Patents

Literature

187 results about "Phosphoric chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphoryl chloride (commonly called phosphorus oxychloride) is a colourless liquid with the formula POCl3. It hydrolyses in moist air releasing phosphoric acid and fumes of hydrogen chloride.

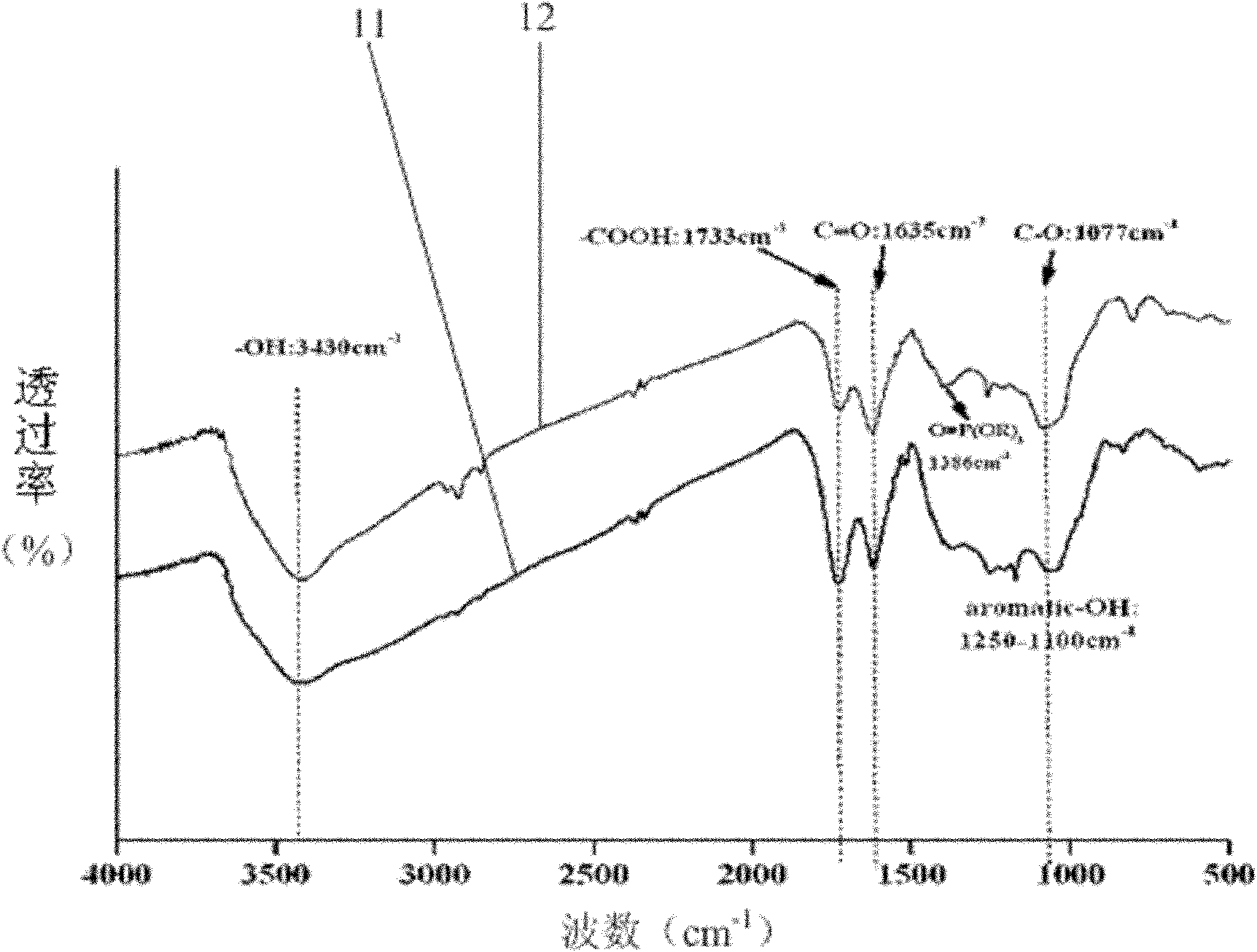

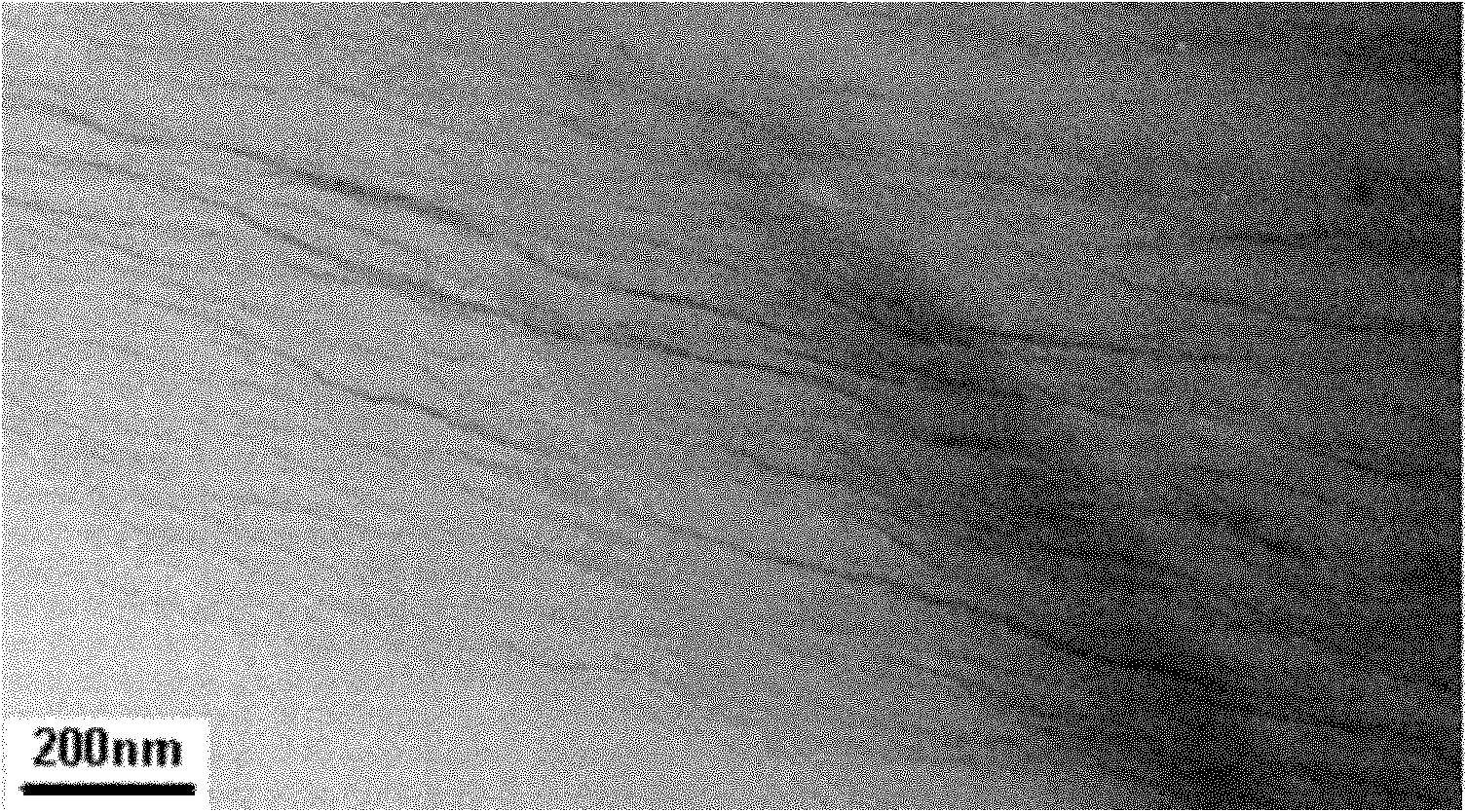

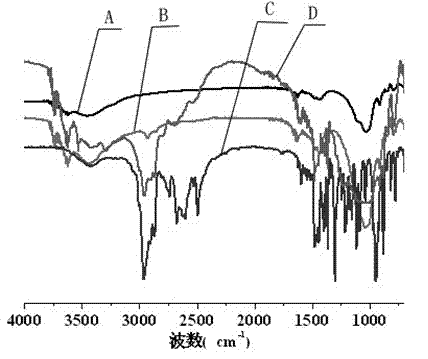

Preparation method of modified graphene oxide and preparation method of composite material containing modified graphene oxide

ActiveCN102127324AImprove flame retardant performanceEvenly dispersedPigment treatment with non-polymer organic compoundsEpoxyPolyamide

The invention provides a preparation method of a modified graphene oxide, comprising the following steps of: (a) reacting a phosphorus oxychloride compound, cyanuric chloride or diisocyanate with glycidol to obtain an intermediate product; and (b) dispersing graphite oxide in an organic solvent, dropwise adding to the intermediate product obtained through reaction, and reacting to obtain the modified graphene oxide. The invention also provides a preparation method of a composite material containing the modified graphene oxide, comprising the following steps of: dispersing the modified graphene oxide obtained through the preparation method in the technical scheme in an organic solvent, mixing the modified graphene oxide containing epoxide groups with epoxy resin oligomers and a polyamide curing agent, and curing to obtain the composite material containing the modified graphene oxide. In the composite material provided by the invention, the modified graphene oxide reacts with a resin substrate, is more uniform to disperse in the obtained composite material, and has better flame-retarding performance.

Owner:UNIV OF SCI & TECH OF CHINA

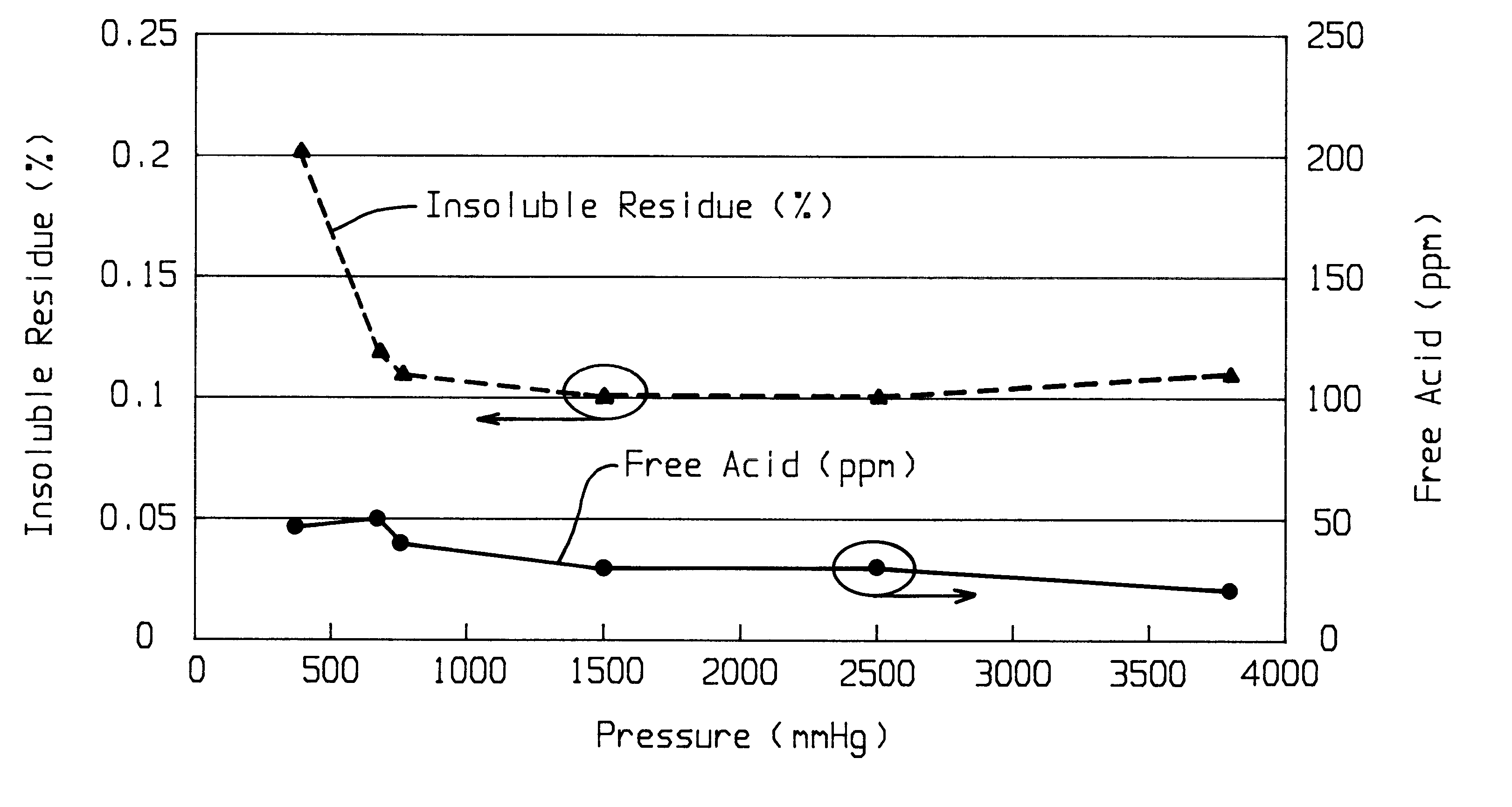

Method of purifying lithium hexafluorosphate

InactiveUS6514474B1Phosphorus halides/oxyhalidesNon-aqueous electrolyte accumulatorsHydrogen fluoridePhosphor

A method of purifying lithium hexafluorosphate that allows to purify lithium hexafluorophosphate, useful as lithium secondary cell electrolyte, organic synthesis medium or the like, to an extremely high purity is provided. Lithium hexafluorophosphate containing harmful impurities such as oxyfluoride, lithium fluoride is purified by adding phosphoric chloride. The purification is performed in the presence of phosphoric chloride and hydrogen fluoride of the quantity equal or superior to the equivalent amount for reacting them, and then by converting lithium fluoride to lithium hexafluorophosphate with generated phosphor pentafluoride.

