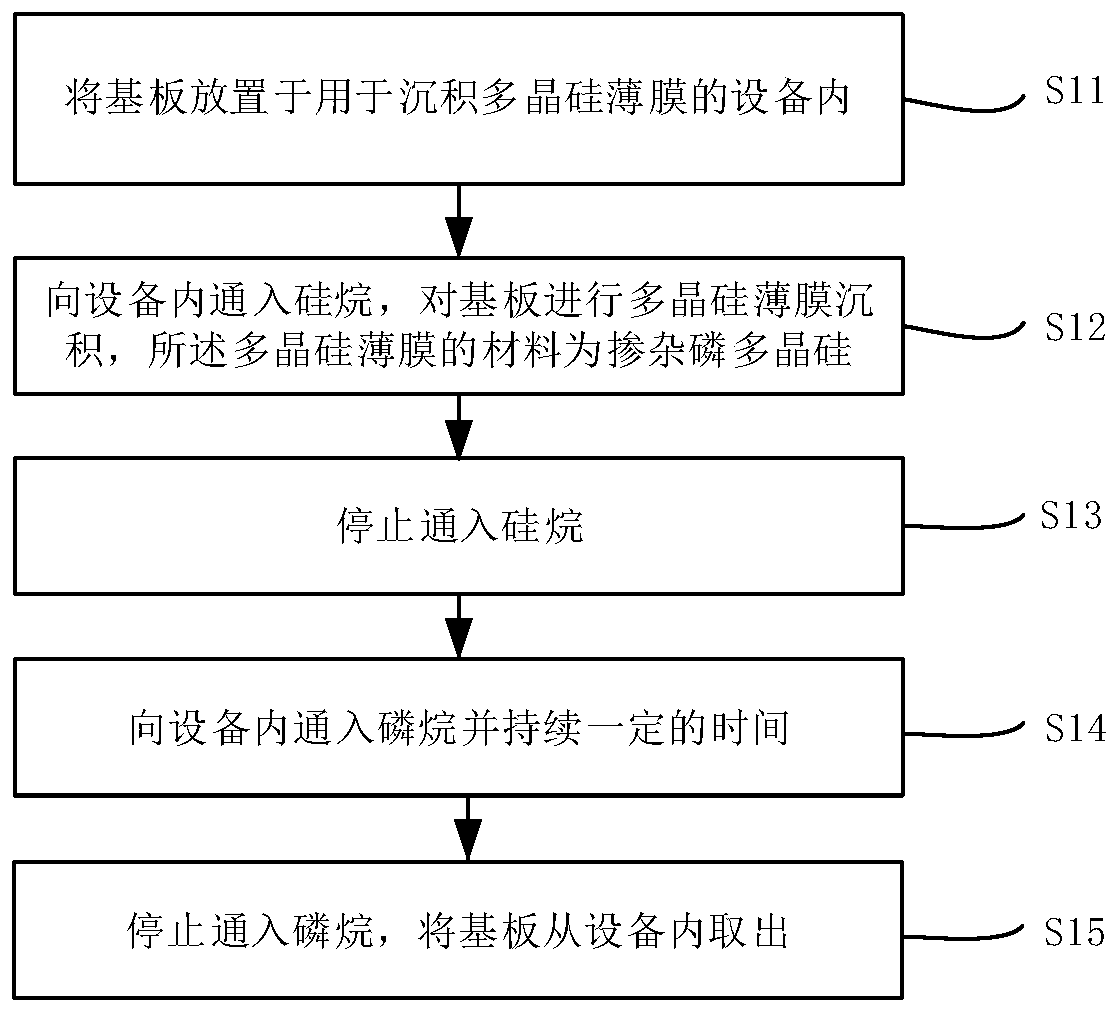

Polycrystalline silicon film deposition method

InactiveCN109778141AReduce particle defectsSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanesPhosphorus doped

The invention provides a polycrystalline silicon film deposition method. The method comprises the following steps: a substrate is placed in equipment for depositing polycrystalline silicon films; silane is introduced in the equipment for depositing the polycrystalline silicon films on the substrate, and the polycrystalline silicon films adopt materials of phosphorus-doped polycrystalline silicon;the introduction of the silane is stopped; phosphorane is introduced in the equipment by a period of time; the introduction of the phosphorane is stopped; and the substrate is taken out from the equipment. In the polycrystalline silicon film deposition method, after the polycrystalline silicon film deposition is finished, the silane is closed, the phosphorane is continuously introduced into the equipment by a set flow, and phosphorus decomposed from the introduced phosphorane is doped in silicon, so that the size uniformity of crystalline particles can be improved, and the particle defects onthe polycrystalline silicon films are reduced.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

