Phosphosilicate glass growth process and phosphosilicate glass

A phosphosilicate glass and process technology, which is applied in glass production and other directions, can solve the problems of narrowing process window, increased risk, unfavorable industrial production, etc., and achieve the effect of reducing sputtering density, increasing the starting point of the bottom, and expanding the process window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

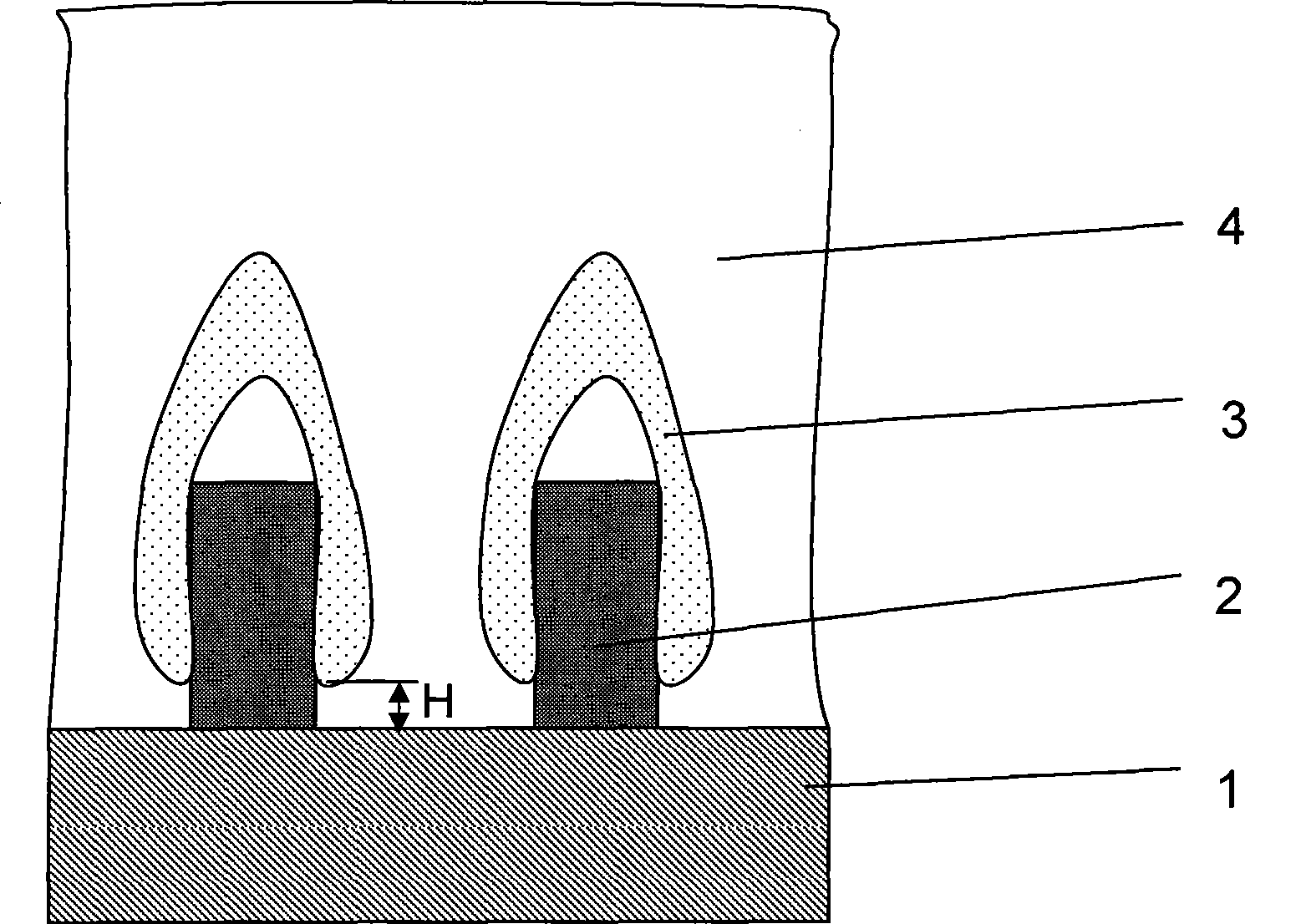

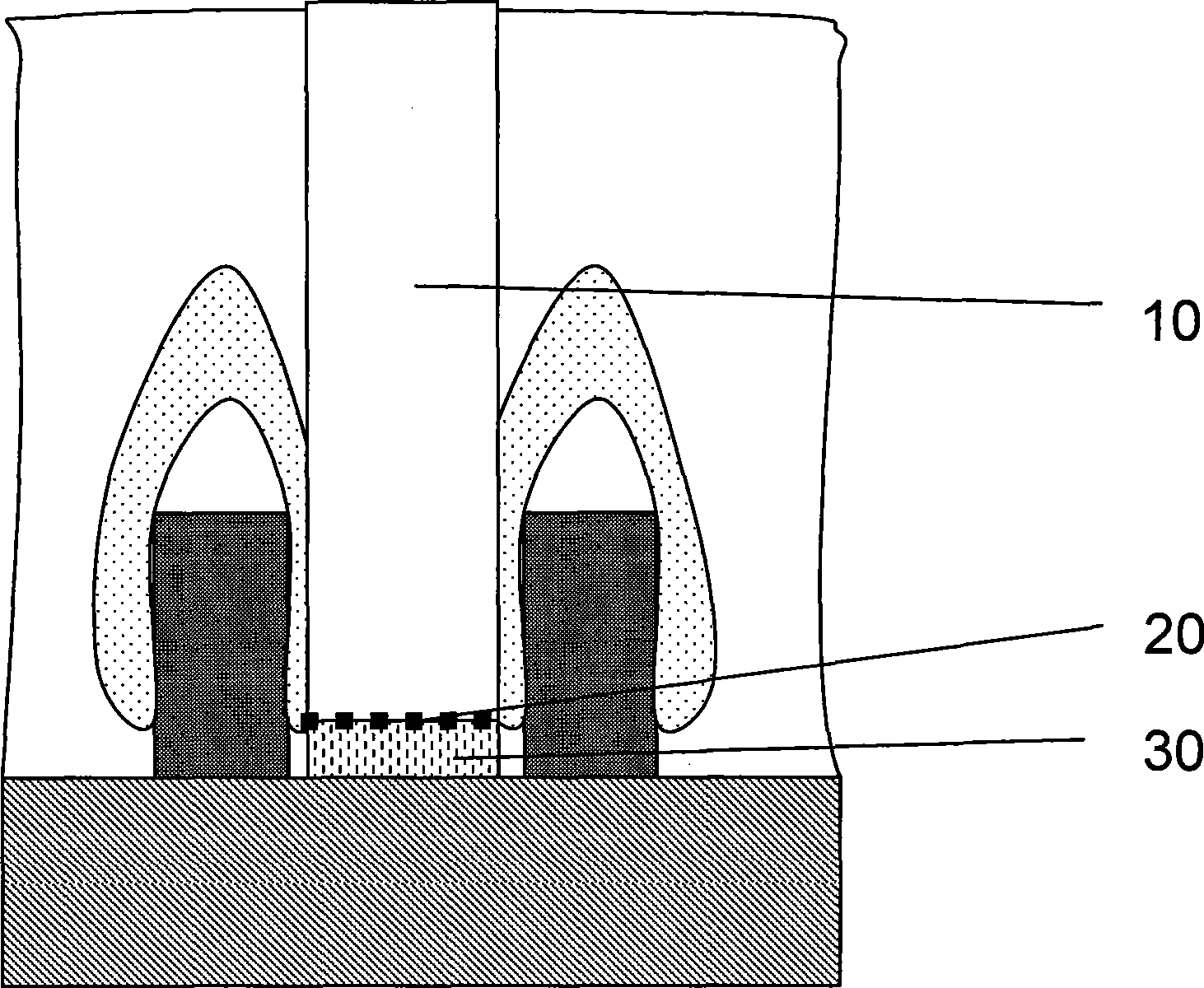