Owner:STELLA CHEMIFA CORP

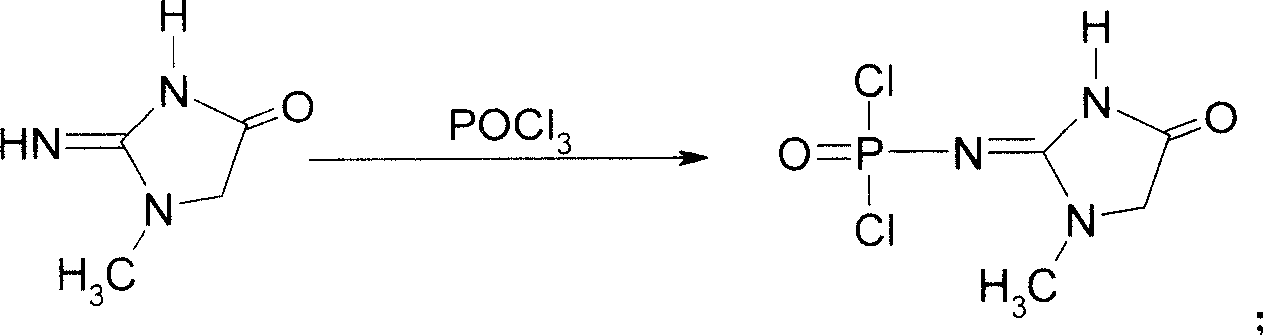

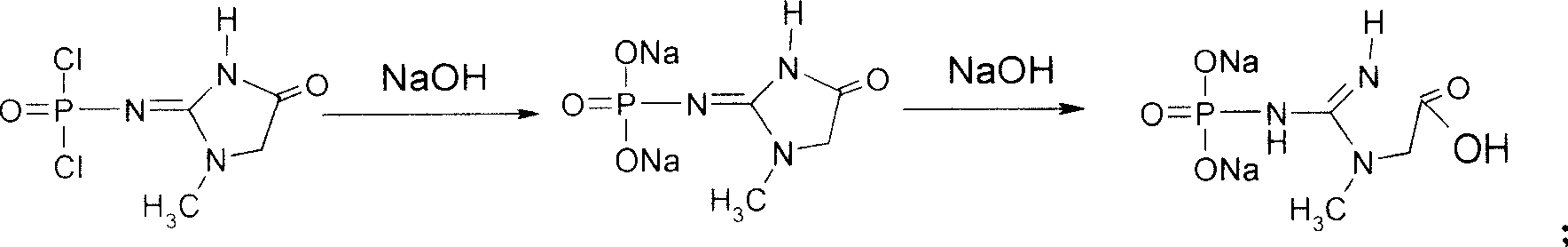

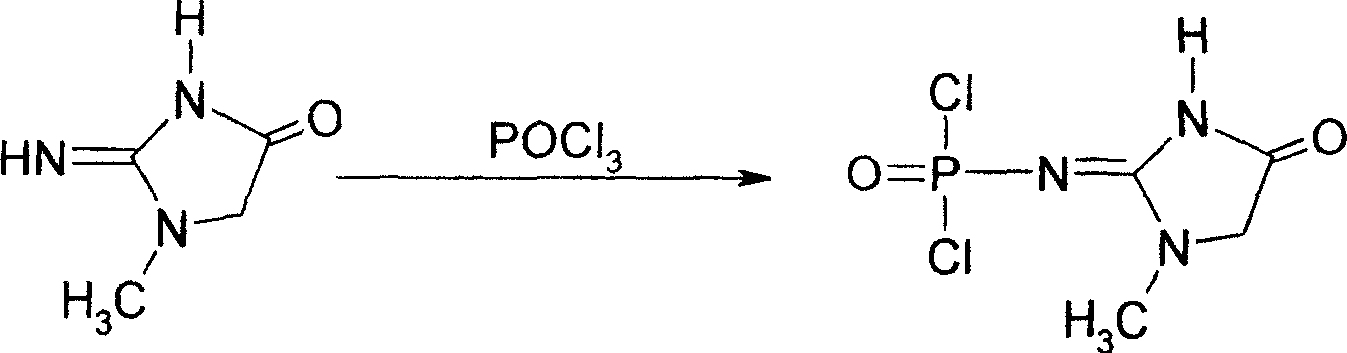

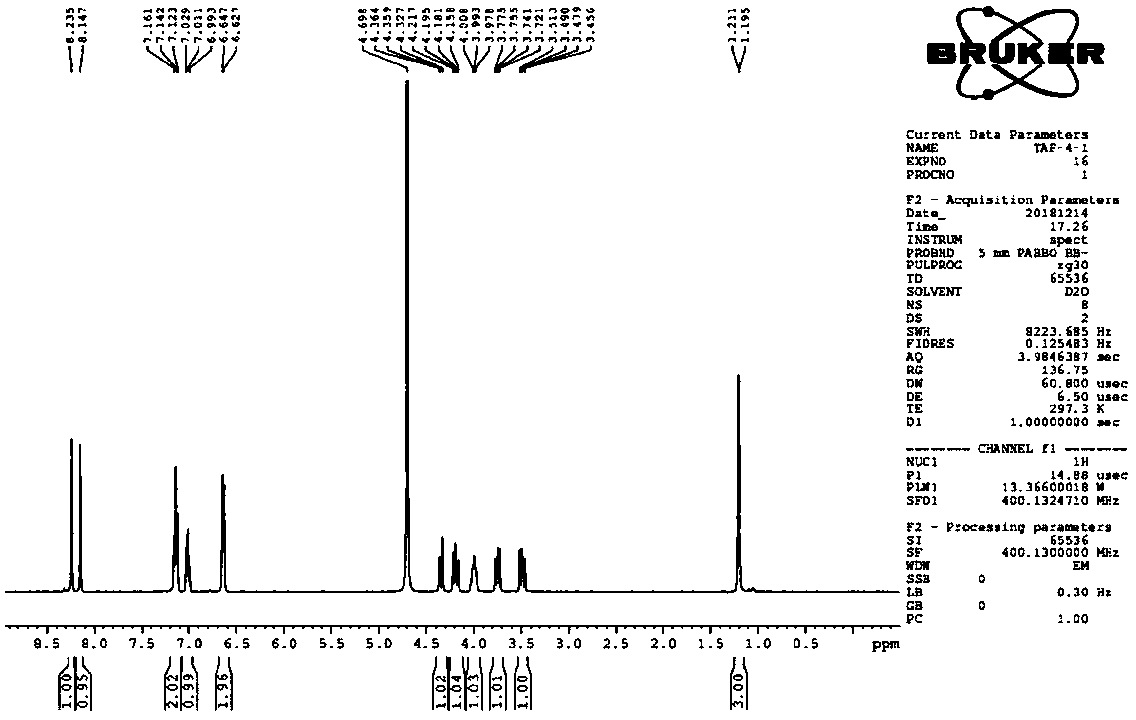

Medicinal disodium creatine phosphate hexahydrate and preparing method thereof

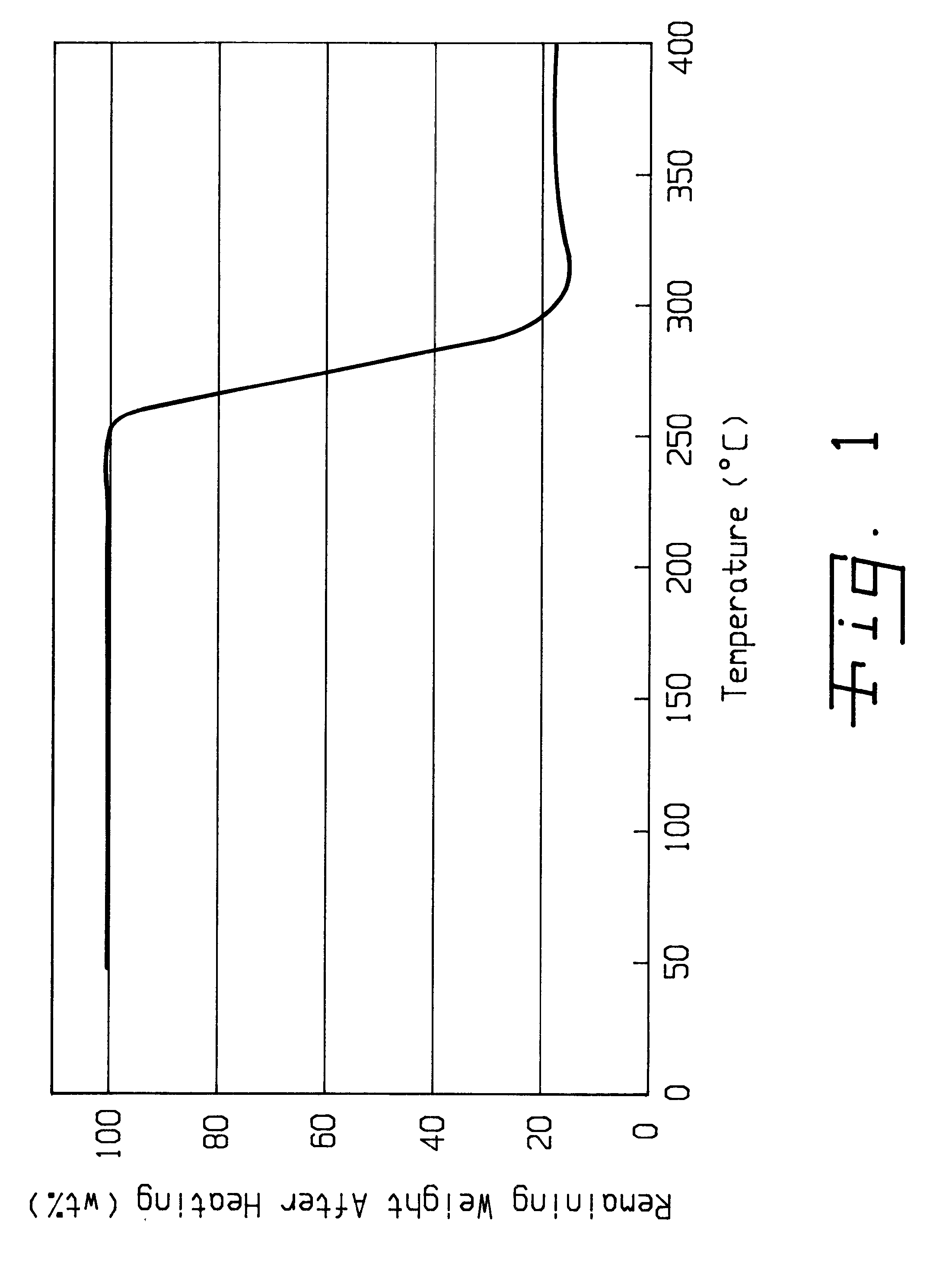

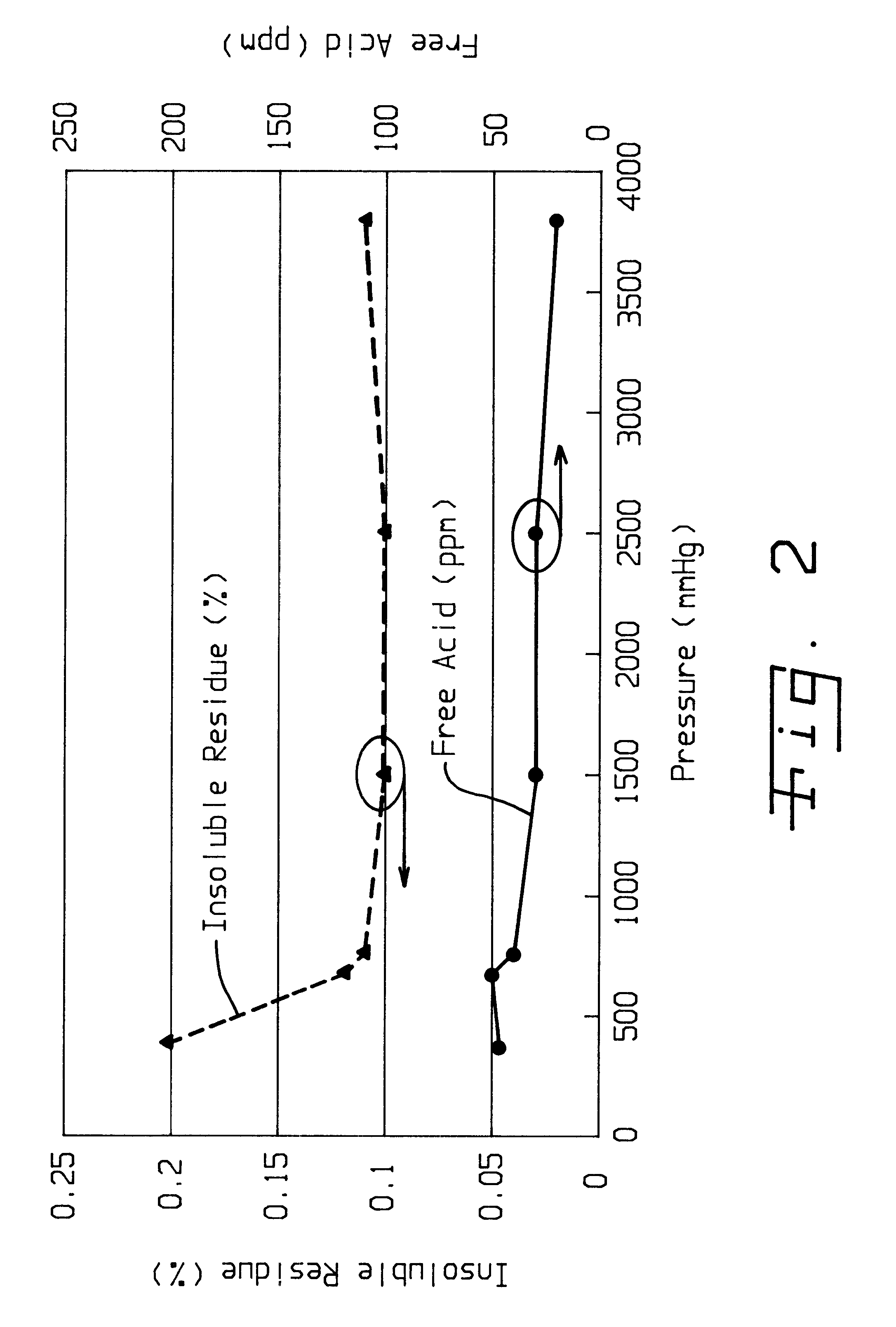

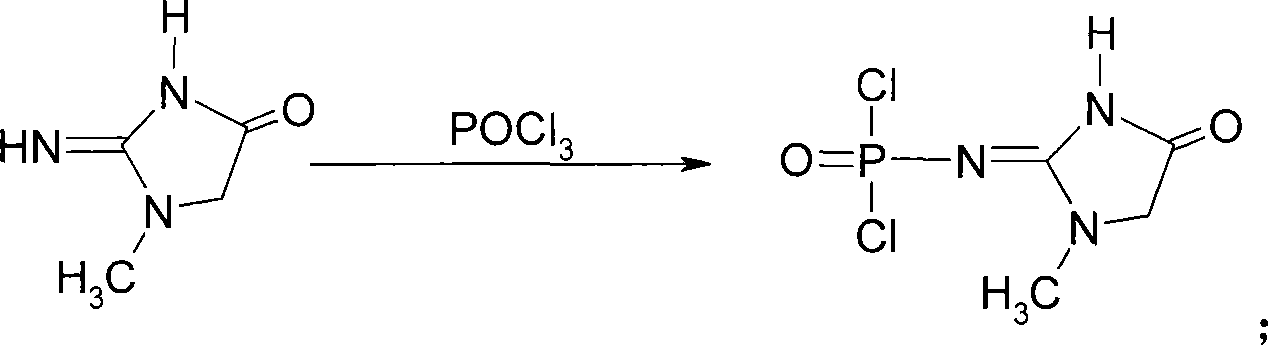

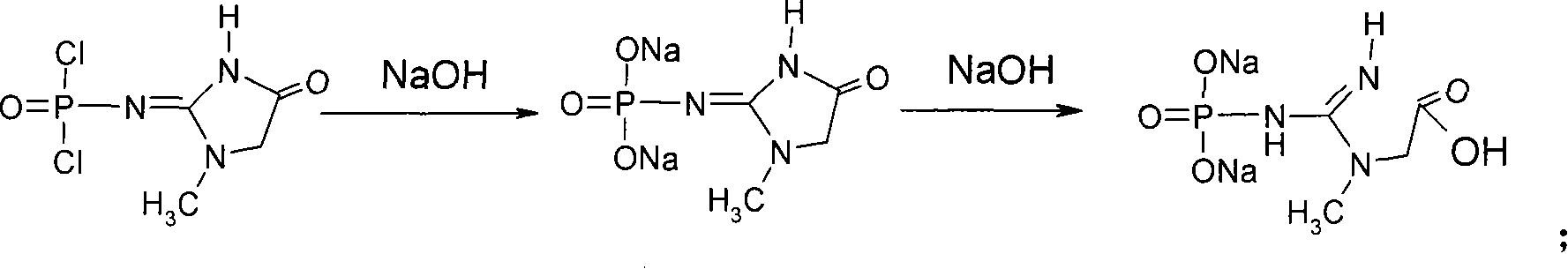

ActiveCN101033237AHigh purityLow drying temperatureGroup 5/15 element organic compoundsCreatinine riseDistillation

