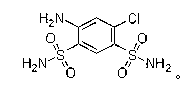

Preparation method of high-purity fine sulfanilamide

A high-purity technology of refined sulfonamide, which is applied in the field of preparation of high-purity refined sulfonamide, can solve problems such as waste of by-products, side effects, and reducing the purity of refined sulfonamide intermediates, and achieve the effects of shortening the reaction time, increasing the reaction rate, and reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

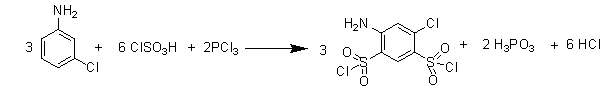

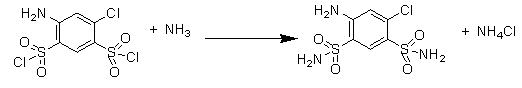

[0039] Weigh and weigh m-chloroaniline, chlorosulfonic acid, and phosphorus trichloride according to the molar ratio of 1:3:1, and add the m-chloroaniline dropwise to the chlorosulfonic acid at a temperature of 30°C within 1 hour. , and then kept for 5min to obtain the first mixed solution; then the phosphorus trichloride was added dropwise to the first mixed solution at a temperature of 30°C within 1 hour, and stirred for 20min; then the steam was turned on and heated to make the material The liquid temperature rises to 65°C, turn off the steam, and let it heat up naturally until the temperature reaches above 105°C, add cuprous chloride and cuprous bromide, which account for 10% of the mass of m-chloroaniline, and mix according to 1:1, at 105 Keep warm for 3 hours between ℃; then stop stirring, let the feed liquid stand for more than 3 hours, then hydraulically transfer the feed from the chlorosulfonation tank to the high-level storage tank, cool naturally, and water-cool, so ...

Embodiment 2

[0062] Weigh and weigh m-chloroaniline, chlorosulfonic acid, and phosphorus trichloride according to the molar ratio of 1:4:2, and add the m-chloroaniline dropwise to the chlorosulfonic acid at a temperature of 45°C within 2 hours. , and then kept for 20min to obtain the first mixed solution; then the phosphorus trichloride was added dropwise to the first mixed solution at a temperature of 45°C within 2 hours, and stirred for 30min; then the steam was turned on and heated to make the material The liquid temperature rises to 80°C, turn off the steam, and let it heat up naturally, until the temperature reaches above 105°C, add cuprous chloride and cuprous bromide, which account for 30% of the mass of m-chloroaniline, and are mixed according to 1:1, at 110 Keep warm for 3 hours between ℃; then stop stirring, let the feed liquid stand for more than 3 hours, then hydraulically transfer the feed from the chlorosulfonation tank to the high-level storage tank, cool naturally, and water...

Embodiment 3

[0069] Weigh and weigh m-chloroaniline, chlorosulfonic acid, and phosphorus trichloride according to the molar ratio of 1:3.4:1.2, and add the m-chloroaniline dropwise to the chlorosulfonic acid at a temperature of 35°C within 1.5 hours. and keep it for 15 minutes to obtain the first mixed solution; then add the phosphorus trichloride dropwise to the first mixed solution at a temperature of 35° C. within 1.5 hours, and stir for 25 minutes; then turn on the steam and heat to make the material Liquid temperature rises to 70°C, turn off the steam, let it heat up naturally, until the temperature reaches above 105°C, add cuprous chloride and cuprous bromide, which account for 15% of the mass of m-chloroaniline, and mix according to 1:1, at 108 Keep warm for 3 hours between ℃; then stop stirring, let the feed liquid stand for more than 3 hours, then hydraulically transfer the feed from the chlorosulfonation tank to the high-level storage tank, cool naturally, and water-cool, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com