An automatic push-pull boat system device for diffusing in and out of the furnace

A system device, push-pull boat technology, applied in the direction of transportation and packaging, conveyor objects, electrical components, etc., can solve the problems of uneven wafer movement speed, uneven silicon wafer junction surface, uneven junction depth, etc., and achieve simple design , less silicon chip fragments, good junction depth consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

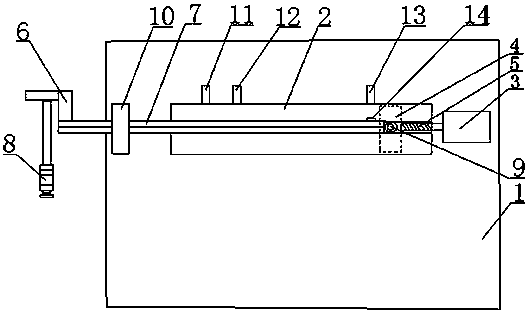

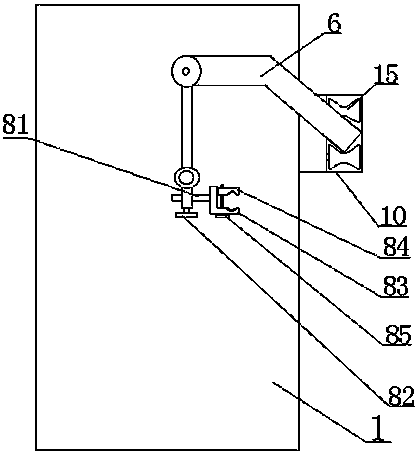

[0012] In order to further explain the present invention, the following is introduced in conjunction with the accompanying drawings of the specification:

[0013] Referring to the attached drawings, an automatic push-pull boat system device for diffusion in and out of the furnace, which includes a diffusion furnace 1, a sliding seat 2, a speed regulating motor 3, a sliding block 4, a screw rod 5, a mechanical arm 6, a push-pull rod 7, and a manipulator 8. One side of furnace 1 is equipped with sliding seat 2, sliding seat 2 is equipped with sliding block 4, sliding block 4 is equipped with screw rod 5, one end of screw rod 5 is equipped with speed-adjusting motor 3, sliding base 2 is equipped with push-pull rod 7, pushing One end of the pull rod 7 is connected to the upper end of the slider 4 through a round pin 9, the other end of the push-pull rod 7 passes through the guide wheel support 10 to connect to the robot arm 6, and the lower end of the robot arm 6 is connected to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com