This invention discloses a phosphocreatine disodium salt six-hydrate and its preparation method. The compound is phosphocreatine disodium salt with high purity and six-crystal water, and the preparation method includes the following steps: (1) Kondens of creatinine and phosphorus oxychloride prepares creatinine phosphorus oxychloride, (2) creatinine phosphorus oxychloride is taken the ring opening reaction to get crude phosphorus disodium, (3) purification and crystallization gets the target product. This invention has the advantages of high purity suitable for the manufacture of injection powder, and it avoids the large use of solvents with high yield of products. The excessive phosphorus oxychloride is reused with distillation, and the product has high purity through intermediate and resin purification. It has no potential safety problem about heavy metal residues, and can effectively improve the clarification to reach the intravenous requirement.

Owner:QIDONG HUATUO PHARMA

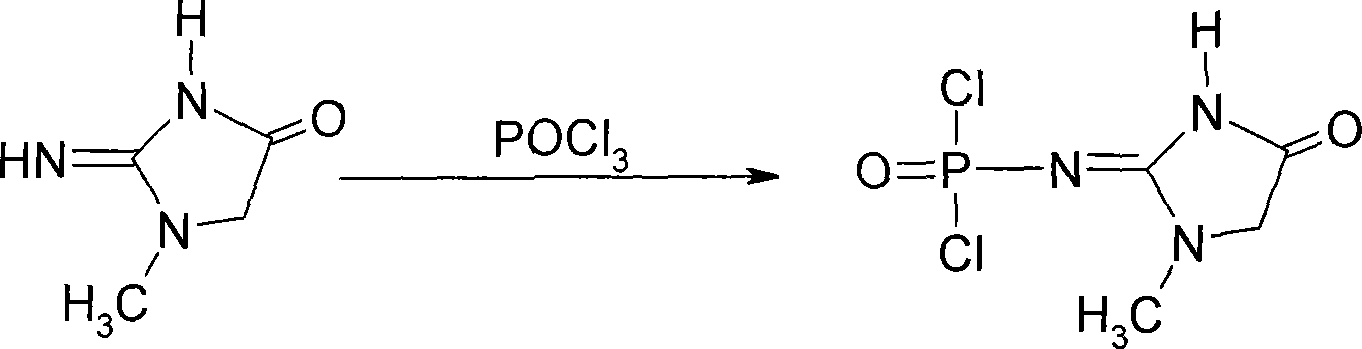

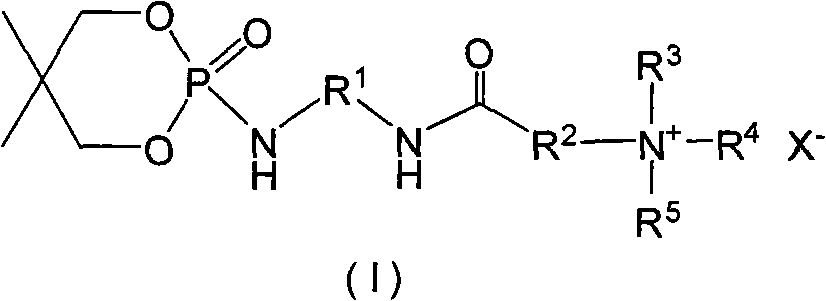

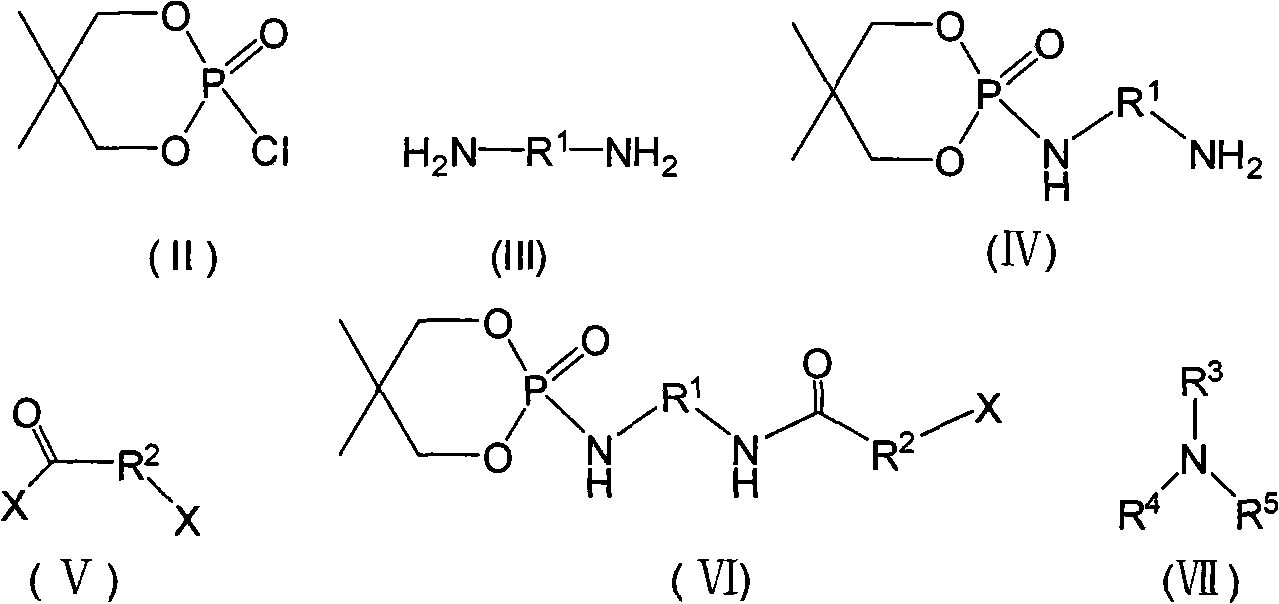

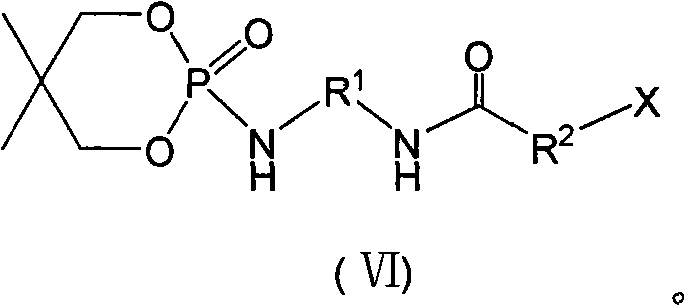

Phosphorus-nitrogen quaternary ammonium as well as preparation method and application thereof

InactiveCN101624403AFlame retardantAddressing Migration IssuesGroup 5/15 element organic compoundsPigment treatment with non-polymer organic compoundsNitrogenIon exchange

The invention discloses a phosphorus-nitrogen quaternary ammonium as well as a preparation method and application thereof. The phosphorus-nitrogen quaternary ammonium has a structure shown in the formula (I) and is prepared by the following steps: volution-contained phosphoryl chloride shown in the formula (II) is reacted with diamine compound shown in the formula (III) to obtain a compound shown in the formula (IV); the compound shown in the formula (IV) is reacted with acyl halide shown in the formula (V) to obtain a compound shown in the formula (VI); and the compound shown in the formula (VI) is reacted with tertiary amine shown in the formula (VII) to obtain the product, i.e. the phosphorus-nitrogen quaternary ammonium. The invention is used for chemically modifying montmrillonoid by using the phosphorus-nitrogen quaternary ammonium, improves the inflaming retarding effect to high polymer materials through the cooperative inflaming retarding function of the montmrillonoid and phosphorus-nitrogen fire retardant, reduces the consumption of the fire retardant in the high polymer materials and lowers the cost of fire-retarding materials.

Owner:ZHEJIANG UNIV OF TECH

High hardness fluorubber material with low-temperature pliability

InactiveCN1919921AImprove the shortcomings of poor low temperature performanceImprove performancePliabilityCompression set

The invention discloses a fluorubber sizing with low temperature pliability and high hardness, which concludes 80-100% fluoride olefin terpolymer, 1-8% activated magnesium oxide, 1-10% superfine calvital, 0.1-3.0% phenmethyl triphenyl phosphoric chloride / Dbu, 0.5-5% fluorine wax / parting medium, 10-50% strengthening agent, 1-5% promoting agent, 1.5-5.0% bisphenol AF, 5-20% plasticizer, 0.1-1.0% peroxide and 0.15-1.5% cross bonding accessory ingredient.

Owner:SHANGHAI XINGLUO SPECIAL SEALS

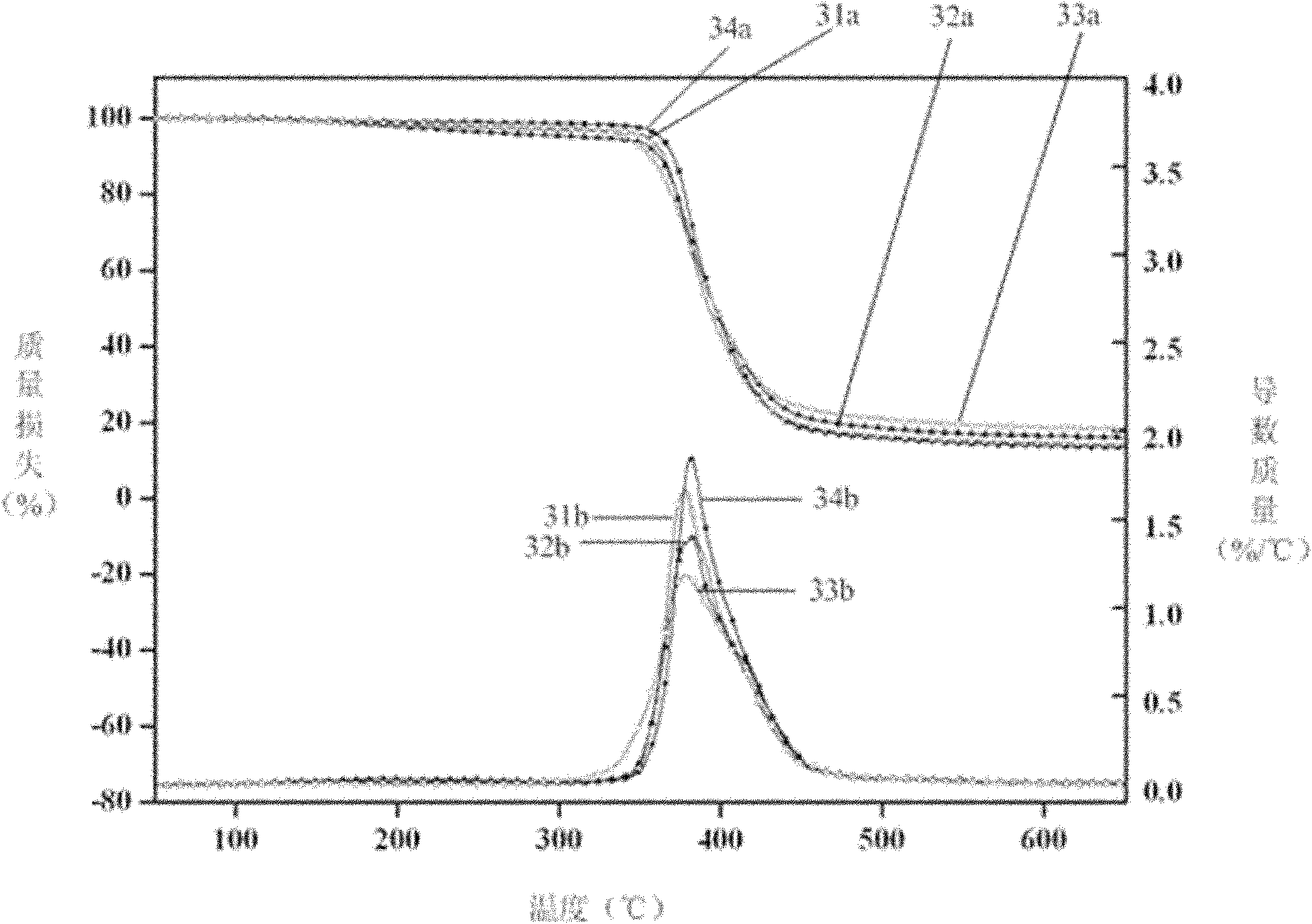

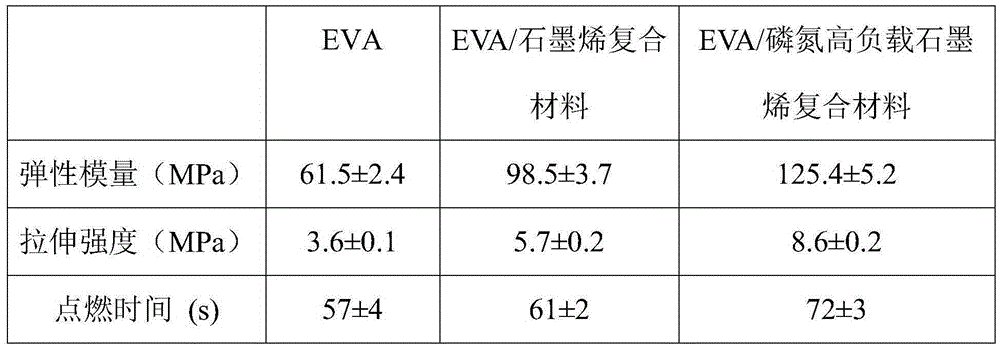

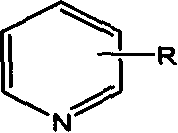

Preparing method of phosphorus nitrogen high load graphene flame retardant

The invention relates to a preparing method of a flame retardant, in particular to a preparing method of a phosphorus nitrogen high load graphene flame retardant. The method comprises the following steps: (1) performing a surface grafting reaction on isocyanate and graphene oxide to prepare isocyanate functionalized graphene; (2) reacting the isocyanate functionalized graphene with dendrimer polyamide-amine (PAMAM) to prepare dendrimer functionalized graphene; (3) reacting the dendrimer functionalized graphene with a phosphoryl chloride compound to prepare the phosphorus nitrogen high load graphene flame retardant. The phosphorus nitrogen high load graphene flame retardant can retard flaming of a modified high polymer material and can improve mechanical properties of the high polymer material.

