Toughened modified material for PE pipes and preparation method thereof

A toughening modification and modification technology, applied in the field of toughening modified materials for PE pipes and its preparation, can solve the problems of easy agglomeration, inability to strengthen and toughen, poor compatibility between fly ash and PE matrix, etc. problems, to achieve the effect of increasing melting temperature, improving flexibility and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] A preparation method for a toughened modified material for PE pipes, comprising the steps of:

[0048] The first step, take polyethylene resin, modified polyethylene octene co-elastomer, modified montmorillonite and maleic anhydride grafted polyethylene by parts by weight, place in a high-speed mixer, and heat up to 170-180 ℃, 1000r / min stirring and mixing for 15-18min, then add antioxidant, lubricant and plasticizer, reduce the speed to 800r / min and continue stirring and mixing for 10-12min to obtain a mixture;

[0049] In the second step, adding the mixed material to a twin-screw extruder to extrude and granulate to obtain a toughened modified material;

[0050] Among them, the screw speed is 80r / min; the temperature of each zone is 172, 190, 210, 210, 210, 210°C respectively.

Embodiment 1

[0052] A toughened modified material for PE pipes, made of the following raw materials in parts by weight: 90 parts of polyethylene resin (PE), 5 parts of modified polyethylene octene co-elastomer (POE), 8 parts of modified montmorillonite , 3 parts of maleic anhydride grafted polyethylene, 0.3 part of antioxidant, 1 part of lubricant, 1 part of plasticizer;

[0053] The material is made by the following steps:

[0054] The first step, weigh polyethylene resin, modified polyethylene octene co-elastomer, modified montmorillonite and maleic anhydride grafted polyethylene by weight parts, place in a high-speed mixer, heat up to 170 ° C, Stir and mix at 1000r / min for 18min, then add antioxidant, lubricant and plasticizer, reduce the speed to 800r / min and continue to stir and mix for 10min to obtain a mixture;

[0055] In the second step, the mixed material is added to a twin-screw extruder for extrusion and granulation to obtain a toughened modified material.

Embodiment 2

[0057] A toughened modified material for PE pipes, made of the following raw materials in parts by weight: 95 parts of polyethylene resin (PE), 6 parts of modified polyethylene octene co-elastomer (POE), 9 parts of modified montmorillonite , 3.5 parts of maleic anhydride grafted polyethylene, 0.4 parts of antioxidant, 1.5 parts of lubricant, 1.5 parts of plasticizer;

[0058] The material is made by the following steps:

[0059] The first step, weigh polyethylene resin, modified polyethylene octene co-elastomer, modified montmorillonite and maleic anhydride grafted polyethylene by weight parts, place in a high-speed mixer, heat up to 175 ° C, Stir and mix at 1000r / min for 16min, then add antioxidant, lubricant and plasticizer, reduce the speed to 800r / min and continue to stir and mix for 11min to obtain a mixture;

[0060] In the second step, the mixed material is added to a twin-screw extruder for extrusion and granulation to obtain a toughened modified material.

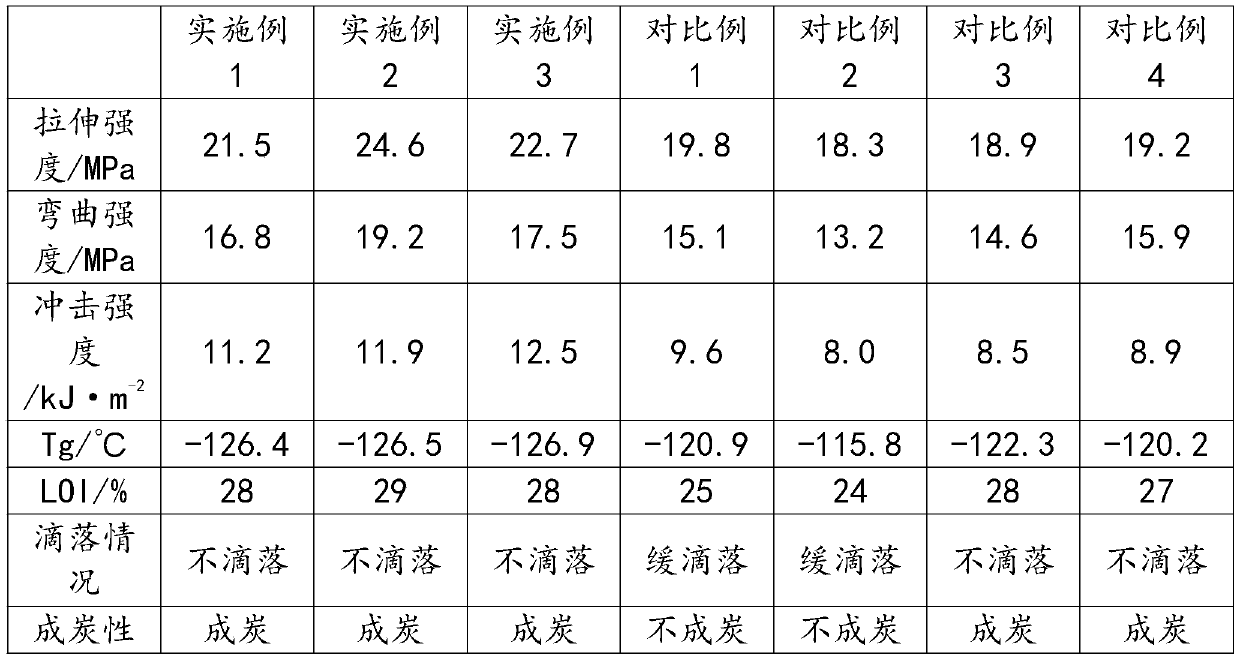

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com