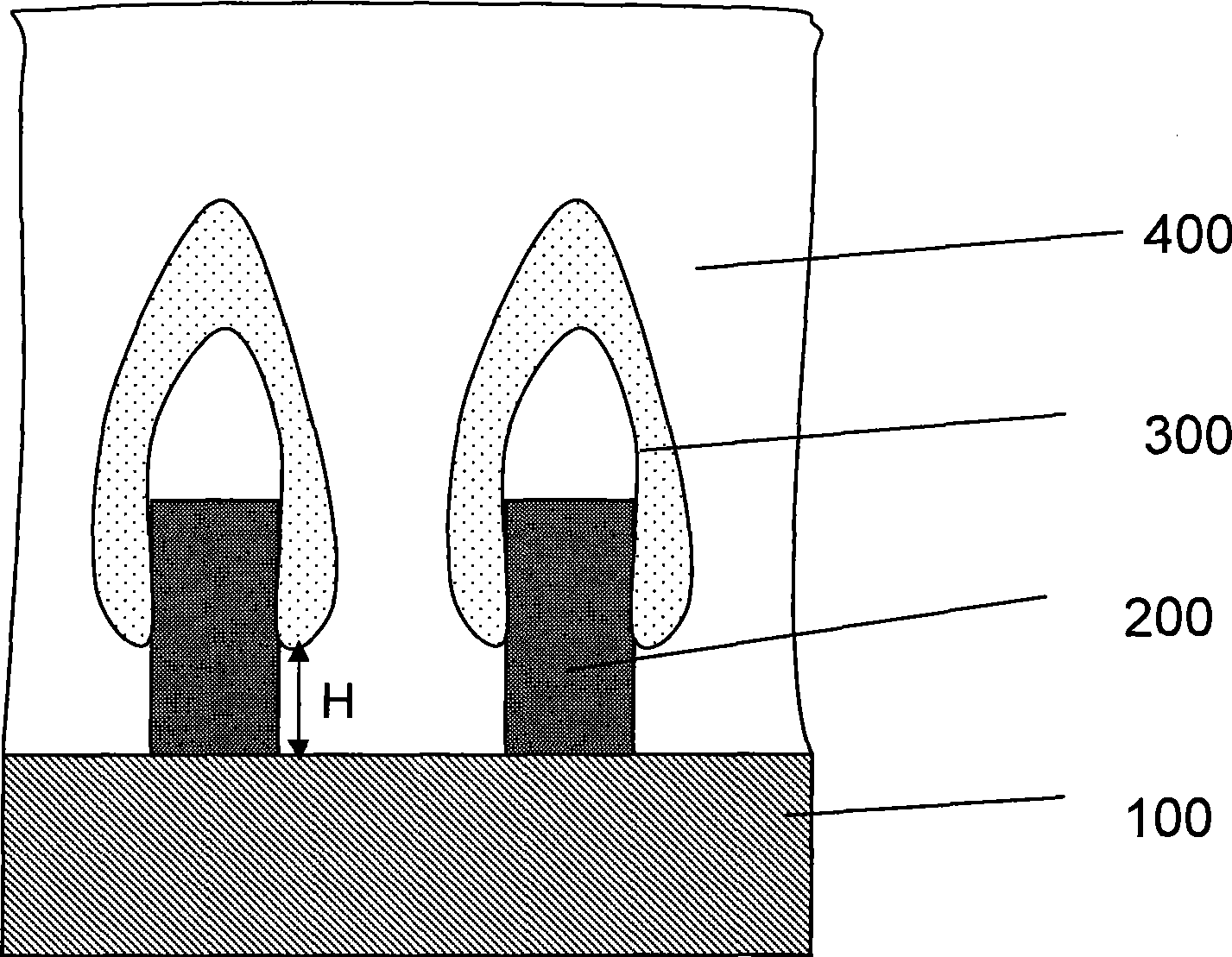

[0014] The inventors have found that the formation of the flower-like shell of phosphosilicate glass is due to the selectivity of ion sputtering to phosphorus, silicon and oxygen during the high-density plasma chemical vapor deposition process, that is, the ratio of the sputtering rate to phosphorus The sputtering rate of silicon and oxygen is large, and the sputtering effect on the side with a certain angle is greater than that on the flat place, so phosphosilicate glass flowers with less phosphorus content will be formed on the side wall of the pattern shell.

[0015] Reducing the sputtering energy and sputtering density during the deposition of phosphosilicate glass can reduce the speed at which the flower-shaped shell of phosphosilicate glass begins to form between patterns, thereby increasing the starting point at the bottom of the flower-shaped shell of phosphosilicate glass. The sputtering energy and sputtering density can be achieved by reducing the sputtering bias vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com