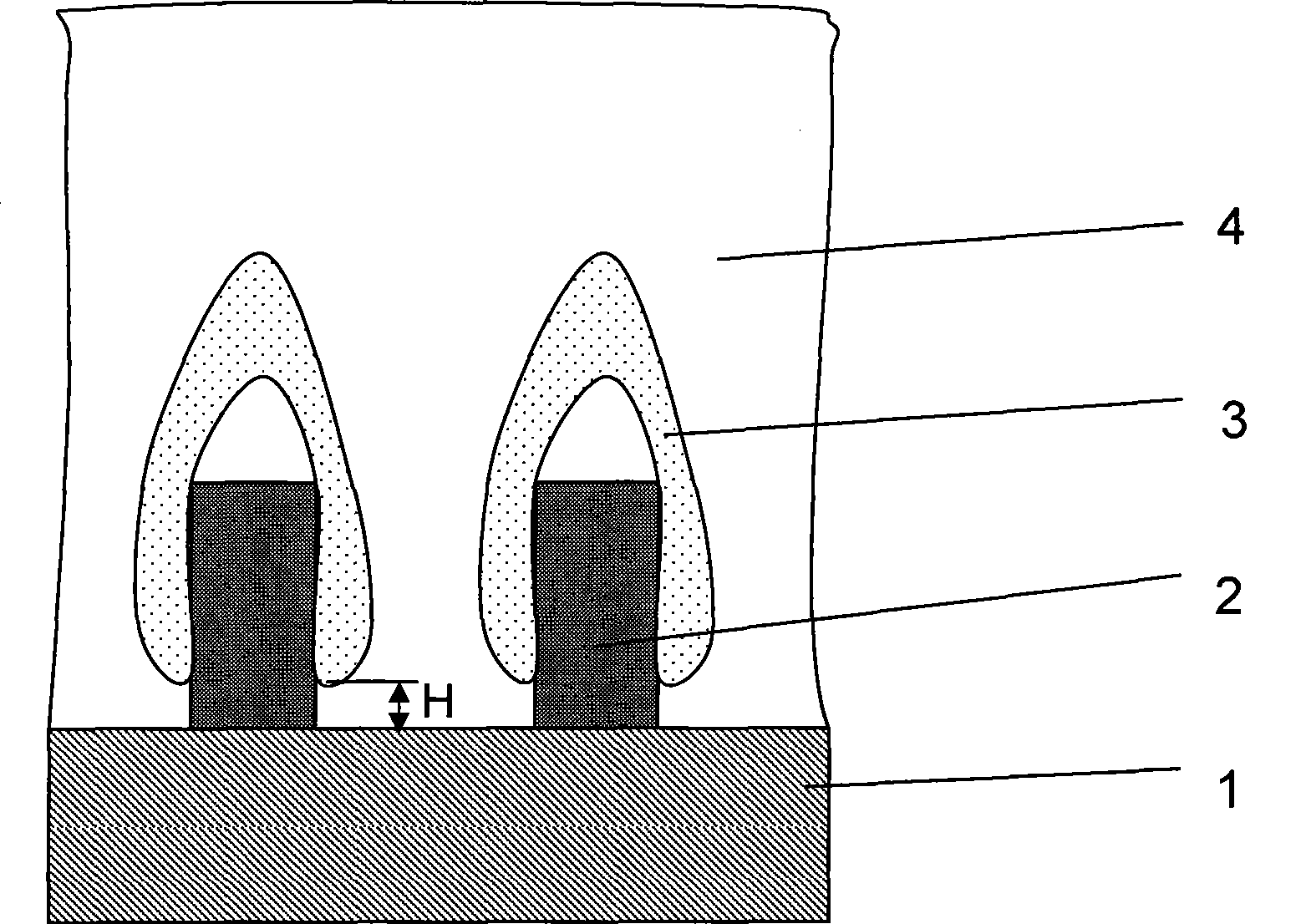

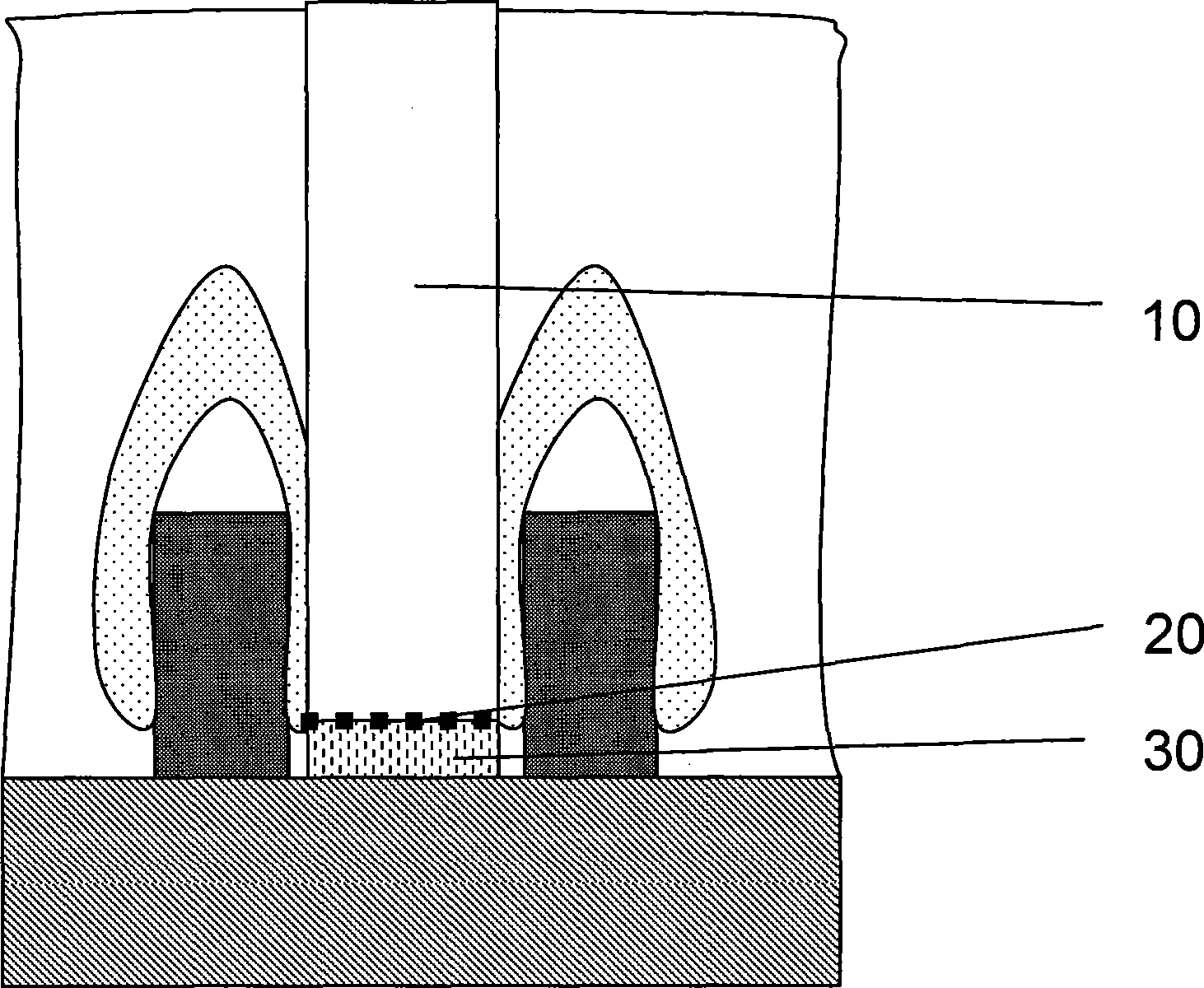

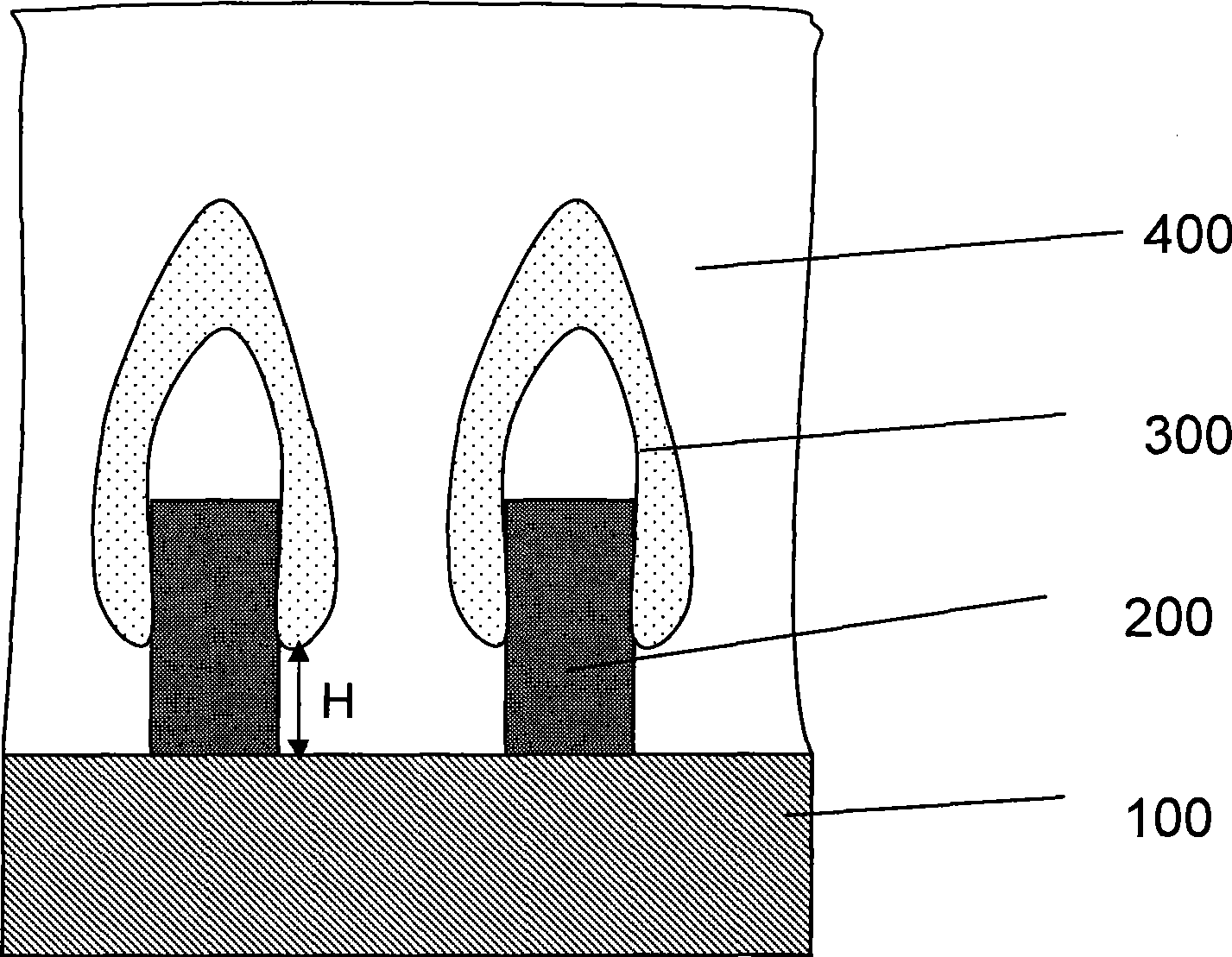

Phosphosilicate glass growth process and phosphosilicate glass

The invention discloses phosphosilicate glass growth technology. The technology adopts high-density plasma to grow phosphosilicate glass through chemical vapor deposition, wherein the ratio of the sputtering bias power to the area of silicon slices during deposition of the phosphosilicate glass is between 2 and 6 W / cm<2>, and the ratio of the molar weight of oxygen to the sum of the molar weight of silicane and the molar weight of phosphorane is between 1.5 and 2. The invention also discloses the phosphosilicate glass grown by the technology, wherein the distance between a bottom starting point of a floriform shell of the phosphosilicate glass and a substrate is more than 40 nanometers. The technology reduces the initial speed of forming the floriform shell of the phosphosilicate glass between figures by selecting proper sputtering bias and proper oxygen flow rate to reduce sputtering energy and the sputtering density, so as to improve the bottom starting point of the floriform shell of the phosphosilicate glass and widen a technological window for selective etching.

