Preparation method for nano-montmorillonite modified organophosphate nucleating agent

An organic phosphate and nano-montmorillonite technology, applied in the field of organic phosphate nucleating agents, can solve problems such as reducing the heat release rate of resin, improve thermal stability and various mechanical properties, reduce agglomeration, and enhance dispersibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: Take 10 g of nano-montmorillonite and disperse it in 50% (weight) ethanol aqueous solution to make a solution with a concentration of 0.048 g / ml, then add 3.28 g of γ-aminopropyltriethoxysilane, and reflux at 70 ° C 24h, rotary steamed to 50ml to obtain amino-modified nano-montmorillonite, and then another 6.18g of 2,2'-methylene-bis(4,6-di-tert-butylphenol) phosphorus oxychloride was dissolved in 50ml of absolute ethanol Add amino-modified nano-montmorillonite, stir at 50°C for 3 hours, filter, wash, and vacuum-dry to obtain nano-montmorillonite-modified organophosphate nucleating agent. The obtained nucleating agent has good nucleating effect, and has the functions of flame retardancy and gas barrier.

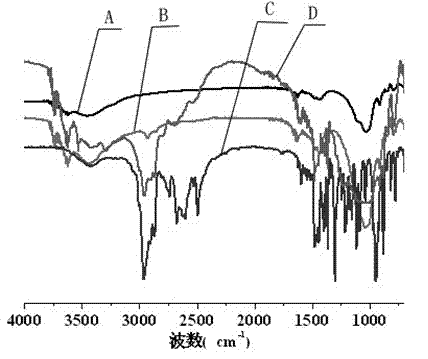

[0016] The infrared spectra of nano-montmorillonite, amino-modified nano-montmorillonite, organophosphorus oxychloride and modified organophosphate are as follows: figure 1 As shown, the amino-modified nano-montmorillonite has a wave number of 1080cm -1 Si...

Embodiment 2

[0022] Embodiment 2: get nanometer montmorillonite 9.5g to be dispersed in the ethanol aqueous solution of 45% (weight) and make the solution that concentration is 0.045g / ml, then add 3.0g gamma-aminopropyltriethoxysilane, at 65 Reflux at ℃ for 24 hours, rotary evaporate to 50ml to obtain amino-modified nano-montmorillonite, and then take another 5.5g of 2,2'-methylene-bis(4,6-di-tert-butylphenol)phosphoryl chloride and dissolve it in 50ml without Add amino-modified nano-montmorillonite to water ethanol, stir at 50° C. for 3 hours, filter, wash, and vacuum-dry to obtain nano-montmorillonite-modified organophosphate nucleating agent. The obtained nucleating agent has good nucleating effect, and has the functions of flame retardancy and gas barrier.

Embodiment 3

[0023] Embodiment 3: get nanometer montmorillonite 11.0g to be dispersed in the ethanol aqueous solution of 55% (weight) and make the solution that concentration is 0.05g / ml, then add 4.5g gamma-aminopropyltriethoxysilane, at 70 Reflux at ℃ for 24 hours, rotary evaporate to 50ml to obtain amino-modified nano-montmorillonite, and then take another 6.8g of 2,2'-methylene-bis(4,6-di-tert-butylphenol)phosphoryl chloride and dissolve it in 50ml without Add amino-modified nano-montmorillonite to water ethanol, stir at 50° C. for 3 hours, filter, wash, and vacuum-dry to obtain nano-montmorillonite-modified organophosphate nucleating agent. The obtained nucleating agent has good nucleating effect, and has the functions of flame retardancy and gas barrier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com