Owner:浙江迪恩新材料有限公司

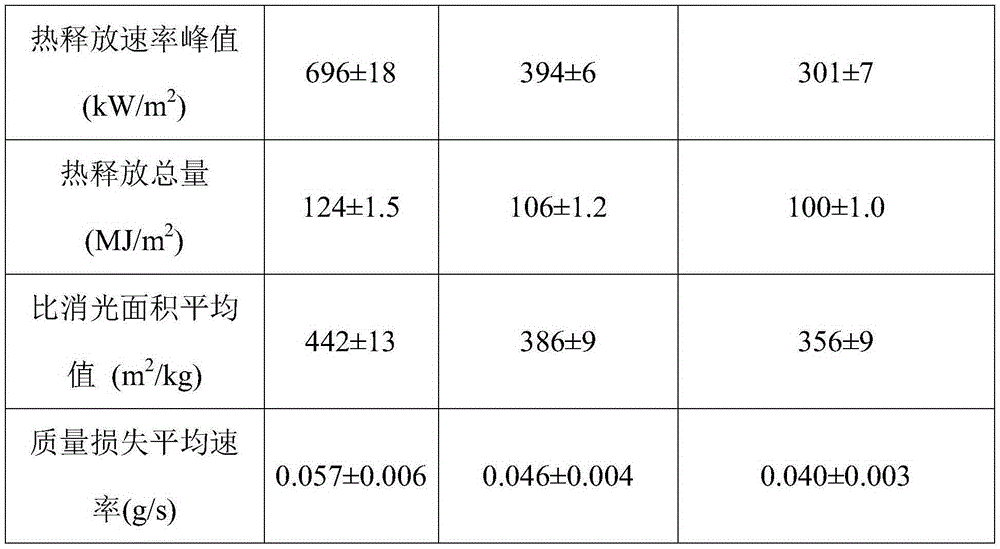

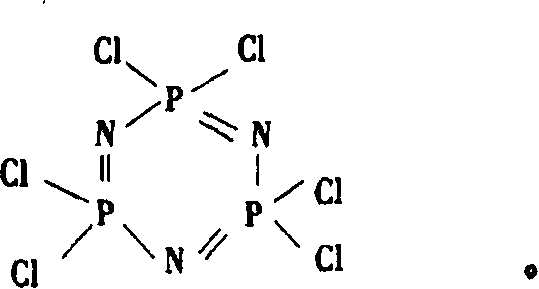

Catalytic synthesizing method of hexa chloro cyclotripolyphosphazene

InactiveCN1850832AShort reaction timeHigh yieldOrganic-compounds/hydrides/coordination-complexes catalystsGroup 5/15 element organic compoundsChlorobenzeneSynthesis methods

This invention discloses hexachloro ring trimerization phosphonitrile catalysis synthesis method. 1.1-1.5mol ammonium chloride, complex catalyst made uo by 0.012-0.022mol metal compound and 0.030-0.070mol pyridine substance are added into reaction kettle, and then 1000-1300 ml chlorobenzene is added and heated to dissolve. 1mol phosphoric chloride is added at back flow state, then 1 mol phosphoric chloride is added and continue back flow 3-5 hours, then stoped and cooled down to room temperature, and filter off unreacted ammonium chloride and distill out chlorobenzene. 550-600ml petroleum ether is added into residual, then they are heated back flow and extracting for 0.5 to 1 hours, then they are cooled down and filtrated, distilled petroleum ether, finally the crystal is recrystallized and sublimed by normal heptane, and pure white srystal hexachloro ring trimerization phosphonitrile is got. The catalysis synthesis method in this invention uses special complex catalyst, that is metal compound and pyridine or its alkyl substitute to shorten reaction time to 3-5 hours, and improves yield to 80-90 percent, its operation is simple, so is worth extending.

Owner:ZHENGZHOU UNIV

Method for preparing 4,6-dichloropyrimidine

Owner:CHONGQING UNISPLENDOUR CHEM

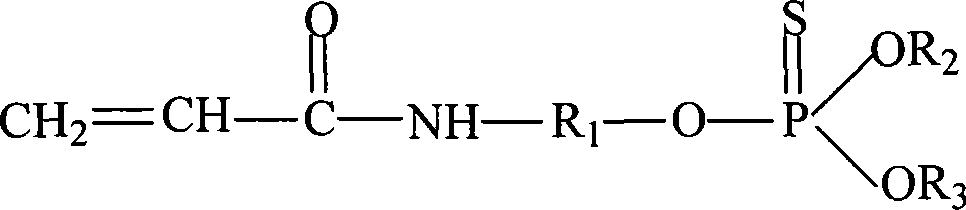

Combustion inhibitor and preparing method and flame-proof acrylic fibre using the same

InactiveCN101113211AImprove flame retardant performanceSimple processFlame-proof filament manufactureDistillationFiltration

The invention relates to a flame retardant, a preparation method and purposes thereof. The flame retardant is called O-alkyl acrylamide dialkyl thiophosphate. The preparation method is that: 1mol new distilled N- hydroxyalkyl acrylamide is dissolved in 500ml dry aether and poured into a 1000ml four-neck reaction flask with a constant pressure funnel, a refluxing condensing tube and a magnetic stirrer, and 1.05mol distilled triethylamine is added, and the reaction temperature is kept at 0-50 DEG C, then 1mol distilled sulfur dialkyl phosphoryl chloride is dripped into the reaction flask through the constant pressure funnel and the time of dripping is controlled for 1-6h; reaction is kept for 10-48 hours under room temperature, then the reaction is stopped and filtration is made to take out triethylamine hydrochloride, the filtrate is washed with 5 percent sodium hydroxide solution, then is washed with distilled water, and distillation is carried out to remove the aether and water, finally drying is carried out with anhydrous magnesium sulfate so as to obtain the O-alkyl acrylamide dialkyl thiophosphate. The flame retardant of the invention is particularly applicable to be used as a comonomer to prepare flame retardant Orlon.

Owner:CHINA PETROLEUM & CHEM CORP +2

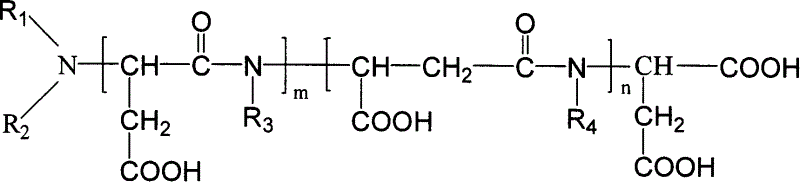

Asparagic acid possessing phosphinic group, its preparation method and uses in water processing

ActiveCN1569922AExcellent resistance to CaCO <sub>3<</sub> Excellent sub>Scale removal and water softeningWater treatmentMedicinal chemistry

The invention discloses an asparagic acid possessing phosphinic group, its preparation method and uses in water processing by using asparagic acid phsophorus trichloride, formaldehyde and water as raw material, wherein the asparagic acid has fine CaCO3 and Ca3(PO4)2 scale resistant function.

Owner:中国石油化工股份有限公司北京燕山分公司研究院

Method of purifying lithium hexafluorosphate

InactiveUS20030143145A1Improve developmentIncrease contentPhosphorus halides/oxyhalidesLithium hexafluorophosphateHydrogen fluorideOrganic synthesis

A method of purifying lithium hexafluorophosphate that allows to purify lithium hexafluorophosphate, useful as lithium secondary cell electrolyte, organic synthesis medium or the like, to an extremely high purity is provided. Lithium hexafluorophosphate containing harmful impurities such as oxyfluoride, lithium fluoride is purified by adding phosphoric chloride. The purification is performed in the presence of phosphoric chloride and hydrogen fluoride of the quantity equal or superior to the equivalent amount for reacting them, and then by converting lithium fluoride lithium hexafluorophosphate with generated phosphor pentafluoride.