Owner:SHANGHAI HUA HONG NEC ELECTRONICS

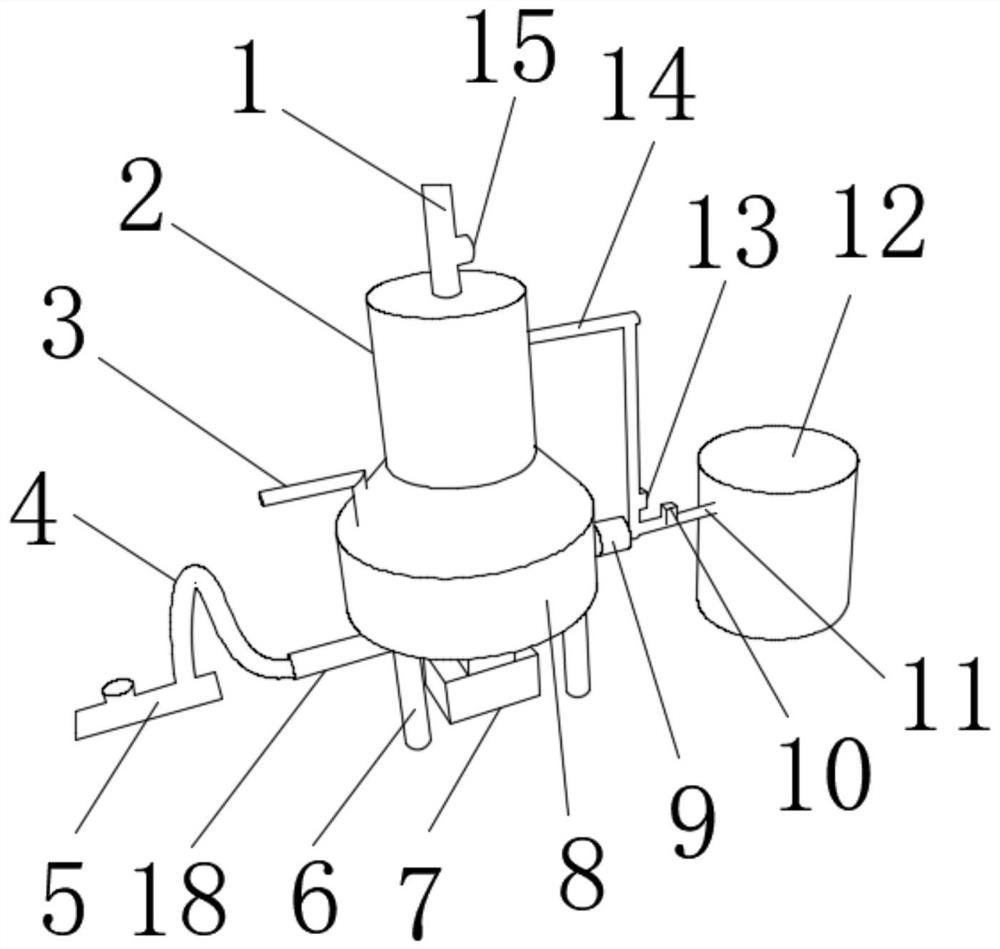

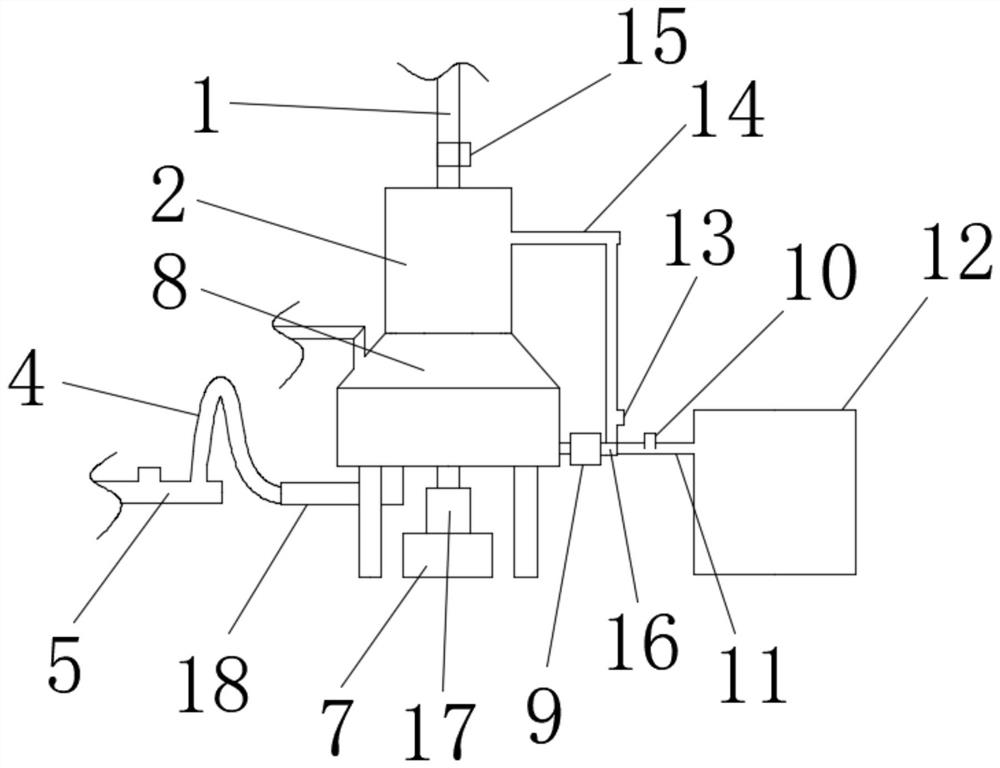

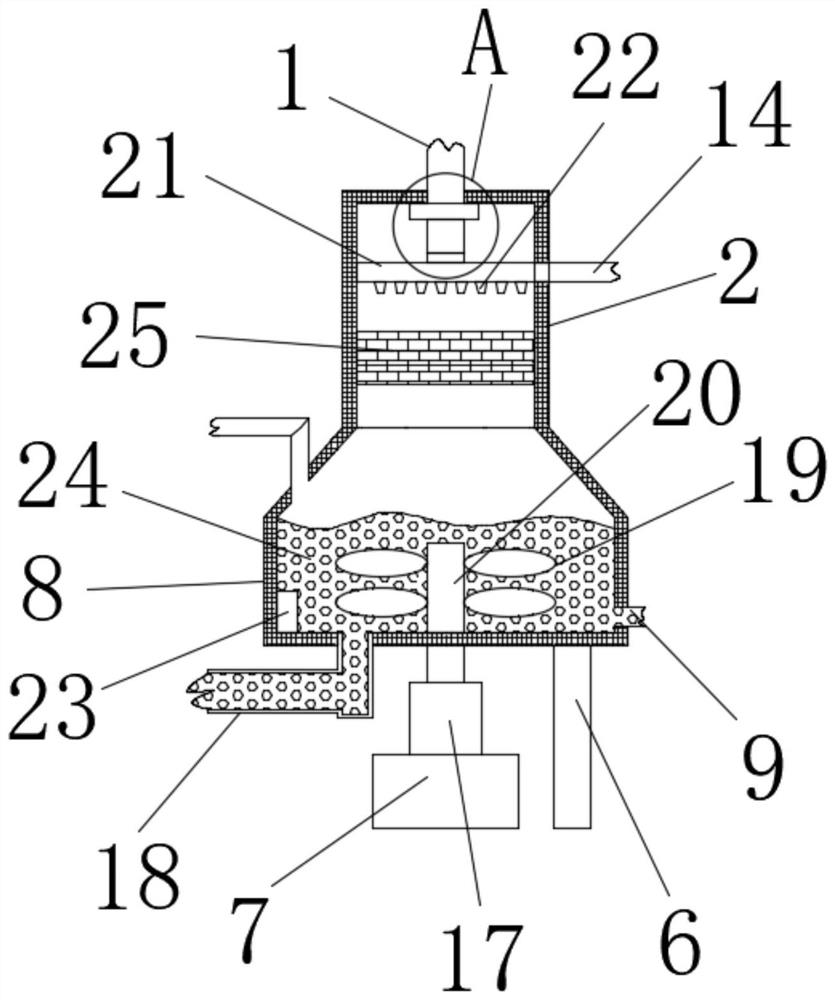

Tail gas treatment device for phosphorane preparation

InactiveCN113041813AEasy to handleEasy to replaceGas treatmentDispersed particle separationPhospholanEngineering

