Composite-DBR-structure-based AlGaInP light-emitting diode

A technology of light-emitting diodes and dopants, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as insufficient reflection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to allow those skilled in the art to understand the present invention more clearly and intuitively, the present invention will be further described below.

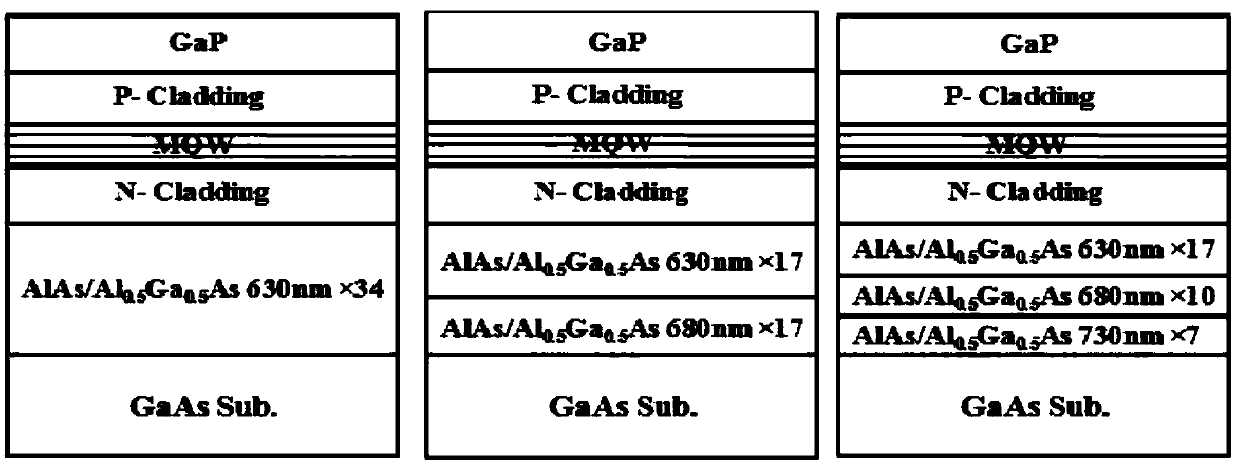

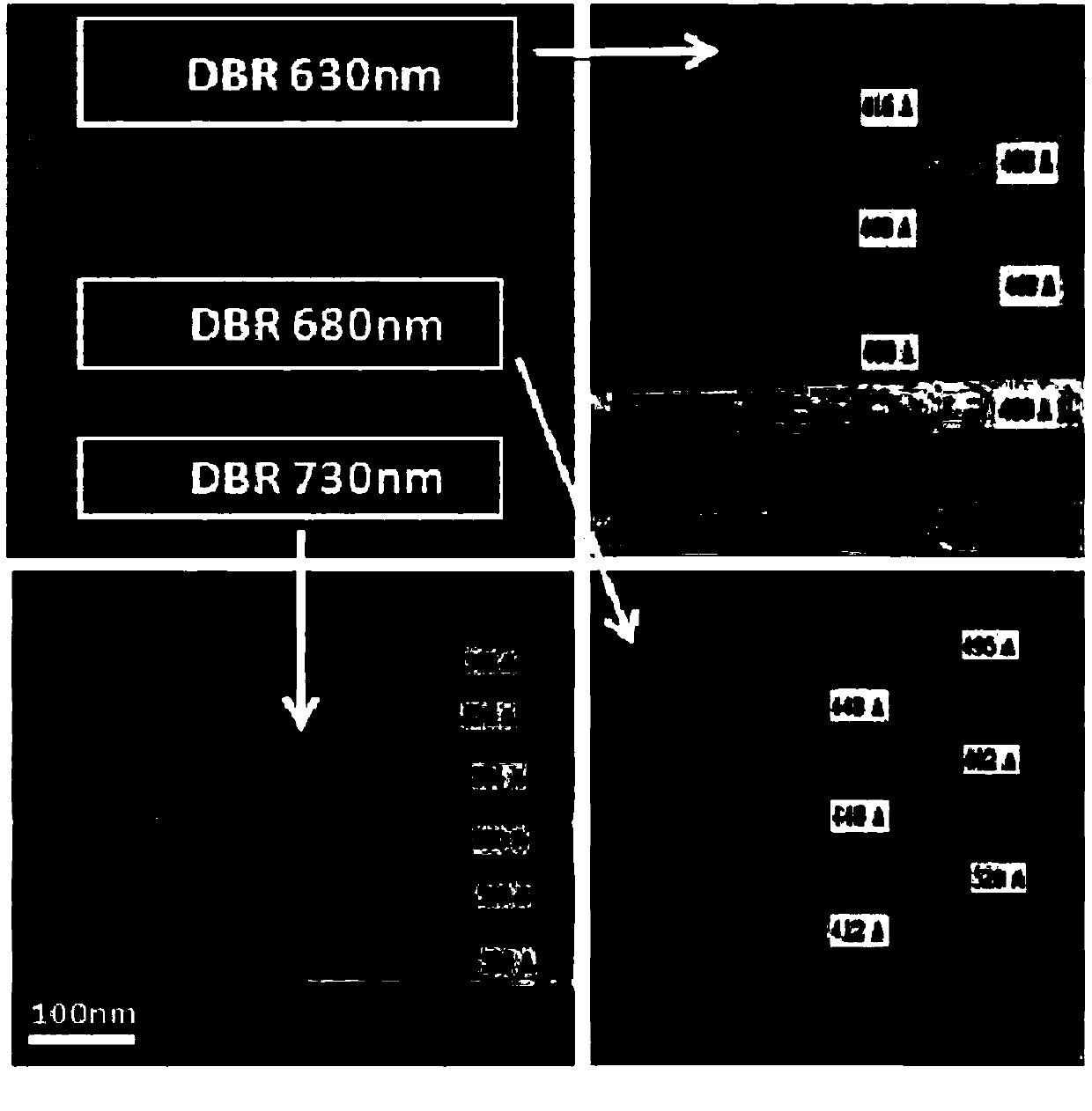

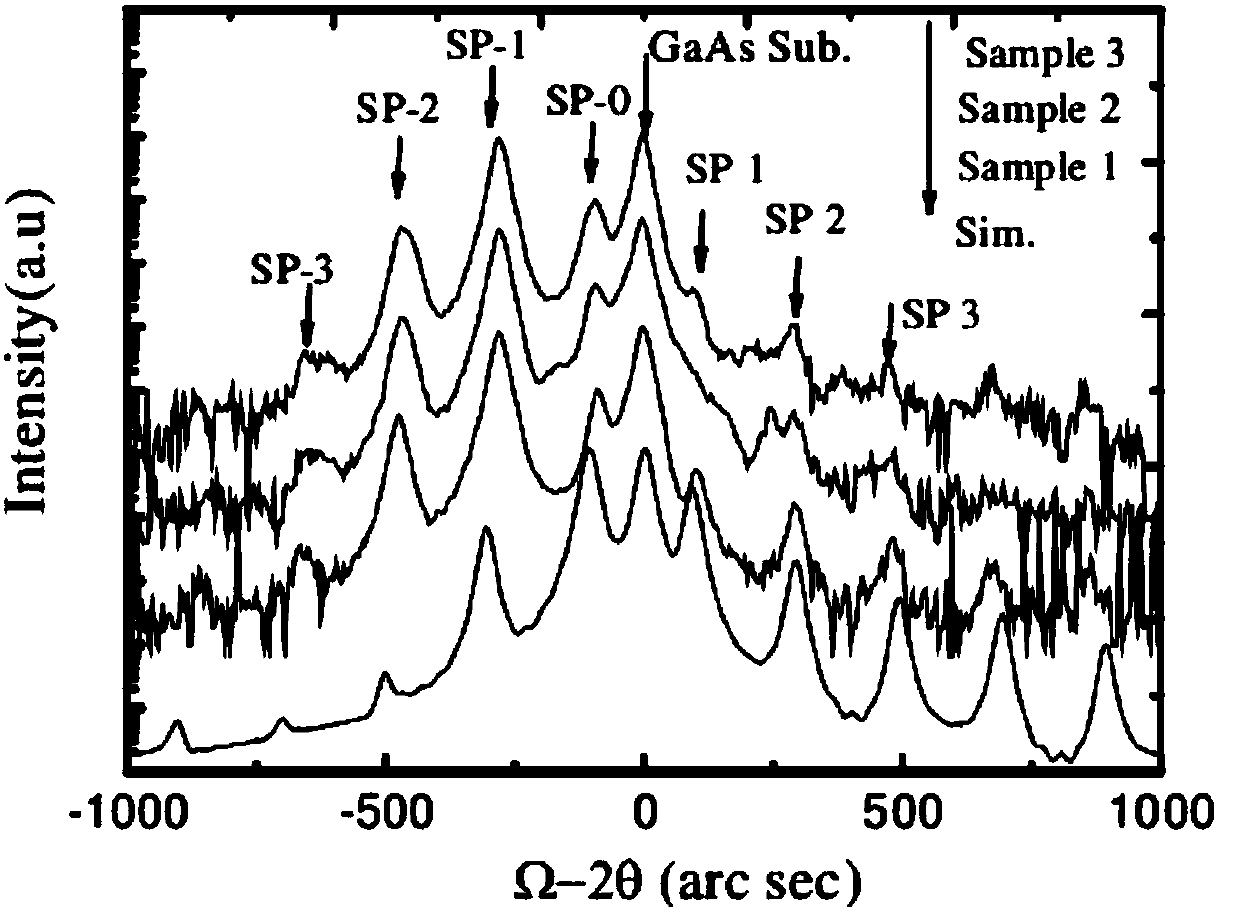

[0015] The DBR material is selected from the high reflectivity AlAs / Al0.5Ga0.5As combination, and three kinds of DBRs with the same total logarithm and different structures are designed experimentally. Sample 1 is a conventional DBR with a reflection center wavelength of 630nm and a logarithm of 34 pairs; sample 2 is a composite DBR with a reflection center wavelength of 630nm and 680nm and a logarithm of 17 pairs respectively; sample 3 is a composite DBR with The wavelengths are 630nm, 680nm and 730nm, and the logarithms are 17 pairs, 10 pairs and 7 pairs respectively. The thickness design of each layer can be calculated according to the theoretical formula H / 4n, where is the reflection center wavelength, n is the refractive index corresponding to the wavelength, and the refractive index of Al As correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com