Owner:STELLA CHEMIFA CORP

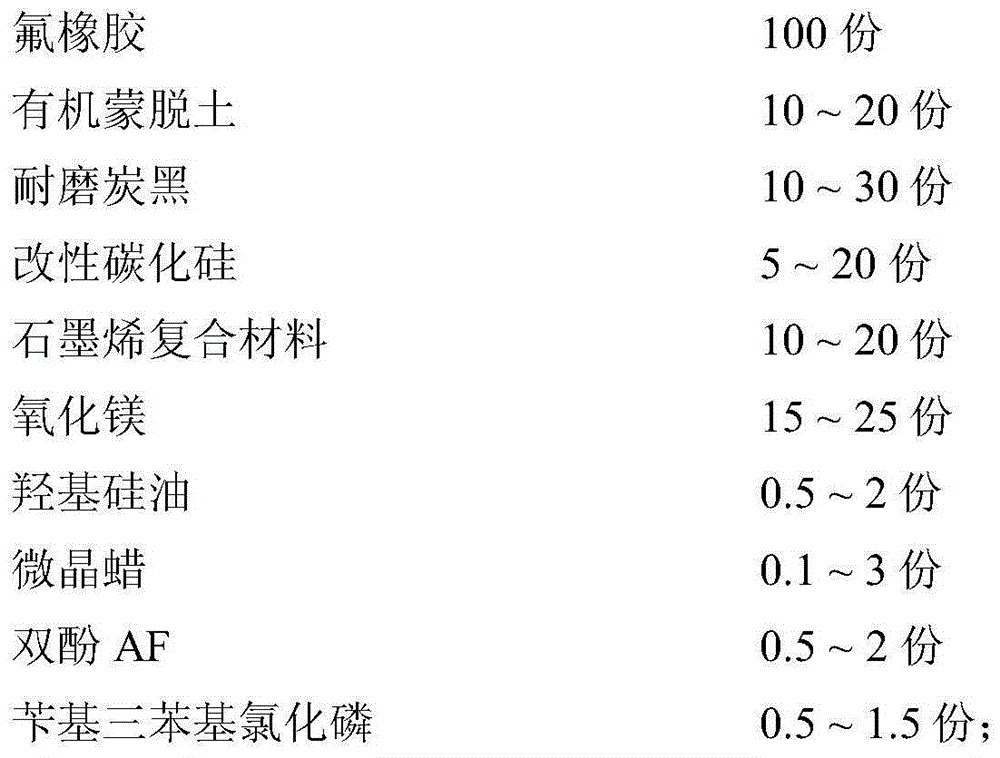

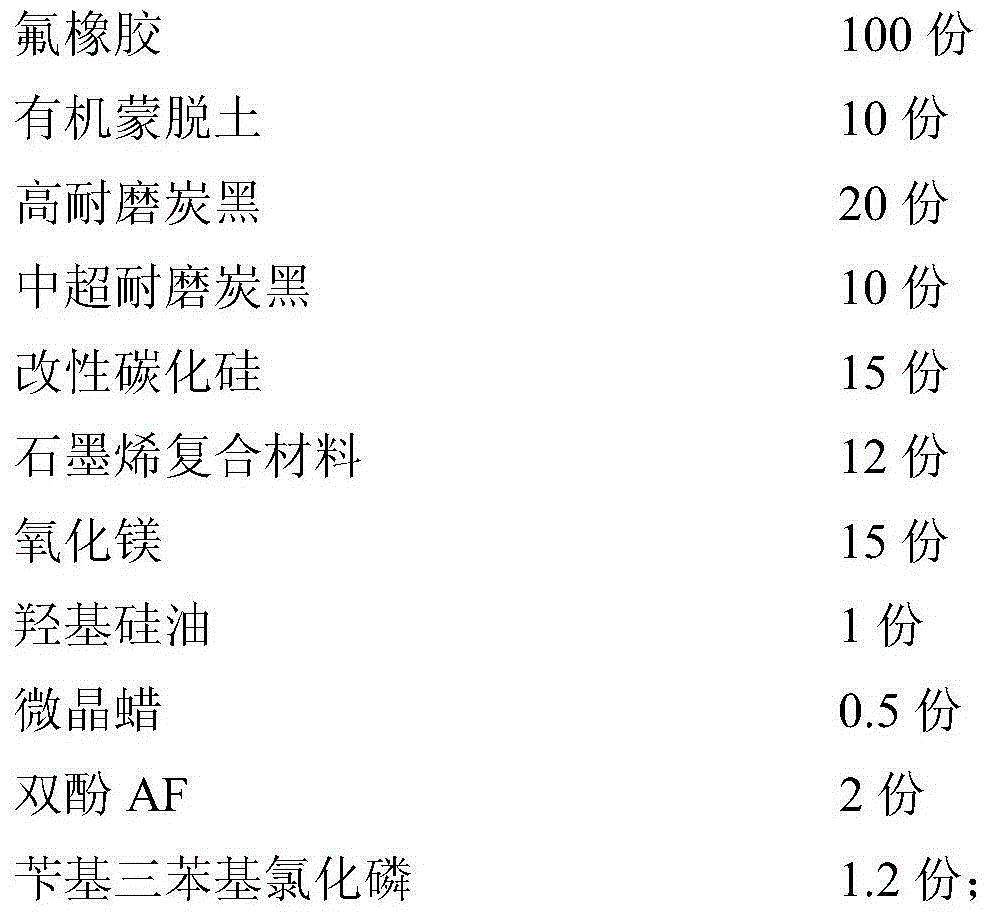

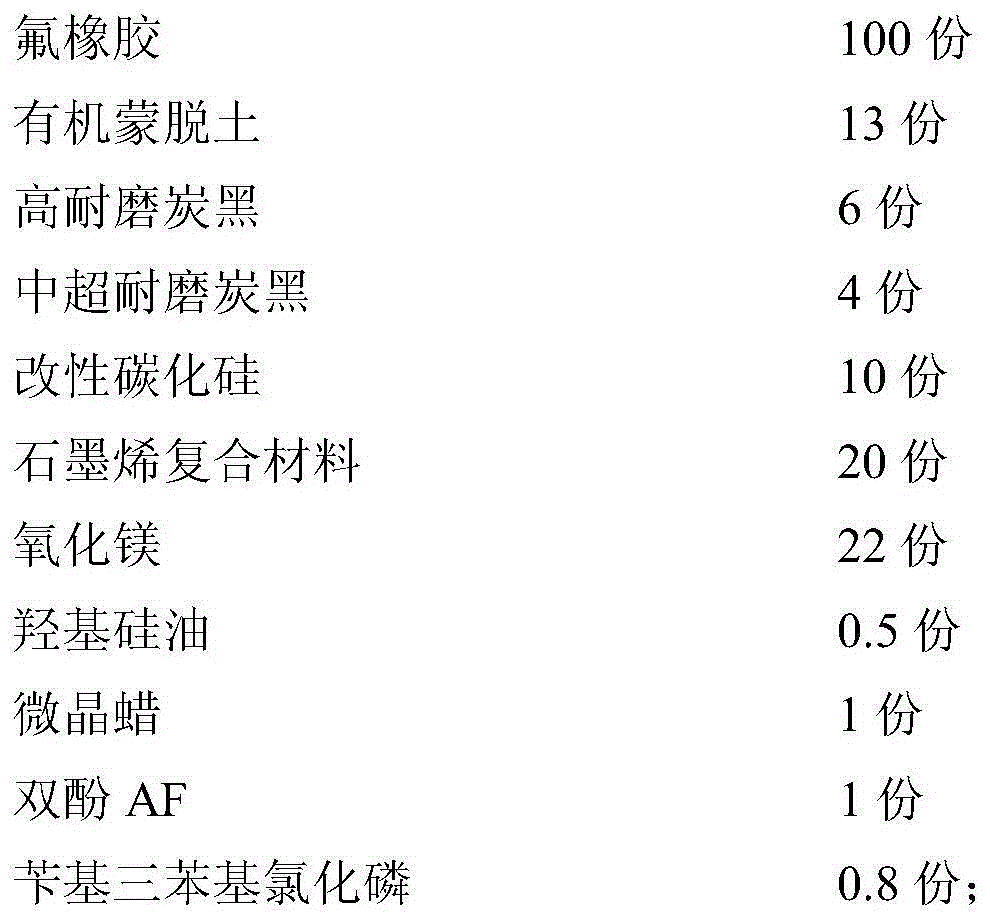

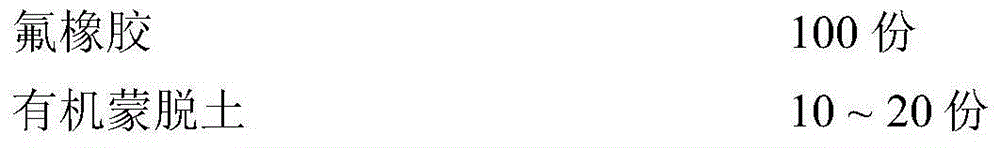

Grinding roller sealing ring materials and preparation method thereof

ActiveCN104530611ASolve difficult peelingSolve densityOther chemical processesMicrocrystalline waxBisphenol AF

The invention relates to grinding roller sealing ring materials. The grinding roller sealing ring materials are characterized by comprising, by weight, 100 parts of fluororubber, 10-20 parts of organic montmorillonite, 10-30 parts of wear-resisting carbon black, 5-20 parts of modified silicon carbide, 10-20 parts of graphene composites, 15-25 parts of magnesium oxide, 0.5-2 parts of hydroxyl silicone oil, 0.1-3 parts of microcrystalline wax, 0.5-2 parts of bisphenol AF and 0.5-1.5 parts of benzyl triphenyl phosphoric chloride. The graphene composites are graphene / hydrogenated styrene- butadiene- styrene compounds subjected to in-situ reduction. The graphene / hydrogenated styrene- butadiene- styrene compounds subjected to in-situ reduction are added, the graphene composites are dispersed easily, the problems of difficult stripping of graphene and difficult addition caused by low apparent density in the prior art are resolved, graphene can be evenly dispersed in the grinding roller sealing ring materials, the function of the graphene is fully played, and the wear resistance and heat resistance of the grinding roller sealing ring materials are effectively improved.

Owner:宁波佳乐特橡塑机电有限公司

Preparation of diethyl phosphoric acid

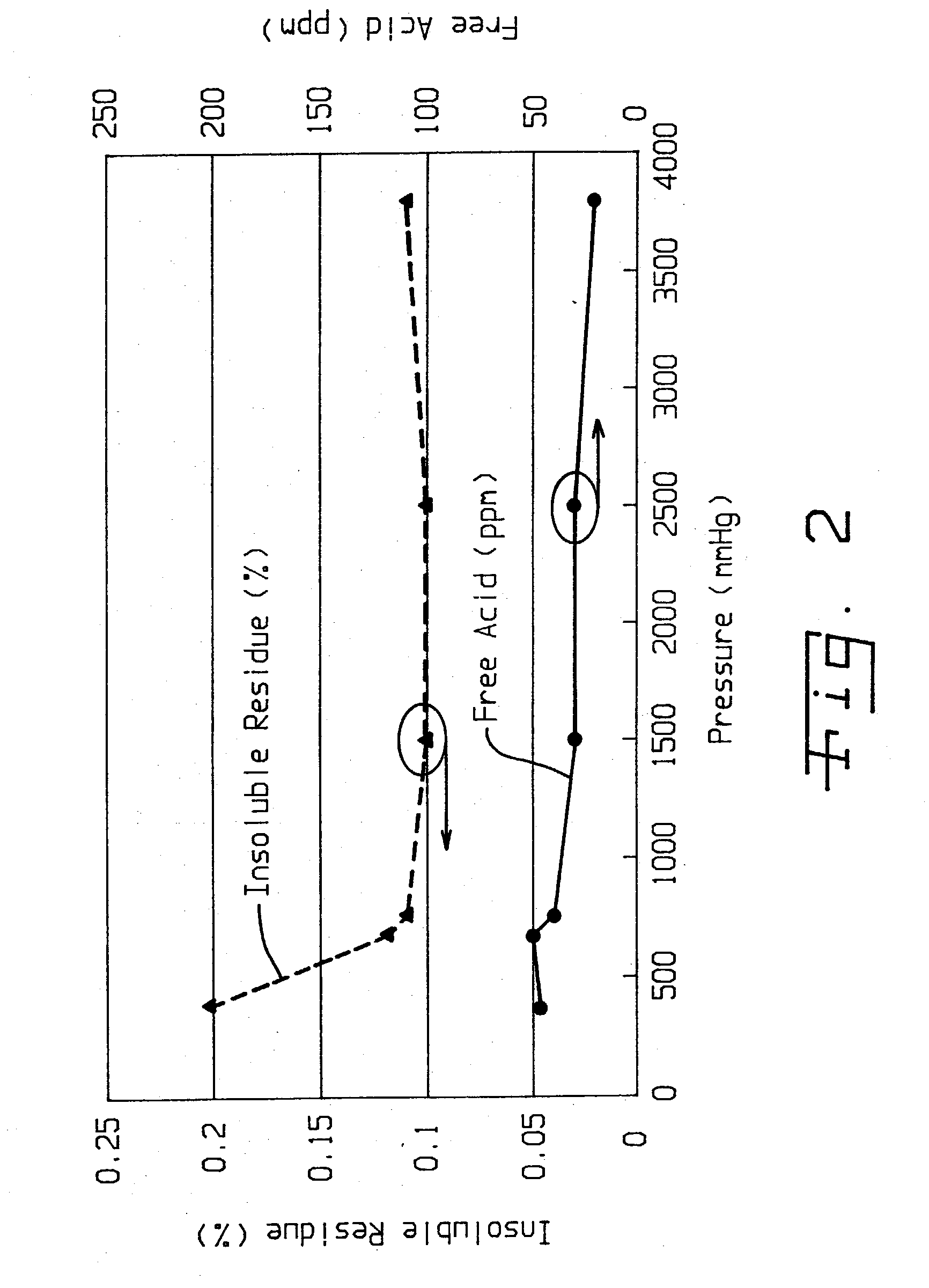

The invention relates to a process for preparing triethyl phosphate by reacting phosphorus oxychloride with a greater than stoichiometric quantity of ethanol under reduced pressure at temperatures of from 0 to 50 DEG C. in a reaction vessel, whereina) the volatile components resulting from the reaction are predominantly condensed by means of a reflux condenser and the remaining volatile components are passed into a scrubber filled with water,b) after the end of the reaction, the reaction mixture is separated distillatively in an outgassing column into a top product and a bottom product which predominantly comprises triethyl phosphate,c) the top product of the outgassing column is combined with the contents of the scrubber and d) the contents of the scrubber are separated distillatively in an azeotropic distillation to obtain water and ethanol as top product and the ethanol, preferably after dewatering, is preferably returned to the reaction.

Owner:BAYER AG

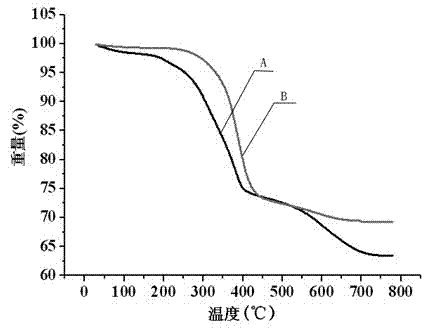

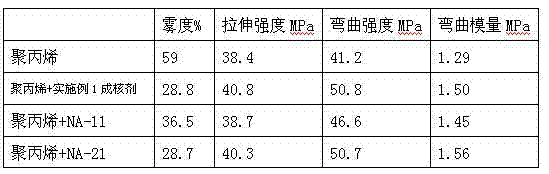

Preparation method for nano-montmorillonite modified organophosphate nucleating agent

The present invention discloses a preparation method for a nano-montmorillonite modified organophosphate nucleating agent. The method comprises the following steps: dispersing nano-montmorillonite in an aqueous solution of ethanol; adding a silane coupling agent; carrying out refluxing under a heating condition to obtain amino-modified nano-montmorillonite; adding a 2,2'-methylene-bis(4,6-di-tert-butylphenol)phosphoryl chloride solution, and stirring; after completing the reaction, carrying out treatments of filtering, washing and vacuum drying to obtain the nano-montmorillonite modified organophosphate nucleating agent. According to the present invention, the organophosphate is linked on the surface of the nano-montmorillonite by chemical bonds so as to effectively reduce the agglomeration of the organophosphate in the resin matrix, and enhance the dispersity of the organophosphate in the matrix, such that the heterogeneous nucleation effect of the nucleating agent can be effectivelyprovided; with the introduction of the inorganic nano-montmorillonite, thermal stability and various mechanical properties of the material can be further improved.