The invention provides a tail gas treatment device for phosphorane preparation, belonging to the field of phosphorane tail gas treatment. The tail gas treatment device for phosphorane preparation comprises an absorption tower, wherein an L-shaped pipe is arranged on one side of the bottom wall of the absorption tower, a gas inlet pipe is fixedly connected to one end of the U-shaped pipe, a neutralizing solution is arranged in the absorption tower, a liquid discharging pipe and a spraying pipe are fixedly connected to one end of a connecting pipe, a first electromagnetic valve is arranged in the middle portion of the liquid discharging pipe, and one end of the spraying pipe penetrates through a spraying chamber and is fixedly connected with a spraying disc. According to the invention, a neutralization solution is stirred through fan blades and can be continuously sprayed from the inner upper part of the spraying chamber through a water pump, the spraying pipe, a spraying disc and a spraying head, so tail gas containing phosphorane is subjected to absorption treatment again, the phosphorane in the tail gas can be fully absorbed, and the tail gas treatment effect is improved; and by closing a second electromagnetic valve and opening the first electromagnetic valve, neutralization solution is convenient to replace continuously, and therefore, the device is worthy of vigorous popularization.

Owner:沧州华宇特种气体科技有限公司

Oxazolidinone combinatorial libraries, compositions and methods of preparation

InactiveUS7002020B1Rapid productionGroup 5/15 element organic compoundsMicrobiological testing/measurementLibrary preparationCombinatorial chemistry

Oxazolidinones and methods for their synthesis are provided. Also provided are combinatorial libraries comprising oxazolidinones, and methods to prepare the libraries. Further provided are methods of making biologically active oxazolidinones as well as pharmaceutically acceptable compositions comprising the oxazolidinones. The methods of library preparation include the attachment of oxazolidinones to a solid support. The methods of compound preparation in one embodiment involve the reaction of an iminophosphorane with a carbonyl containing polymeric support.

Owner:PHARMACIA & UPJOHN CO

Modified acidic ion-exchange resin and method for preparing bisphenol

ActiveUS20100324341A1High selectivityKeep for a long timeCation exchanger materialsOrganic compound preparationPolymer sciencePhosphonium

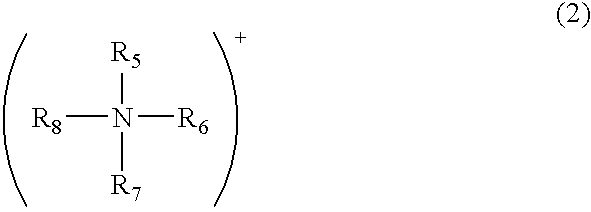

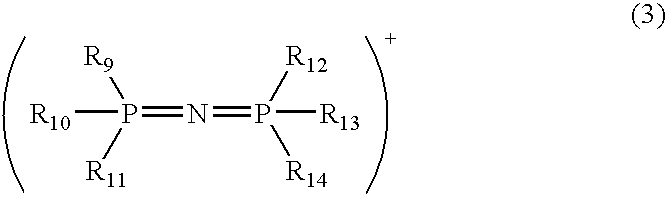

The present invention provides an ion-exchange resin catalyst, as a catalyst for preparing bisphenol from phenol compounds and ketone, which has a higher selectivity to bisphenol and a longer life time, as compared to a conventional ion-exchange resin, and a method for preparing the same.The present invention also provides a method for preparing bisphenol comprising reacting phenol compounds with ketone, wherein the modified acidic ion-exchange resin in which at least one kind of cationic compound selected from the following (a), (b), (c) and (d) ionically binds to an acidic functional group, is used as a catalyst: (a) a quaternary phosphonium ion, (b) a quaternary ammonium ion, (c) a bis(phosphoranylidene) ammonium ion, and (d) an N-substituted nitrogen-containing aromatic cation.

