Preparing method of phosphorus nitrogen high load graphene flame retardant

A graphene and high-load technology, which is applied in the field of preparation of graphene flame retardants with high phosphorus and nitrogen loads, can solve the problems that graphene and flame retardants are difficult to disperse evenly and affect the synergistic flame retardant effect, and achieve a wide range of applications , improve the mechanical properties, the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

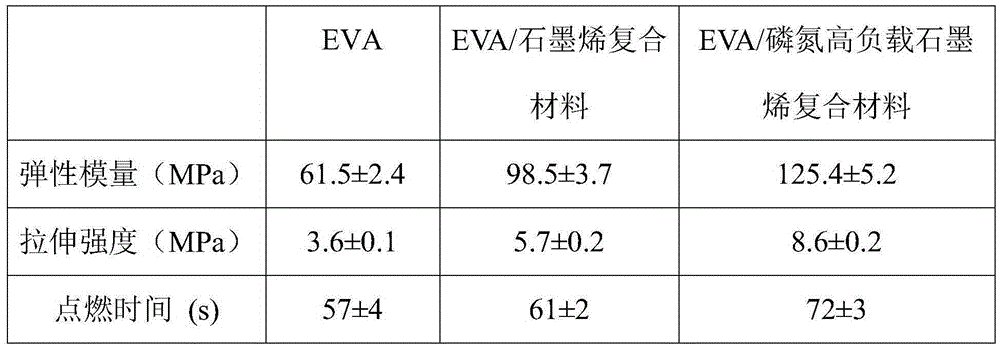

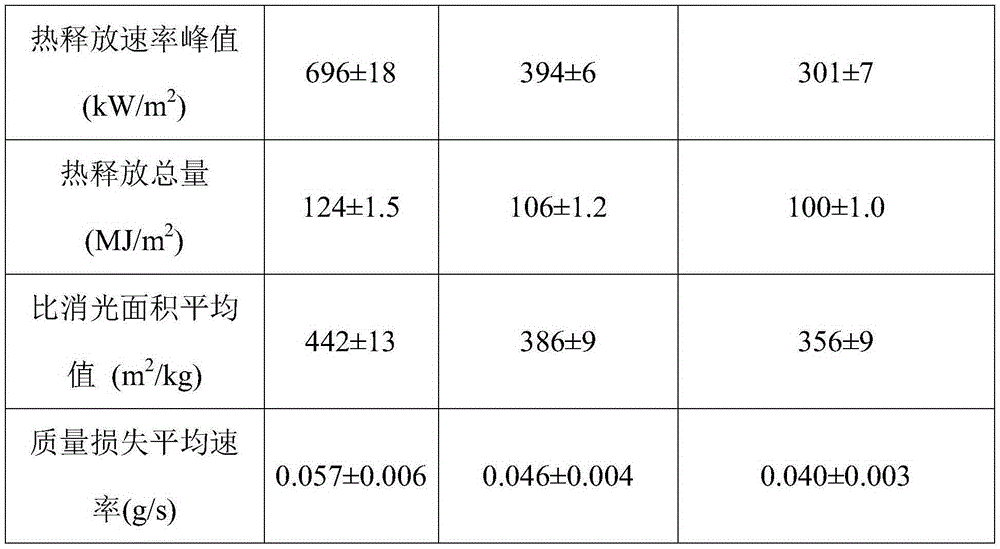

Examples

Embodiment 1

[0022] 1. Synthesis of isocyanate-functionalized graphene: Add 1.0g of graphene oxide powder particles into 200mL of chloroform, ultrasonically disperse for 120 minutes, and then transfer to a drying oven equipped with mechanical stirring, thermometer, reflux condenser and dropping funnel. In a 250mL four-necked flask, add 0.05g of isophorone diisocyanate at room temperature, raise the temperature to 45°C, continue to stir and react for 5 hours, then filter the slurry obtained from the reaction, wash repeatedly with chloroform, and dry to obtain isocyanate function Graphene.

[0023] 2. Synthesis of dendrimer functionalized graphene: disperse 1.0 g of the above-mentioned isocyanate functionalized graphene into 80 mL of acetonitrile, then add 0.5 g of the first generation of PAMAM, react at 20 ° C for 10 hours, and then react to obtain The slurry was filtered to obtain a black solid powder, and after drying, dendrimer functionalized graphene was obtained.

[0024] 3. Synthesis...

Embodiment 2

[0026] 1. Synthesis of isocyanate-functionalized graphene: the synthesis operation is the same as in Example 1, except that the isocyanate is diphenylmethane diisocyanate, and the reaction temperature between graphene oxide and diphenylmethane diisocyanate is 90°C, and the reaction time is 2 hours, the mass ratio of graphene oxide to diphenylmethane diisocyanate is 1.0:0.3, and the solvent is ethyl acetate.

[0027] 2. Synthesis of dendrimer functionalized graphene: disperse 1.0 g of isocyanate functionalized graphene prepared by the above reaction into 80 mL of N,N-dimethylformamide, and then add the second-generation polyamide-amine PAMAM to make the isocyanate The mass ratio of functionalized graphene to second-generation polyamide-amine is 1.0:2.0, and the mixture is reacted at 50°C for 3.5 hours, and then the slurry obtained from the reaction is filtered to obtain a black solid powder, which is dried to obtain dendrimer functionalized Graphene.

[0028] 3. Synthesis of g...

Embodiment 3

[0031] 1. Synthesis of isocyanate functionalized graphene:

[0032] The synthesis operation is the same as in Example 1, except that the isocyanate is hexamethylene diisocyanate, the reaction temperature between graphene oxide and hexamethylene diisocyanate is 35°C, and the reaction time is 4 hours. The mass ratio of methyl diisocyanate is 1.0:0.01, and the solvent is toluene.

[0033] 2. Synthesis of dendrimer functionalized graphene:

[0034] The synthetic operation is the same as that in Example 1, the difference being that the reaction temperature between the isocyanate-functionalized graphene and the polyamide-amine is 90° C., the reaction time is 3 hours, and the mass ratio of the isocyanate-functionalized graphene to the first-generation polyamide-amine is The ratio is 1.0:1.0, and the solvent is chloroform.

[0035] 3. Synthesis of graphene flame retardant with high phosphorus and nitrogen loading:

[0036] The synthesis operation is the same as in Example 1, except t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com