Owner:贵州省复合改性聚合物材料工程技术研究中心

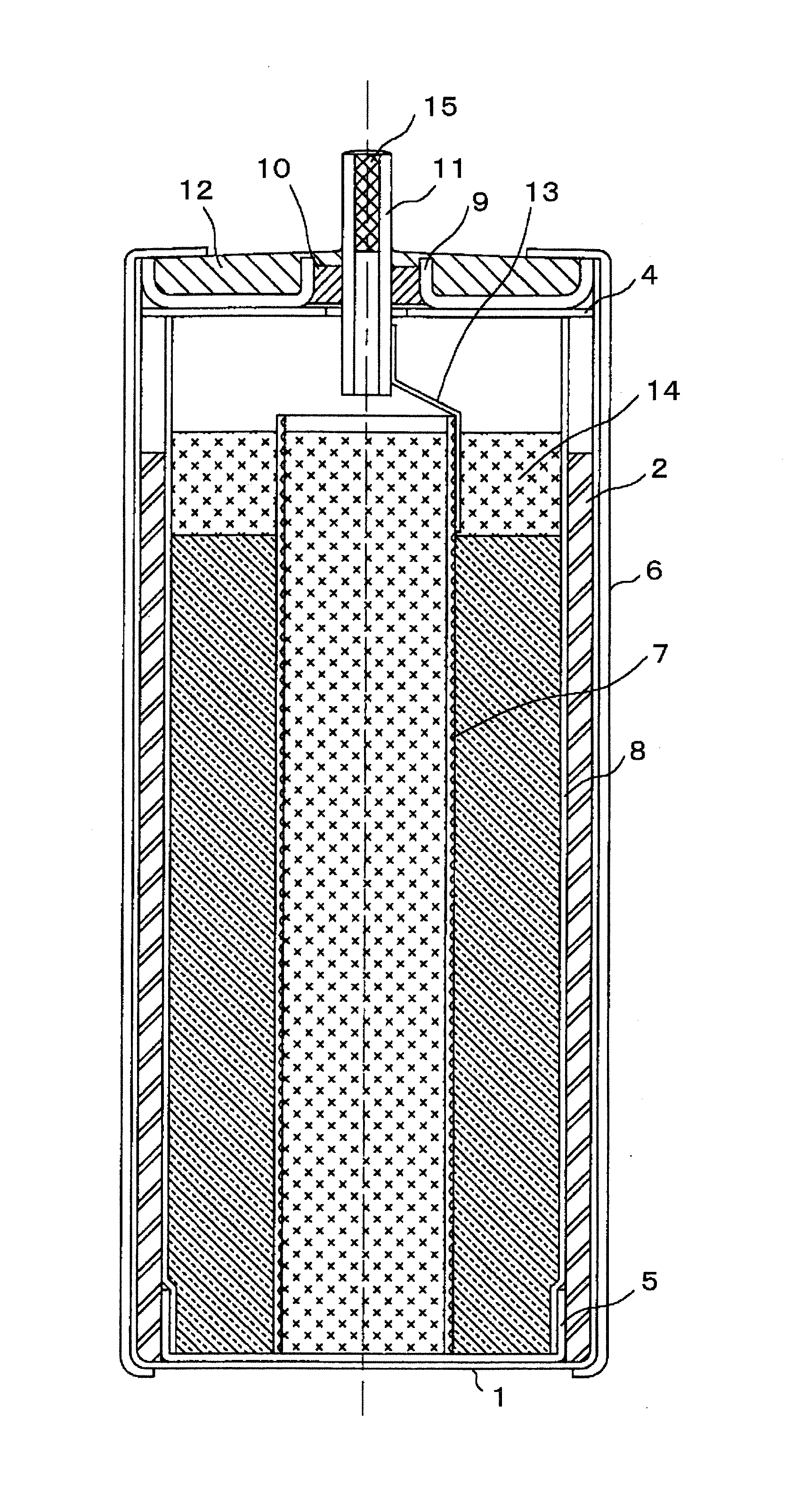

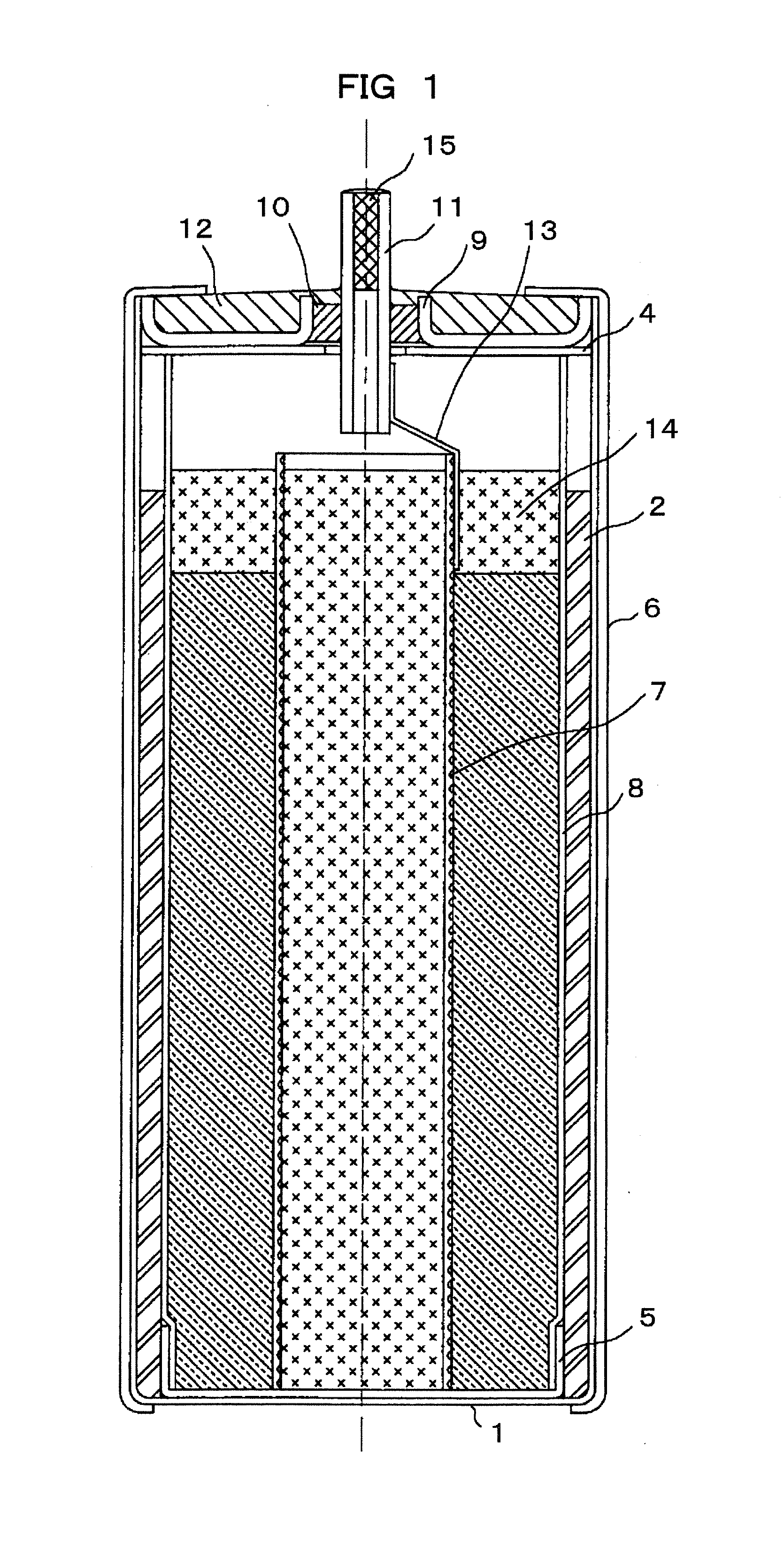

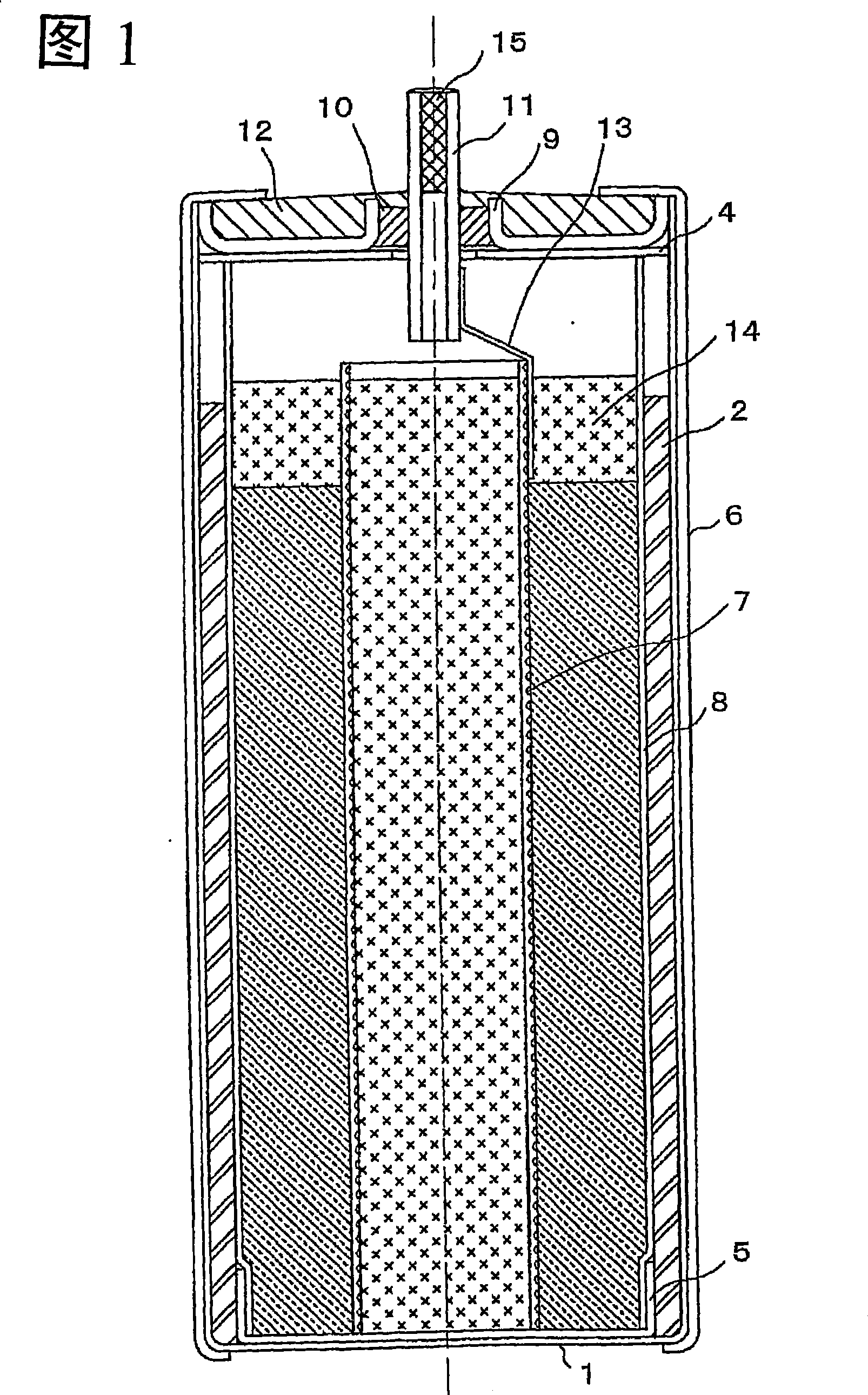

Non-aqueous electrolyte battery

InactiveUS20110171510A1Improved pulse discharge characteristicsAvoid impedanceNon-aqueous electrolyte cellsPrimary cell electrodesRoom temperatureAlloy

A non-aqueous electrolyte battery using an oxyhalide as an anodic action material, which can improve pulse discharge characteristics and provide a sufficient operating voltage. A non-aqueous electrolyte battery using an oxyhalide such as thionyl chloride, sulfuric chloride and phosphoryl chloride that are liquid at room temperature as an anodic action material, wherein, in place of a conventionally used metal lithium, a lithium alloy containing at least one kind of element selected from a group consisting of Zn, Ga, Cd, In, Sn, Sb and Bi is used as a cathode to thereby reduce the impedance of a battery and prevent a reduction in operating voltage at pulse discharging. Especially, a battery is obtained that gives a significant improvement effect at high temperature and is excellent in pulse discharge characteristics having long discharge duration days.

Owner:TOSHIBA BATTERY

High-performance fluorine rubber gasket and manufacturing method thereof

The invention discloses a high-performance fluorine rubber gasket. The high-performance fluorine rubber gasket comprises, by weight, 40-80 parts of binary fluorine rubber, 20-30 parts of silane-modified fluororubber, 12-20 parts of atomized carbon black, 5-10 parts of barium sulfate, 5-15 parts of calcium hydroxide, 1-5 parts of calcium titanate, 1-3 parts of chelate titanate coupling agents, 2-6 parts of molybdenum disulfide, 2-6 parts of phenyl methylpolysilicone resin, 1-2 parts of magnesium oxide, 1-3 parts of dicumyl peroxide, 0.5-1.2 parts of dibenzothiazyl disulfide, 0.5-1.2 parts of triallyl isocyanurate, 1-1.8 parts of bisphenol A, 1-3 parts of hexafluoride isopropylidene diphenol, 1-3 parts of benzyl triphenyl phosphoric chloride, 1-2 parts of sodium stearate, 1-3 parts of palm wax, 1-3 parts of fluorinated polyamide and 1-2 parts of fatty alcohol. The invention further discloses a manufacturing method of the high-performance fluorine rubber gasket. The compression deformation and high-temperature steam resistance of the fluorine rubber gasket are excellent, and the manufacturing method is simple.

Owner:ANHUI JINYANG FLUORINE CHEM

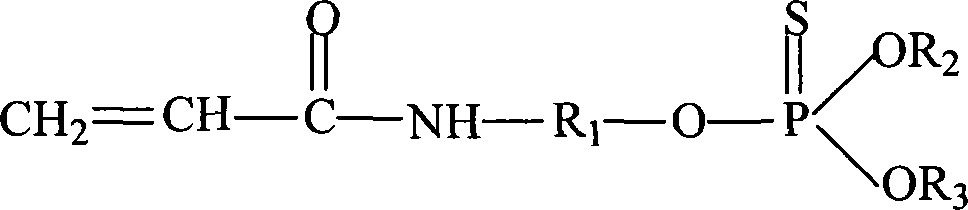

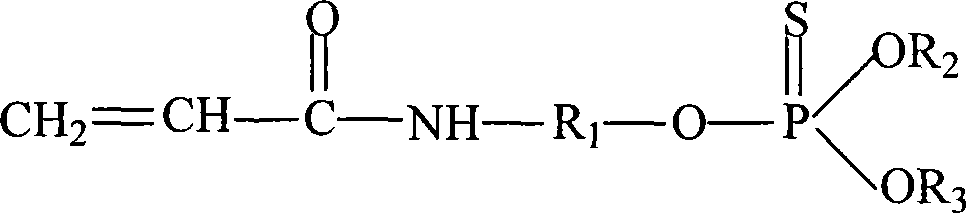

Flame-retardant acrylonitrile copolymer and preparation method thereof

The invention discloses a flame-retardant acrylonitrile copolymer and a preparation method thereof. The flam-retardant acrylonitrile copolymer comprises the following structural formula: in the structural formula, X is R2OP(O)-substitutional group or R2OP(S)-substitutional group and R is methyl or ethyl. The preparation method adopts the following steps of: (1) co-polymerization: preparing an acrylonitrile-vinyl acetate copolymer; (2) hydrolyzation: preparing a neutral acrylonitrile-vinyl alcohol colymer generated by hydrolyzing a vinyl acetate unit; and (3) flame-retardant modification: adding a flame-retardant modifying agent for modifying reaction to obtain the copolymer, wherein the flame-retardant modifying agent is dimethoxy phosphoryl chloride, diethoxy phosphoryl chloride, dimethoxy thiophosphoryl chloride or diethoxy thiophosphoryl chloride.

Owner:TIANJIN POLYTECHNIC UNIV

Method for preparing high-content creatine phosphate disodium salt

ActiveCN102702253AImprove securityImprove effectivenessGroup 5/15 element organic compoundsHalohydrocarbonAqueous sodium hydroxide

The invention discloses a method for preparing high-content creatine phosphate disodium salt, comprising the steps as follows: (1) conducting a condensation reaction on creatinine and phosphorus oxytrichloride to obtain crude creatinine phosphorus oxychloride; (2) dissolving the crude creatinine phosphorus oxychloride in a solvent A, then stirring and filtering, adding a solvent B to the filtrate to separate out the crystal and obtain fine creatinine phosphorus oxychloride; (3) hydrolyzing fine creatinine phosphorus oxychloride in sodium hydroxide aqueous solution to obtain the high-content creatine phosphate disodium salt, wherein the solvent A is halohydrocarbon and the solvent B is aliphatic hydrocarbon.

Owner:SHANGHAI LONGXIANG BIO MEDICINE DEV CO LTD

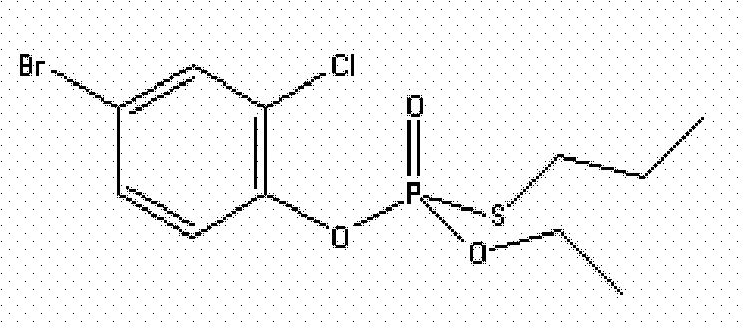

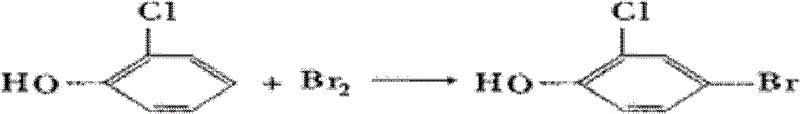

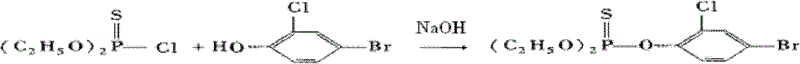

Preparation method of high-purity profenofos

The invention relates to a preparation method of high-purity profenofos. The preparation method improves purity of 2-chloro-4-bromophenol by repeated recrystallization, and the purity of profenofos prepared by the method can reach 96 mass%. The preparation method comprises the following steps: (1) brominating; (2) recrystalizing for 3-5 times; (3) enabling O,O-diethyl sulfo phosphoryl chloride to react with a recrystalized bromination product to obtain O,O-diethyl-O-(2-chloro-4-bromophenyl)-phosphorothioate; (4) in the presence of trimethylamine, obtaining O-ethyl-O-(2-chloro-4-bromophenyl) thiophosphoric acid trimethylamine by backflow of O,O-diethyl-O-(2-chloro-4-bromophenyl)-phosphorothioate, and obtaining amine salt intermediates by dehydration and trimethylamine removal; (5) adding bromopropane and catalyst dimethyl formamide into the product obtained in the step (4) to react so that profenofos is formed; and (6) carrying out layering, washing and solvent removal to the product obtained in the step (5), and obtaining a profenofos product.