Owner:MITSUI CHEM INC

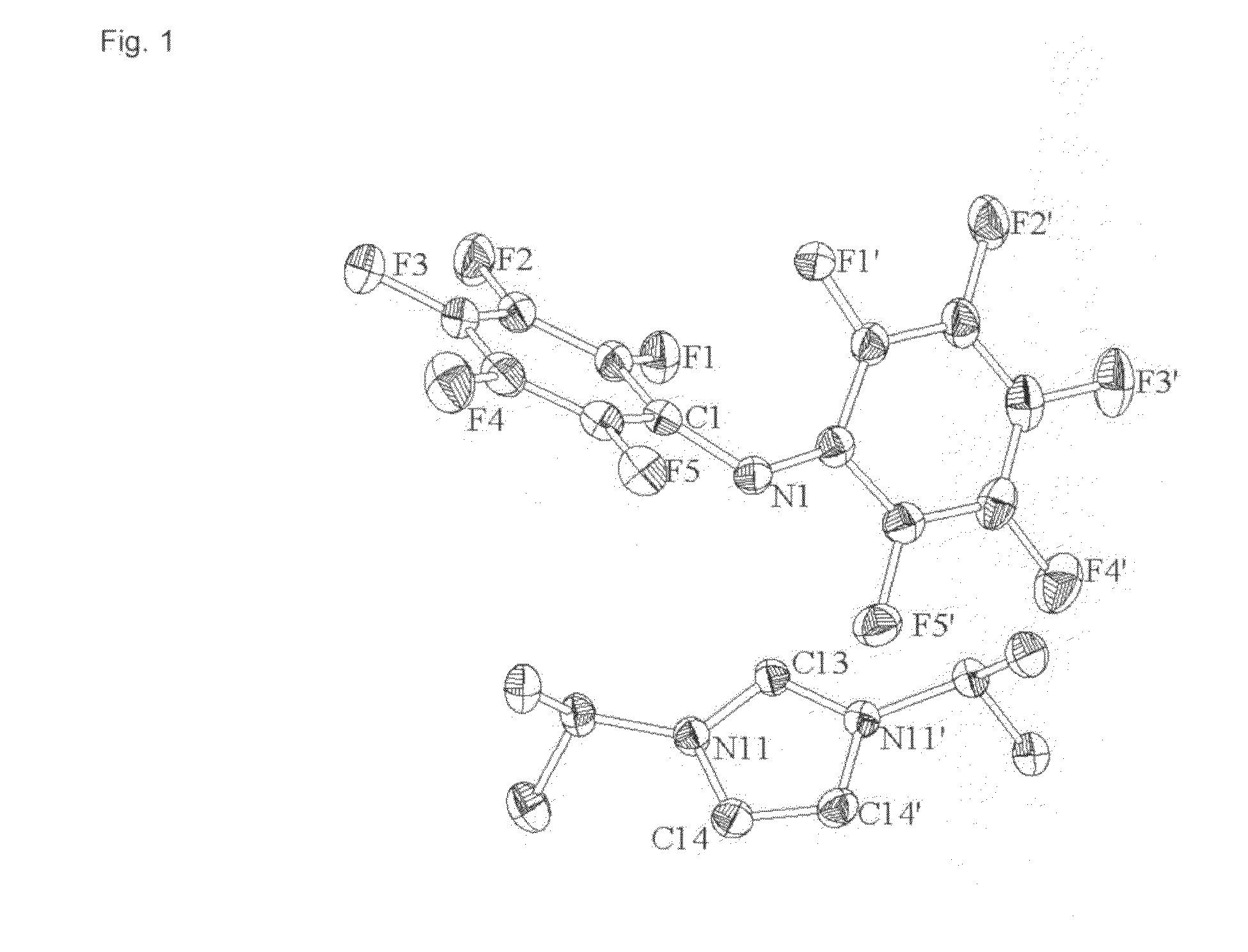

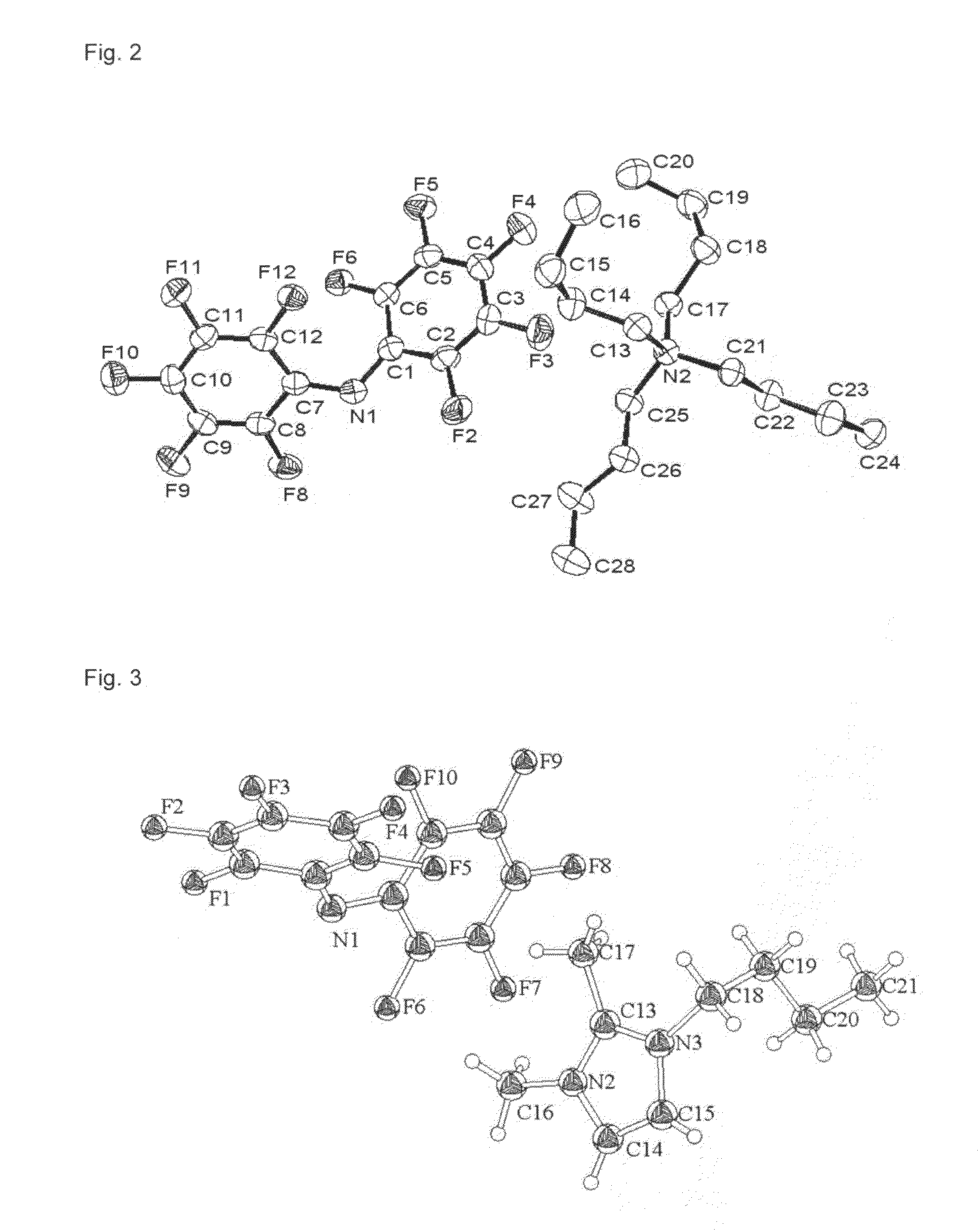

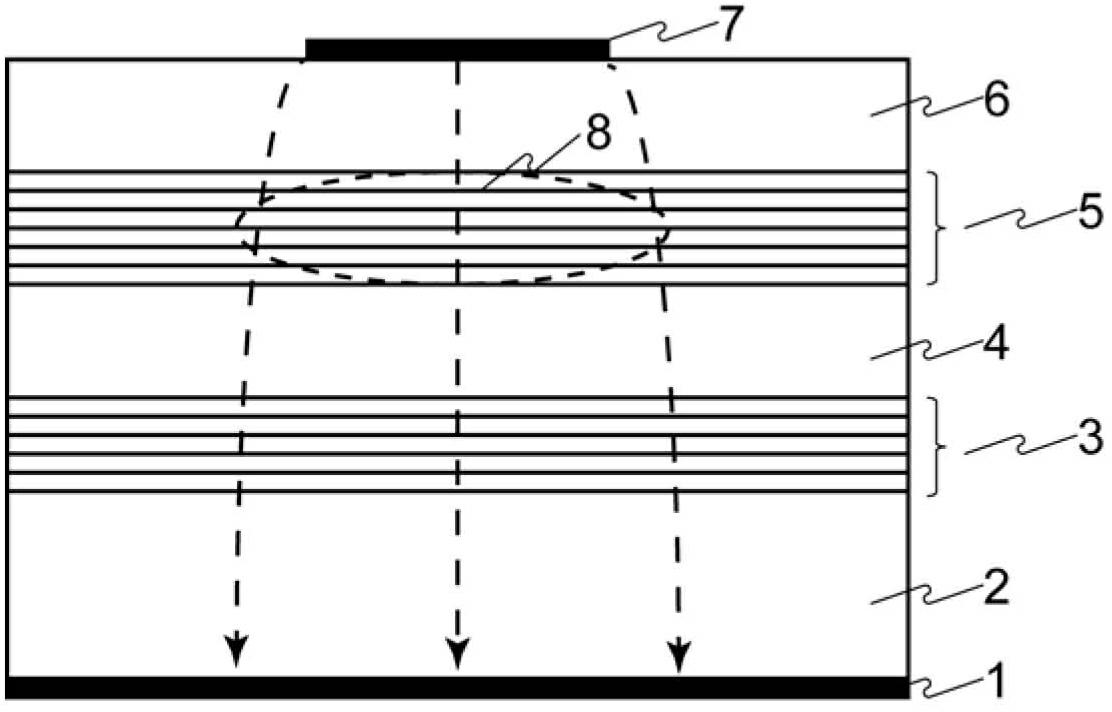

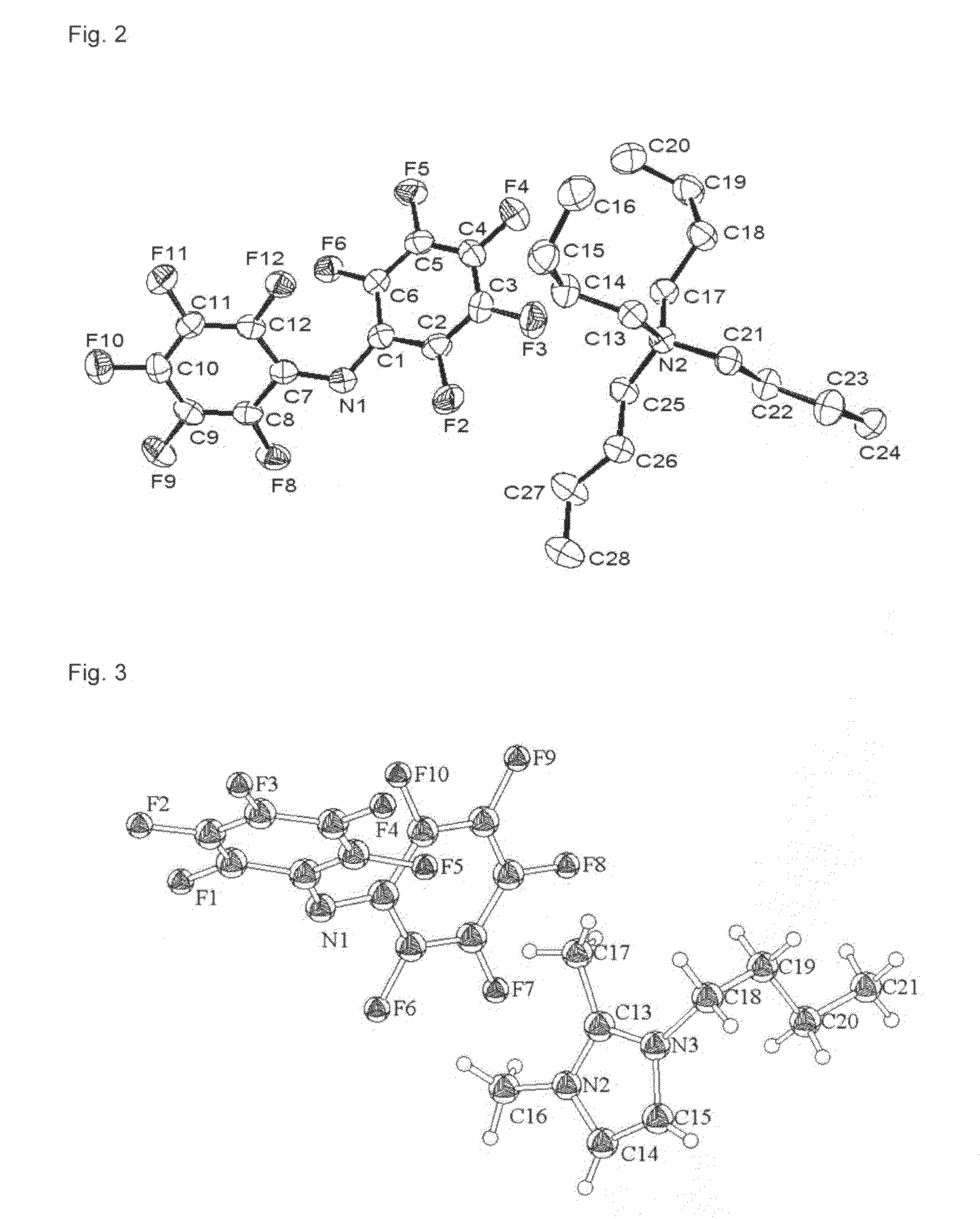

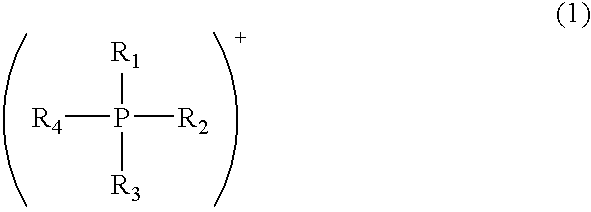

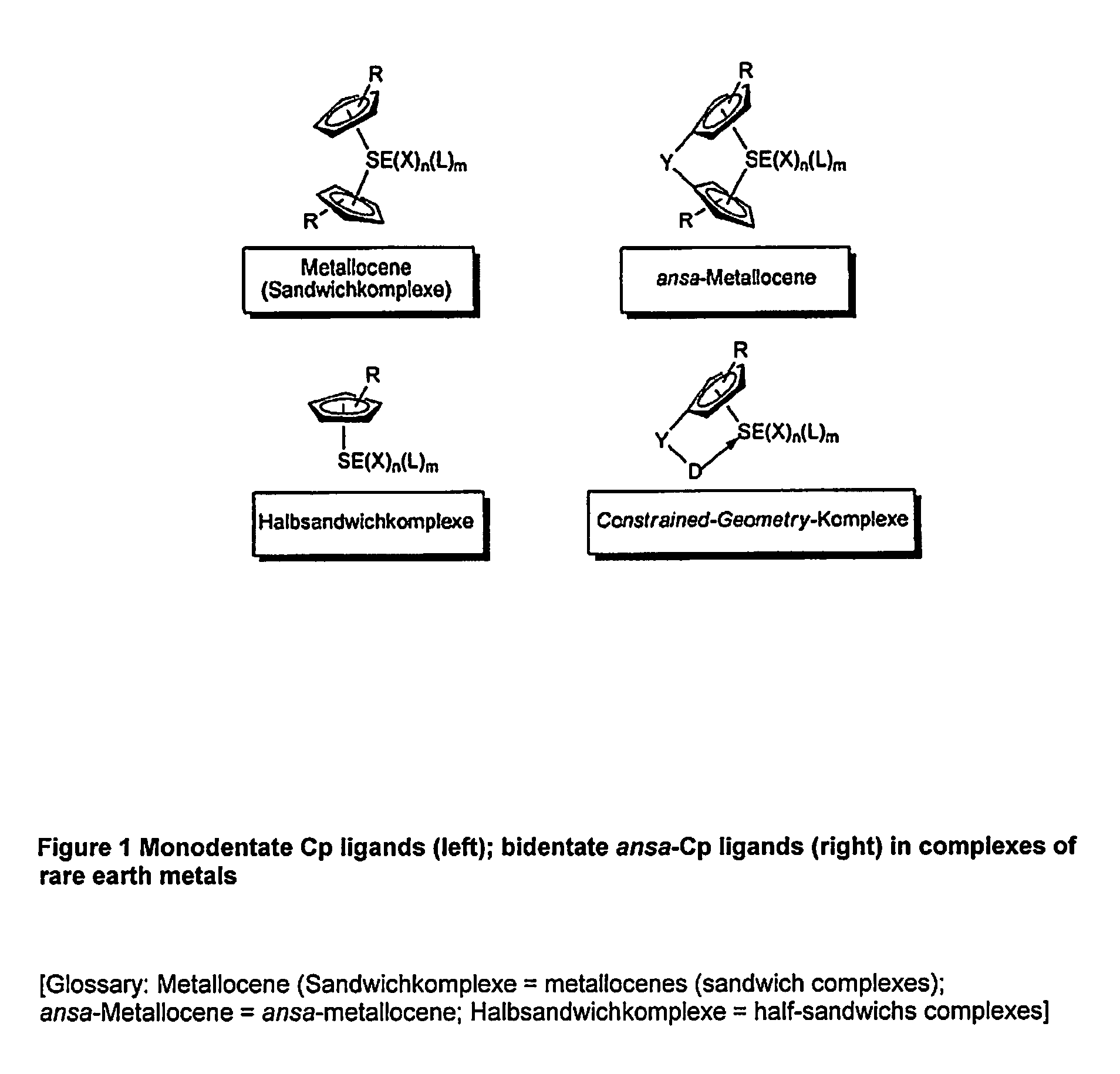

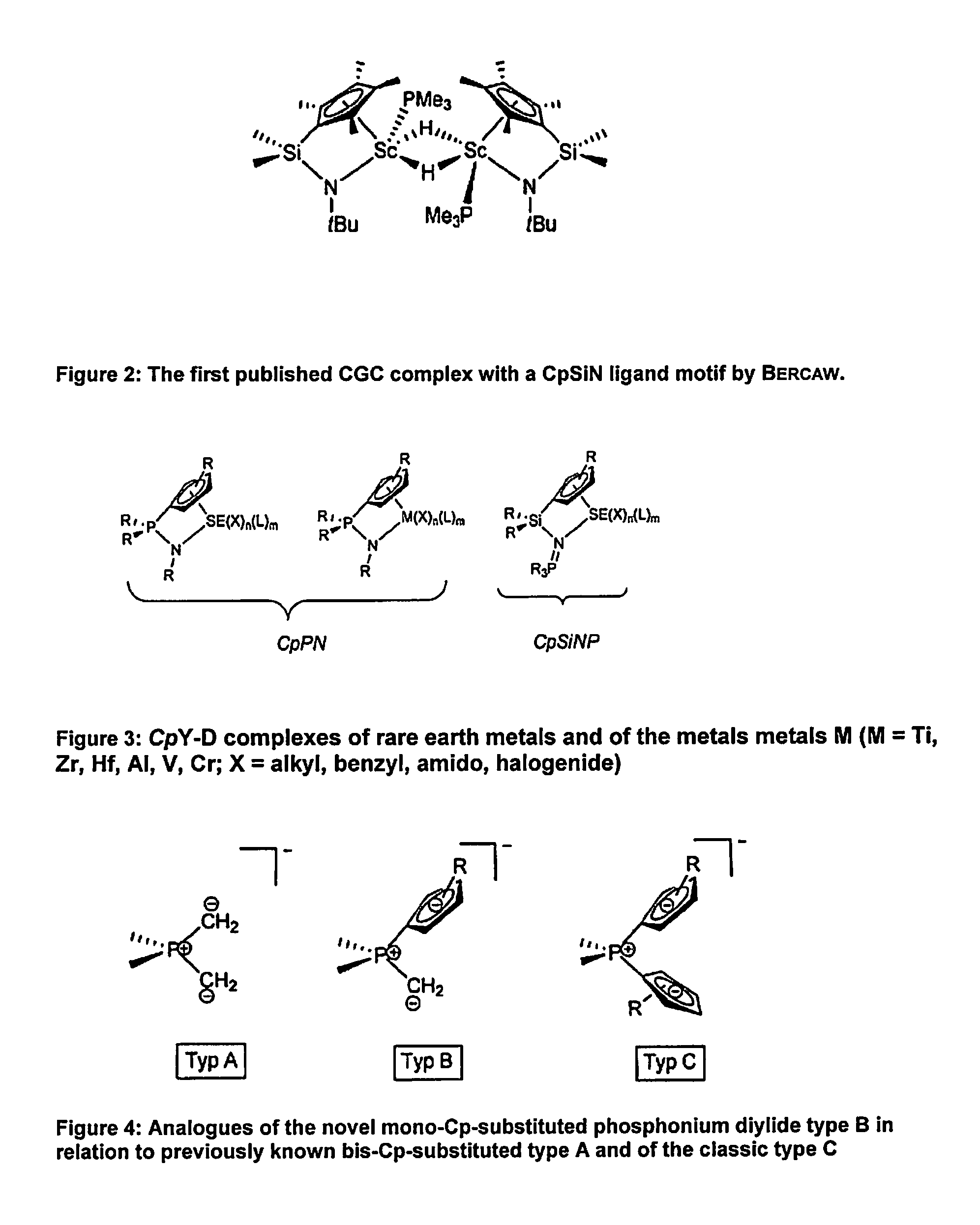

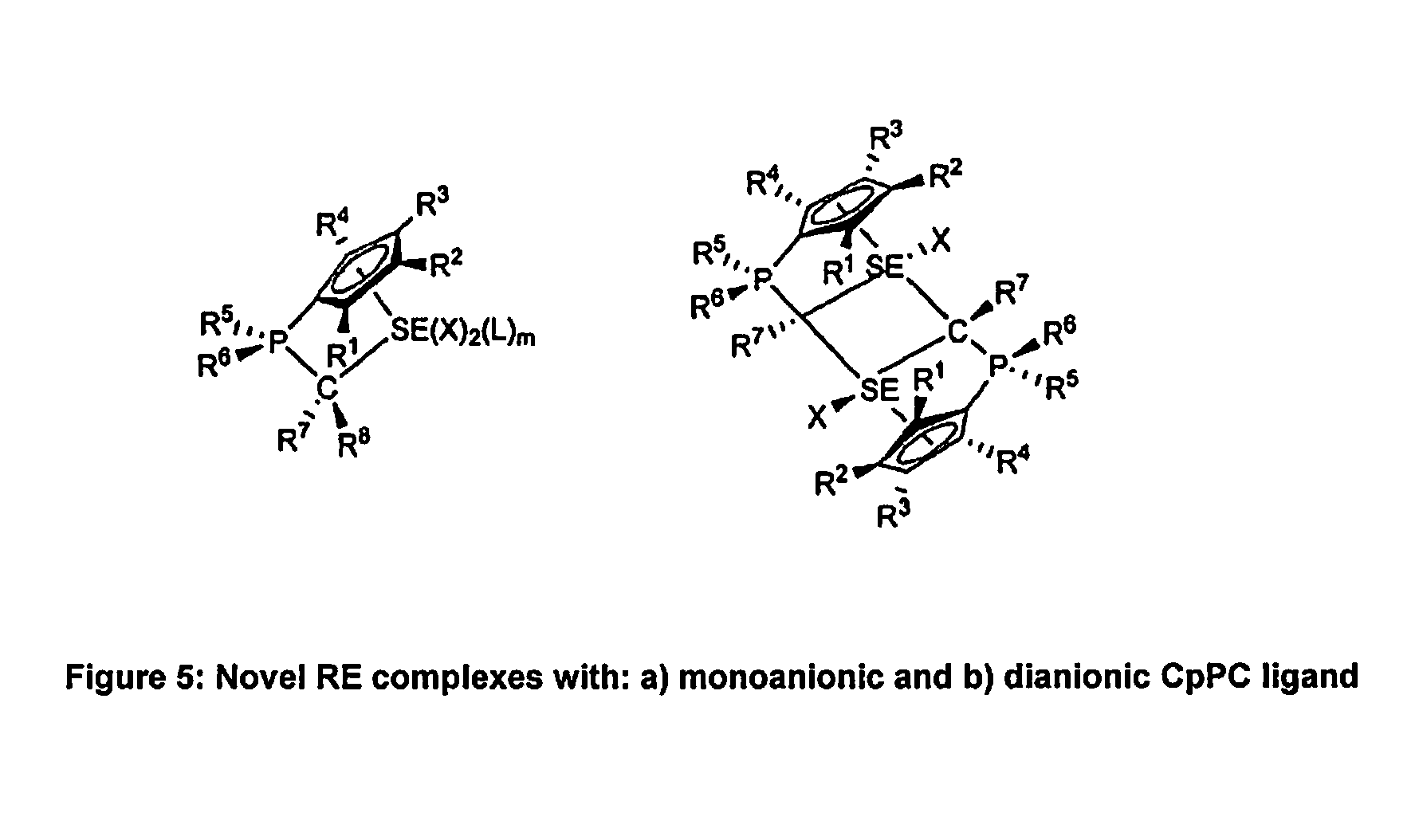

Η5:η1-cyclopentadienylidene-phosphorane constrained geometry complexes of rare earth metals

ActiveUS9200092B2Group 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsSolvent moleculeRare earth

The invention relates to η5:η1-cyclopentadienylidene-phosphorane constrained geometry complexes of rare earth metals, abbreviated to η5:η1-CpPC-CGC, method for production and use of same. The η5:η1-CpPC-CGCs correspond to the general formula (1), wherein SE=Sc, Y, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb or Lu; X=independently of one another, a mono-anionic