Field strength diffusion method of solar cell

A technology of solar cell and diffusion method, which is applied in the field of field strength diffusion of solar cells, and can solve the problems of inconsistent PN junction depth of solar cells, inconsistent photoelectric conversion performance of solar cells, and difficulty in high-temperature sintering, etc. , to achieve the effects of reduced impurity molecules, short diffusion time, and reduced sintering difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

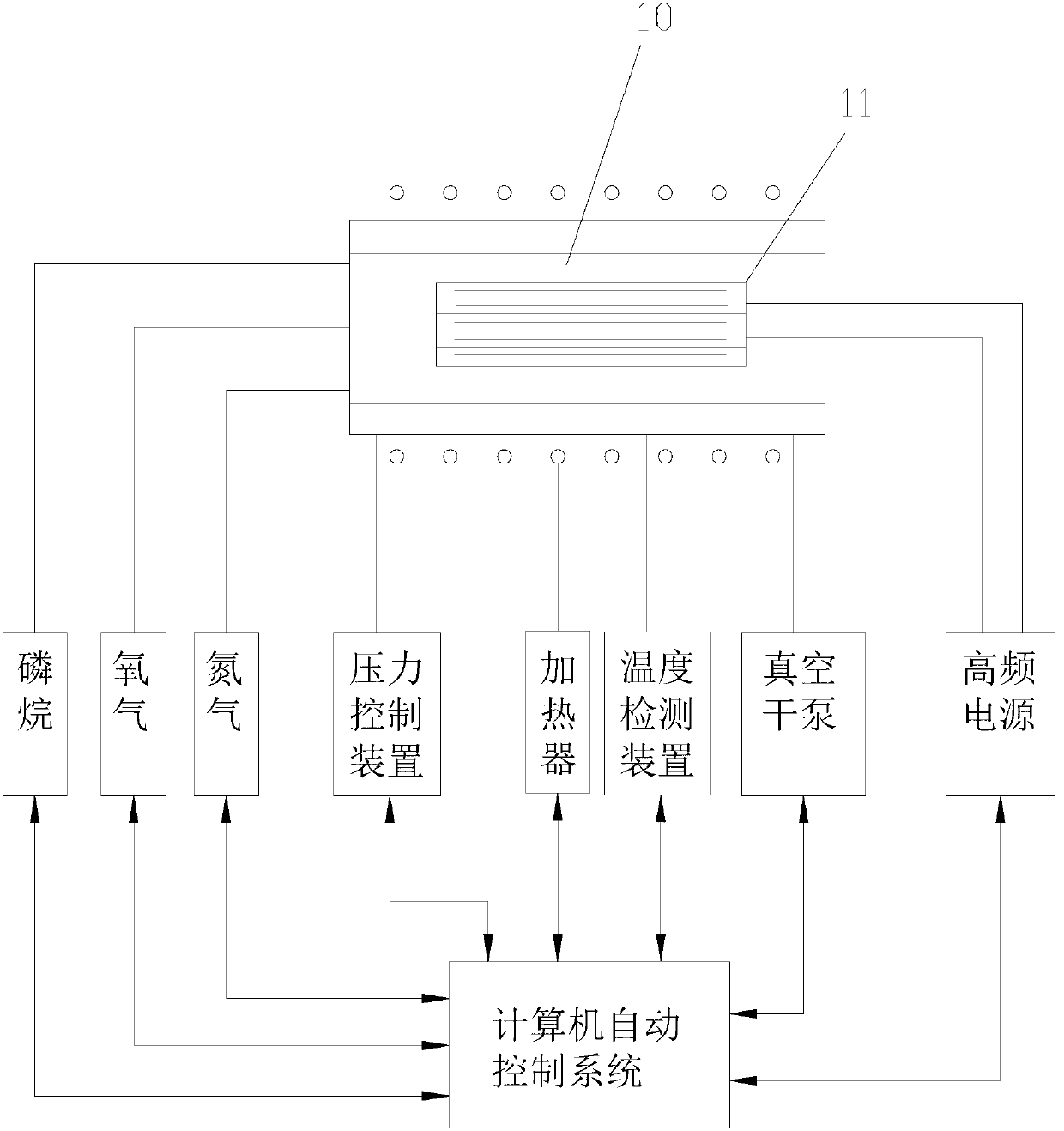

[0009] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0010] see figure 1 , the present invention provides a kind of diffusion method of solar cells, it is characterized in that, comprises the following steps: put the solar cells loaded on the dischargeable graphite boat 11 into HPEVCD (plasma enhanced chemical vapor deposition) refitted through high temperature resistance performance ) in the reaction chamber 10 of the equipment, the number of sheets per boat is 252, and the size of the solar cell sheet is 156mm*156mm; the graphite boat 11 is connected to the electrode of the HPEVCD device; the temperature in the reaction chamber 10 Raise the temperature to 850°C; feed phosphine, oxygen and nitrogen into the reaction chamber 10, wherein the flow rate of phosphine is 0.5-1L / min, the flow rate of oxygen is 0.5-1L / min, and the flow rate of nitrogen is 5-10L / min, and automatically control the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com