Owner:山东科源化工有限公司

Non-aqueous electrolyte battery

InactiveCN101084594ALower impedanceReduce voltageNon-aqueous electrolyte cellsPrimary cell electrodesRoom temperatureAlloy

A non-aqueous electrolyte battery using an oxyhalide as an anodic action material, which can improve pulse discharge characteristics and provide a sufficient operating voltage. A non-aqueous electrolyte battery using an oxyhalide such as thionyl chloride, sulfuric chloride and phosphoryl chloride that are liquid at room temperature as an anodic action material, wherein, in place of a conventionally used metal lithium, a lithium alloy containing at least one kind of element selected from a group consisting of Zn, Ga, Cd, In, Sn, Sb and Bi is used as a cathode to thereby reduce the impedance of a battery and prevent a reduction in operating voltage at pulse discharging, Especially, a battery is obtained that gives a significant improvement effect at high temperature and is excellent in pulse discharge characteristics having long discharge duration days.

Owner:TOSHIBA BATTERY

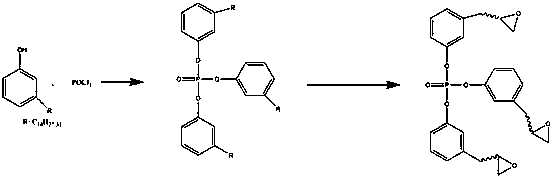

Phosphorus-containing cardanol polyglycidyl ether and preparation method thereof

InactiveCN108373484ALow costImprove toughnessGroup 5/15 element organic compoundsPhosphatePhosphoric acid

The invention relates to phosphorus-containing cardanol polyglycidyl ether with a flame-retarding effect and a toughening effect and a preparation method thereof. The preparation method comprises thefollowing steps: enabling cardanol and phosphoryl chloride to react through nucleophilic substitution reaction to prepare tricardanol phosphate; then carrying out peroxidation reaction on unsaturatedhydrocarbons on phosphate; oxidizing to generate an epoxy group to prepare the phosphorus-containing cardanol polyglycidyl ether. The glycidyl ether prepared by the preparation method has the advantages of low cost, environment protection, renewable performance and the like; meanwhile, the generated phosphorus-containing cardanol polyglycidyl ether has more epoxy groups and contains a flame-retarding element, i.e., phosphorus. The polyglycidyl ether synthesized by the method has a plurality of long alkyl chains so that the polyglycidyl ether has good toughness. On one hand, the phosphorus-containing cardanol polyglycidyl ether synthesized by the method can be used as an epoxy diluting agent; on the other hand, the phosphorus-containing cardanol polyglycidyl ether can be used for modifyingan epoxy resin amine type curing agent; the two methods can be used for improving the toughness of epoxy resin.

Owner:李嘉顺

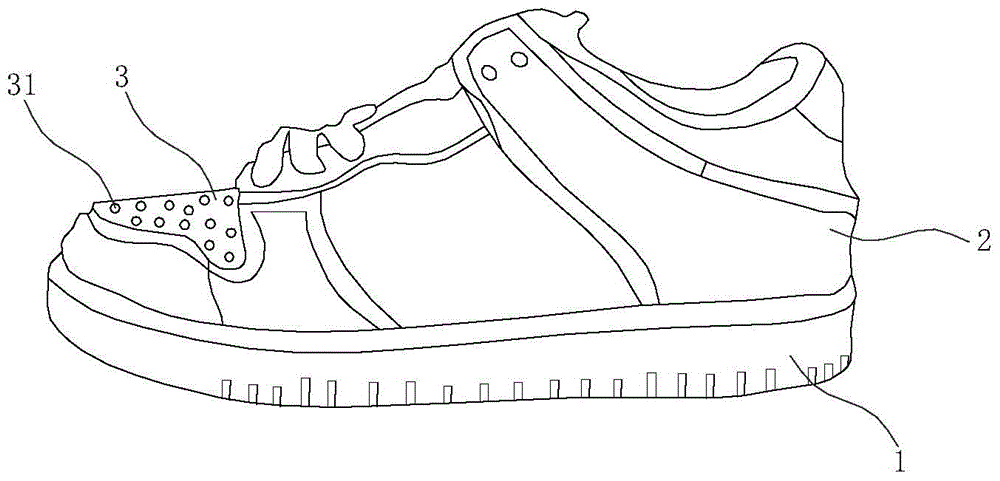

Wear-resisting climbing boot

The invention relates to a wear-resisting climbing boot. The wear-resisting climbing boot comprises a sole, an upper and a vamp, wherein the upper and the vamp are arranged on the sole, and a plurality of air-permeable holes are formed in the vamp at intervals. The wear-resisting climbing boot is characterized in that the materials of the sole comprise, by weight, 100 parts of fluororubber, 10-20 parts of organic montmorillonite, 10-30 parts of wear-resisting carbon black, 5-20 parts of modified silicon carbide, 10-20 parts of graphene composites, 15-25 parts of magnesium oxide, 0.5-2 parts of hydroxyl silicone oil, 0.1-3 parts of microcrystalline wax, 0.5-2 parts of bisphenol AF and 0.5-1.5 parts of benzyl triphenyl phosphoric chloride. Fluororubber rubber serves as the main materials, graphene / hydrogenated styrene- butadiene- styrene compounds subjected to in-situ reduction are added, the graphene composites are dispersed easily, the problems of difficult stripping of graphene and difficult addition caused by low apparent density in the prior art are resolved, graphene can be evenly dispersed in the sole materials, the function of the graphene is fully played, and the wear resistance of the sole materials is effectively improved.

Owner:NINGBO ZHONGDI SHOES

Novel synthesis method for 3-(alkoxy methyl phosphoryl)propionate

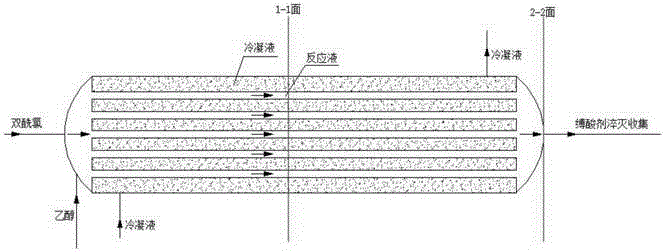

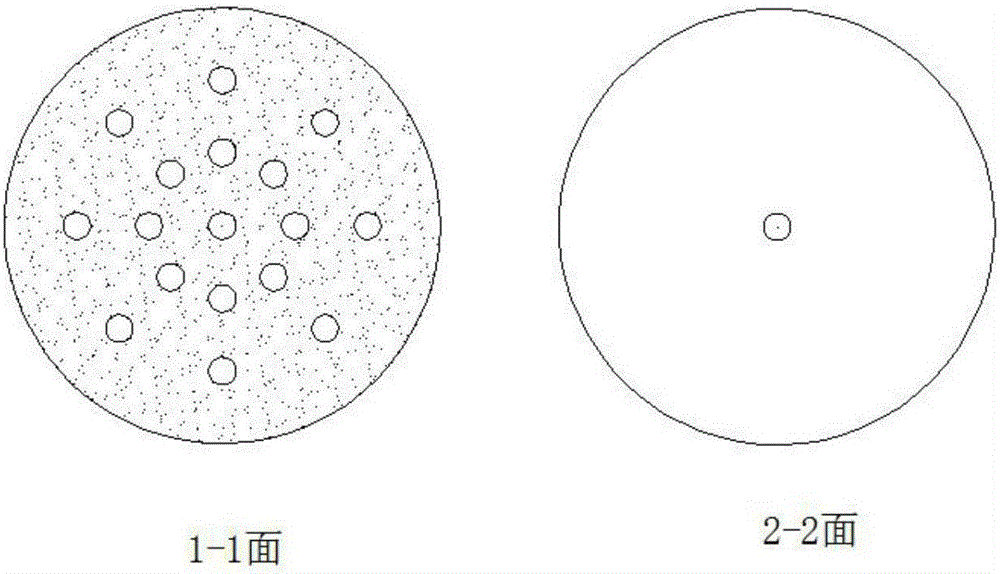

ActiveCN106565778AImprove heat exchange capacityEasy to operateGroup 5/15 element organic compoundsChemical/physical/physico-chemical processesSynthesis methodsReaction tube

The invention discloses a novel synthesis method for 3-(alkoxy methyl phosphoryl)propionate (short for "propionate") by carrying out esterification reaction on 3-(methyl phosphoryl chloride)propionyl chloride (short for "bis(acyl chloride) ") serving as a raw material. The method in which a novel array tubular reaction device is mainly adopted comprises the steps: feeding raw materials including bis(acyl chloride) and a hydroxyl compound from one side, then, releasing heat by reaction in glass tubes, enabling a condensed fluid to be in cross flow contact with the glass tube on the outer layer of a reaction tube, carrying out strong heat exchange, carrying out quenching treatment by using an acid binding agent after discharging as an esterification product, and then, collecting a product, so that continuous esterification synthesis reaction and sufficient heat exchange with a reaction solution can be realized, and an HCl gas serving as a byproduct has no corrosion to equipment. The method is simple in operation, high in heat exchange capability, precise in temperature control, environment-friendly and wide in large-scale application prospect.

Owner:ANHUI COSTAR BIOCHEM CO LTD

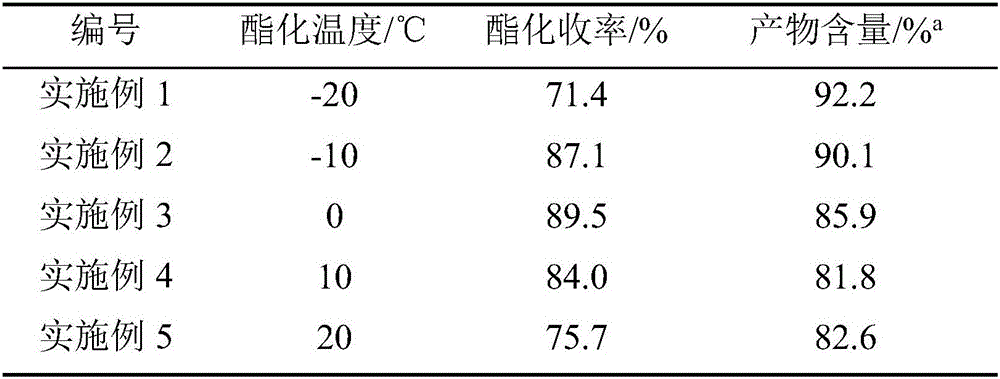

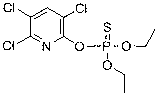

Method for preparing chlorpyrifos by clean technology

InactiveCN102977138AEasy to operateReduce manufacturing costGroup 5/15 element organic compoundsChlorpyrifosPhase method

The present invention discloses a novel method for preparing chlorpyrifos by the clean technology. Sodium 3,5,6-trichloropyridine-2-alkoxide and O,O-diethyl phosphoryl chloride are used as main raw materials. The reactants are added once, water is used as medium, and a highly dispersed system is formed under the action of a composite catalyst for reaction. The reaction time is greatly shortened, and the target product of chlorpyrifos can be obtained by simple separation and purification. The invention is environmental-friendly, and is simple in the synthetic method. The water phase method of chlorpyrifos synthesis can be efficiently conducted through a simple process operation. The product is high in purity, and high in yield. The method is suitable for large-scale industrial production.

Owner:ANHUI COSTAR BIOCHEM CO LTD

Medicinal disodium creatine phosphate hexahydrate and preparing method thereof

ActiveCN100488968CHigh purityLow drying temperatureGroup 5/15 element organic compoundsCreatinine riseDistillation

This invention discloses a phosphocreatine disodium salt six-hydrate and its preparation method. The compound is phosphocreatine disodium salt with high purity and six-crystal water, and the preparation method includes the following steps: (1) Kondens of creatinine and phosphorus oxychloride prepares creatinine phosphorus oxychloride, (2) creatinine phosphorus oxychloride is taken the ring opening reaction to get crude phosphorus disodium, (3) purification and crystallization gets the target product. This invention has the advantages of high purity suitable for the manufacture of injection powder, and it avoids the large use of solvents with high yield of products. The excessive phosphorus oxychloride is reused with distillation, and the product has high purity through intermediate and resin purification. It has no potential safety problem about heavy metal residues, and can effectively improve the clarification to reach the intravenous requirement.