diorganoamido-, bistrimethylsilylamido-, halogenido-, alkyl-, aryl-, alkoxo-, aryloxo- or alkylaluminate (AlR4−) substituent; L=neutral ligand (PR3, NR3, pyridine), solvent molecule (THF, ether, DMF, DMSO, HMPT, tetrahydropyran THP, tetrahydrothiofuran THT); R=alkyl with up to 1-10 C atoms or mono- or polycyclical aryl with 6 to 20 C atoms; R1, R4=independently of one another H or methyl; R2, R3=independently of one another, H or methyl or tertiary butyl or together a substituted cycloalkyl group; R5, R6=methyl, n-butyl, tertiary butyl or phenyl; R7, R8=independently of one another H, trimethylsilyl, alkyl with 1-10 C atoms or mono- or polycyclical aryl with 6 to 20 C atoms, and m=0, 1, 2 or 3.

Owner:ROCKWOOD LITHIUM GMBH

Gallium indium aluminum low congruent melting molten mass and use thereof in air purification

InactiveCN101380540AImprove purification efficiencyExtended service lifeDispersed particle separationAlkaneIndium

The invention discloses a gallium indium aluminum eutectic molten mass and the application thereof for purifying the alkane-typed gas (silane, arsine, phosphorane, germane, ammonia and borane) or the mixed gas formed by alkane-type and hydrogen and pertains to the high pure substance field. In the invention, adding 4-5% of mercury in the existing gallium indium aluminum eutectic molten mass results in that the aluminum dissolves quickly in the molten mass at the condition of room temperature, therefore heating the molten mass to 180-220 DEG C for dissolving the aluminum is unnecessary, in this way, the service life of a bubbler is prolonged greatly (the service life of the bubbler can be prolonged six times), meanwhile, for the molten mass does not need to be dissolved at high temperature, the production cost is reduced further. Additionally, compared with the existing method, the efficiency that the eutectic molten mass of the invention purifies gas is improved 10-40 times.