Owner:QIDONG HUATUO PHARMA

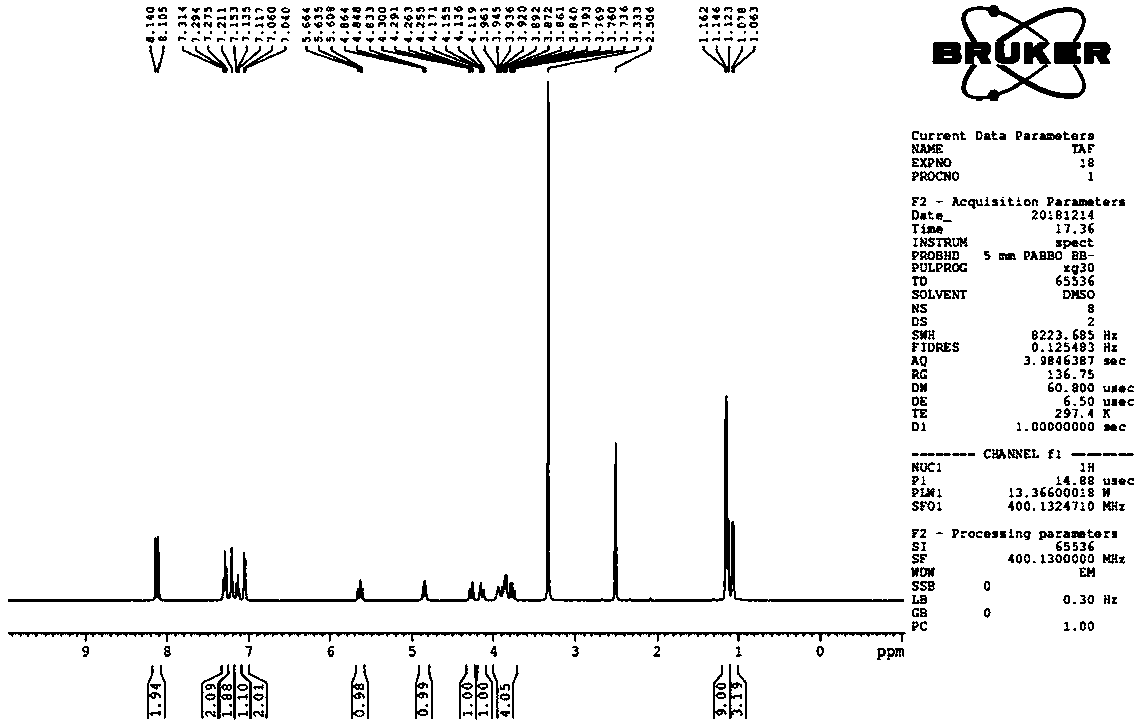

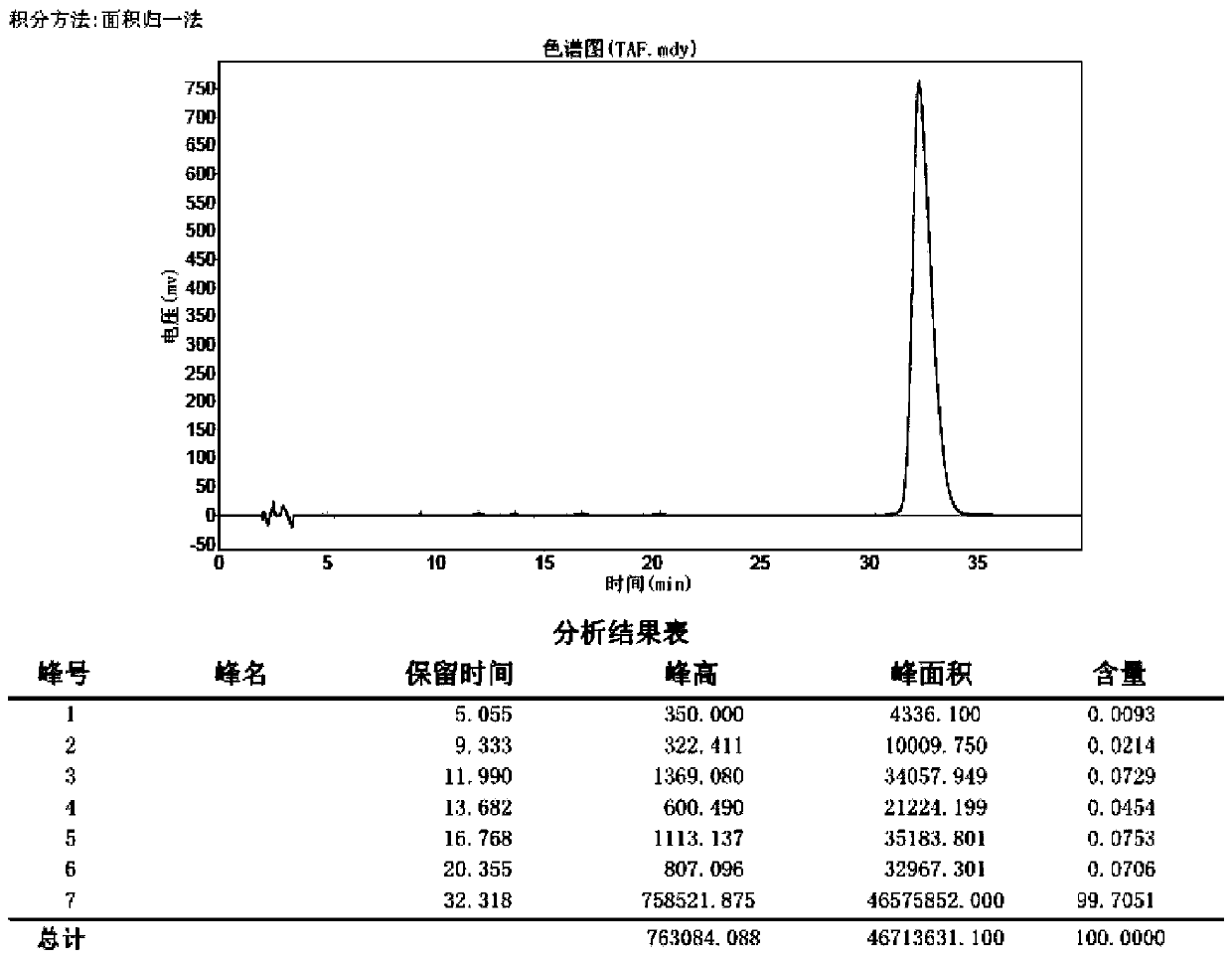

Efficient synthesis technology of tenofovir alafenamide

InactiveCN110105392AHigh purityShort conversion timeGroup 5/15 element organic compoundsIsomerizationReaction temperature

The invention discloses an efficient synthesis technology of tenofovir alafenamide. The efficient synthesis technology comprises the steps that A, tenofovir reacts with triphenyl phosphite under an alkali catalysis condition to prepare tenofovir monophenyl ester, wherein the initial reaction temperature is 50-70 DEG C, the reaction temperature rises according to the gradient of 5-10 DEG C / h, and the total reaction duration is 6-10 h; B, the tenofovir monpohenyl ester is subjected to acylating chlorination to prepare tenofovir phenyl ester phosphoryl chloride; C, the tenofovir phenyl ester phosphoryl chloride is isomerized, then the isomerized tenofovir phenyl ester phosphoryl chloride reacts with an L-alanine isopropyl ester compound to prepare a target compound, wherein methylbenzene andother non-polar solvents are adopted for an isomerization solvent. The prepared tenofovir alafenamide has high purity and high yield, the technology operation is simple, the cost is low, complicated technology operation and purification means like using chiral resolution agents are omitted, and the efficient synthesis technology is very suitable for industrial production.

Owner:石家庄凯赛医药科技有限公司

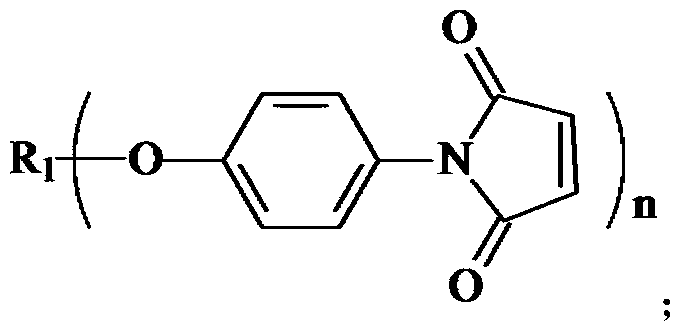

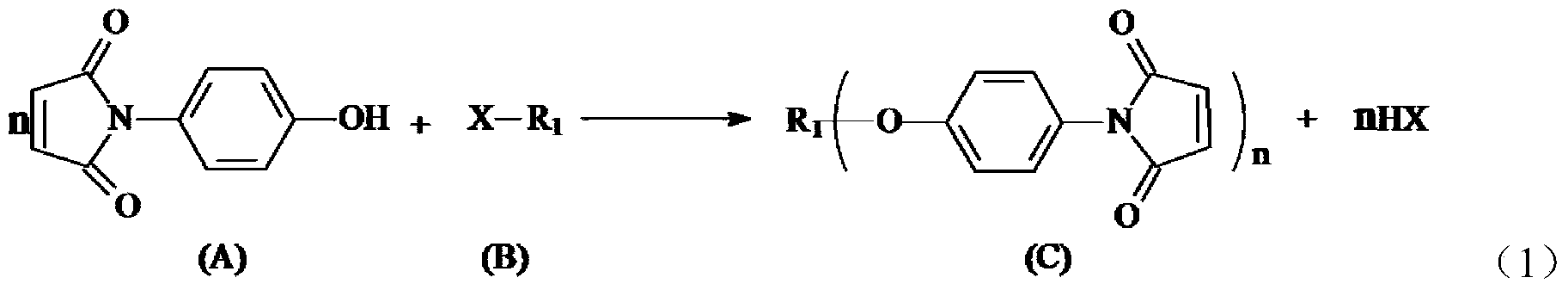

Heat-resisting reaction type phosphorate containing flame retardant with maleimide structure and preparation method thereof

ActiveCN103588990ANot easy to migrateIncreased durabilityGroup 5/15 element organic compoundsPolymer resinDistillation

The invention discloses a heat-resisting reaction type phosphorate containing flame retardant with a maleimide structure and a preparation method thereof. The preparation method is characterized in that maleimide based phenol and phosphoryl chloride or phosphoryl bromide are added into a reactor, a reaction solvent is added into the reactor, then an inert gas is fed into the reactor, and materials in the reactor are heated to 70-100 DEG C; continuous stirring is performed during heating, and stirring is continued during a constant temperature reaction until no hydrogen halide gas is released; the materials are cooled to a room temperature, distillation under reduced pressure is performed to remove the reaction solvent, and an obtained orange-yellow product is the heat-resisting reaction type phosphorate containing flame retardant with the maleimide structure. The prepared heat-resisting reaction type phosphorate containing flame retardant with the maleimide structure can serve as a reaction type flame retardant to react with a polymer resin matrix, is not prone to movement and has superior service durability and good flame-retardant effect, and the heat resistance of a material can be improved simultaneously.

Owner:UNIV OF SCI & TECH OF CHINA

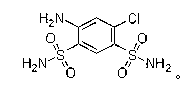

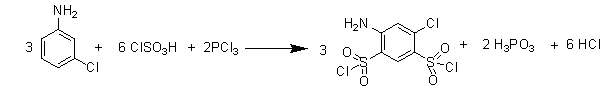

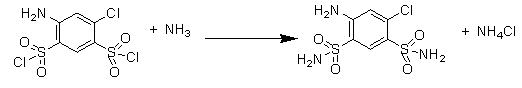

Preparation method of high-purity fine sulfanilamide

ActiveCN103319381AReduce dosageShort reaction timeSulfonic acid amide preparationSulfanilamideAniline

The invention relates to a preparation method of fine sulfanilamide and particularly relates to a preparation method of high-purity fine sulfanilamide. The preparation method sequentially comprises the following steps of: proportioning m-chloroaniline, chlorosulfonic acid and phosphorus trichloride, then, mixing chlorosulfonic acid, m-chloroaniline and phosphorus trichloride at the temperature of 30-45 DEG C, heating to 105-120 DEG C and carrying out heat preservation for 2-4hours; standing and cooling to obtain a chlorosulfonated substance; introducing ammonia gas to an amination reaction device for the first time, adding the obtained chlorosulfonated substance, then, introducing ammonia gas to the amination reaction device for the second time, carrying out amination reaction at the temperature of 40-45 DEG C and the pressure of 0.1-0.2MPa, and carrying out heat preservation for 1-3hours to obtain an amide; and carrying out dissolution, decoloration, crystallization and purification on the obtained amide: adding a sodium hydroxide solution to adjust the pH value to 10-11, then, adding active carbon, heating to 80-95 DEG C, carrying out heat preservation for 0.3-0.8h, filter pressing while the solution is hot, adding hydrochloric acid into the obtained filtrate to adjusting the pH to 2-4, separating out white crystal substances, and then, cooling, washing, centrifuging and drying to obtain a finished product of the fine sulfanilamide. The preparation method is few in reaction by-product and high in product purity.

Owner:中瑞(内蒙古)药业股份有限公司

Method for preparing tri-(2, 4-di-tertiary butyl phenyl) phosphite ester antioxidant

InactiveCN104744506AReduce manufacturing costHigh catalytic activityGroup 5/15 element organic compoundsAlcoholAntioxidant

The invention relates to a method for preparing a tri-(2, 4-di-tertiary butyl phenyl) phosphite ester antioxidant. The method comprises the following steps: by taking 2, 4-di-tertiary phenol and phosphorus trichloride as raw materials and an aromatic compound as a reaction solvent, carrying out reaction at 25-60 DEG C under the action of ethanol amine catalysts; then raising the temperature to 100-130 DEG C and reacting for 1-4 hours at the temperature; distilling at a reduced pressure, removing the reaction solvent, and adding lower alcohol as a solvent to crystallize; and severely stirring for a certain time, and filtering to obtain tri-(2, 4-di-tertiary butyl phenyl) phosphite ester.

Owner:ANQING FULLTIME CHEM INDAL

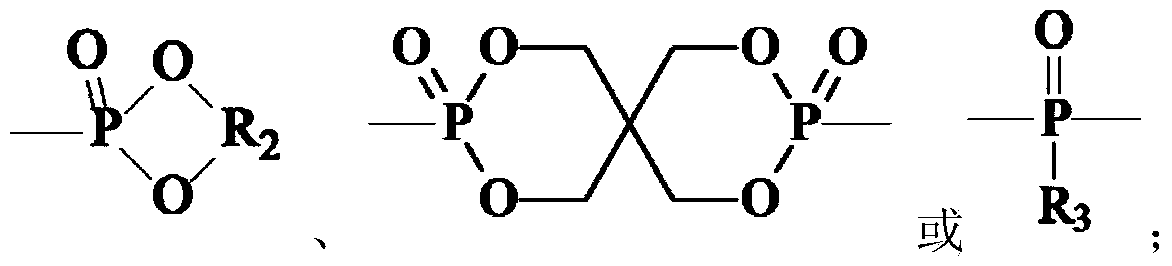

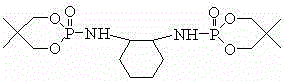

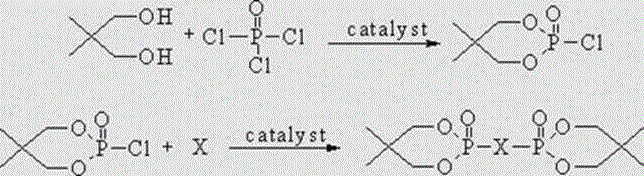

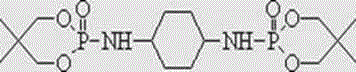

Phosphorus-nitrogen intumescent flame retardant and preparation method thereof

ActiveCN104558039AThe synthesis process is simpleShort reaction timeGroup 5/15 element organic compoundsPolymer sciencePtru catalyst

The invention relates to a phosphorus-nitrogen intumescent flame retardant and a preparation method thereof. The preparation method comprises the steps: mixing neopentyl glycol and a solvent, adding a catalyst, dissolving the catalyst, then, adding phosphorus oxychloride into a reaction solution under the condition of stirring at the temperature of 0-10 DEG C, reacting for 4-8 hours at the temperature of 20-50 DEG C after phosphorus oxychloride is added completely, removing the solvent through distilling after reacting ends, and washing and drying residues, so as to obtain cyclic phosphoryl chloride; adding the obtained cyclic phosphoryl chloride and an acid binding agent into a solvent, stirring to dissolve, adding diamine into a reaction solution under the condition of stirring at the temperature of 15-30 DEG C, then, reacting for 8-12 hours at the temperature of 50-110 DEG C, removing the solvent through distilling after reacting ends, and washing and drying residues, thereby obtaining the phosphorus-nitrogen intumescent flame retardant. The phosphorus-nitrogen intumescent flame retardant and the preparation method thereof have the advantages that the synthesis process is simple, the reaction time is short, the product has a melting point, the transparency is good when the flame retardant is added into materials, the flame-retardant effect is good, the influence on mechanical properties is low, and the like; and meanwhile, the disadvantage that intumescent flame retardants cannot be applied to the flame retardance of engineering plastics due to poor thermal stability is overcome.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com