Owner:刘庚宇

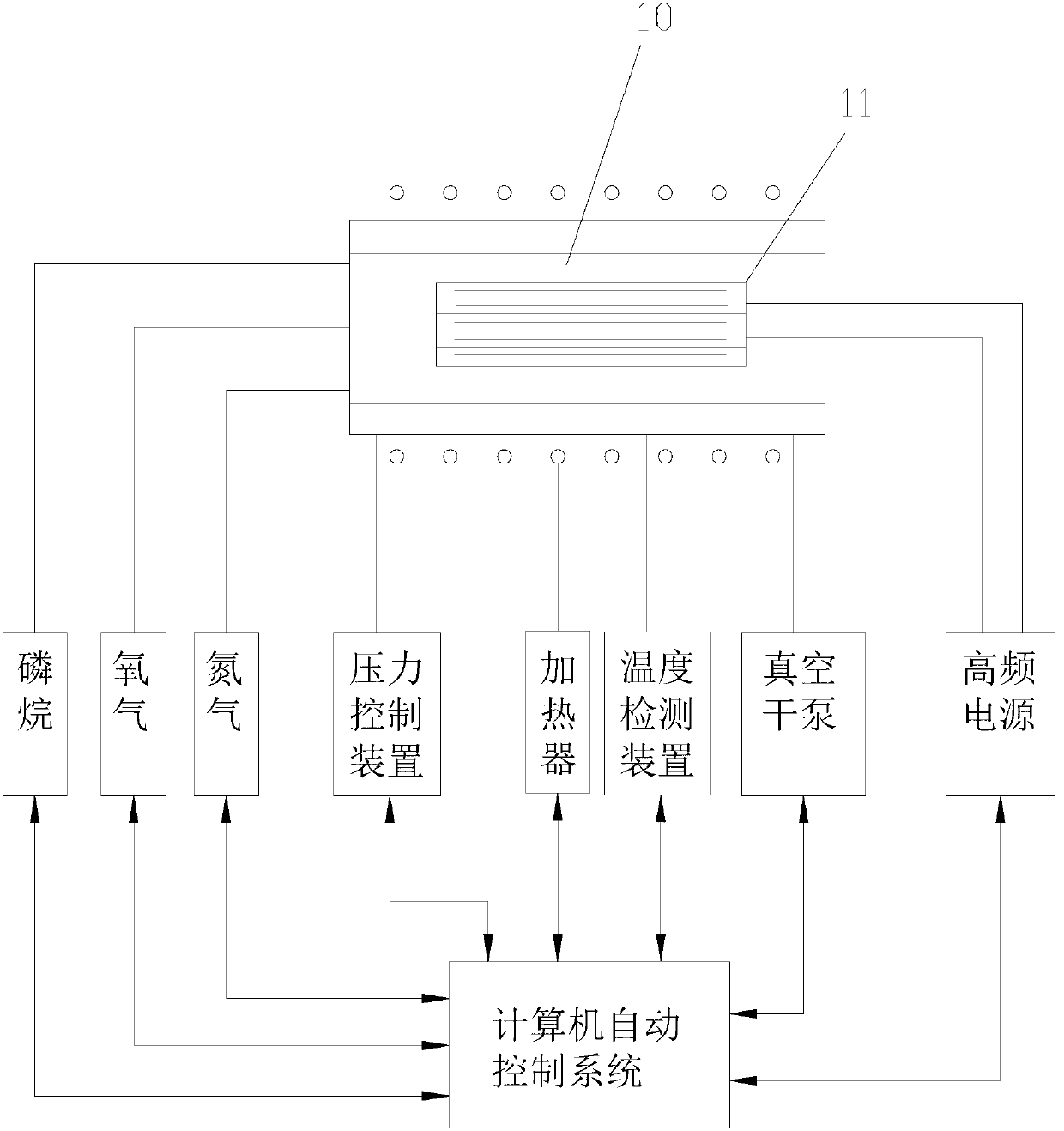

Field strength diffusion method of solar cell

InactiveCN102738312AGood knot depthReduce the difficulty of sinteringFinal product manufactureDiffusion/dopingDiffusion methodsHigh frequency power

The invention provides a field strength diffusion method of a solar cell and is characterized by comprising the following steps: placing the solar cell loaded on a dischargeable graphite boat in a high temperature diffusion furnace, wherein electrodes for high-frequency discharge are arranged in the high temperature diffusion furnace and the graphite boat is connected with the electrodes; increasing the temperature in the high temperature diffusion furnace to 850 DEG C; introducing phosphorane, oxygen and nitrogen in the high temperature diffusion furnace, wherein the flux of phosphorane is 0.5-1 L / min, the flux of oxygen is 0.5-1 L / min, the flux of nitrogen is 5-10 L / min, and the pressure in the high temperature diffusion furnace is automatically controlled to be 170 Pa; applying high frequency power source on the graphite boat through the electrodes so that the graphite boat discharge to the solar cell, wherein the discharge power of the high frequency power source is 3000W to 5000W, the discharge time is 120s, and the diffusion is finished when discharge is ended.

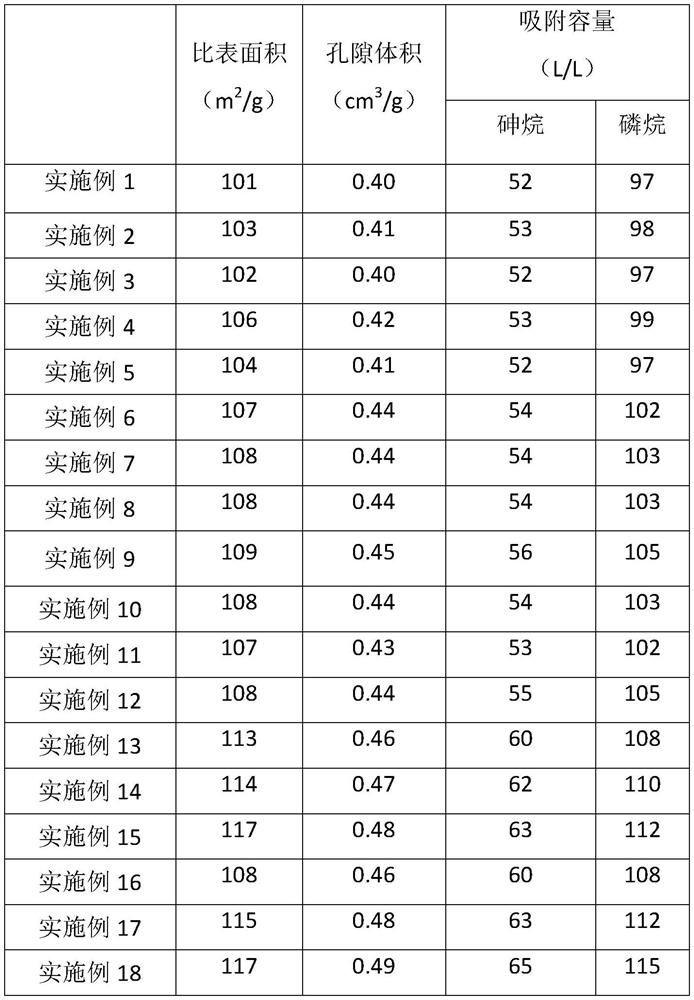

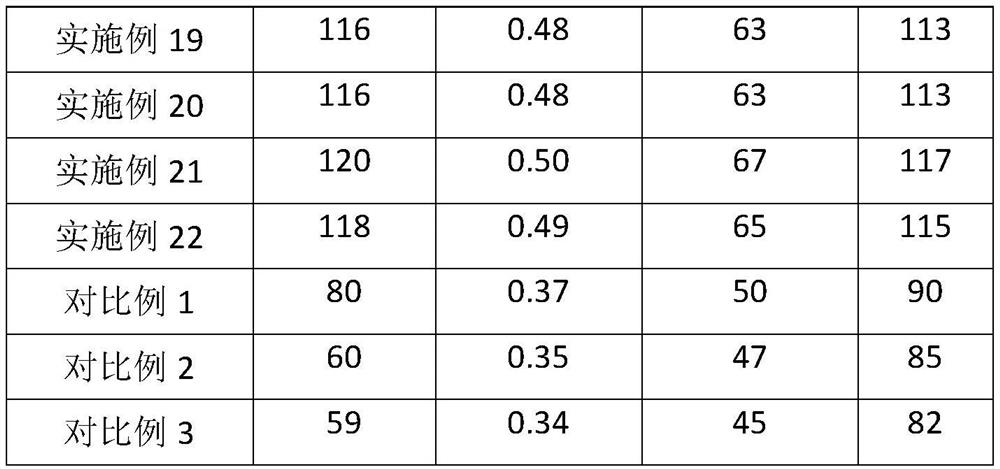

Arsine phosphine special gas adsorbent and preparation method thereof

PendingCN114870803AImprove adsorption capacityImprove the ability to adsorb phosphineOther chemical processesDispersed particle separationArsineSorbent

The invention relates to the technical field of waste gas adsorbents, and particularly discloses an arsine phosphine special gas adsorbent and a preparation method thereof.The arsine phosphine special gas adsorbent comprises a component A and a component B, and the volume ratio of the component A to the component B is 1: (0.1-0.3); the component A comprises the following raw materials in percentage by weight: nano active copper oxide, active aluminum oxide and silicon dioxide; the specific surface area of the nano active copper oxide is greater than 100m < 2 > / g; the specific surface area of the nano active copper oxide is greater than 100m < 2 > / g; and the component B is aluminum sol. The arsine-phosphine special gas adsorbent obtained in the invention has a specific surface area and a pore volume of 120m < 2 > / g and 0.50 cm < 3 > / g respectively, and has relatively high specific surface area and pore volume; the highest adsorption capacities of arsine and phosphorane are 67 L / L and 117 L / L respectively, and the arsine and phosphorane adsorption capacity of the arsine and phosphorane special gas adsorbent is improved.

Owner:常州诚铒正环保技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com